Grooving machining is a common but important metalworking process used to create narrow channels or recesses on a workpiece. While it might sound simple, grooving is a precise operation that plays a big role in how parts fit together, функция, and even how they look. From sealing grooves for O-rings to decorative accents on metal products, grooving is used across industries like automotive, космическото пространство, масло & газ, и производство.

This guide breaks down what grooving machining is, как работи, the types of machines and tools used, techniques for success, Общи предизвикателства, и практически приложения.

What is Grooving Machining?

Grooving machining is a subtractive manufacturing process where a cutting tool removes material to form a channel, слот, or recessed section on the surface of a workpiece.

Grooves can be външен (on the outside diameter), вътрешни (inside a hole or bore), or on a flat surface.

The main purposes of grooving include:

Запечатване – e.g., O-ring grooves in hydraulic components.

Сглобяване – providing a space for retaining rings or snap rings.

Функционалност – making pathways for fluids or wires.

Decoration – adding aesthetic details to products.

How Grooving Machining Works

Holding the Workpiece Steady

Първо, детайлът (the material you’re machining) is clamped in place — usually on a lathe, фреза, or CNC machine. This makes sure it doesn’t move while the tool is cutting.

Избор на правилния инструмент

The grooving tool is specially shaped to match the groove you want. например, it can be straight for a simple channel, or have a rounded tip for special shapes. В много случаи, carbide-tipped or coated tools are used for better wear resistance.

Positioning the Tool

The tool is carefully aligned with the spot where the groove will be made. в CNC обработка, this positioning is done automatically with very high precision.

Making the Cut

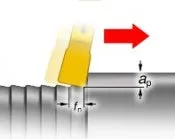

The tool moves into the material and cuts out a narrow section. The depth and width of the groove depend on the part’s design and the tool’s shape. Cutting can be done in one pass for shallow grooves, or in multiple passes for deeper ones to avoid tool stress.

Controlling Speed and Feed

The cutting speed (how fast the tool moves) and feed rate (how quickly it advances into the material) are adjusted to prevent tool wear, прегряване, or poor surface finish. Harder materials require slower speeds and careful cooling.

Finishing the Groove

After the groove is cut, the tool may make a final pass to smooth out the surface. Sometimes additional processes like polishing or deburring are used to remove sharp edges and ensure the groove meets exact specifications.

Tools Used in Grooving Operations

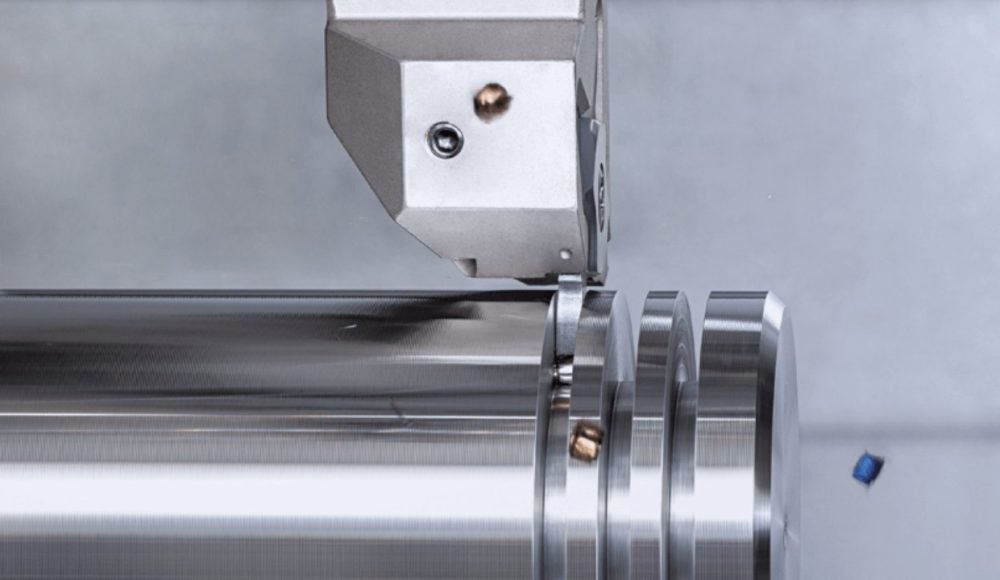

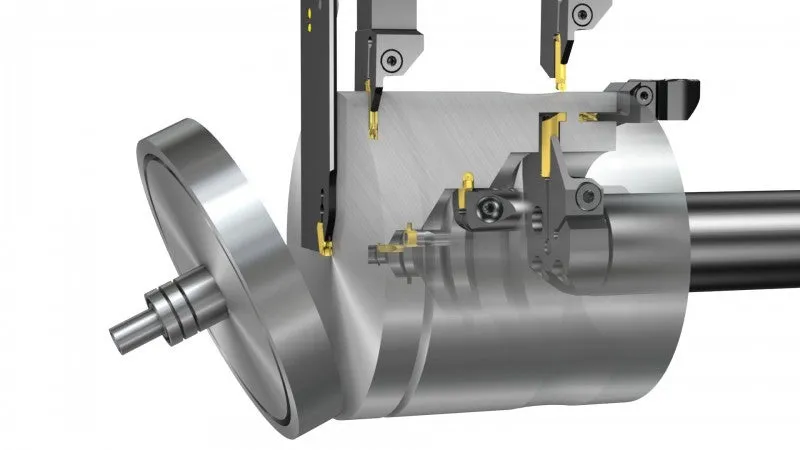

Grooving Inserts

These are tiny, replaceable cutting tips that fit into a tool holder. They come in lots of shapes and sizes to match the groove you need to cut. Carbide inserts are popular because they’re tough and last long, even on harder materials.

Grooving Turning Tools

Used mostly on lathes, these tools help cut grooves along a spinning workpiece. They come in different designs for straight grooves, face grooves, or even special contour grooves.

Parting Tools (Cut-Off Tools)

Think of these as groove tools with a dual role — they’re mainly for cutting off a finished part from the leftover material but can also cut narrow grooves when needed.

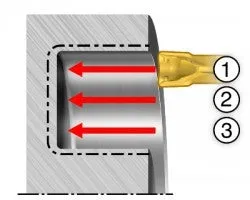

Internal Grooving Tools

These tools get inside hollow parts, like tubes or pipes, to cut grooves on the inside surfaces. They’re longer and thinner so they can reach those tight spots.

External Grooving Tools

Used to cut grooves on the outside surface of a part, these come in a variety of shapes to suit different groove sizes and profiles.

Face Grooving Tools

Designed for grooves on the flat face of a part, these tools can reach areas that regular grooving tools can’t.

Chip Breakers

Not exactly a cutting tool but an important add-on — chip breakers help break up the metal chips into smaller pieces so they don’t get tangled or cause damage during cutting.

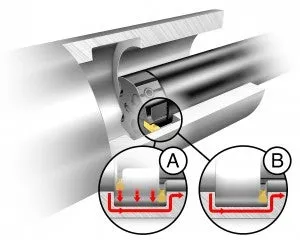

Coolant Delivery Systems

Keeping things cool during grooving is crucial. Specialized coolant nozzles aim liquid right at the cutting zone to reduce heat, Разширяване на живота на инструмента, and improve the finish.

Types of Grooving Machines

Lathe Machines

These are the most common for grooving. The workpiece spins while the cutting tool slowly carves out the groove.

Perfect for making round parts like shafts, тръби, и втулки.

Great for both small custom parts and large-scale production.

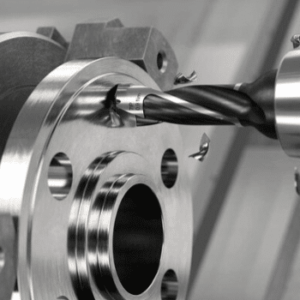

Фрезови машини

Instead of spinning the workpiece, the milling cutter spins and moves across the material to cut grooves.

Excellent for flat surfaces, слотове, and more complex shapes.

Works well when you need high precision and sharp details.

CNC Grooving Machines

Fully computer-controlled for maximum accuracy.

Can produce consistent grooves quickly and with minimal human error.

Ideal for high-volume production and complex groove patterns.

Specialized Grooving Machines

Built for specific tasks, like cutting grooves in brake discs, лагери, or tubing.

Often used in industries like automotive, космическото пространство, и масло & газ.

Provide faster and more efficient cutting for specialized needs.

Grooving Machining Techniques

External Grooving

Cutting a groove on the outside surface of a part.

Think of it like carving a ring around the outer edge of a cylinder or pipe.

Common for making O-ring seats, snap ring grooves, or decorative patterns.

Internal Grooving

Cutting grooves inside a hole or bore.

Useful for adding sealing grooves inside cylinders or creating recesses for components.

Requires special tools to reach inside without damaging the part.

Face Grooving

Making grooves on the flat face of a part, not the side.

Imagine drawing a circle on a flat surface and then cutting it into the material.

Often used for sealing surfaces in flanges or valve seats.

Parting and Grooving Combination

Some tools can cut a groove and then go deeper to fully separate the part.

Saves time and reduces tool changes in production.

Multi-Groove Cutting

Cutting several grooves in a single pass using special tooling.

Ideal for parts that need repeated patterns or multiple parallel grooves.

Material Choices for Grooving Machining

Алуминий — The Easygoing Metal

Aluminum is soft and lightweight, which makes it super friendly for grooving. You can run the machines faster, and the tools don’t wear out as quickly. But watch out for those sticky chips that can get tangled and slow things down. Using sharp tools and keeping the chips moving with good coolant helps keep things smooth.

Неръждаема стомана — The Tough Guy

Stainless steel is strong and a bit stubborn. It’s harder on your tools and creates more heat, which means you have to slow things down a bit. Също, stainless steel can harden as you cut it (called work hardening), so keeping your speeds and feeds just right is key. Don’t forget plenty of coolant to keep things cool and your tools happy.

Месинг — The Smooth Operator

Brass is like the happy medium. It’s soft enough to cut quickly but tough enough to hold a good shape. It makes small, manageable chips that don’t clog up your machine, which is a big plus. плюс, it’s gentle on your tools, but a bit of lubricant goes a long way to keep everything running smoothly.

Излято желязо — The Rough and Ready

Cast iron is hard and brittle. It’s not the easiest material to groove because it can cause your tools to wear fast or even break if you’re not careful. But if you use the right tools and slower speeds, you can get nice grooves without too much trouble. Coolants and chip control are important here.

Пластмаси — The Flexible Friend

Grooving plastics is usually easier because they’re softer, but they can melt or deform if you get the speeds wrong. Keep your cutting speed moderate and use sharp tools to avoid melting or cracking.

What’s the Difference Between Grooving and Other Machining Techniques?

| Техника на обработка | What It Does | Как работи | Типична употреба | How It Differs from Grooving |

| Набраздяване | Cuts narrow grooves or channels | Cutting tool creates precise, narrow cuts on a rotating workpiece (usually on a lathe) | Making grooves for seals, О-пръстени, retaining rings | Focused on small, precise grooves rather than shaping whole parts |

| Обръщане | Shapes round or cylindrical parts | Workpiece spins, and tool removes material to create external or internal shapes | Making shafts, конуси, цилиндри | Grooving is a specialized form of turning focused on grooves instead of full shapes |

| Фрезоване | Removes material to create flat surfaces, джобове, или сложни форми | Spinning cutting tool moves over a stationary workpiece | Creating flat faces, слотове, or complex 3D features | Milling cuts stationary parts, grooving cuts rotating parts; milling shapes large features |

| Смилане | Smooths and finishes surfaces | Abrasive wheel removes tiny amounts of material to polish or size parts | Довършителни работи, achieving tight tolerances | Grinding finishes surfaces; grooving cuts material to form grooves |

| Прорязване | Creates long, narrow cuts (слотове) | Tool cuts linear slots in the workpiece, often wider and deeper than grooves | Keyways, fastener slots | Slots are usually bigger and serve different functions than grooves |

Common Challenges in Grooving Machining

Tool Breakage

Grooving tools are often narrow and fragile compared to standard turning tools.

If the feed rate is too aggressive or the material is too hard, the tip can snap.

Съвет: Use the correct tool size, and don’t push it harder than recommended.

Лош контрол на чиповете

When chips don’t break properly, they can get stuck in the groove, scratch the surface, or wrap around the tool.

Съвет: Choose insert geometries and cutting parameters designed for better chip breaking.

Vibration and Chatter

Long or thin tools can vibrate, leaving ripples on the groove surface.

Съвет: Keep the tool overhang short, reduce cutting speed, and ensure the setup is rigid.

Прегряване

Grooving generates a lot of heat in a small area. Without enough cooling, the tool can wear quickly, and the part’s surface can burn.

Съвет: Use proper coolant flow or, for some materials, high-pressure coolant to flush chips and control temperature.

Surface Finish Problems

If the groove looks rough or uneven, it may be due to dull tools, вибрация, or improper feed rates.

Съвет: Keep the tool sharp and adjust cutting conditions for smoother finishes.

Maintaining Tight Tolerances

In sealing or fitting applications, even tiny errors in groove width or depth can cause leaks or part failure.

Съвет: Measure carefully during and after machining, and use tools with high dimensional accuracy.

Applications of Grooving Machining

Автомобилни части – From piston rings to drive shafts, grooving helps create the spaces needed for seals, snap rings, or lubrication channels. Without those grooves, engines and transmissions wouldn’t run nearly as smoothly (or last as long).

Аерокосмически компоненти – Airplanes and spacecraft use grooved parts for critical functions, like holding retaining rings in place or managing fluid flow in hydraulic systems. Precision is key here—tiny errors can cause big problems.

Hydraulics and pneumatics – Grooves help hold O-rings or sealing elements that prevent leaks in high-pressure systems. Without them, hydraulic cylinders or pneumatic actuators wouldn’t stay sealed under heavy loads.

Electronics and connectors – Many electrical connectors and small mechanical parts use fine grooves for locking mechanisms or guiding assemblies together.

Индустриални машини – From pumps to conveyor systems, grooves are cut into shafts, ролки, and housings for alignment, locking, or lubrication purposes.

Медицински изделия - Хирургически инструменти, импланти, and diagnostic equipment often have micro-grooves for fluid channels, attachment points, or anti-slip designs.

Заключение

Grooving machining is a versatile process that can be as simple as cutting a narrow slot or as precise as creating micron-level sealing grooves in aerospace parts. The key to success is using the right tools, машини, and techniques while understanding the material’s properties and the groove’s function.

With advancements in CNC technology, grooving has become faster, по -прецизно, and more repeatable—making it an essential skill for any modern machinist.

Често задавани въпроси

1. What is the difference between an external groove and a face groove?

The difference is the orientation on the workpiece:

-

External Groove: A channel cut around the outside diameter (OD) of a cylindrical part (напр., cutting a ring on a shaft). This is typically performed on a lathe.

-

Face Groove: A channel cut on the flat face of a part, perpendicular to the axis of rotation. This is often used for sealing flanges or specialized valve seats and also requires specialized tooling on a lathe or sometimes a mill.

2. Why is “chip control” often the biggest challenge in grooving compared to standard turning?

Chip control is difficult because the grooving tool is narrow and only engages the material on three sides (front and both sides). This tight confinement makes it hard for the chips to curl and break cleanly. If the chips don’t break, they form long, stringy spirals that can get re-cut, scratch the finished surface, wrap around the tool, or block the coolant, all leading to overheating and tool failure.

3. Какво е P/M/K designation often found on grooving inserts?

The P/M/K designation refers to the three primary ISO material groups for which the insert geometry and coating are optimized:

-

П (Синьо): Стомана (напр., Carbon and Alloy Steels).

-

М (Yellow): Неръждаема стомана.

- К (Red): Cast Iron.Choosing an insert designed for the correct material group is crucial for achieving optimal chip breaking and tool life.

4. How does the type of groove (O-ring vs. Snap Ring) affect machining requirements?

The type of groove dictates the required precision and tool profile:

-

O-Ring Groove (Запечатване): Requires extremely smooth surface finishes and precise dimensional control (depth and width) to ensure a perfect, leak-proof seal. The groove floor is usually slightly rounded.

-

Snap Ring / Retaining Ring Groove (Сглобяване): The key requirement is precise groove width and location to correctly anchor the ring. The side walls must be vertical and the corners sharp.

5. What is the main cause of vibration and chatter in grooving operations?

The primary cause is Инструмент надвес (the length the tool extends from the holder). Because grooving tools are narrow and relatively long, they lack the stiffness of wider tools. If the overhang is too long, the tool acts like a tuning fork, причиняване бърборене which results in poor surface finish, шум, and premature tool wear. Keeping the tool overhang as short as possible is the primary fix.

6. Why do stainless steel and soft aluminum pose different challenges when grooving?

They pose challenges due to different physical properties:

-

Неръждаема стомана: The primary issue is work hardening (the material gets harder as you cut it) и генериране на топлина. This requires robust tools, по -бавни скорости, and aggressive feeds to cut below the hardened surface layer.

-

Soft Aluminum: The primary issue is smearing and chip sticking. The material is sticky and tends to adhere to the cutting edge, формиране изграден ръб (ЛЪК), which ruins the surface finish. This requires extremely sharp tools, higher rake angles, and excellent chip evacuation.

7. When is a milling machine used for grooving instead of the standard lathe?

A milling machine is used when the groove needs to be created on a non-cylindrical surface or when the groove needs to be interrupted (not a full circle). Примерите включват:

-

Нарязване шпонкови канали on the flat end of a shaft.

-

Creating a groove pattern on a flat plate or housing.

-

Cutting very deep or wide rectangular slots (which fall between milling and grooving).