En los últimos años, Prototipo de CNC mecanizado se ha convertido en un cambio de juego en el mundo de la fabricación y el desarrollo de productos. A medida que las empresas buscan más rápido, más rentable, y métodos más precisos para crear prototipos, Mecanizado CNC ha aumentado como una alternativa atractiva a los métodos de fabricación tradicionales como la fundición, moldeo por inyección, y mecanizado manual.

Este enfoque innovador utiliza avanzado control numérico por computadora (CNC) tecnología para crear prototipos de alta calidad con una precisión excepcional. A diferencia de los procesos tradicionales, Prototipo de CNC mecanizado Permite a las empresas, especialmente a las pequeñas empresas y nuevas empresas, experimentar, innovar, y probar nuevas ideas sin incurrir en costos prohibitivos.

Este artículo explora el mecanizado del prototipo CNC en detalle, incluyendo sus principios, ventajas, limitaciones, opciones de material, y estrategias prácticas para optimizar los costos.

¿Qué es el mecanizado del prototipo CNC??

Prototipo de CNC mecanizado es un proceso que utiliza diseño asistido por computadora (CANALLA) Modelos y programación de CNC para guiar la maquinaria en la creación de prototipos o componentes finales de varios materiales. Es un proceso de fabricación sustractiva, lo que significa que el material se elimina de un bloque sólido (pieza de trabajo) Para lograr la forma deseada.

🛠️ ¿Cuáles son los cuatro pasos en el proceso de mecanizado de creación de prototipos de CNC?

Alguna vez me preguntó cómo un La idea simple se convierte en un verdadero, parte sólida Usar prototipos CNC? 🤔 Puede parecer magia, Pero en realidad sigue Cuatro pasos sencillos. Cada paso juega un papel crucial en Convirtiendo su diseño en un prototipo preciso.

🖥️ Paso 1: Diseñar la parte (Modelado CAD) 🎨

El viaje comienza con un Diseñar en una computadora. Aquí es donde creas un 3D Modelo de la parte que quieres hacer.

🔍 como funciona:

- Los ingenieros usan Software CAD (Diseño asistido por computadora)para dibujar la parte.

- El modelo incluye Todos los detalles—El tamaño, forma, agujeros, y características de superficie.

- Cada medición y especificación está bloqueado aquí, así que la máquina CNC sabe exactamente que hacer.

💡 Ejemplo de la vida real:

Piense en diseñar un puesto de teléfono personalizado. Agregarás Ranuras para cargar cables, soportes en ángulo para estabilidad, y grabar tu nombre si quieres!

🎯 Consejo profesional:

Diseños simples son más barato y más rápido a la máquina. Si no necesitas curvas elegantes o pequeños agujeros, Mantenlo directamente!

🛠️ Paso 2: Convertir el diseño en código de máquina (Programación de cámaras) 🧠

Ahora, El modelo de computadora necesita "Habla el idioma de la máquina". Ahí es donde Software CAM (Fabricación asistida por computadora) llegar.

🔍 como funciona:

- El archivo CAD se convierte en código g.

- código g es como un receta para la máquina CNC, velliéndola donde moverse, que tan rápido, y que tan profundo por cortar.

- El Verificaciones del operador de la máquina el programa para asegurarse Todo está configurado correctamente.

💡 Ejemplo de la vida real:

Imagina que estás horneando galletas 🍪. El Diseño CAD es como el Plantilla de forma de galleta, y el código g es como el receta paso a paso Para que la máquina lo siga.

🎯 Consejo profesional:

Aunque las máquinas son súper preciso, a Prueba de programa rápida poder atrapar errores antes de Comienza el mecanizado real.

⚙️ Paso 3: Configure la máquina CNC 🔩

Ahora es el momento de Prepara la máquina. Sin una configuración adecuada, incluso el El mejor diseño no saldrá a la derecha.

🔍 como funciona:

- El pieza de trabajo(bloque de material) es asegurado Entonces no se mueve Durante el mecanizado.

- El herramientas de corte(como ejercicios, molinos, o tornos) son instalado.

- El Configuración de la máquina(como velocidad, tasa de alimentación, y profundidad) son afinado basado en el material siendo utilizado.

💡 Ejemplo de la vida real:

Piensa en esto como Configurar una parrilla de barbacoa. Necesitas el Herramientas correctas, el calentar correcto, y el Ingredientes listos antes Empiezas a cocinar.

🎯 Consejo profesional:

Verifique el doble Colocación de la pieza de trabajo—Even a pequeña desalineación puede conducir a un error costoso.

🏎️ Paso 4: Machine el prototipo e inspeccione la parte final 🛠️

Aquí es donde el Magic sucede! La máquina CNC sigue la Instrucciones programadas a cortar, esculpir, y dar forma al prototipo.

🔍 como funciona:

- La máquina comienza a cortar el material, siguiendo el Instrucciones de código G

- Mientras la máquina funciona, él elimina las capas de material, como un escultor cincelando una estatua.

- Una vez que el mecanizado está completo, La parte pasa por un cheque de calidad para asegurarlo cumple con todas las especificaciones.

💡 Ejemplo de la vida real:

Imagina que estás usando un 3D impresora, Pero en lugar de Agregar capas, La máquina CNC es eliminar capas Para crear la parte final.

🎯 Consejo profesional:

Usar calibrador o MMC (Coordinar la máquina de medir) a Dimensiones críticas de doble verificación—Pecialmente para piezas de tolerancia apretada.

🔍 Resumen rápido de los cuatro pasos

| 🛠️ Paso | ⚙️ Lo que sucede |

| 🖥️ Diseñar la parte | Crear un modelo CAD 3D del prototipo. |

| 🧠 Programa la máquina | Convertir el modelo CAD en código G legible por máquina. |

| 🔩 Configurar la máquina | Asegurar el material y preparar las herramientas. |

| 🛠️ Máquina & Inspeccionar | Cortar la pieza y verificar la precisión. |

🎯 ¿Por qué son tan importantes estos pasos??

El mecanizado de creación de prototipos de CNC no se trata solo de material de corte— Se trata precisión, consistencia, y eficiencia. Salto a la comba o apresurado a través de cualquier paso puede conducir a:

- Partes defectuosas🚨

- Materiales desperdiciados💸

- Daños a la máquina🛠️

Cuando termine correctamente, aunque, Prototipos de CNC Transforma tus ideas en realidad-rápidamente, exactamente, y eficientemente.

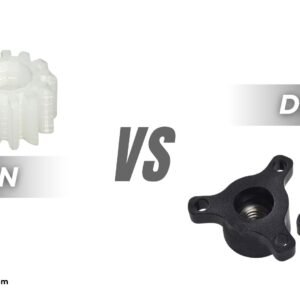

🔍 ¿Cuál es la diferencia entre el mecanizado CNC y el mecanizado del prototipo CNC?

Si eres nuevo en la fabricación, Mecanizado CNC y Prototipo de CNC mecanizado podría sonar como lo mismo. Después de todo, Ambos involucran Materiales de corte de máquinas controladas por computadora en formas precisas. Pero estos procesos sirven Propósitos diferentes y se usan en diferentes etapas de producción.

📊 Comparación de lado a lado

| Característica | Mecanizado CNC | Mecanizado de prototipos CNC |

| 🛠️ Objetivo | Producción en masa de piezas terminadas | Prueba rápida de conceptos de diseño |

| ⚙️ Material utilizado | Materiales finales (p.ej., aluminio, acero) | Materiales más baratos para la eficiencia rentable |

| 🎯 Nivel de precisión | Alta precisión & exactitud | Alta precisión, pero enfoque funcional |

| 🕒 Tiempo de producción | Más extenso (Optimizado para la consistencia) | Más rápido (optimizado para pruebas rápidas) |

| 💰 Costo | Más alto (Debido al material & configuración) | Más bajo (Utiliza materiales temporales) |

| 🔍 Cambios de diseño | Más difícil de ajustar después de la producción | Fácil de modificar y probar nuevas ideas |

| 🏭 Producción | Piezas listas para la producción | Prototipos o modelos de prueba |

🧠 ¿Cuándo debería usar el mecanizado CNC??

🔧 Mecanizado CNC es el elegir Cuando necesite:

- producción en masa de piezas para Uso a largo plazo.

- Componentes de alta precisión que encajan perfectamente.

- Fuerte, piezas duraderas hecho de metales o plásticos duros.

💡 Ejemplo:

- Bloques de motor de fabricación para miles de autos. 🚗

- Producción de implantes médicos con tolerancias apretadas. 🏥

🚀 ¿Cuándo debería usar el mecanizado CNC Prototype??

🔧 Prototipo de CNC mecanizado es la mejor opción cuando:

- Necesidad Prototipos rápidos para probar forma, adaptar, y función.

- Esperar Cambios de diseño y necesitar flexibilidad.

- Querer ahorrar utilizando materiales más baratos.

💡 Ejemplo:

- Prueba de un nuevo diseño de caja de teléfonos inteligentes Antes de la producción en masa. 📱

- Creación de un prototipo para una parte de máquina personalizada Para obtener comentarios de los clientes.

🤯 ¿Puedes usar ambos?? Absolutamente!

Muchas empresas usan ambos métodos juntos:

- Comience con mecanizado de prototipo CNC Para probar el diseño. 🛠️

- Una vez que finalice el diseño, cambiar CNC mecanizado o producción en masa. 🏭

💡 Ejemplo del mundo real:

Imagina que estás diseñando un Parte de coche nuevo. Primero, Crearías un prototipo Para probar su Ajuste y función. Una vez que estés satisfecho con el diseño, te mudarías a Mecanizado CNC para producción en masa.

🏆 el resultado final: ¿Cuál deberías elegir??

- Necesidad partes únicas o piezas de prueba? Ir con Prototipo de CNC mecanizado.

- Planificación producción en masa con calidad consistente? Elegir Mecanizado CNC.

🔍 Consejo profesional: Empiece con un prototipo Para probar su diseño. Una vez que es perfecto, cambiar mecanizado CNC a gran escala para el mejor equilibrio de costo, velocidad, y calidad. 💡

Aplicaciones de prototipos mecanizados CNC: Donde se usan?

Los prototipos mecanizados por CNC están en todas partes, desde los autos que conducimos hasta los dispositivos médicos que salvan vidas. Estos prototipos ayudan a los ingenieros y diseñadores a probar, refinar, y perfeccionar sus ideas antes de la producción en masa.

🚗 1. Industria automotriz: Edificio más seguro, Mejores autos

La industria automotriz depende en gran medida de los prototipos mecanizados por CNC para probar nuevos diseños y mejorar el rendimiento. Los prototipos ayudan a los fabricantes de automóviles:

- Probar componentes del motor como cabezas de cilindro y pistones.

- Crear modelos aerodinámicos Para mejorar la eficiencia del combustible.

- Partes interiores prototipo tales como paneles y paneles de control.

- Diseñar y probar nuevas características de seguridad, Como carcasas de airbag.

🔧 Dato divertido:

Compañías de automóviles principales como Tesla, BMW, y Ford usa prototipos CNC para probar piezas de vehículos eléctricos antes de la producción en masa.

🛩️ 2. Aeroespacial y Aviación: Precisión a gran altitudes

Cuando se trata de aviones, helicópteros, e incluso la nave espacial, La precisión no es negociable. El mecanizado CNC ayuda a crear prototipos de componentes de aeronaves para probar:

- Aerodinámica: Prueba de formas de ala y piezas de motor.

- Integridad estructural: Verificar la fuerza del tren de aterrizaje y las piezas de fuselaje.

- Diseños de cabina: Prototipos de diseños de asientos y sistemas de ventilación.

🚀 Sabías?

La NASA utiliza prototipos CNC para probar piezas para Mars Rovers y Componentes de la nave espacial para garantizar que puedan soportar condiciones extremas.

🏥 3. Atención médica y de salud: Salvar vidas con precisión

El mecanizado de CNC juega un papel vital en la innovación médica mediante la creación de prototipos de equipos y dispositivos que salvan vidas. Estos prototipos ayudan:

- Prueba de nuevos instrumentos quirúrgicos Para una mejor precisión.

- Crear prótesis personalizado para pacientes individuales.

- Desarrollar dispositivos de diagnóstico Como componentes de MRI y máquina de rayos X.

- Producir implantes dentales y herramientas de ortodoncia.

💉 Impacto de la vida real:

Las prótesis maquinadas con CNC personalizadas han ayudado a los amputados a recuperar la movilidad con dispositivos que se ajustan perfectamente a sus cuerpos.

⚙️ 4. Equipo industrial: Fábricas de alimentación en todo el mundo

Las fábricas y las plantas de fabricación utilizan maquinaria de servicio pesado que necesita resistencia, partes confiables. Los prototipos mecanizados de CNC ayudan a los fabricantes:

- Probar nuevas piezas de la máquina por durabilidad.

- Desarrollar herramientas de precisión para líneas de ensamblaje.

- Prototipo de equipo personalizado Para tareas específicas.

🏭 Por qué importa:

La creación de prototipos de equipos industriales ayuda a evitar errores costosos y garantiza que las máquinas funcionen suavemente en condiciones intensas.

📱 5. Dispositivos electrónicos y tecnológicos: Detrás de los dispositivos que amamos

Desde teléfonos inteligentes hasta consolas de juegos, Los prototipos maquinados en CNC son esenciales para probar nuevas electrónicas. Ayudan con:

- Diseño de carcasas para teléfonos, tabletas, y computadoras portátiles.

- Prototipos de componentes internos, como disipadores de calor y tableros de circuito.

- Prueba de diseños ergonómicos Para dispositivos fáciles de usar.

🔋 Ejemplo de tecnología:

Apple usa mecanizado CNC para prototipos de marcos de iPhone, Garantizar diseños elegantes y durabilidad antes de la producción en masa.

🚜 6. Agricultura: Equipo duro para trabajos difíciles

La industria agrícola depende de maquinaria pesada como tractores, cosechadores, y sistemas de riego. Ayuda de prototipos mecanizados de CNC:

- Pruebe las piezas del motor para la confiabilidad a largo plazo.

- Mecanismos de engranaje prototipo Para un mejor rendimiento.

- Crear herramientas personalizadas Para necesidades agrícolas especializadas.

🌾 Dato curioso:

La creación de prototipos ayuda El equipo agrícola dura más probando Durabilidad en entornos duros.

🏗️ 7. Construcción y equipo pesado: Construido para durar

La maquinaria de construcción requiere componentes duraderos que puedan soportar fuerzas extremas. Los prototipos mecanizados de CNC ayudan con:

- Prueba de sistemas hidráulicos para excavadoras.

- Prototipos de cajas de cambios para grullas y excavadoras.

- Desarrollo de nuevas herramientas para tareas de construcción.

🏢 Por qué es importante:

La creación de prototipos garantiza que la maquinaria de construcción funcione de manera segura y eficiente en sitios de trabajo.

🎮 8. Robótica: Precisión en movimiento

La industria de la robótica se basa en precisión para construir máquinas que puedan realizar tareas delicadas, como robots quirúrgicos o recolectores de almacén. Ayuda de prototipos mecanizados de CNC:

- Diseñe los brazos y las articulaciones del robot con alta precisión.

- Engranajes de prueba y carcasas automotrices Para el movimiento suave.

- Desarrollar herramientas robóticas personalizadas Para tareas específicas.

🤖 Hecho genial:

Muchos robots de almacén que clasifican y mueven paquetes para Amazon comenzaron como prototipos mecanizados por CNC!

🎨 9. Productos de consumo: Desde gadgets de cocina hasta juguetes

Los prototipos de CNC se utilizan en artículos cotidianos como:

- Electrodomésticos de cocina(mezcladores, mezcladores).

- Artículos deportivos(palos de golf, bicicletas).

- Juguetes y gadgets(drones, controles remotos).

🏓 Sabías?

El diseño de la paleta de ping pong se refinó con prototipos CNC para encontrar el equilibrio y el agarre perfectos.

🌱 10. Energía Renovable: Alimentando un futuro más verde

A medida que las industrias cambian hacia la energía sostenible, CNC Machining ayuda a crear componentes innovadores para:

- Turbinas eólicas(Prueba de diseños de cuchillas).

- Paneles solares(Desarrollo de sistemas de montaje).

- Equipo hidroeléctrico(Diseño de mecanismos de flujo de agua).

🌞 Por qué importa:

La creación de prototipos ayuda a optimizar los sistemas de energía para que sean más eficientes y rentables.

🔍

Consideraciones importantes para elegir el mecanizado del prototipo CNC

Antes de seleccionar el mecanizado del prototipo CNC sobre otros métodos, Varios factores deben considerarse:

- Limitaciones de materiales:

Las máquinas CNC generalmente funcionan con un material a la vez. Si un proyecto requiere prototipos con múltiples materiales, Se pueden necesitar máquinas adicionales o métodos alternativos. - Tamaño por lotes:

CNC Prototype Machining es ideal para Producción de tamaño pequeño a mediano. Para grandes cantidades, El moldeo por inyección o la fundición a troqueles pueden proporcionar una mejor eficiencia de rentabilidad. - Requisitos de complejidad y precisión:

El prototipo de CNC mecanizado se destaca en la producción de piezas con geometrías complejas y tolerancias estrechas. Sin embargo, Los diseños intrincados pueden requerir avanzado 5-Máquinas CNC del eje o herramientas especializadas. - Presupuesto y tiempo de entrega:

El mecanizado del prototipo de CNC tiende a ser más caro que la impresión 3D para unidades individuales pero ofrece un mejor rendimiento mecánico y precisión. Los tiempos de entrega dependen de la complejidad del diseño, con piezas más simples a menudo producidas en cuestión de días.

Ventajas del mecanizado de prototipos CNC

CNC Prototype Machining ofrece varias ventajas convincentes:

- Velocidad

El mecanizado del prototipo CNC reduce drásticamente el tiempo necesario para crear prototipos funcionales en comparación con las técnicas tradicionales como fundición, forja, y moldeo por inyección. Un prototipo que puede tardar semanas en producir con métodos tradicionales a menudo se puede completar en solo unos días con mecanizado CNC. - Rentabilidad

El mecanizado del prototipo CNC minimiza la necesidad de herramientas y moldes costosos. Esto lo hace altamente rentable para prototipos y pequeñas carreras de producción. Por ejemplo, Las empresas pueden crear prototipos sin comprometerse con una costosa fabricación de moho, que a menudo se requiere para moldeo por inyección. - Alta precisión y precisión

El mecanizado del prototipo CNC puede lograr tolerancias tan apretadas como ± 0.001 pulgadas. Este nivel de precisión garantiza que los prototipos representen con precisión el producto final, que es particularmente crítico en industrias como aeroespacial, dispositivos médicos, y fabricación de automóviles. - Versatilidad de materiales

El mecanizado del prototipo CNC es compatible con un amplia gama de materiales, incluyendo metales, plástica, composicion, e incluso cerámica. Esta flexibilidad permite a los fabricantes probar diferentes materiales durante la fase prototipo.. - Ecológico

Prototipo de CNC Machinine produce menos desechos materiales en comparación con muchos métodos tradicionales. Su proceso sustractivo se optimiza a través del software CAM para maximizar el uso del material y minimizar el desecho. - Personalización

El mecanizado del prototipo CNC es ideal para crear costumbre, componentes únicos. Los ajustes se pueden hacer rápidamente modificando el archivo CAD, sin la necesidad de reorganizar o nuevos moldes.

Materiales comúnmente utilizados en mecanizado prototipo CNC

La selección de materiales influye significativamente en el rendimiento, costo, y maquinabilidad de los prototipos CNC. Aquí hay algunos materiales de uso común:

Rieles

- Aluminio: Ligero, resistente a la corrosión, y altamente maquinable. Comúnmente utilizado en aeroespacial, automotor, y electrónica de consumo.

- Latón: Duradero y eléctricamente conductor, ideal para componentes eléctricos y artículos decorativos.

- Acero inoxidable: Conocido por su fortaleza, resistencia a la corrosión, y durabilidad, utilizado con frecuencia en dispositivos médicos y equipos industriales.

Plástica

- abdominales (Acrilonitrilo Butadieno Estireno): Rentable, fuerte, y versátil.

- policarbonato (ordenador personal): Resistente al impacto y transparente, a menudo usado en componentes ópticos.

- Nylon (Pensilvania): Alta resistencia y resistencia, ideal para engranajes y rodamientos.

Composicion

- Compuestos de fibra de carbono: Ligero y fuerte, ampliamente utilizado en Aplicaciones aeroespaciales y automotrices.

- Compuestos de fibra de vidrio: Rentable y duradero, a menudo utilizado para prototipos de recintos y componentes estructurales.

Precisión y consistencia en el mecanizado de prototipos CNC

Una de las principales ventajas de CNC Prototype Machining son sus precisión y consistencia excepcionales. Equipo moderno de CNC, como 5-centros de mecanizado de eje, puede lograr tolerancias dimensionales dentro ± 0.001 pulgadas.

Beneficios de consistencia:

- Asegura que todos los prototipos en una producción mantener dimensiones idénticas.

- Reduce la variabilidad en actuación, adaptar, y montaje.

- Mejora la fiabilidad en sectores críticos como médico, automotor, y las industrias aeroespaciales.

Tecnologías avanzadas:

- 3-Máquinas CNC del eje son adecuados para componentes más simples.

- 4-Máquinas CNC de eje y 5 ejes manejar geometrías más complejas con menos configuraciones.

Desventajas del mecanizado del prototipo CNC

Mientras que el mecanizado del prototipo CNC ofrece numerosos beneficios, También presenta algunos desafíos:

- Altos costos iniciales:

Las máquinas y las herramientas CNC son intensivo, haciéndolos menos accesibles para operaciones más pequeñas. - Lento para diseños complejos:

Las piezas intrincadas pueden requerir tiempos de mecanizado más largos, Especialmente cuando se usa equipo de múltiples eje. - Limitaciones de materiales:

Las máquinas CNC funcionan principalmente con rieles, plástica, y compuestos. Los materiales exóticos pueden requerir equipos especializados. - Requisitos de habilidad:

Los operadores deben tener Conocimiento de programación(p.ej., Software G-código G y CAD/CAM) y experiencia técnica para garantizar eficientes, producción de alta calidad.

Consejos de ahorro de costos para mecanizado por prototipo CNC

Maximizar la rentabilidad es crucial para cualquier proyecto de creación de prototipos. Aquí hay algunas estrategias prácticas:

- Elija el material correcto:

Seleccionar materiales que equilibren rendimiento y costo. Por ejemplo, aluminio a menudo es más rentable que acero inoxidable para componentes no críticos. - Optimizar el diseño de piezas:

Simplificar la geometría de la pieza puede Reducir el tiempo y los costos de mecanizado. Evitar complejidad innecesaria A menos que se requiera funcionalmente. - Mecanizado paralelo:

Correr múltiples máquinas simultáneamente puede aumentar la productividad y reducir costos por unidad. - Ordenar:

Muchos fabricantes ofrecen descuentos para pedidos más grandes, Entonces el plan de producción se ejecuta estratégicamente.

- Use la impresión 3D para los prototipos iniciales:

Para la validación de diseño en etapa temprana, 3D La impresión puede proporcionar Prototipos rápidos y rentables. - Asociarse con fabricantes de buena reputación:

Trabajar con Proveedores de CNC experimentados para minimizar errores, rehacer, y retrasos de producción.

🆚 Mecanizado de prototipo CNC vs. 3Impresión D: ¿Cuál deberías elegir??

Cuando se trata de Hacer prototipos o piezas personalizadas, Mecanizado CNC y 3impresión D son dos de las opciones más populares. Pero, ¿cómo decides cuál es mejor para tu proyecto?? 🤔

📊 Comparación de lado a lado: CNC Machinine VS. 3Impresión D

| Característica | Mecanizado de prototipos CNC | 3Impresión D |

| 🛠️ Tipo de proceso | Sustractivo (Elimina material) | Aditivo (agrega material) |

| ⚙️ Opciones de materiales | Rieles, plástica, madera, composicion | Mayormente plásticos, algunos metales |

| 🎯 Precisión & Exactitud | Extremadamente alto (±0,01mm) | Bien, Pero menos preciso |

| 🕒 Velocidad de producción | Más lento para lotes pequeños; Más rápido para carreras grandes | Rápido para prototipos; más lento para la producción |

| 💪 Parte de la fuerza | Partes fuertes y duraderas | buena fuerza (Depende del material) |

| 💰 Costo | Mayor costo inicial, Pero más barato para la producción a granel | Más barato para prototipos únicos |

| 🌐 Diseños complejos | Puede manejar detalles intrincados, pero requiere herramientas complejas | Sobresale con geometrías complejas |

| 🌱 Desperdiciar | Produce desechos de material | Residuos de material mínimo |

| 🔄 Personalización | Puede personalizarse con ajustes manuales | Diseños digitales fáciles de ajustar |

🏆 ¿Cuándo debería elegir el mecanizado CNC??

Ir con Mecanizado CNC Si lo necesitas:

- Piezas de alta precisión con tolerancias apretadas.

- Fuerte, componentes duraderos esa necesidad de manejar estrés o calor.

- Prototipos hechos de Materiales de metal o resistentes.

- Lotes grandes de piezas con calidad consistente.

💡 Aplicaciones de ejemplo:

- Piezas de automóviles como bloques de motor. 🚗

- Componentes aeroespaciales para aviones. ✈️

- Dispositivos médicos como herramientas quirúrgicas. 🏥

🔍 Insight clave:

El mecanizado CNC es Perfecto para piezas mecánicas eso deben encajar con precisión o Necesita alta durabilidad.

🖨️ ¿Cuándo debería elegir la impresión 3D??

Elegir 3impresión D Si lo necesitas:

- Prototipos rápidos para probar formas o conceptos.

- Complejo, intrincado diseños el sombrero sería caro o imposible a la máquina.

- Piezas livianas para aplicaciones no estructurales.

- Producción de lotes pequeños con Cambios de diseño frecuentes.

💡 Aplicaciones de ejemplo:

- Carcasas prototipopara la electrónica. 📱

- Modelos médicos Para la planificación de la cirugía. 💉

- Juguetes y figuras personalizados. 🧸

🔍 Insight clave:

3D Impresión brilla cuando Necesita velocidad y flexibilidad sin preocuparse por la fuerza o precisión extrema.

🤯 ¿Puedes usar ambos métodos juntos??

Absolutamente! Muchas industrias usan Mecanizado CNC e impresión 3D juntos.

🔧 Cómo funciona:

- 3D Imprima el prototipo inicial Para probar el diseño rápidamente.

- Una vez que estés contento con la forma y el ajuste, usar Mecanizado de CNC para crear la final, partes funcionales.

Este enfoque híbrido ayuda a equilibrar costo, velocidad, y fuerza.

💲 ¿Cuánto cuesta el costo de mecanizado por prototipos CNC??

Si alguna vez te has preguntado, "¿Cuánto cuesta la creación de prototipos de CNC??"—No estas solo! El mecanizado de creación de prototipos de CNC puede sentirse como un misterio si eres nuevo en él. La verdad es, no hay una respuesta única para siempre Porque los costos dependen de algunos factores clave.

🧾 Rango de precios típico para la creación de prototipos CNC

Dependiendo de la tamaño parcial, material, y complejidad, Los costos de creación de prototipos de CNC pueden variar desde:

- $50 a $500para Prototipos simples 🛠️

- $500 a $5,000+para Partes más complejas con tolerancias apretadas 🎯

- $10,000 o más para grande, Prototipos de alta precisión o Pequeñas carreras de producción 🚀

💡 Ejemplo:

- A Soporte de aluminio pequeño podría costar $75.

- A grande, intrincado prototipo aeroespacial podría toparse con el miles.

⚙️ lo que afecta los costos de prototipos de CNC?

Veamos los factores más importantes que Influir en su factura de mecanizado CNC:

Elección de material 🪵🛠️

El material que elige tiene un gran impacto en costo. Algunos materiales son barato y fácil de mecanizar, Mientras que otros son caro y difícil de trabajar con.

| Material | Gama de precios (por kg) | Notas |

| 🛠️ Aluminio | $2 – $5 | Ligero, asequible, fácil de mecanizar |

| 🔩 Acero | $3 – $6 | Fuerte y duradero, Pero más difícil de mecanizar |

| 🚗 Titanio | $15 – $25 | Súper fuerte pero caro y difícil de cortar |

| 🌱 Plástica | $1 – $4 | Barato, fácil de mecanizar, ideal para prototipos |

💡 Consejo: Si es Solo un prototipo y No es el producto final, considerar materiales más baratos como De plástico de los abdominales en lugar de aluminio.

Parte complejidad 🧩

Cuanto más detallado e intrincado Tu prototipo, el más extenso se necesita para la máquina y El tiempo es igual a dinero.

Piezas simples = costo más bajo.

Diseños complejos con finos detalles = mayor costo.

🔍 Ejemplo:

- A bloqueo rectangular con un par de agujeros podría costar $50.

- A componente aeroespacial complejo con múltiples cavidades, hilos, y tolerancias estrictas podría ser $5,000+.

💡 Consejo: Simplifique su diseño si es posible. Menos detalles innecesarios significar Menos tiempo de mecanizado-y costos más bajos.

Tolerancias & Acabado superficial 🎯✨

Quiero que tu prototipo sea súper preciso? O tal vez necesitas un liso, superficie pulida?

Estos extras agregan Más pasos de mecanizado—¿Qué significa costos más altos.

| Factor | Impacto en el costo | Notas |

| 🎯 Tolerancias estrictas | Moderado a alto | Se necesita más tiempo para detalles finos |

| ✨ Acabado pulido | Alto | El pulido lleva tiempo y utiliza herramientas especiales |

| ⚙️ Anodizante/revestimiento | Moderado | Protege y colorea la superficie pero agrega un paso de producción |

💡 Consejo: Adherirse a las tolerancias estándar a menos que tú Realmente necesito una precisión adicional.

Tiempo de la máquina ⏱️

Las máquinas CNC cobran por hora, con tasas dependiendo de Tipo de máquina y complejidad.

| Tipo de máquina | Tarifa por hora | Notas |

| 🛠️ 3-Axis CNC Mill | $35 – $70 | Bien Partes más simples |

| 🔄 4-Axis CNC Mill | $50 – $100 | Agrega capacidades de rotación |

| 🧠 5-Axis CNC Mill | $75 – $150 | Perfecto para geometrías complejas |

💡 Consejo: Las piezas complejas necesitan más tiempo—¿Qué significa costos más altos. Si Funciones de formas básicas, adherirse a 3-mecanizado del eje a ahorrar.

Cantidad importa 📦

Cuando se trata de prototipos de CNC, Los pedidos a granel ahorran dinero.

- Prototipo único= Mayor costo por pieza 🆙

- Lote de 10, 50, o 100= Menor costo por pieza 💲

💡 Ejemplo:

- 1 prototipo podría costar $300.

- 10 prototipos idénticos podría costar $1,200 Total, pero solo $120 cada.

Ubicación de la tienda CNC 🌎

Donde obtienes tu prototipo mecanizado puede afectar el costo.

Tiendas nacionales puede tener mayores costos laborales Pero ofrecer entrega más rápida y mejor comunicación.

Opciones en el extranjero (p.ej., Porcelana) podría ser más económico, pero tiempos de envío más largos y posibles barreras de comunicación puede agregar costos ocultos.

💡 Consejo: Costo de saldo con confiabilidad. A veces pagando un poco más para mejor servicio vale la pena.

📊 Ejemplo de desglose de costos rápidos

Imagina que quieres un prototipo para un nuevo puesto telefónico. Aquí hay un desglose:

| Factor de costo | Costo estimado |

| 📐 Complejidad del diseño | $150 |

| 🧱 Material (Aluminio) | $50 |

| ⏱️ Tiempo de máquina (3-eje) | $120 |

| ✨ Acabado de la superficie (Pulido) | $80 |

| 🚚 Envío & Manejo | $30 |

| 🛠️ Total | $430 |

💡 Nota: Los precios varían ampliamente Residencia en requisitos del proyecto. Siempre obtener una cotización para la mayoría estimación precisa.

💡 Cómo ahorrar dinero en la creación de prototipos de CNC

- Elija materiales asequibles: De plástico de los abdominales es más económico que aluminio-y sigue siendo genial para Diseños de prueba.

- Simplifique su diseño: Menos características = Menos tiempo de la máquina.

- Ordenar en lotes: Mayores cantidades reducir costos por pieza.

- Sigue a los acabados estándar: Fantasía termina como anodizado y pulido se ve bien, pero agregan costos adicionales.

- Trabajar con una tienda de CNC de confianza: Socios confiables ayuda Evite errores costosos y retrasos.

🤔 ¿Vale la pena la creación de prototipos de CNC??

Absolutamente! 🎯

La creación de prototipos de CNC puede parecer costoso por adelantado, Pero el beneficios a largo plazo-como Validación de diseño más rápida y errores de producción reducidos—Dame un inversión inteligente.

Entonces, la próxima vez que te preguntes, "¿Por qué cuesta tanto la creación de prototipos de CNC??", recordar:

Se trata precisión, eficiencia, y dar vida a sus ideas-con menos conjeturas y más confianza. 🚀🔧

9. Conclusión

El mecanizado del prototipo de CNC ha transformado cómo las empresas se acercan al desarrollo de productos. Es velocidad, exactitud, rentabilidad, y versatilidad material Haz que sea una opción atractiva para industrias que van desde automotor a aeroespacial.

A medida que el paisaje de fabricación continúa evolucionando, Las empresas que adoptan el mecanizado prototipo de CNC se encontrarán mejor posicionado para innovar, competir, y prosperar.

Listo para comenzar su próximo proyecto de mecanizado de prototipo CNC? Póngase en contacto con un proveedor de mecanizado CNC confiable hoy para explorar cómo Prototipo de CNC mecanizado puede dar vida a sus diseños!

Preguntas frecuentes

Q1: ¿Qué es el mecanizado de prototipos CNC??

El mecanizado de prototipos CNC es una forma de fabricación sustractiva en la que las piezas se fabrican mediante la eliminación de material de una sola pieza utilizando máquinas controladas numéricamente por computadora., que proporcionan alta precisión y consistencia dimensional.

Q2: ¿Qué tipo de materiales se pueden aplicar a los prototipos CNC??

El mecanizado CNC puede trabajar con muchos tipos diferentes de materiales.. Por ejemplo; rieles (aluminio y acero) y plasticos (ABS y policarbonato), No solo se busca la estética sino también la funcionalidad de los prototipos..

Q3: ¿Cómo le permite el mecanizado CNC tener alta precisión??

El mecanizado CNC se caracteriza por movimientos precisos de las herramientas alrededor de la pieza de trabajo., que está definido por un diseño asistido por computadora y puede permitir pequeñas tolerancias.

Q4: Por qué el mecanizado de prototipos CNC es mejor que la impresión 3D en la fabricación de prototipos?

Comparado con la impresión 3D, El mecanizado CNC es más rápido en producción y proporciona una mejor selección de materiales.. Además, es más preciso para piezas prototipo funcionales y confiables.

4 pensamientos sobre "Mecanizado de prototipos CNC: Todo lo que necesitas saber”