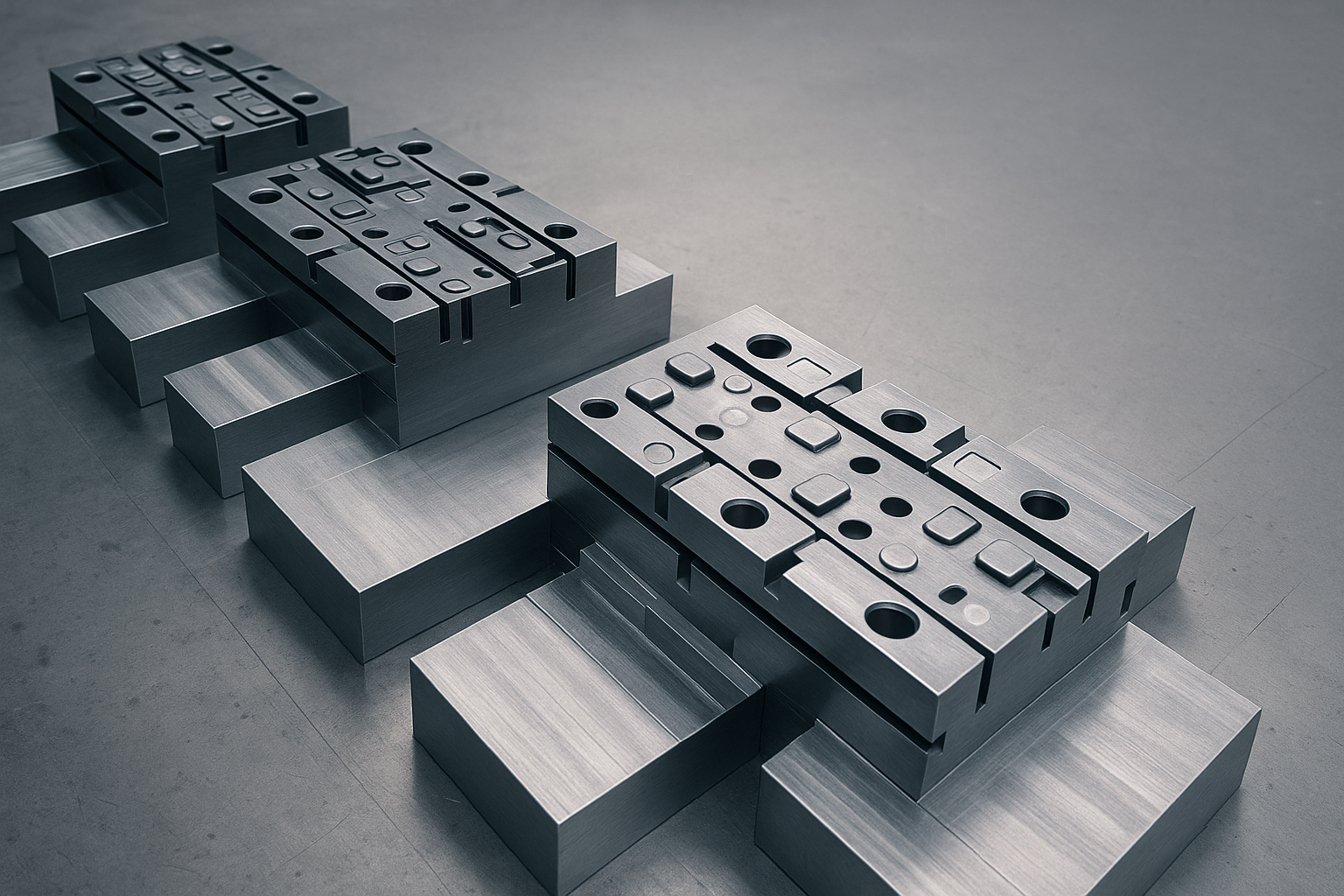

Какви са различните налични титанови сплави?

Ние се прибираме най-търсените титанови сплави в Китай.

Сплав | Описание | Приложения |

Ti-6Al-4V (Степен 5) | Това е най -широко използваната сплав. Силен, топлинен устойчив. | Космонавтика, медицински |

Ti-6Al-4V ELI (Степен 23) | По -висока чистота. Подобрена пластичност. | Импланти, хирургически инструменти |

Ti-3Al-2.5V (Степен 9) | Висока устойчивост на корозия, средна сила. | морски, спорт |

Търговски чист (Cp) Титан | оценки 1-4. Ковък, устойчиви на корозия. | Топлообменници, медицински |

Изпратете вашето запитване днес

Свойства на материала на титан

Високо съотношение на якост към тегло

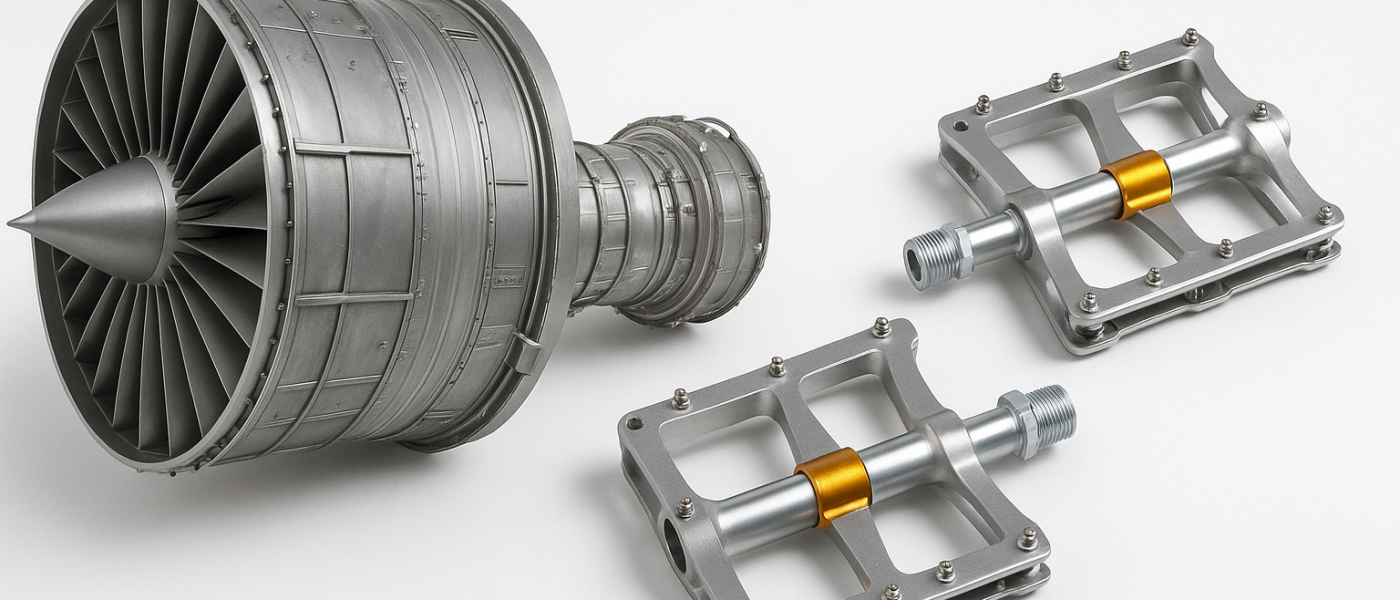

Титанът доставя силата на стоманата, докато е почти 45% запалка, което го прави идеален за аерокосмиче, автомобилен, и премиум приложения, при които намаляването на теглото е от решаващо значение.

Устойчивост на корозия

Естествено устойчив на корозия, Титанът се представя изключително добре в тежки среди като солена вода и агресивни химикали, което го прави най -добрият избор за морска и химическа обработка.

Биосъвместимост

Титанът е нетоксичен и силно съвместим с човешкото тяло, Ето защо често се използва в медицински импланти, хирургически инструменти, и стоматологични приложения.

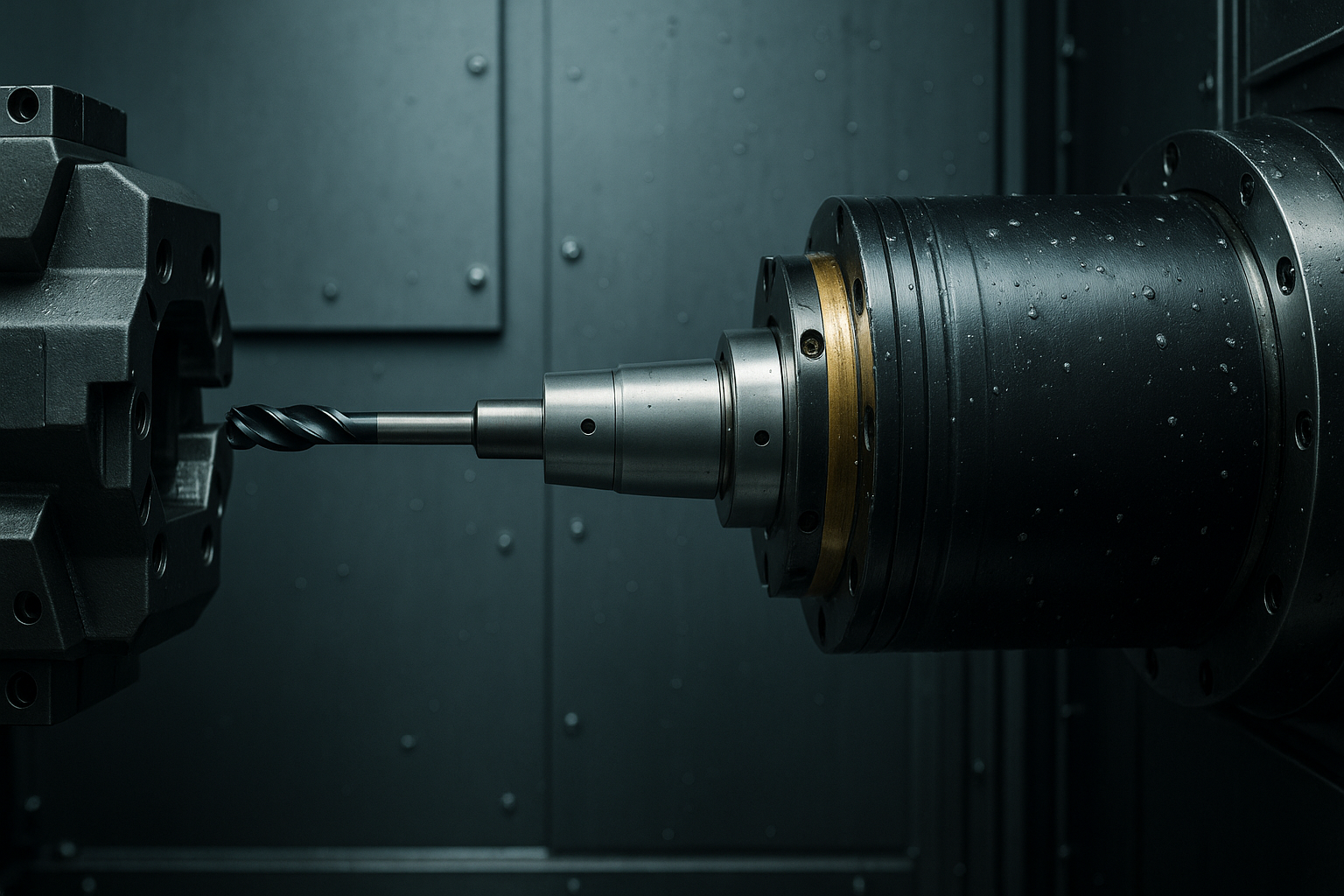

Ниска топлопроводимост

Титанът има лоша топлинна проводимост, Изискване на усъвършенствани стратегии за охлаждане по време на обработката, за да се предотврати прегряване и поддържане на точността на размерите.

Немагнитни

Немагнитната му природа прави титан подходящ за среда, при която магнитната намеса може да компрометира производителността, като например в медицински изделия, електроника, и аерокосмически системи.

Отлична устойчивост на умора

Способни да издържат многократни цикли на стрес без неуспех, Титанът предлага изключителна надеждност за структурни компоненти и приложения за носене на товари.

Изпратете вашето запитване днес

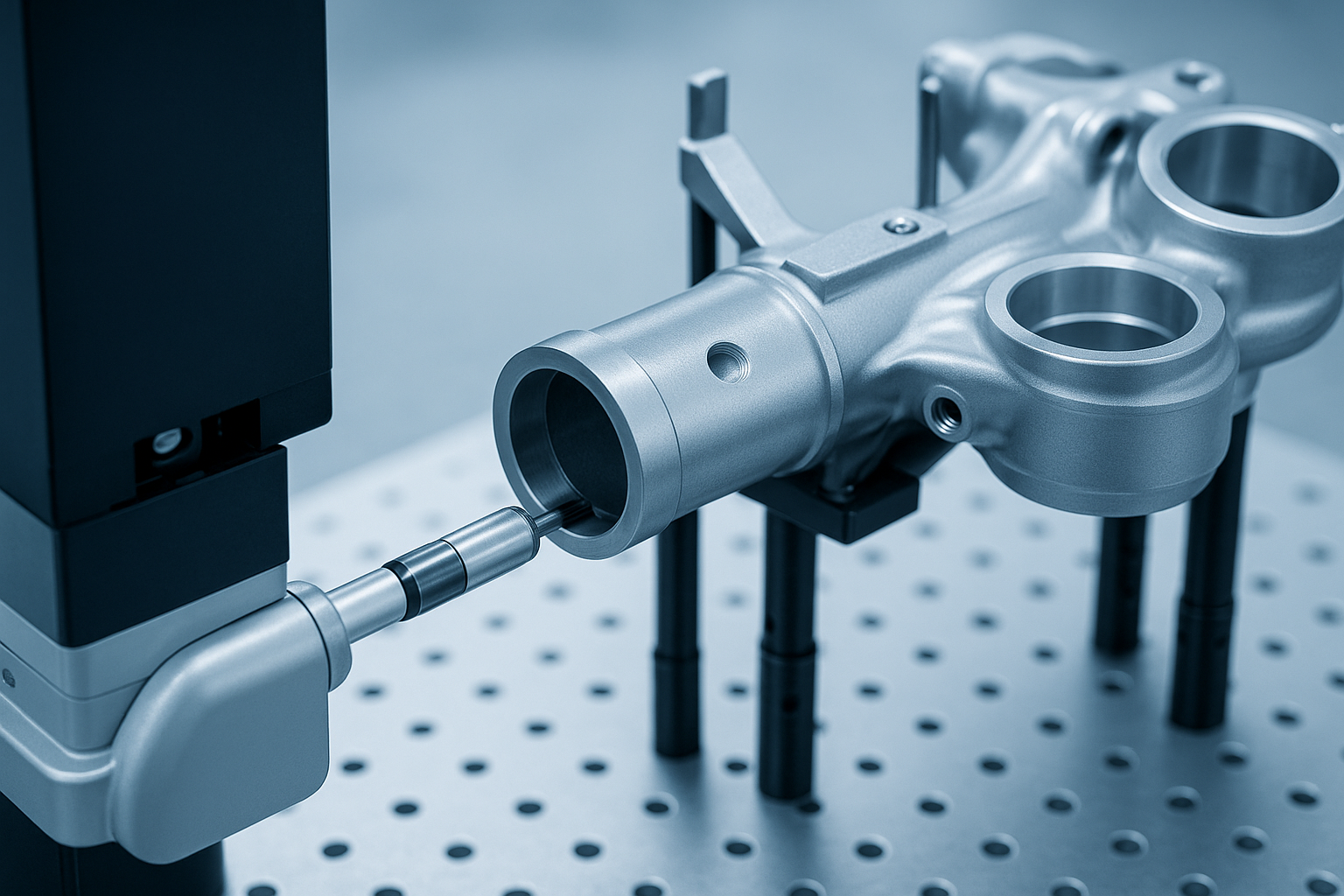

Приложения на титан

Свойствата на Titanium го правят безценен в индустриите, които изискват сила, лекота, и издръжливост.

Свойства на материала на титан

Космонавтика: структурни елементи, крепежни елементи, и части от двигатели.

медицински: Импланти, Хирургически апарат, протезиране.

Автомобилна: части (Части за изпълнение, клапан, изпускателни системи).

морски: Подводни части, валове на витлото, и системи за морска вода.

енергия: Сондажно оборудване за офшорно описание, Ядрени енергийни системи.

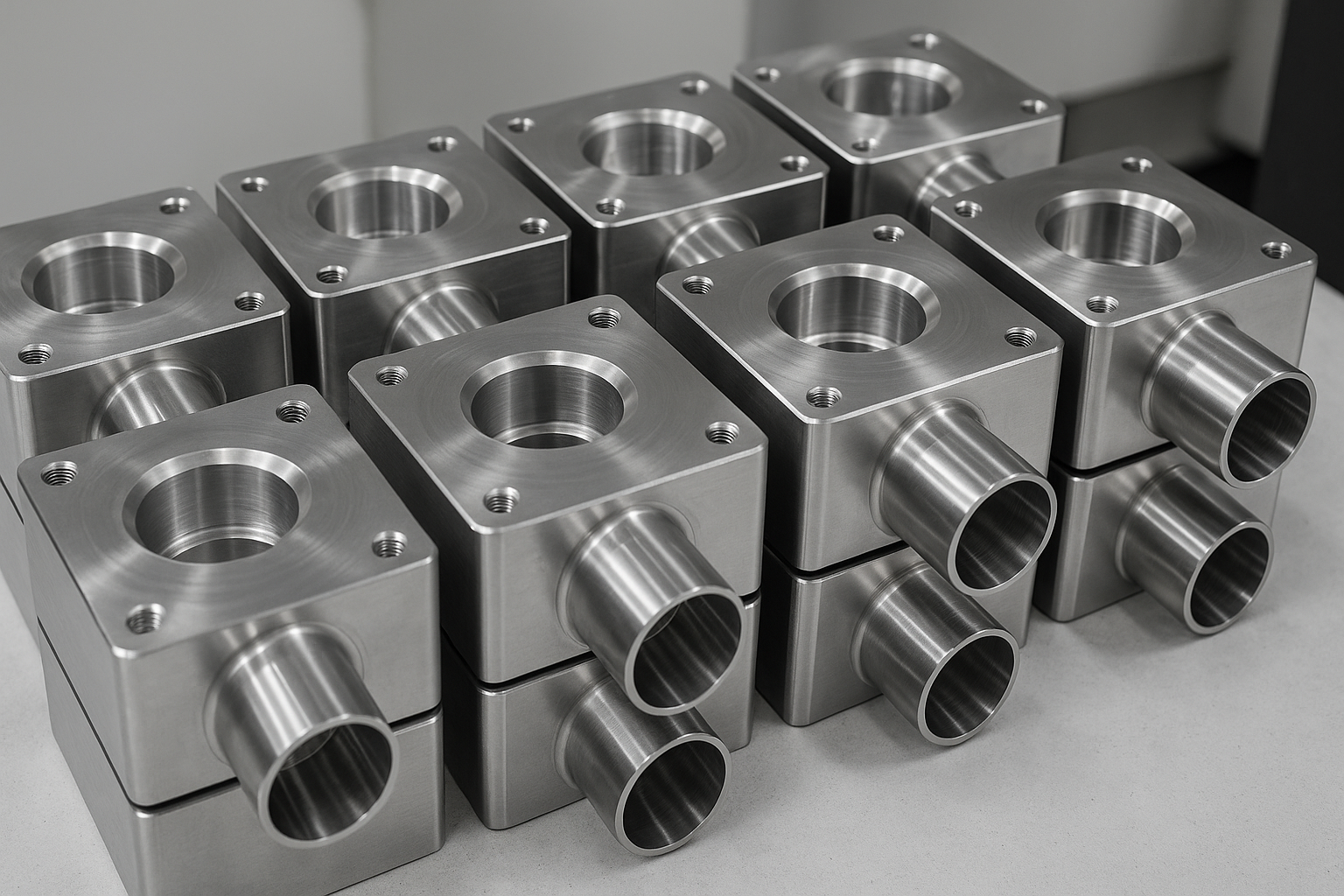

Индустриален: Топлообменници, съдове под налягане, инструментална екипировка.

Изпратете вашето запитване днес

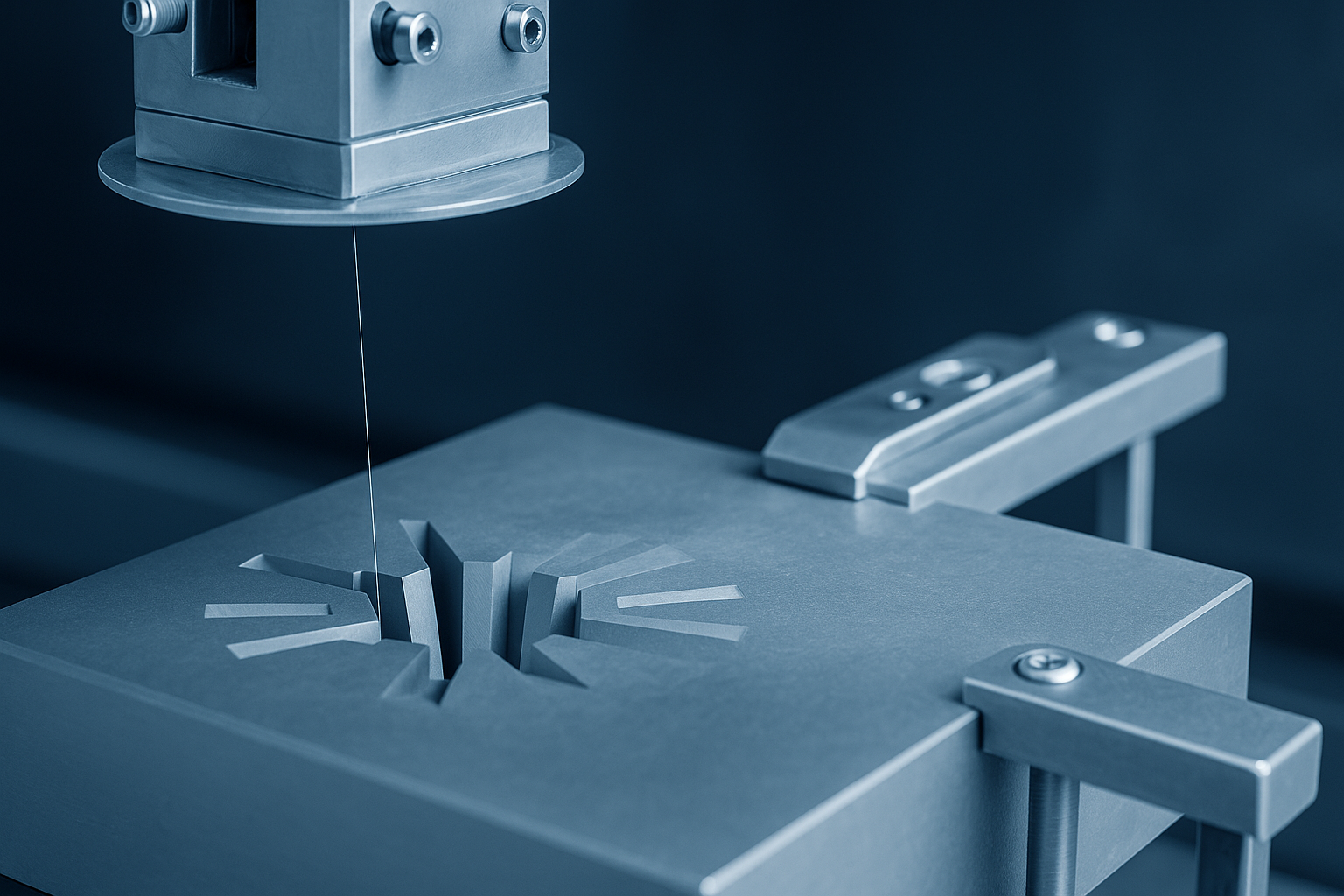

Титанови степени, ние машинираме

Така, Ето няколко степени на титан, които машинираме

Свойства на материала на титан

| Степен | Ключови характеристики | Приложения |

| Степен 1 | Мека, Силно устойчив на корозия | морски, Химическо оборудване |

| Степен 2 | Силен, формируем, широко използвани | медицински, автомобилен, индустриален |

| Степен 5 | Висока якост, топлинен устойчив | Космонавтика, Части за изпълнение |

| Степен 9 | Средна сила, Заваряващ се | Тръба, импланти |

| Степен 23 | Допълнителна пура, Силно биосъвместими | Хирургически, аерокосмически компоненти |

Изпратете вашето запитване днес

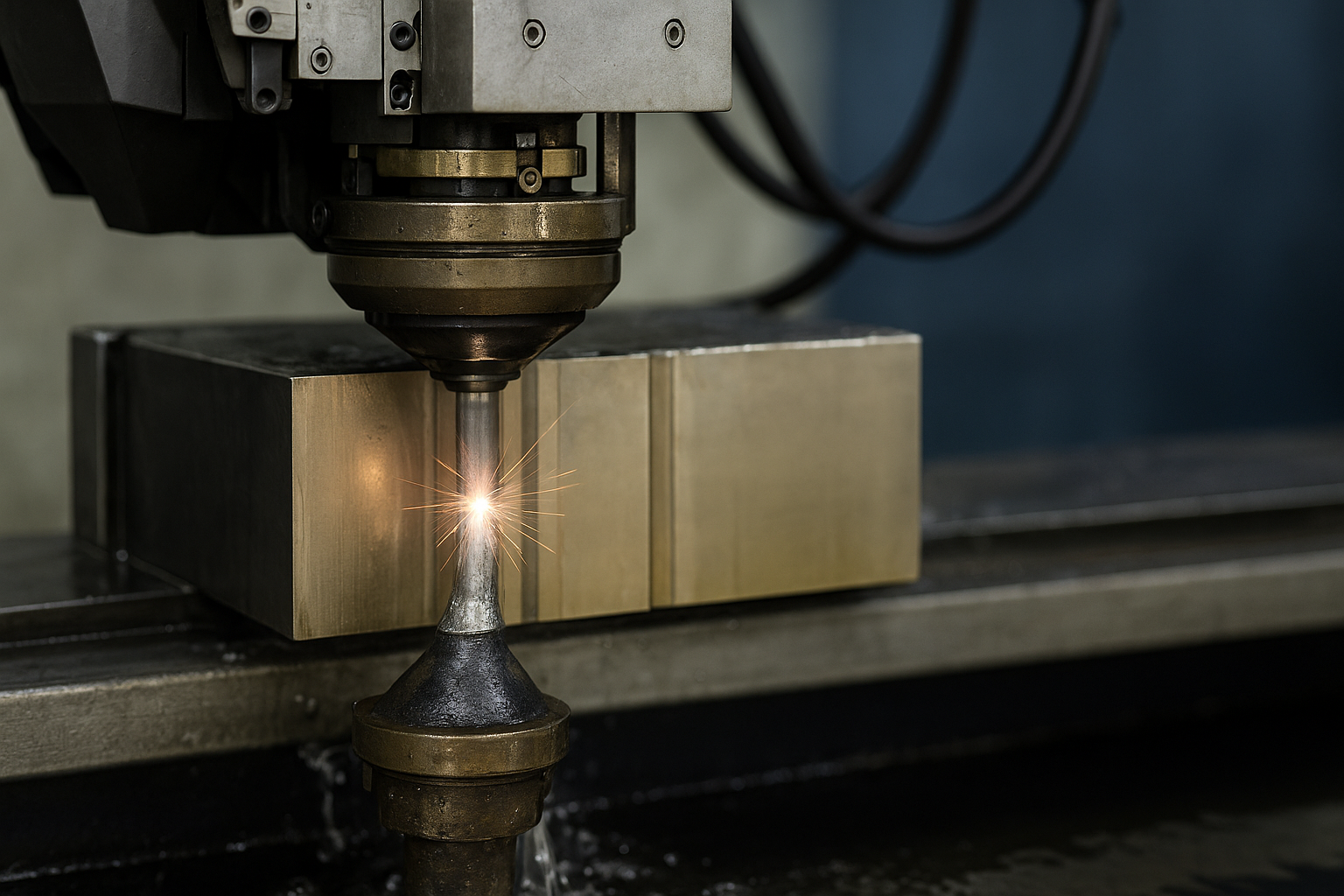

Предимства на обработващите титанови части

Сила без тегло:По -силен от стоманата и 45% запалка.

Корозия-устойчив: Не ръждясват, когато са изложени на морска вода, киселина, и тежки условия.

Дълъг служебен живот: Подходящ за висок стрес, среди за дългосрочна употреба.

Висока температурна съпротивление: Работи добре при силна топлина.

Биосъвместимост: Нетоксичен и нереактивен с човешкото тяло.

Изпратете вашето запитване днес