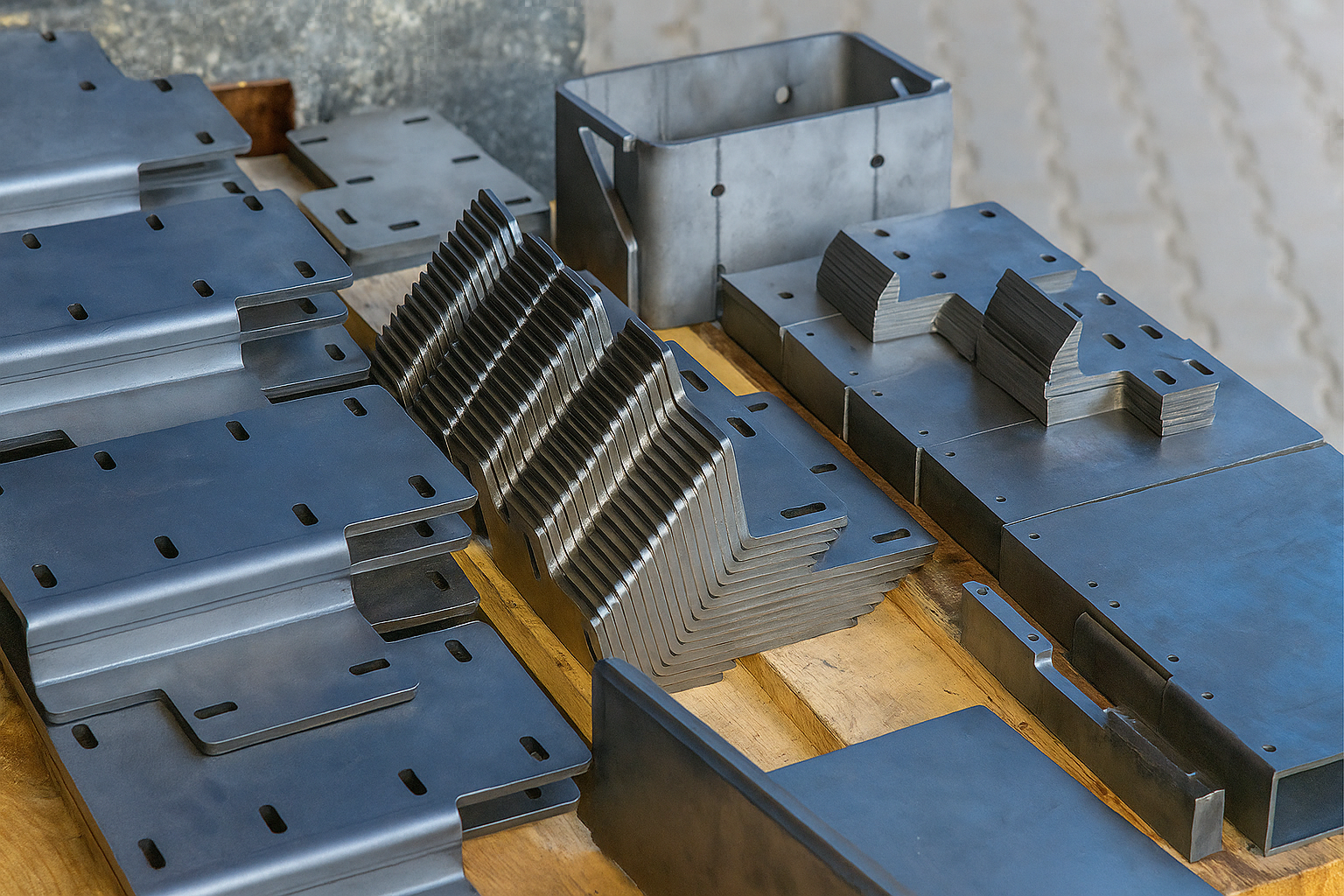

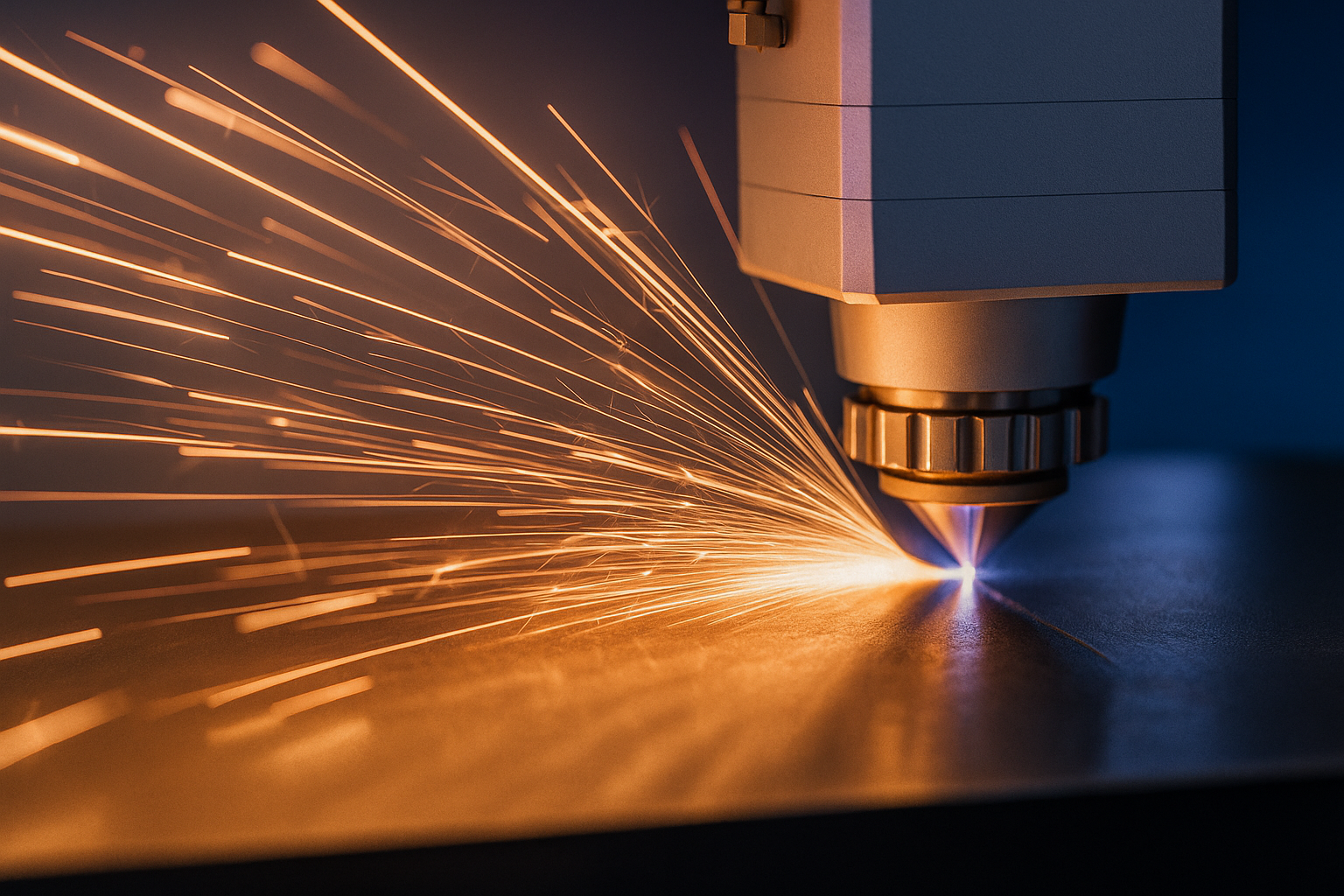

Какво е обработката на ламарина?

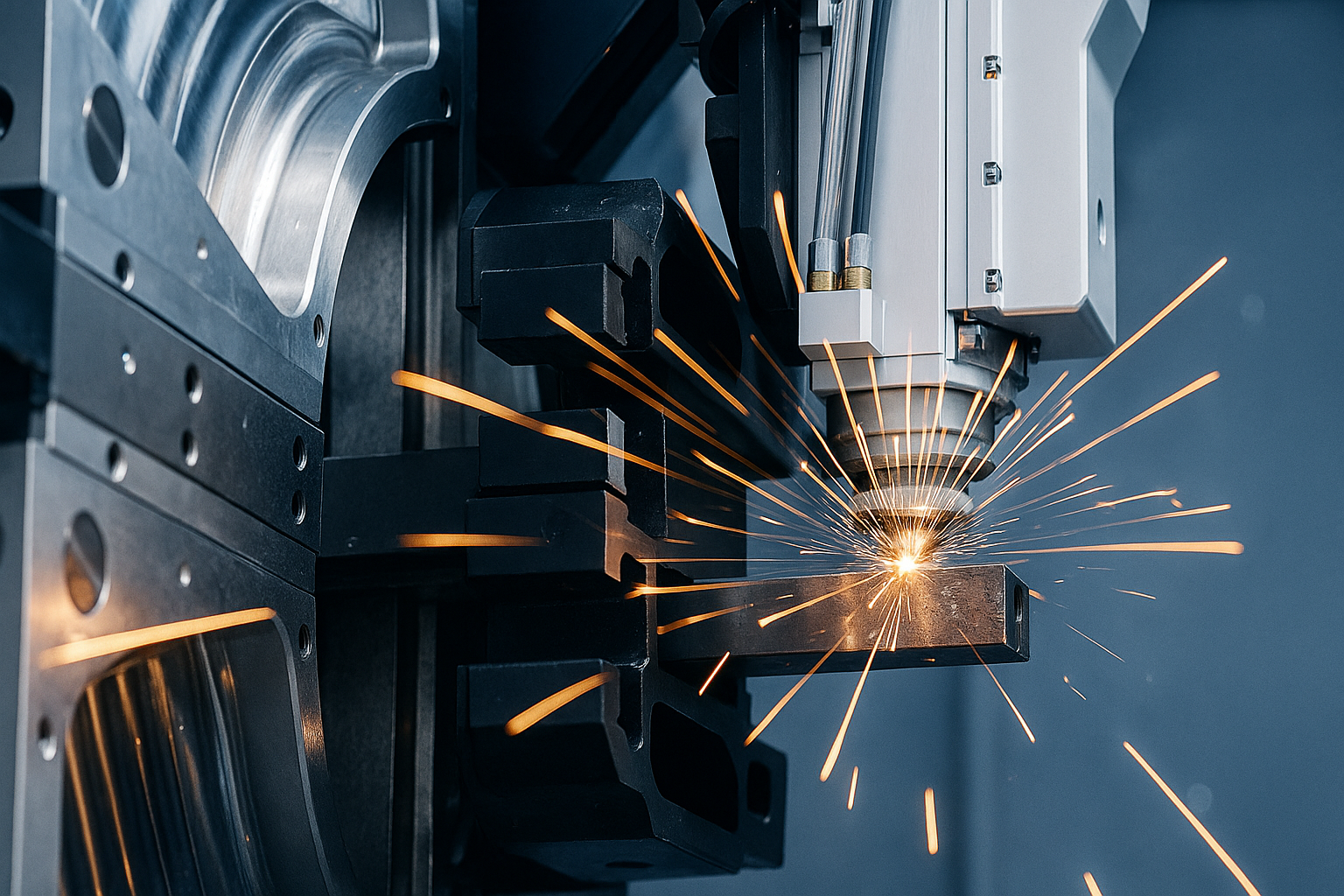

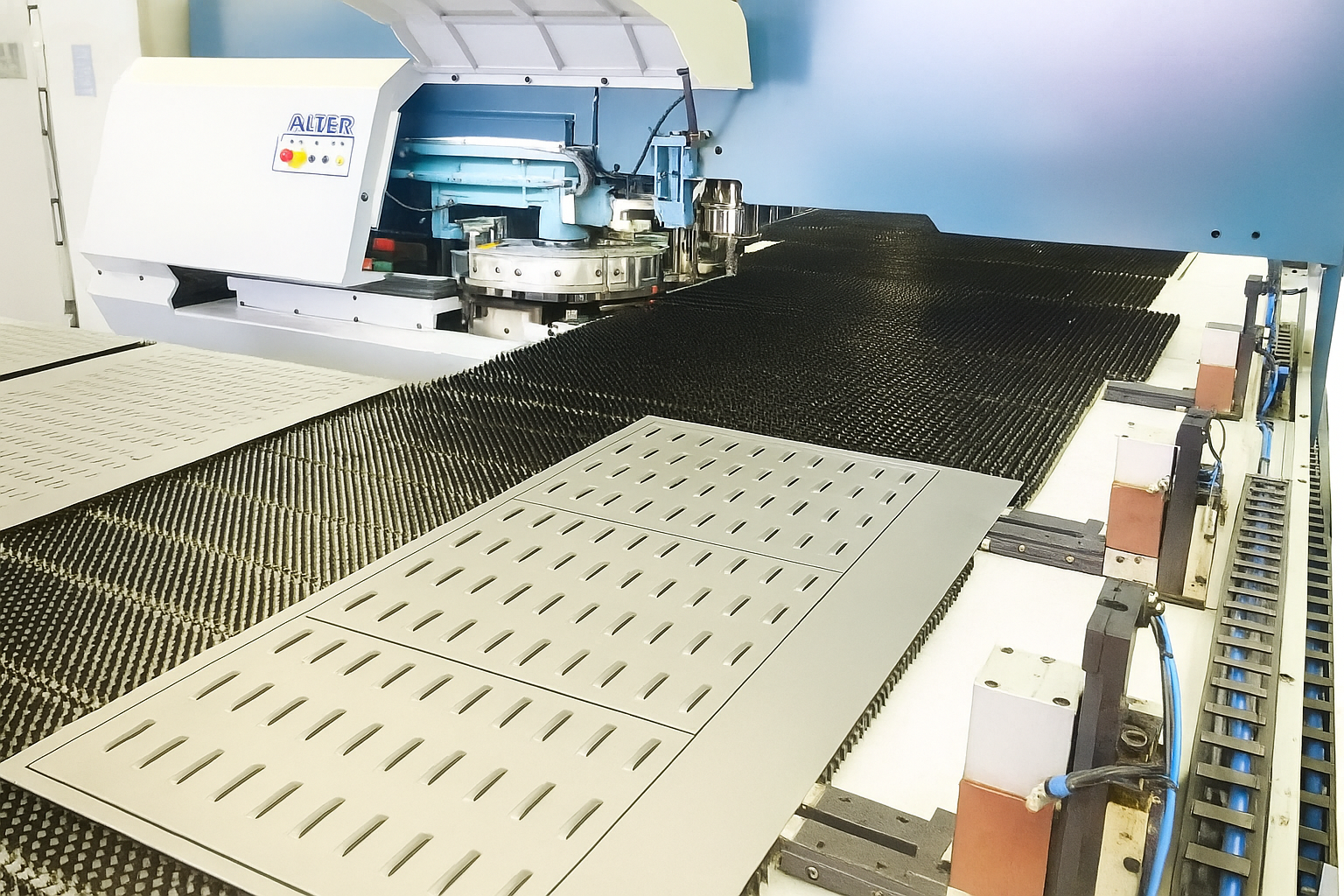

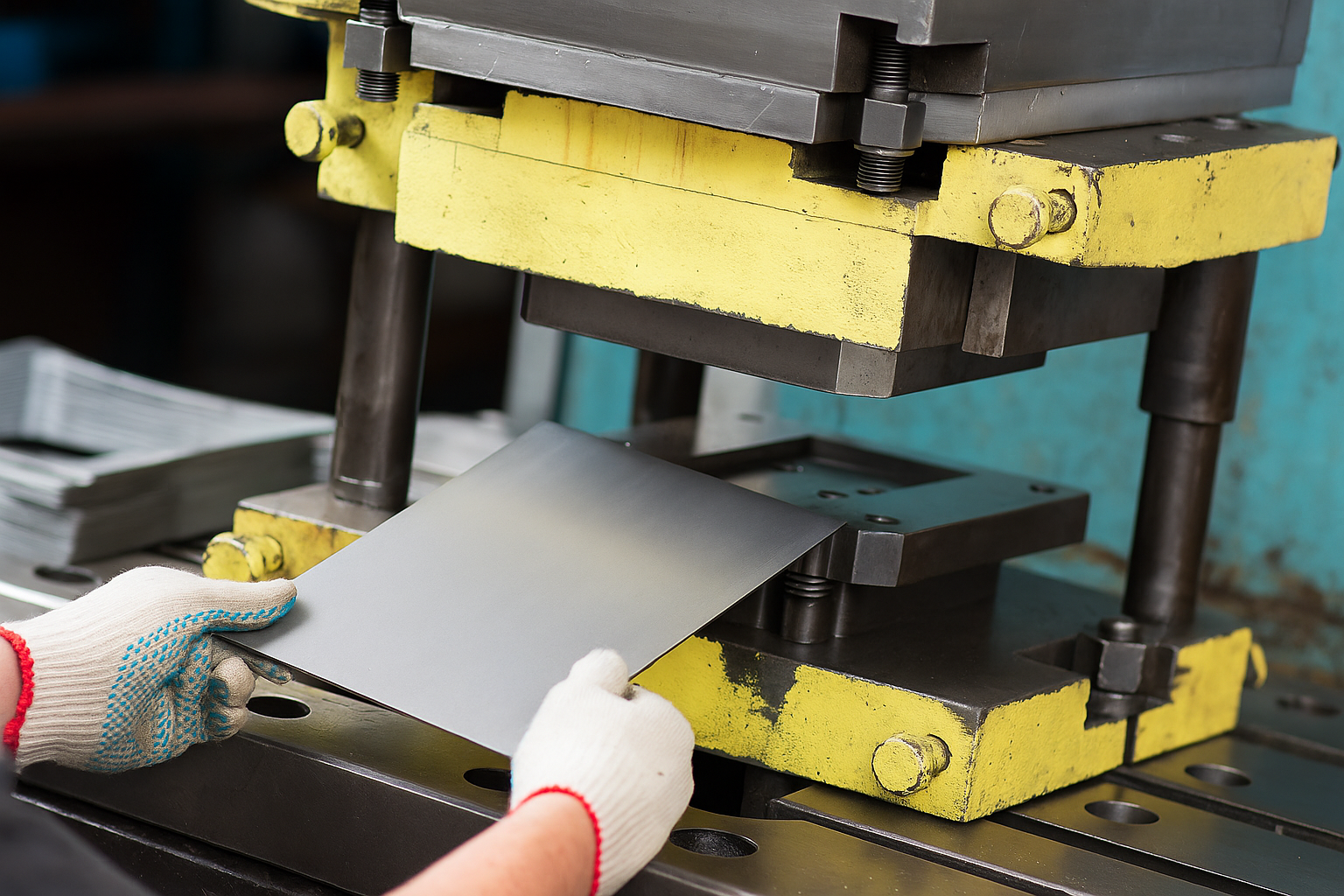

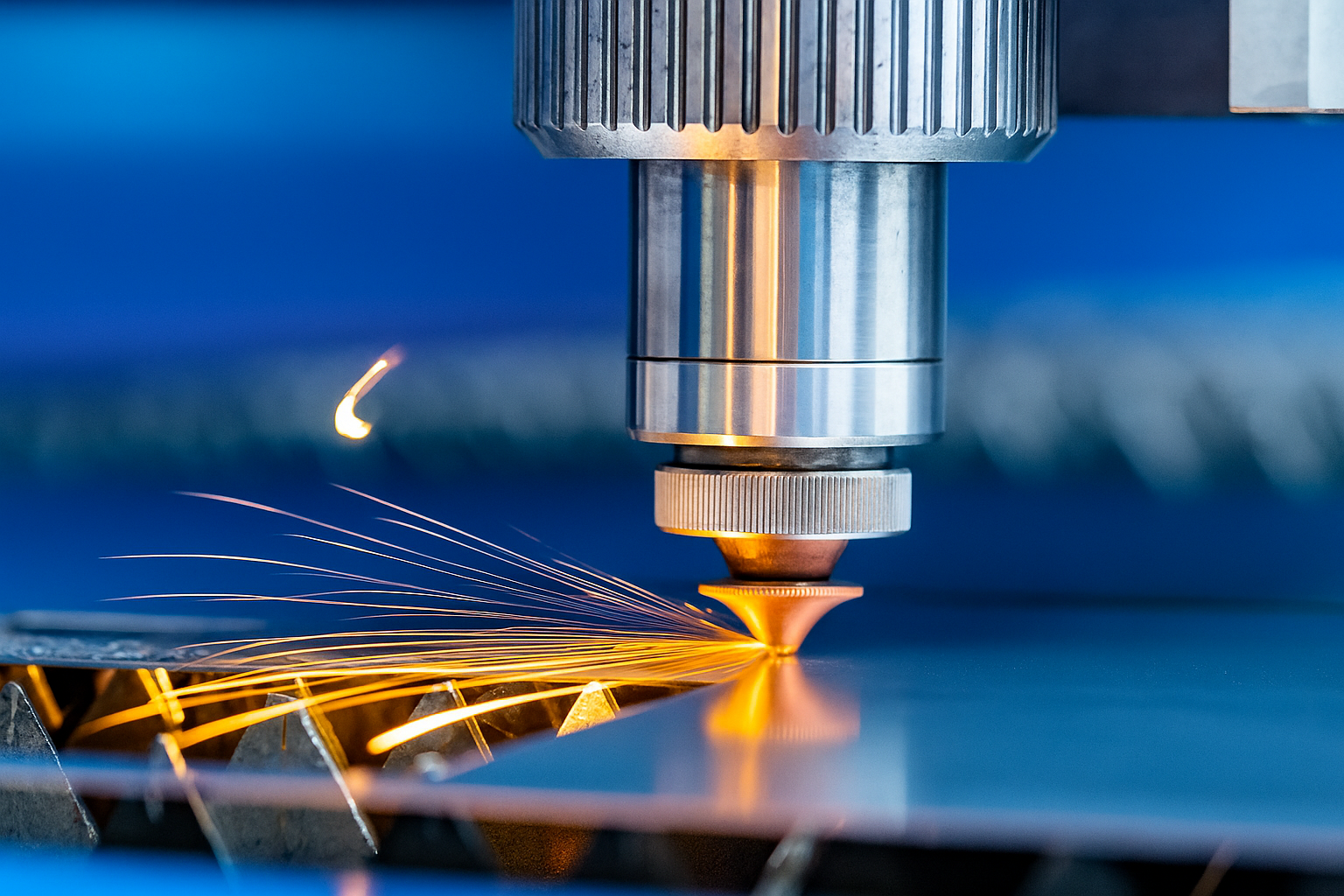

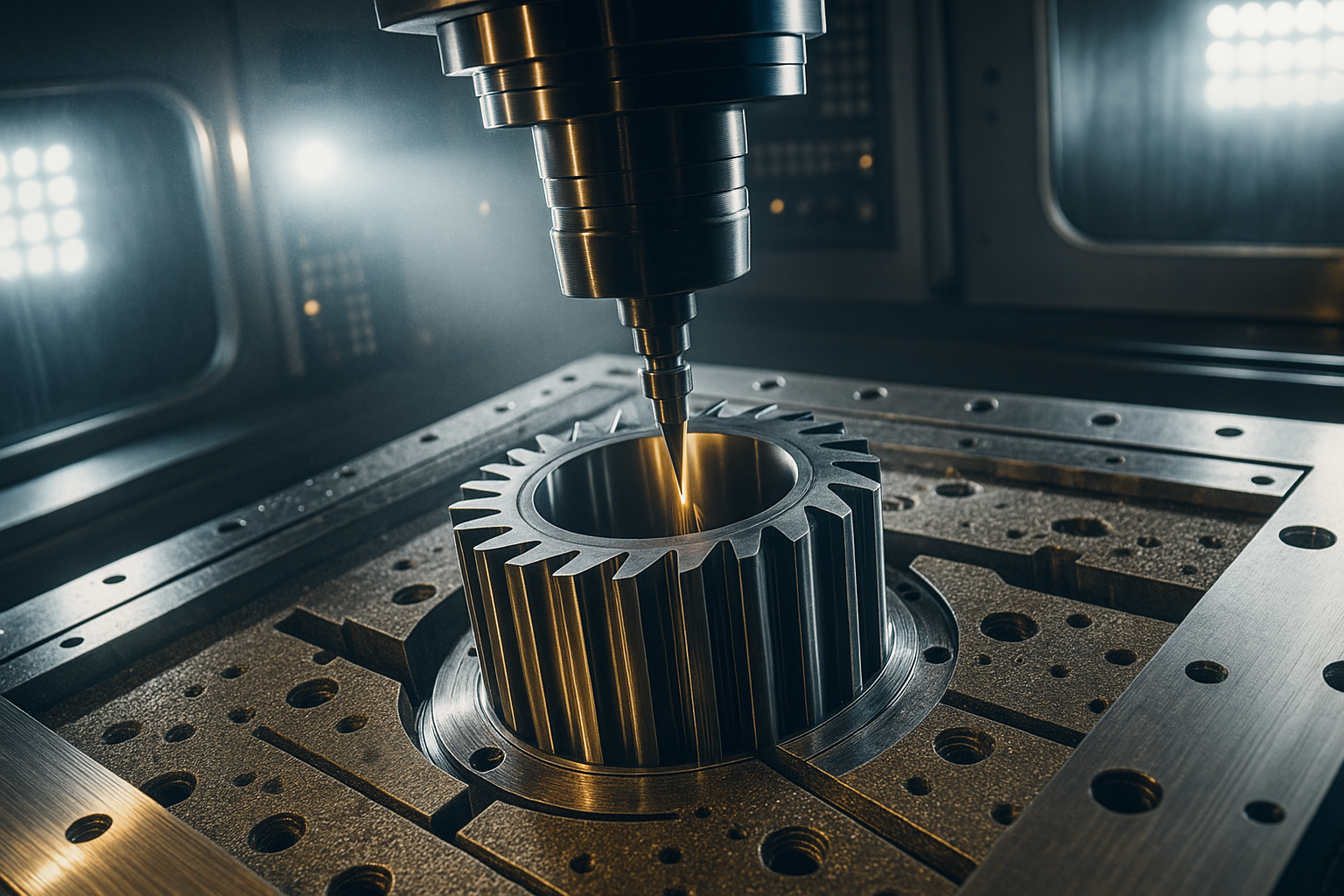

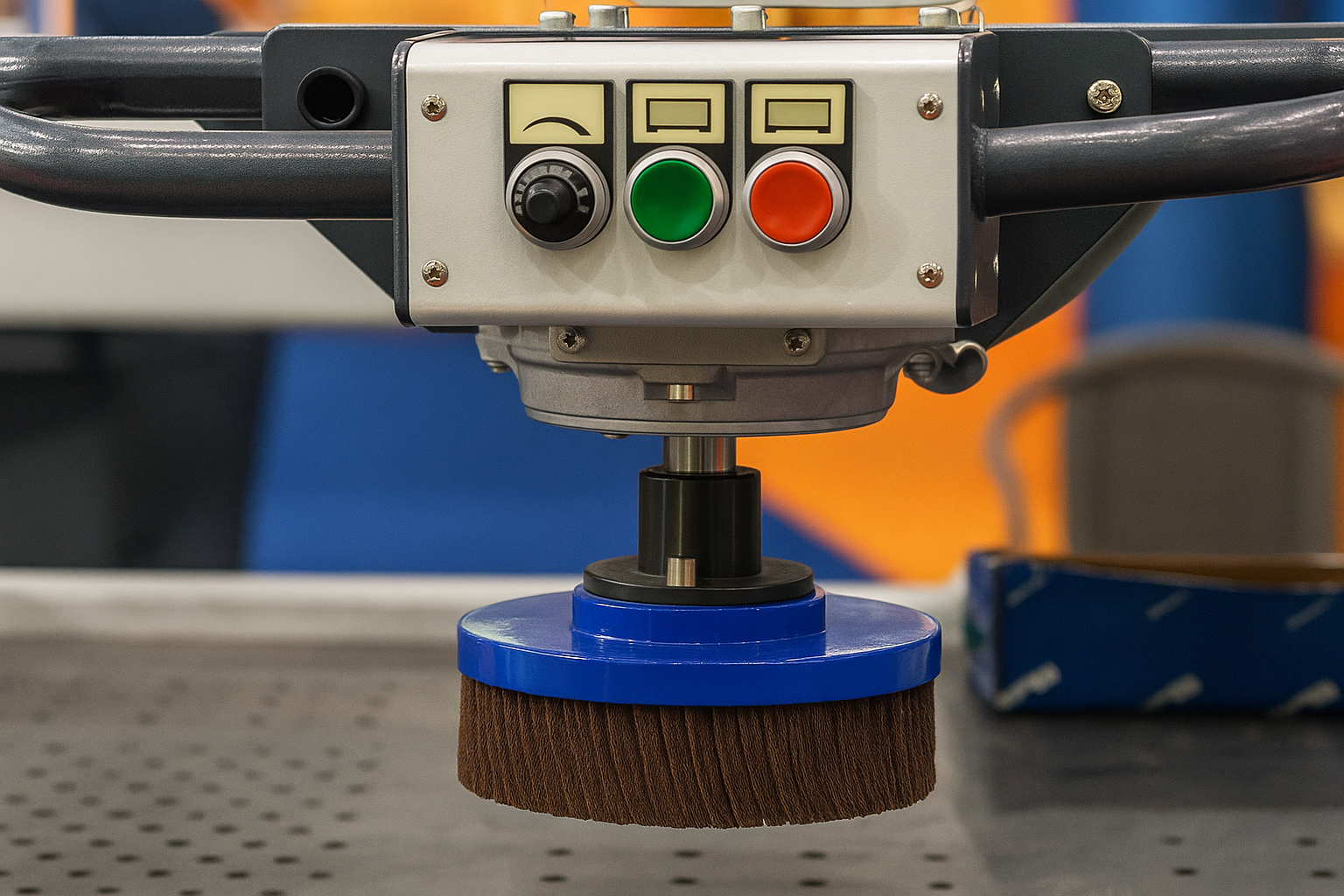

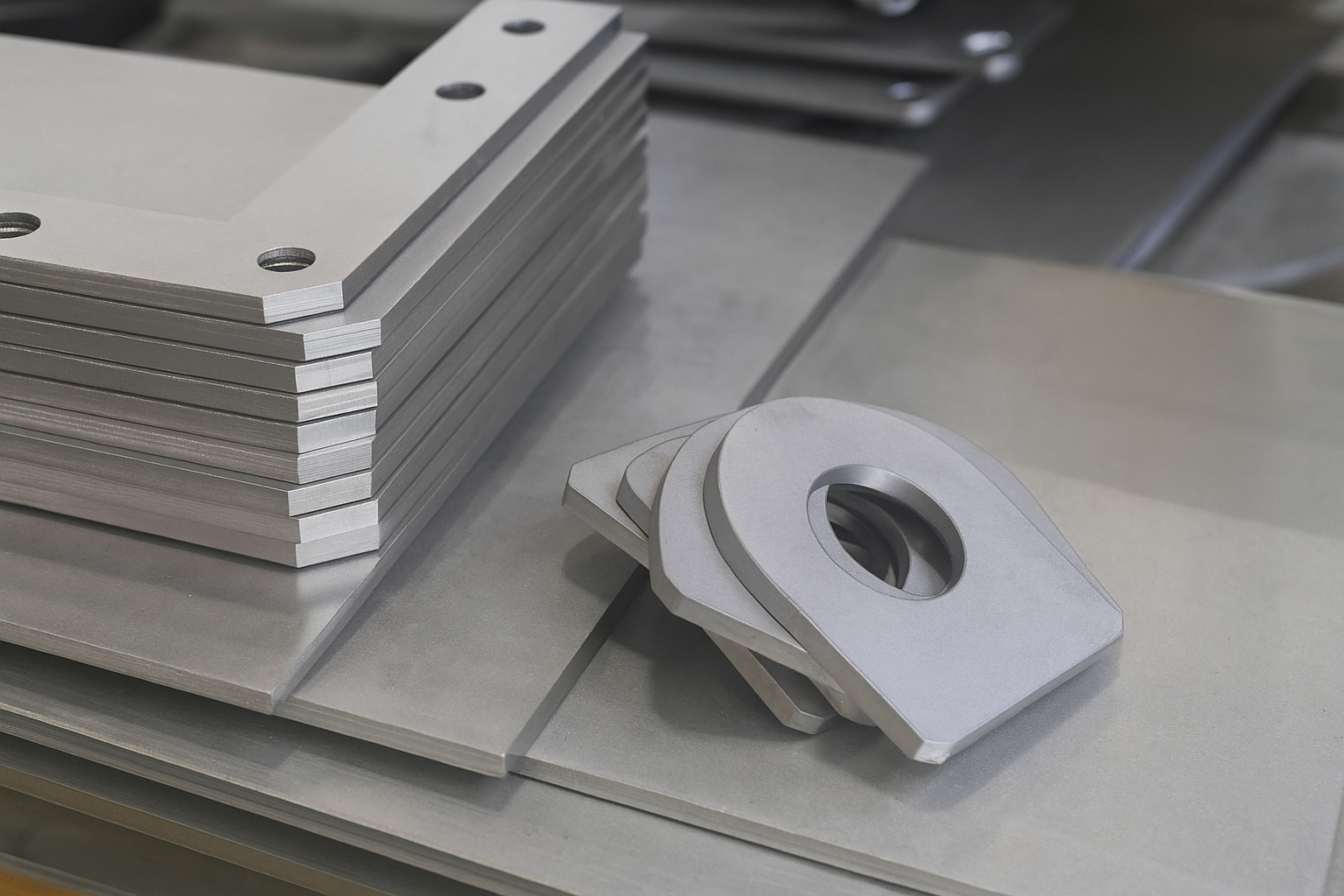

Sheet metal machining is shaping metal sheets into different parts using a wide range of manufacturing processes. These processes are cutting, огъване, щанцоване, заваряване, формиране, и довършителни. It is a main process for industries to make strong, светлина, and carefully engineered parts. Certain devices include machined sheet metal parts.