Las máquinas de perforación se encuentran entre las herramientas más fundamentales en metalurgia y fabricación. Whether you’re a machinist, diseñador de productos, or plant engineer, understanding how these machines work and what types are available can greatly impact your ability to produce accurate, partes funcionales. This comprehensive guide covers everything from basic principles to the parts and various types of drilling machines used in modern workshops.

What is a Drilling Machine?

A drilling machine, also known as a drill press or simply a drill, is a device used to cut holes in solid materials using a rotating cutting tool — typically a drill bit. The machine operates by applying a downward force to the spinning tool, which removes material from the workpiece.

Depending on the model, either the spindle or the workpiece may move, and some machines allow movement in multiple axes for complex hole placement. Most drilling machines are vertical (spindle perpendicular to the table), but special-purpose horizontal and adjustable-angle machines also exist.

Adjustable spindle speeds and feed rates are essential features, allowing compatibility with different materials (p.ej., aluminio, acero, plástica, cerámica) and hole size requirements.

Uses of a Drilling Machine

Perforación

This is the main job — making a straight hole through a material like metal, madera, o plástico. It’s the first step for many kinds of parts and projects.

escariado

If you’ve already drilled a hole but need it to be smoother, rounder, or just a tiny bit wider, you can use a reamer. It helps make the hole more precise — for example, if you want a perfect fit for a pin or shaft.

Countersinking

A veces, you don’t want a screw head to stick out. Countersinking creates a small cone-shaped dip at the top of a hole so a flat-head screw can sit flush with the surface.

tocando

Need threads inside a hole so you can screw a bolt into it? That’s what tapping is for. You use a tool called a tap to cut threads inside the hole — kind of like making grooves for a screw to twist into.

Aburrido

Nope, not the boring that puts you to sleep! In machining, boring means enlarging a hole that’s already been drilled. It’s helpful when you want better accuracy or need to reach a specific size that a standard drill bit can’t handle alone.

Counterboring

Think of counterboring as making a hole-within-a-hole. You first drill a normal hole, then use a bigger cutter to make the top part of the hole wider — usually to fit a bolt head or a special fastener.

How a Drilling Machine Works

Los conceptos básicos

Most drilling machines use an electric motor. When you turn the machine on, the motor powers a spindle — that’s the part that spins. Attached to the spindle is a arrojar, which holds the drill bit (la herramienta de corte). As the spindle spins, the drill bit spins too, cutting into the workpiece.

Applying Pressure

Spinning alone isn’t enough. The drill bit also needs to be pushed downward into the material. Depending on the machine, you might push it manually using a lever (like on a small drill press), or the machine might do it for you automatically using a powered feed system.

Holding the Workpiece

Ahora, here’s something super important: your material — whether it’s a piece of metal, plástico, or wood — has to stay completely still. If it moves while the drill is running, things can go very wrong. That’s why we use clamps, vices, or special tables to keep the part locked in place.

Drill Direction and Angles

Most drilling machines drill straight down (vertical). But some machines let you change the angle or even drill sideways. That’s handy when you’re working on odd shapes or tricky positions.

Speed and Control

You can usually change the spinning speed depending on what you’re drilling. Softer materials might need slower speeds, while harder ones need faster ones. The same goes for how fast you push the drill into the material — too fast, and the bit could break; too slow, and it takes forever.

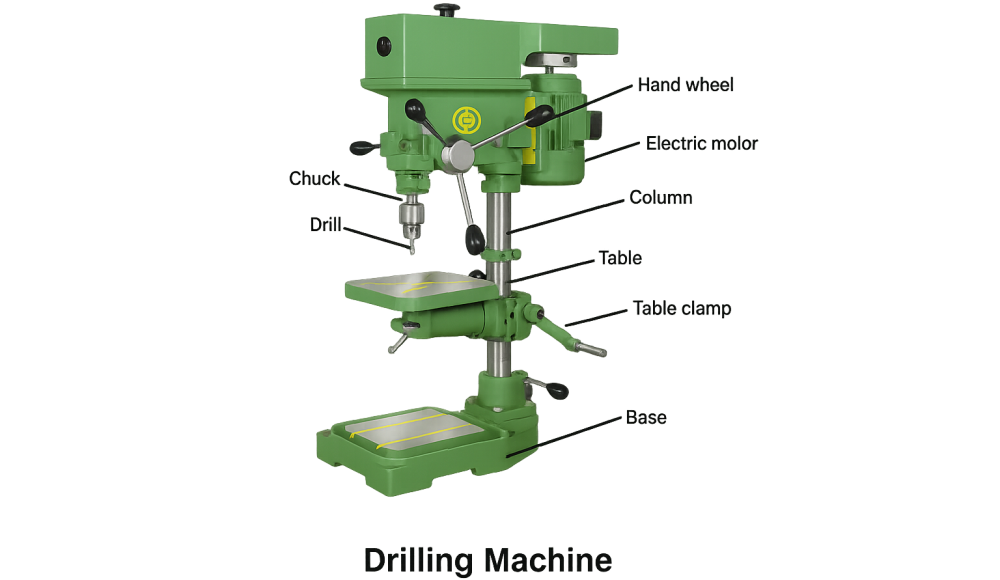

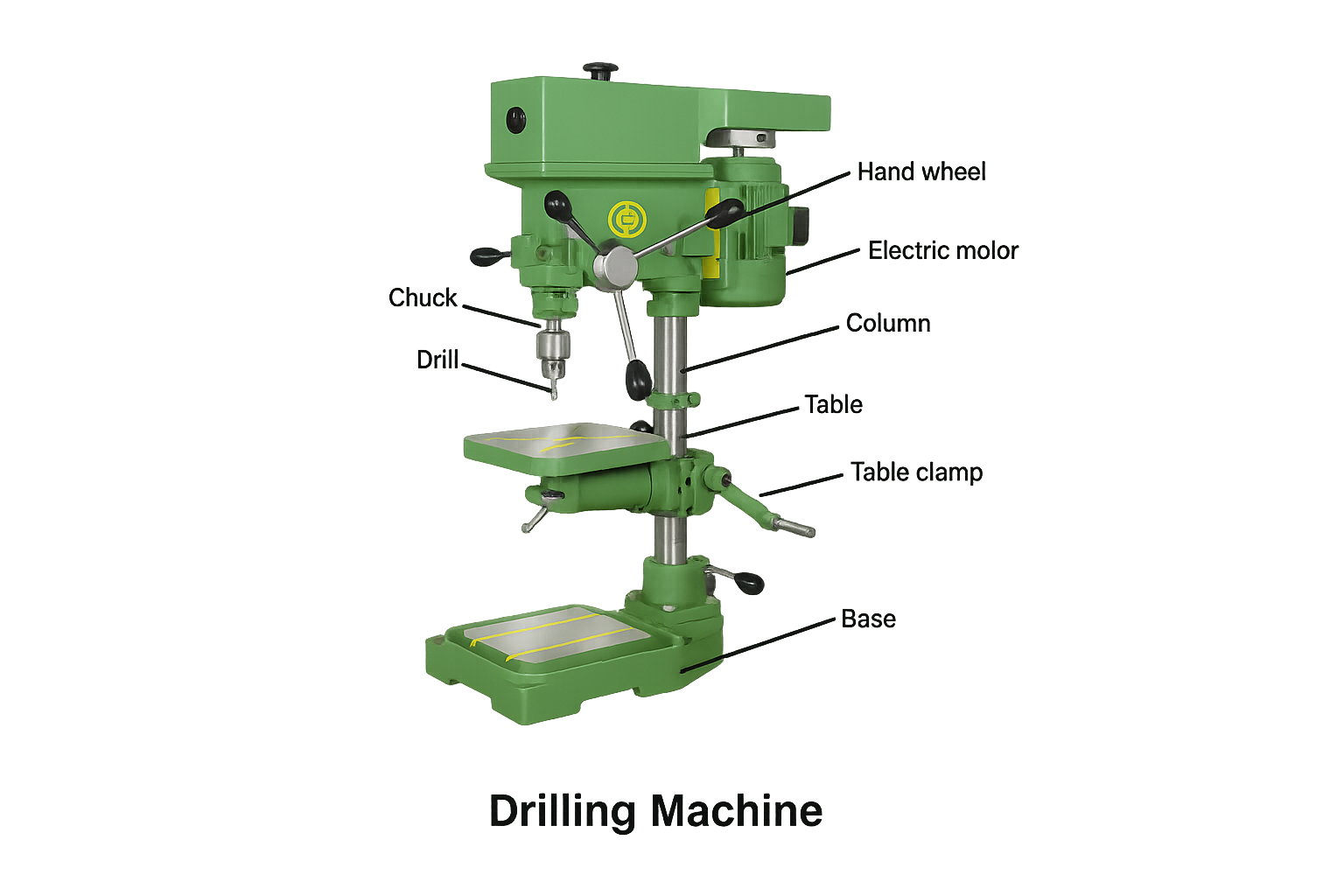

Parts of a Drilling Machine

Understanding the key components helps users operate and maintain the machine effectively:

Base – The foundation that supports the entire machine.

Columna – Vertical support structure connecting the base to the arm or head.

Radial Arm – A horizontal arm (on radial machines) that allows lateral movement of the spindle.

Drill Head – Contains the motor and controls the vertical motion of the spindle.

Mesa de trabajo – Surface on which the workpiece is placed and secured.

Feed Mechanism – Controls the descent of the drill into the material.

Huso – The rotating axis holding the drill bit.

Arrojar – A tool holder that grips the drill bit.

Electric Motor – Powers the machine, usually via belt or gear drive.

Types of Drilling Machines

CNC Drilling Machine

This is the high-tech one. A CNC (Control numérico por computadora) drilling machine doesn’t need much manual work. You just load the program, and it follows instructions to drill holes exactly where they need to be — super accurate and great for repeating the same job over and over.

👉 Mejor para: producción en masa, partes complejas, or super-precise work.

Sensitive Drilling Machine

This is the classic, hand-controlled type you might find in school workshops or small machine shops. You lower the drill bit using a lever, and it gives you good “feel” or feedback while drilling.

👉 Mejor para: Light-duty work and when you want more control by hand.

Radial Drilling Machine

Think of this like a long arm with a drill on the end. The arm can swing around and move the drill to different positions without moving the part you’re working on. Super handy for big, heavy stuff that’s hard to shift.

👉 Mejor para: Large or awkward-shaped pieces that can’t be moved easily.

Upright Drilling Machine

This one is tougher than the sensitive drill. It usually has a power feed to push the drill bit automatically. That means less work for your arms and more consistent results.

👉 Mejor para: Medium to heavy-duty jobs with thicker materials.

Gang Drilling Machine

It’s like several drills in a row, all mounted on the same base. Each one does a different task — like drill, tap, or countersink — without moving the part. Slide the workpiece down the line, and it’s done.

👉 Mejor para: Doing many operations quickly on the same part.

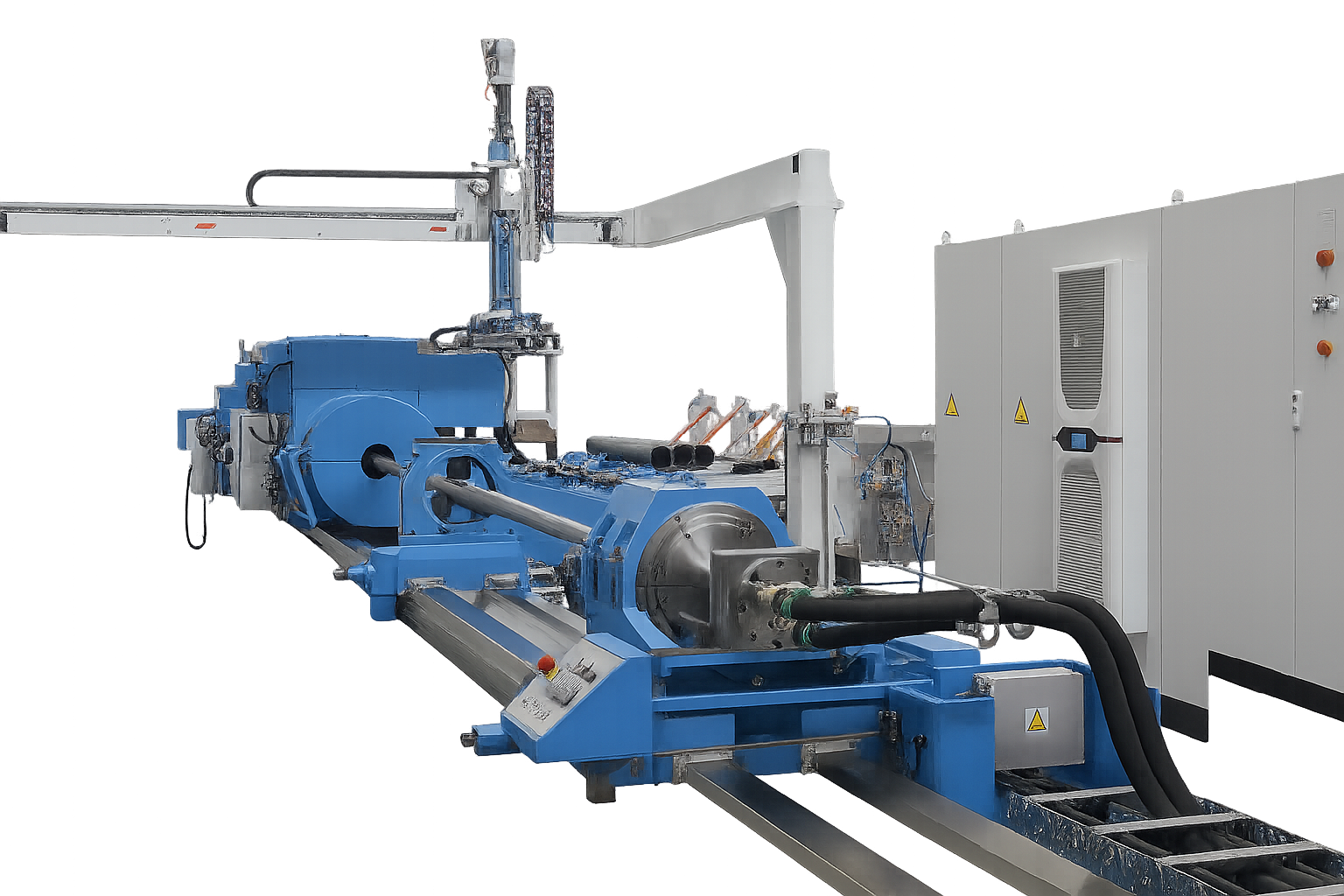

Deep Hole Drilling Machine

This one is made for drilling really deep holes — way deeper than normal drills can handle. It usually lies flat (horizontal) and uses special bits and coolant to keep things clean and accurate.

👉 Mejor para: Ejes, barrels, or anything with long holes.

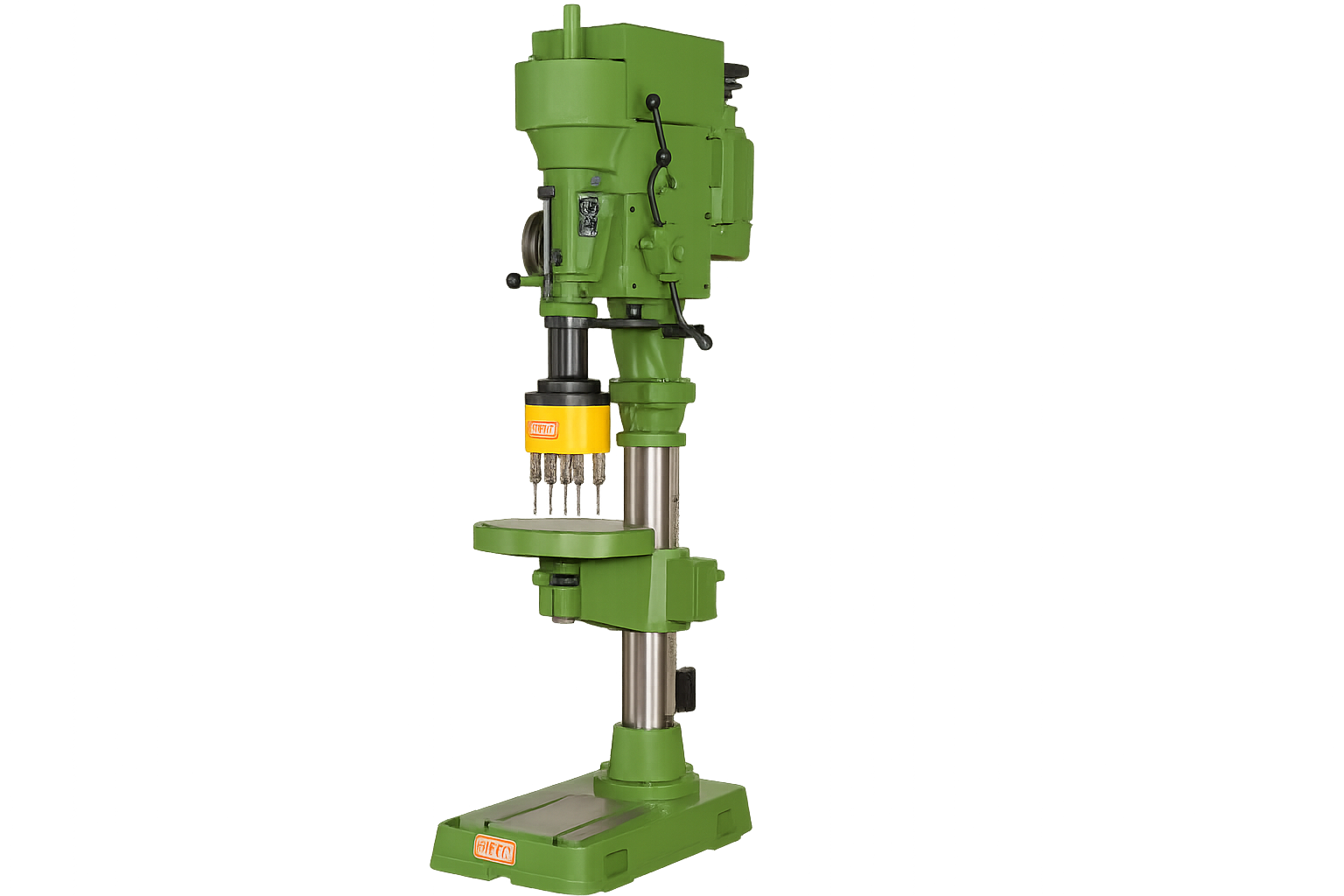

Multi-Spindle Drilling Machine

Need to drill lots of holes at once? This machine has several drill bits working at the same time. It saves a ton of time if you’re making the same part over and over.

👉 Mejor para: High-volume production when you need many holes drilled fast.

Portable Drilling Machine

Yep — this is the handheld drill most people know. It’s easy to carry and great for drilling in tight spaces or on-site construction work. Some are battery-powered, others plug in.

👉 Mejor para: Quick jobs, repairs, or when you can’t bring the part to a machine.

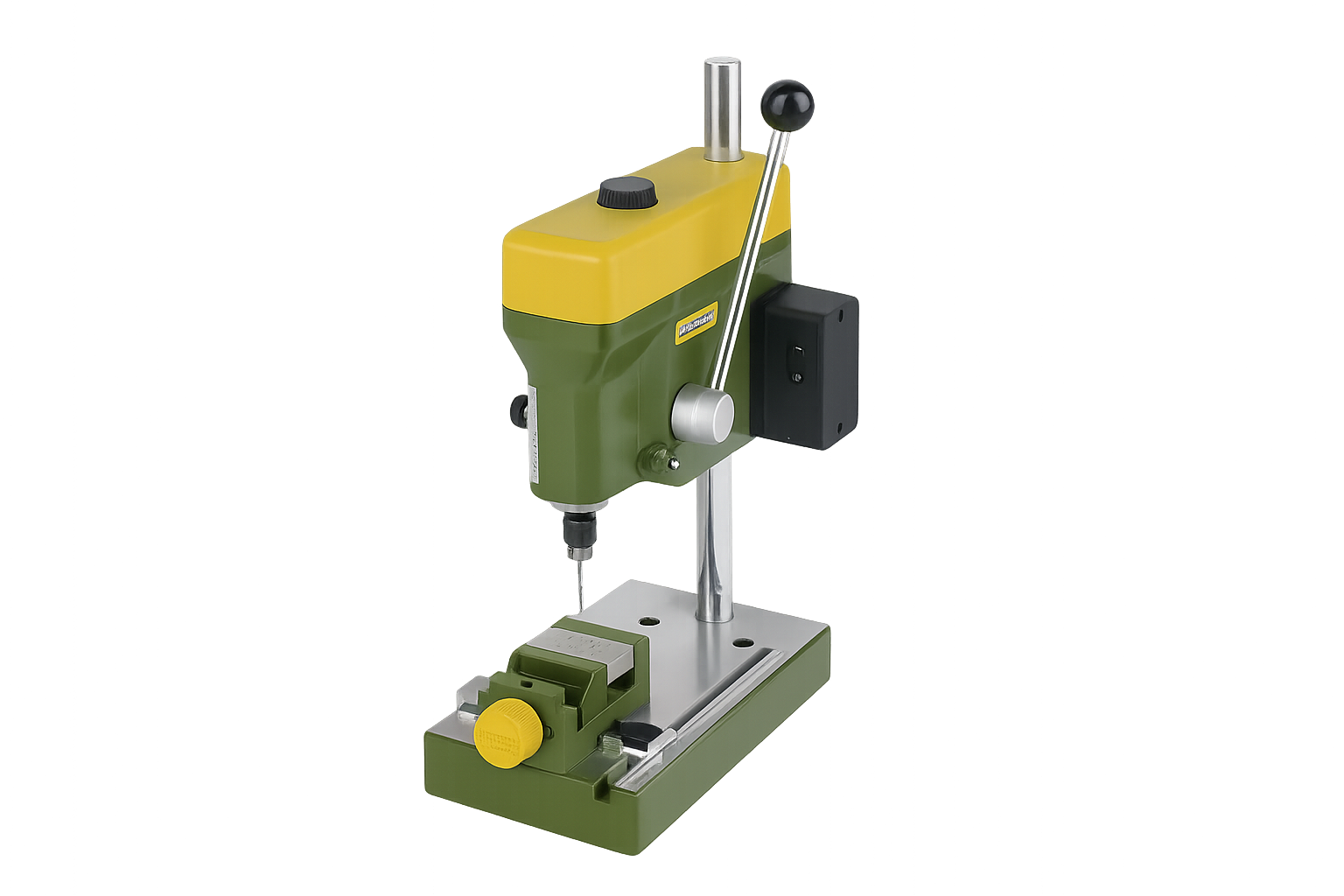

Micro Drill Press

Tiny but powerful. This one is used for drilling very small holes — often smaller than a millimeter. You’ll need a steady hand and lots of patience.

👉 Mejor para: Electrónica, joyas, or tiny mechanical parts.

Turret-Type Drilling Machine

This one’s like a tool carousel. It can hold several drill bits at once, and you can switch between them without having to stop and change tools manually.

👉 Mejor para: When you need to do multiple operations in one setup — saves time and improves accuracy.

Resumen

Drilling machines are indispensable in modern manufacturing, capable of producing everything from simple through-holes to precision-threaded bores and complex, multi-stage hole features. From manual bench-top units to advanced CNC turrets, each type serves unique roles in the workshop or factory.

Understanding the correct type of machine to use—and maintaining proper operation—is key to ensuring part accuracy, eficiencia, and long-term productivity.

Want Professional Drilled Parts?

En Tapas de precisión, we specialize in high-precision CNC drilling, escariado, tocando, y más. Upload your design file to receive an instant quote and start your project with expert support today.

Preguntas frecuentes

Q1: What is the difference between boring and reaming?

A: Boring enlarges a pre-drilled hole with precision; reaming improves its roundness and surface finish.

Q2: Can portable drills perform precision work?

A: ellos pueden, but fixed or CNC machines are better for high-accuracy and repeatable tasks.

Q3: What materials can drilling machines handle?

A: Rieles (acero, titanio, aluminio), plástica (acetal, Ultem), composicion, and some ceramics.

Q4: What is a common feed mechanism for drilling?

A: Manual lever feed in sensitive machines; motor-driven power feed in upright and CNC drills.

Leer más:

Machining Drawing for CNC Machining