Undercut machining is a specialized CNC process used to produce recessed features that are challenging—or impossible—to reach with standard milling tools. As modern product designs become more complex and compact, the demand for undercuts grows in industries such as aerospace, медицински, и автомобилостроенето. This article provides an in-depth look at undercut machining: what it is, защо има значение, how it’s done, различните видове, and expert tips for success.

What Is Undercut Machining?

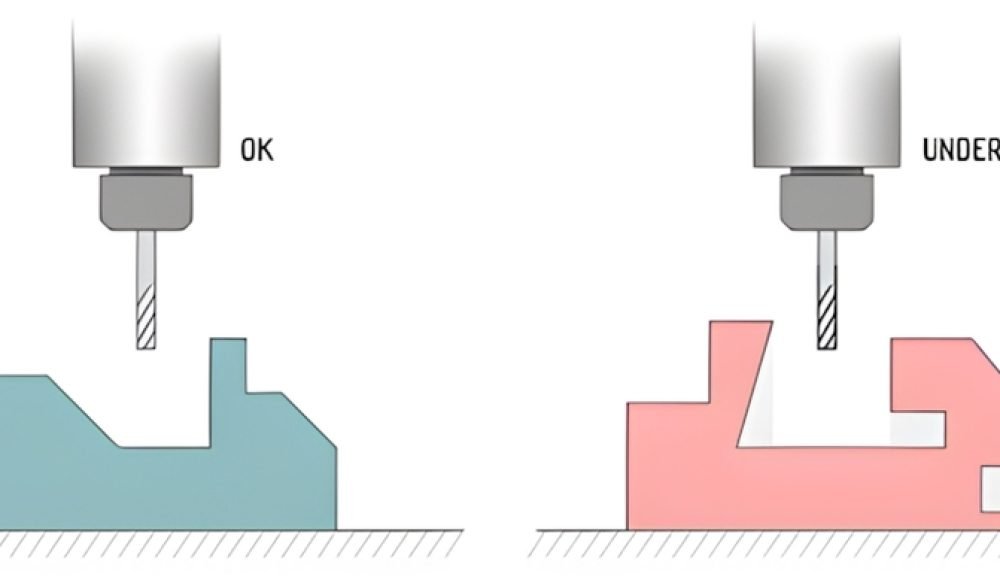

Undercut machining refers to the process of removing material beneath an overhanging section or from an area that is partially obstructed, making it inaccessible by conventional vertical tools. Traditional 3-axis mills struggle with these features due to geometric constraints, so machinists rely on specialized tools—like lollipop cutters and T-slot mills—and advanced CNC машини, включително 4- and 5-axis setups.

There are two primary categories:

Internal Undercuts – Recessed features within a component, such as grooves inside a gear hub or cavities in medical instruments.

External Undercuts – Visible indentations or recesses like those found in molded parts or locking mechanisms.

Why Are Undercuts Important?

Undercuts are essential in both functional and aesthetic aspects of part design. They serve several purposes:

Mechanical Functionality: Provide locking features or retention points in assembly designs without requiring fasteners.

Weight Reduction: Enable internal hollowing of components to reduce mass while maintaining structural integrity—critical in aerospace and motorsport applications.

Fluid Channels: Act as pathways for liquids or lubricants in hydraulic and pneumatic systems.

Improved Fit: Facilitate tight frictional fits or allow for movement, such as in spherical or threaded joints.

Despite their complexity, undercuts are sometimes the only way to meet specific performance or assembly requirements.

Step-by-Step Guide to the Undercut Machining Process

1. Look at the Design First (Evaluate the Geometry)

Before you even touch the machine, take a good look at your 3D model in CAD software. Запитайте се:

Is the undercut on the inside or outside of the part?

Can the tool actually reach that area?

What angles will you need?

This will help you decide how to approach the job.

2. Pick the Right Tool for the Job (Select the Right Tool)

Different undercuts need different tools. Here are some common ones:

Lollipop cutters – Great for rounded or one-sided undercuts.

Dovetail cutters – Perfect for angled grooves.

T-slot cutters – Ideal for that classic “T” shape.

Keyway cutters or broaches – Used when you need to lock parts together with a key.

Choosing the right tool makes everything easier (and prevents broken bits).

3. Get the CNC Machine Ready (Prepare the CNC Setup)

Time to set up your machine. Here’s what to do:

If your part has tricky angles, а 4- or 5-axis CNC machine will give you better access.

Load the CAM program with all the correct tool paths.

Make sure your part is held tight in the fixture so it won’t shift or vibrate during cutting.

Good prep = smooth machining.

4. Let the Machine Do Its Job (Machine the Undercut)

След като всичко е настроено, hit go! Keep an eye on things:

Make sure chips (the little bits of metal that get cut away) are being cleared properly—especially in tight spots.

Watch for tool wear. Narrow areas and deep cuts can be hard on your cutter.

It’s okay to pause and check things if needed.

5. Check That Everything’s Right (Inspect and Verify)

След изрязване, it’s time to double-check your work:

Use tools like a CMM, optical comparator, или profile projector to measure dimensions and surface quality.

If you’re working on something high-precision, you might need to do a finishing pass for a smoother surface.

Don’t skip this step—quality control saves time and money later!

Common Types of Undercuts in CNC Machining

-

One-Sided Undercut

🛠 Какво е: A groove or cut on just one side of a part—like a notch that doesn’t go all the way through.

🔧 Tool used: Lollipop cutter (named because it looks like a lollipop!)

📦 Където се използва: Snap-fit connections, grooves for retaining rings, or any area needing a clean one-sided slot. -

Dovetail Undercut

🛠 Какво е: A wedge-shaped cut that’s wider at the base—kind of like a trapezoid. It locks in a matching piece.

🔧 Tool used: Dovetail cutter

📦 Където се използва: Tooling setups, sliding joints, or even wood-style joints in metal parts. -

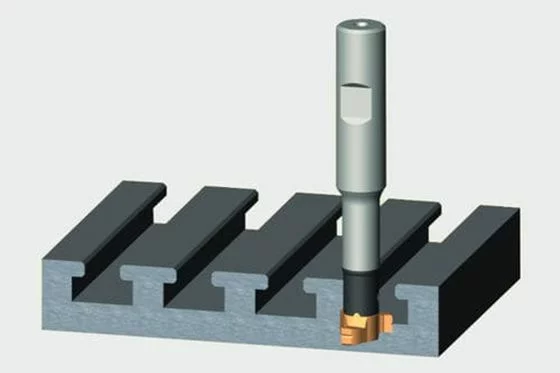

T-Slot Undercut

🛠 Какво е: A “T”-shaped groove that allows bolts to slide and lock in.

🔧 Tool used: T-Slot резачка

📦 Където се използва: CNC machine tables, modular assembly platforms—basically anywhere you need adjustable fixtures. -

Tapered Undercut

🛠 Какво е: A groove that gets narrower as it goes—like a ramp or slope inside the part.

🔧 Tool used: Tapered end mill

📦 Където се използва: Self-locking fits parts that need to look sleek, or areas where a taper helps hold things in place. -

Spherical Undercut

🛠 Какво е: A rounded, ball-like groove that curves inward.

🔧 Tool used: Ball-nose end mill

📦 Където се използва: Лагери, ball joints, or any part that rotates smoothly and needs a round cavity. -

Threaded Undercut

🛠 Какво е: An undercut that has threads inside for screwing things together.

🔧 Tool used: Thread mills or taps

📦 Където се използва: Pressure fittings, tight mechanical assemblies—especially when space is limited. -

O-Ring Groove

🛠 Какво е: A circular groove made specifically to hold an O-ring (rubber gasket).

🔧 Tool used: O-ring groove cutter

📦 Където се използва: Hydraulic connectors, помпи, engine components—anywhere you need a tight, leak-free seal. -

Relief Undercut

🛠 Какво е: A small recess added near rotating parts to reduce stress and friction.

🔧 Tool used: Slotting cutter or undercut end mill

📦 Където се използва: Лагери, gear shafts, or rotating parts that need just a bit of clearance. -

Keyway Undercut

🛠 Какво е: A slot cut into a shaft to hold a key that locks two rotating parts together.

🔧 Tool used: Keyway cutter or broach

📦 Където се използва: Двигатели, скоростни кутии, or anything that transfers torque without slipping.

Specialized Tools for Undercut Machining

Lollipop Cutters: Ideal for spherical and hidden grooves.

T-Slot Cutters: Designed to mill both bottom and side of T-slots in one pass.

Dovetail Cutters: Angled blades match common dovetail profiles.

Keyway Broaches: Remove material linearly to create uniform slots.

Undercut End Mills: Versatile tools with side and bottom flutes.

Tips for Successful Undercut Machining

Avoid Deep Cuts: Design shallow undercuts to ensure tool access and reduce deflection.

Use Multi-Axis CNC: Enables better access angles and smoother paths.

Optimize CAM Paths: Minimize sudden changes in direction or depth.

Partner with Specialists: Shops with experience and tooling for undercuts improve part quality and reduce cost.

Дизайн за производство: Eliminate unnecessary undercuts during early design when possible.

Заключение

Undercut machining is a high-precision, technically demanding process that enables engineers to incorporate complex features into parts where conventional tools fall short. Whether you’re creating locking mechanisms, optimizing fluid channels, or achieving lightweight performance, undercut features play a critical role in modern mechanical design.

С правилните инструменти, техники, and CNC equipment, manufacturers can machine undercuts efficiently and repeatably. Чрез разбиране на нюансите на избора на инструменти, geometry analysis, and process planning, designers and machinists can push the boundaries of what’s possible in CNC machining.

Често задавани въпроси

1. What is the fundamental difference in tool access between an undercut and a conventional pocket?

The difference lies in the line of sight from the cutting tool to the feature:

-

-

Conventional Pocket: The cutting tool can approach and mill the entire feature using a straight vertical path (along the Z-axis).

-

Undercut: The feature has an overhanging section or a recessed area that makes it inaccessible by a tool moving only along the Z-axis. Specialized tools, like lollipop cutters or T-slot cutters, are required to reach под the obstruction by cutting laterally or at an angle

-

2. Защо са 4- and 5-axis CNC machines often necessary for complex undercut machining?

While simple undercuts (like T-slots) can be done on a 3-axis machine using special tooling, 4- и 5-осни CNC машини are necessary for complex undercuts because they allow the workpiece or the tool to rotate and tilt. This multi-axis capability:

-

Improves Access: Allows the tool to approach the undercut from multiple angles without obstruction.

-

Reduces Setup Time: Complex features can be machined in a single setup, eliminating the need for manual re-fixturing and reducing cumulative error.

3. What is the primary functional advantage of a Dovetail Undercut?

The primary functional advantage of a dovetail undercut is mechanical locking and retention. Because the groove flares out (becomes wider) at its base, it creates a wedge shape. When a matching dovetail feature is inserted, it provides a strong mechanical lock that can handle tension and shear forces, ensuring the assembled components are securely held together without requiring separate fasteners.

4. What key design constraint should be avoided to prevent tool deflection during undercut machining?

Designers should avoid deep, narrow undercuts with long tool reach. Undercut tools (like lollipop or T-slot cutters) are often thin and long, making them inherently less rigid than standard end mills. When a long tool is forced to reach deep into a confined space, it is highly prone to tool deflection (огъване). Deflection leads to inaccurate undercut dimensions, Лошо повърхностно покритие (бърборене), and significantly increases the risk of tool breakage.

5. How do Relief Undercuts enhance the performance of mating rotating parts (Като валове и зъбни колела)?

Relief undercuts are small recesses added at the junction where a shaft diameter changes or where a bearing/gear mates with a shoulder. Their function is to ensure perfect, stress-free seating of the mating part. The relief provides clearance so that the gear or bearing is seated precisely against the vertical shoulder, предотвратяване:

-

Концентрация на стрес: Eliminating sharp corners that could lead to fatigue failure.

-

Fit Interference: Ensuring the mating component doesn’t bottom out on a machining radius instead of the intended flat surface.

6. When designing an O-Ring Groove, which tool dimension must match the groove’s radius and width?

When designing an O-Ring Groove, на groove width и radius of the corner must be precisely controlled. Specialized O-Ring Groove Cutters are typically used. The width of the cutter determines the groove width, и на radius of the tool’s cutting edge determines the fillet radius in the bottom corners of the groove. This precision ensures the O-ring is seated correctly and performs its vital sealing function without being pinched or extruded under pressure.