El sector electrónico exige componentes cada vez más pequeños, tolerancias más estrictas, y rápido tiempo de comercialización. Mecanizado CNC satisface estas necesidades entregando precisión, repetibilidad, y flexibilidad, ya sea con prototipos de un nuevo diseño de PCB o produciendo miles de disipadores de calor. Esta buceo profundo explora cómo CNC transforma la fabricación de electrónica, qué Partes que puedes hacer, cual Las técnicas y los materiales están involucrados, y cómo Los acabados superficiales y las capacidades avanzadas elevan sus productos.

Cómo se beneficia al mecanizado CNC La fabricación de electrónica

Calidad consistente

Precisión automatizada: Los programas de CNC ejecutan las mismas trayectorias a la precisión a nivel de micron, eliminar la variabilidad del operador.

Funciones complejas: Desde micro-canales en placas de enfriamiento hasta rutas de PCB fina, Las máquinas CNC contienen tolerancias estrechas parte tras parte.

Alta precisión & Exactitud

Tolerancias estrictas: La electrónica a menudo requiere ± 0.005–0.001 mm. Los modernos centros de CNC de múltiples eje logran rutinariamente estas especificaciones.

Adaptar & Función: Características de apareamiento de precisión (agujeros, ajustado) Asegurar los componentes ensamblados de manera confiable, prevenir la desalineación que puede arruinar los circuitos.

Creación rápida de prototipos

Bajos costos de herramientas: A diferencia del moldeo por inyección, Los prototipos de CNC no necesitan moldes caros, solo un modelo CAD y una configuración.

Diseño iterativo: Los ingenieros pueden probar el formulario, adaptar, y funcionar en unos días, luego refine las trayectoria de herramientas inmediatamente para la próxima ejecución.

Escalabilidad & Personalización

Carreras flexibles: Cambiar de un solo prototipo a cientos sin reorganizar, Simplemente cargando un nuevo programa.

Piezas a pedido: Conectores personalizados, carcasas especializadas, o piezas de reparación únicas: CNC acomoda lotes pequeños o grandes con igual facilidad.

Tiempos de entrega reducidos

Sin herramientas complejas: Las configuraciones CNC implican abrazaderas y accesorios., No moldes personalizados ni troqueles de estampado..

Cambios rápidos: Los modernos sistemas de cambio de herramientas intercambian herramientas de corte en segundos, mantener la producción avanzando rápidamente.

Productos electrónicos comunes de CNC mecanizados con CNC

El mecanizado CNC se utiliza para fabricar todo tipo de piezas electrónicas, grandes, pequeño, simple, y súper preciso. Vamos a dividirlo en las partes del mundo real que probablemente hayas visto. (o incluso usado) sin darme cuenta que venían de una máquina CNC.

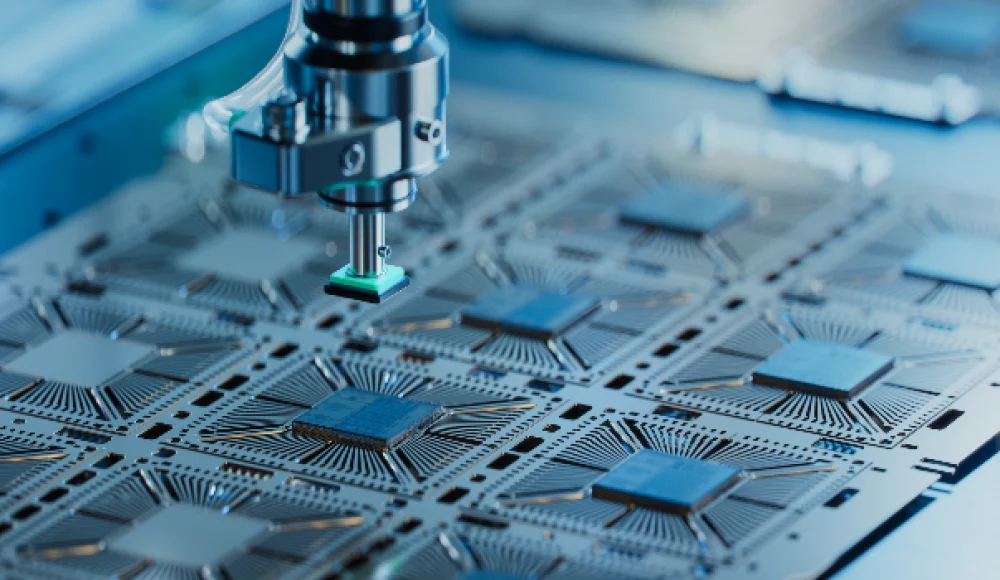

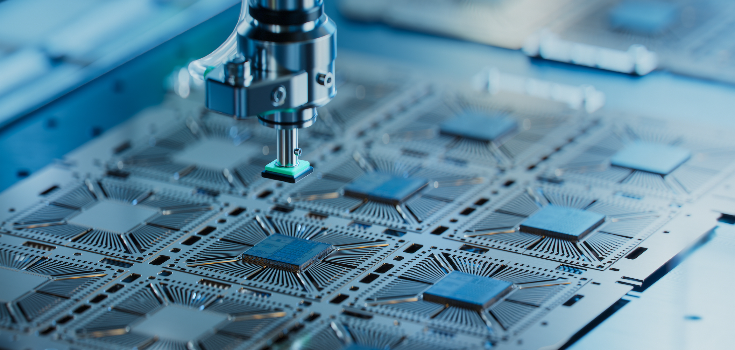

Placas de circuito impreso (PCBS)

Estos son los planos verdes. (o azul) tableros dentro de casi todos los dispositivos electrónicos. Las máquinas CNC ayudan a cortar la forma exacta, perforar pequeños agujeros, e incluso crear caminos para que fluya la electricidad.. Sin precisión CNC, Estas tablas no encajarían ni funcionarían correctamente..

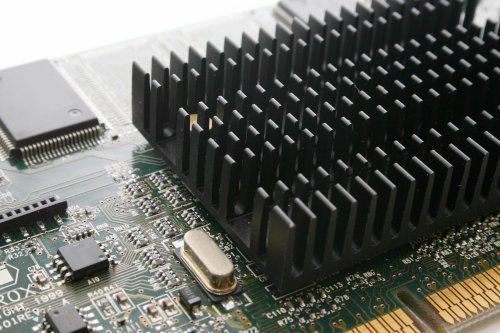

Disipadores de calor

¿Alguna vez te has preguntado cómo tu computadora portátil o consola de juegos no se sobrecalienta?? Esto se debe en parte a los disipadores de calor: pequeñas piezas metálicas con aletas que alejan el calor de los procesadores.. Las máquinas CNC les dan forma según especificaciones exactas para que puedan mantener los componentes electrónicos frescos y funcionando sin problemas..

Recintos y carcasas

Desde carcasas de teléfonos inteligentes hasta carcasas de cajas de control, El mecanizado CNC ayuda a crear los cuerpos exteriores que protegen los componentes electrónicos delicados.. Ya sea aluminio para una carcasa exterior resistente o plástico para una elegante carcasa de teléfono, El CNC ayuda a que encaje y luzca perfecto.

Conectores y enchufes

El mecanizado CNC produce pequeños conectores de metal o plástico que permiten que los cables encajen perfectamente, como puertos USB., conectores de carga, o pines de transferencia de datos. La precisión lo es todo aquí, o las cosas simplemente no encajan en su lugar.

Interruptores y botones

los botones de encendido, interruptores de palanca, y las perillas de control que usa en dispositivos electrónicos a menudo están mecanizadas por CNC para garantizar que se sientan bien y duren mucho tiempo.. Especialmente para electrónica personalizada o industrial., El CNC garantiza formas perfectas y un movimiento fiable.

Componentes semiconductores

En electrónica de alta tecnología, CNC se utiliza para hacer los marcos., cubiertas, y piezas de refrigeración para semiconductores: los pequeños chips que alimentan todo, desde su teléfono hasta los satélites..

Cabras de cámara y sensor

Para drones, camaras de seguridad, y escáneres médicos, El mecanizado CNC ayuda a crear carcasas compactas que protegen lentes y sensores, al mismo tiempo que permite una alineación precisa para el rendimiento.

Técnicas de CNC para electrónica

Husillos de alta velocidad: 20,000–Las fresadoras de 60.000 RPM tallan pequeños detalles con fresas de mango de 0,5 a 1 mm..

Microfresado: Herramientas tan pequeñas como 0.2 mm permiten canales finos en PCB de microfluidos o disipadores de calor.

Tornos de herramientas vivas: Combina operaciones de torneado y fresado para pasadores., enfrentamientos, e inserciones roscadas en una sola configuración.

Ejes de alta precisión: Lograr concentricidades de unas pocas micras para contactos eléctricos..

Cabezales multihusillo: Taladre conjuntos de vías o orificios de montaje simultáneamente, reduciendo el tiempo del ciclo.

Ciclos de picoteo: Limpie las virutas en orificios profundos perforados en circuitos impresos para evitar rebabas y sobrecalentamiento..

Grabado CNC

Marcado láser: Sin contacto, Láseres de alta velocidad graban números de serie., códigos de barras, o logotipos en carcasas sin desgaste de herramientas.

Grabado de diamantes: En plásticos duros o metales para interruptores táctiles y leyendas con control de profundidad a nivel de micras..

Materiales comunes en mecanizado electrónica

Rieles

Aluminio: 6061, 5052 aleaciones para recintos ligeros, disipadores de calor, y escudos EMI.

Cobre & Aleaciones de cobre: Mecanizado para aplicaciones térmicas y contactos eléctricos de alto rendimiento..

Latón: Resistencia a la corrosión y buena conductividad para conectores y adornos decorativos..

Acero inoxidable: Soportes estructurales, sujetadores, y carcasas resistentes que requieren durabilidad.

No metales

Ingeniería de plásticos: OJEADA, abdominales, ordenador personal, y PTFE para aislamiento, cubiertas de pantalla, y piezas resistentes a productos químicos.

Acrílico & policarbonato: Ventanas transparentes, guías de luz, y paneles resistentes a impactos.

Composicion & Laminados: FR-4, G-10 para PCB; compuestos especiales para aplicaciones de RF y alto voltaje.

Acabados superficiales típicos para componentes electrónicos

Granallado: Acabado mate uniforme que oculta las marcas de herramientas y mejora la adhesión de la pintura..

Niquelado no electrolítico: Mejora la resistencia a la corrosión y la conductividad superficial de piezas metálicas..

Anodizado: Agrega una capa de óxido duradera (y opciones de color) a cerramientos de aluminio.

Recubrimiento en polvo: Decorativo, Recubrimientos resistentes en variados colores y texturas..

Pasivación: Limpia y fortalece el acero inoxidable., evitando la oxidación de la superficie.

Pulido: Acabados espejados en contactos y sellos de RF para una conductividad óptima.

Capacidades de mecanizado CNC en electrónica

Centros multieje: 5-pórticos de ejes y fresadoras socavados de máquinas, cavidades profundas, y agujeros en ángulo en una sola configuración.

Husillos de micromecanizado: Husillos de altas RPM (arriba a 100,000 RPM) para rasgos ultra finos.

Sondeo automatizado: Los sistemas de medición en la máquina verifican las dimensiones críticas a mitad del ciclo.

Operación sin luces: Los cambiadores de herramientas y alimentadores de barras automatizados permiten producciones nocturnas.

Híbrido Aditivo/Sustractivo: Combine CNC con sinterización láser selectiva para canales de enfriamiento conformes o estructuras integradas.

Conclusión

El mecanizado CNC permite a los fabricantes de productos electrónicos ofrecer precisión, consistencia, y velocidad que ningún otro proceso sustractivo iguala. Desde complejos enrutamientos de PCB hasta robustas carcasas con blindaje EMI, La flexibilidad y precisión del CNC ayudan a dar vida a los dispositivos electrónicos modernos. Entendiendo las técnicas correctas, materiales, y acabados, y aprovechando las capacidades avanzadas de CNC, puede lograr piezas que cumplan con las tolerancias más estrictas y el tiempo de comercialización más rápido..

Preguntas frecuentes

¿Qué impulsa los costos del mecanizado electrónico CNC??

Complejidad de la pieza, elección de material, requisitos de tolerancia, y el volumen de producción influyen en el precio.

¿Qué tolerancias puede alcanzar el mecanizado CNC electrónico??

Las tolerancias típicas oscilan entre ±0,005 mm y ±0,001 mm., dependiendo de la precisión de la máquina y los métodos de inspección.

¿Es el mecanizado CNC mejor que la impresión 3D para electrónica??

CNC ofrece opciones de materiales superiores (metales y plásticos de alto rendimiento), tolerancias más estrictas, y mejores acabados superficiales para piezas electrónicas funcionales, mientras que la impresión 3D sobresale en geometrías internas complejas y modelos conceptuales rápidos..