Кастинг is a highly efficient metal manufacturing process used to produce precise metal parts with complex geometries. въпреки това, the die-casting process alone does not always guarantee parts with the desired final surface appearance or properties. Следователно, applying the correct surface finish is critical to achieving functional, естетически, and durable fabricated parts.

В тази статия, we’ll deeply explore 13 types of surface finishes commonly used in die casting, highlighting their definitions, ползи, suitable applications, and considerations.

Importance of Choosing the Right Surface Finish

Selecting the appropriate повърхностно покритие impacts the following critical properties:

Издръжливост: Enhances corrosion resistance and prolongs part lifespan.

Външен вид: Improves visual appeal and market value of components.

Функционалност: Ensures suitability for specific applications and conditions.

Choosing an incorrect surface finish can lead to premature part failures, poor aesthetics, increased maintenance, и ненужни разходи.

13 Types of Die Casting Surface Finishes

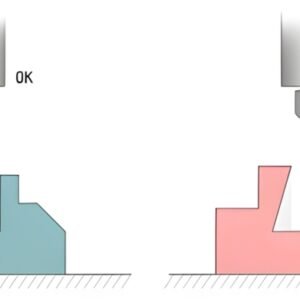

1. Пясъкоструене (Abrasive Blasting)

Sandblasting involves forcibly propelling fine abrasive particles (напр., пясък, стъклени мъниста) onto the part surface under high pressure.

Ползи:

Uniform matte finish

Enhanced adhesion for coatings

Efficient removal of impurities and contaminants

Приложения:

Автомобилни и индустриални компоненти

Parts requiring high adhesion for painting or coating

2. Прахово боядисване

Powder coating is a dry finishing process involving applying electrostatically charged powdered pigments, followed by heat curing.

Ползи:

Excellent corrosion and chemical resistance

Durable and impact-resistant surface

Available in numerous colors and finishes

Приложения:

Automotive wheels and components

Домакински уреди, Електронични обвивки, outdoor products

3. Полиране

Polishing removes microscopic imperfections through abrasive buffing, producing a smooth, отразяваща повърхност.

Ползи:

Mirror-like, high-quality aesthetic finish

Improved cleanability and reduced friction

Приложения:

Автомобилна тапицерия, бижута, Декоративен хардуер, медицинско оборудване

4. Покритие (Галванопластика & Електрическо покритие)

Plating involves depositing a thin layer of metal (никел, хром, злато, и т.н.) onto die cast parts through chemical or electrolytic means.

Ползи:

Enhanced corrosion protection and wear resistance

Improved electrical conductivity

Декоративна, high-gloss appearance

Приложения:

Electronic components, автомобилни части, Декоративни тела

5. Анодиране

Anodizing creates a controlled oxide layer on aluminum alloy surfaces through electrolytic treatment.

Ползи:

Superior corrosion and wear resistance

Aesthetic appearance with various color options

Increased surface hardness

Приложения:

Architectural fittings, electronics enclosures, потребителски продукти

6. Electrophoretic Coating (E-coating)

E-coating utilizes electrical currents to deposit paint or resin onto conductive surfaces uniformly.

Ползи:

Excellent corrosion protection

Uniform and consistent coating thickness

Good chemical resistance and durability

Приложения:

Automotive chassis components, индустриално оборудване, тежки машини

7. Рисуване

Painting involves applying liquid coatings via spray, brush, or dipping techniques to improve aesthetics and protective properties.

Ползи:

Cost-effective with extensive color options

Easy to repair or update finishes

Приложения:

Потребителски продукти, automotive body parts, уреди, мебели

8. Vibratory Deburring

This process removes burrs and sharp edges using vibrating equipment with abrasive media.

Ползи:

Efficient deburring without manual labor

Consistent and uniform surface finish

Improved safety and handling

Приложения:

Small to medium die-cast automotive parts, предавки, крепежни елементи, конектори

9. Parkerizing (Phosphating)

Parkerizing involves chemically coating steel parts with phosphate solutions to create a robust corrosion-resistant layer.

Ползи:

Cost-effective corrosion protection

Improved adhesion for subsequent coatings or paints

Durable matte-black finish

Приложения:

Огнестрелни оръжия, automotive suspension components, heavy-duty industrial equipment

10. Безелектрическо никелиране

Electroless nickel plating deposits nickel-phosphorus alloy layers chemically, without external electricity.

Ползи:

Uniform thickness distribution, even on complex shapes

Excellent wear and corrosion resistance

Increased hardness and lubricity

Приложения:

Аерокосмически компоненти, industrial valves, precision automotive parts

11. Impregnation

Impregnation involves sealing microscopic porosities in die-cast parts using vacuum-assisted polymer sealants.

Ползи:

Enhanced leak-proof properties for high-pressure components

Improved structural integrity and longevity

Reduced porosity-related defects

Приложения:

Hydraulic pumps, автомобилни двигателни блокове, fluid containment components

12. Физическо отлагане на пари (PVD)

PVD is an advanced vacuum-based coating method vaporizing metals or ceramics onto substrates, forming ultra-thin and highly durable coatings.

Ползи:

Superior wear and scratch resistance

Excellent aesthetic finish with various colors

High hardness and chemical resistance

Приложения:

Luxury automotive parts, режещи инструменти, Декоративни тела, медицински инструменти

13. Пасивация

Passivation chemically enhances stainless steel’s inherent corrosion resistance by removing surface iron contaminants.

Ползи:

Improved natural corrosion resistance

Cleaner and smoother stainless steel surface

Safer for applications in hygienic environments

Приложения:

Оборудване за обработка на храни, медицински изделия, pharmaceutical machinery

Factors Influencing Die Casting Surface Finish

Several key factors influence the outcome of die casting surface finishes:

Тип материал: Specific finishes are best suited to particular alloys or metals.

Die and Mold Quality: High-quality molds ensure consistent and smooth surfaces.

Casting Parameters: Контрол на температурата, injection pressure, and cooling rates directly affect surface quality.

Post-processing Methods: Proper selection and execution determine the final surface characteristics.

How to Improve Die Cast Surface Finish

Improving surface finishes involves:

Поддръжка на плесен: Regularly clean and maintain molds to avoid imperfections.

Controlled Casting Conditions: Optimize temperature and injection parameters.

Use Appropriate Post-processing Techniques: Пясъкоструене, полиране, анодиране, and others as required.

Design Optimization: Design parts to reduce complexity and minimize surface imperfections.

Заключение

Clearly understanding the variety of available surface finishing methods is crucial in achieving die-cast parts with optimal aesthetics, издръжливост, and functional performance. Selecting the appropriate finish according to the application requirements will significantly enhance product quality and customer satisfaction.

Consulting with professional die-casting specialists further ensures you select the ideal finishing processes tailored to your specific manufacturing needs.

Често задавани въпроси

Q1: What is a Die Casting Surface Finish Chart?

A reference tool showing different finishes, their characteristics, подходящи материали, и приложения, assisting manufacturers in selection.

Q2: What is Typical Surface Roughness in Die Casting?

Roughness typically ranges from 1 да се 5 µm depending on alloy, casting methods, and chosen finishes.

Q3: Does Die Casting Naturally Produce Good Surface Finishes?

Die casting alone provides decent surface quality, but post-processing finishes typically are needed to achieve enhanced aesthetics and functional properties.

Q4: How Can Surface Finish Be Improved in Die Casting?

By optimizing mold designs, controlling casting processes, and employing post-processing methods like polishing, обшивка, или покритие.

Q5: What Factors Affect Die Cast Surface Finish Quality?

Тип материал, mold temperature, die design, casting process controls, and chosen surface treatments.