1. Preparación de materiales

We select premium rubber materials—sheets, varillas, or blocks—based on hardness and application. Consistent quality ensures excellent dimensional stability and performance.

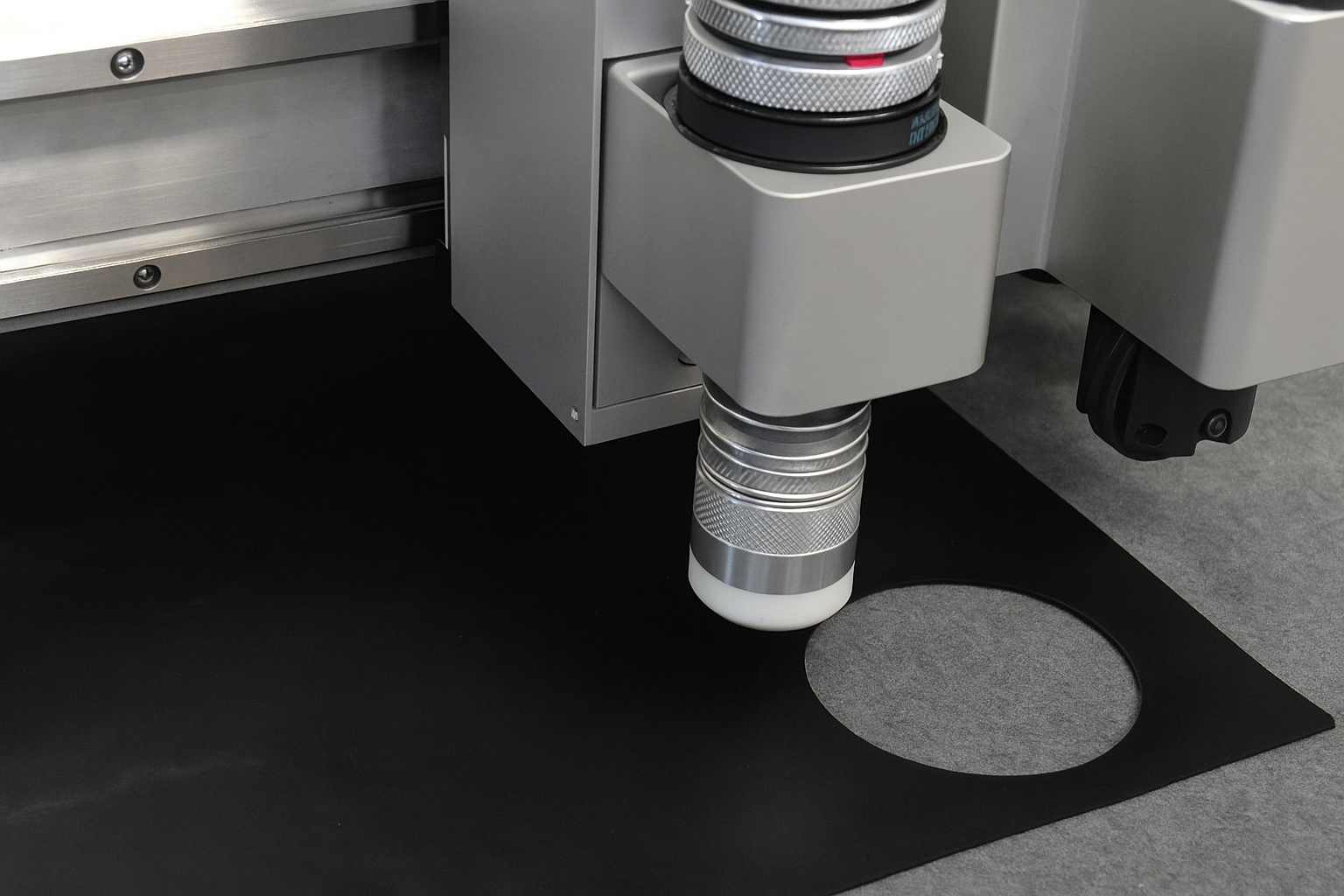

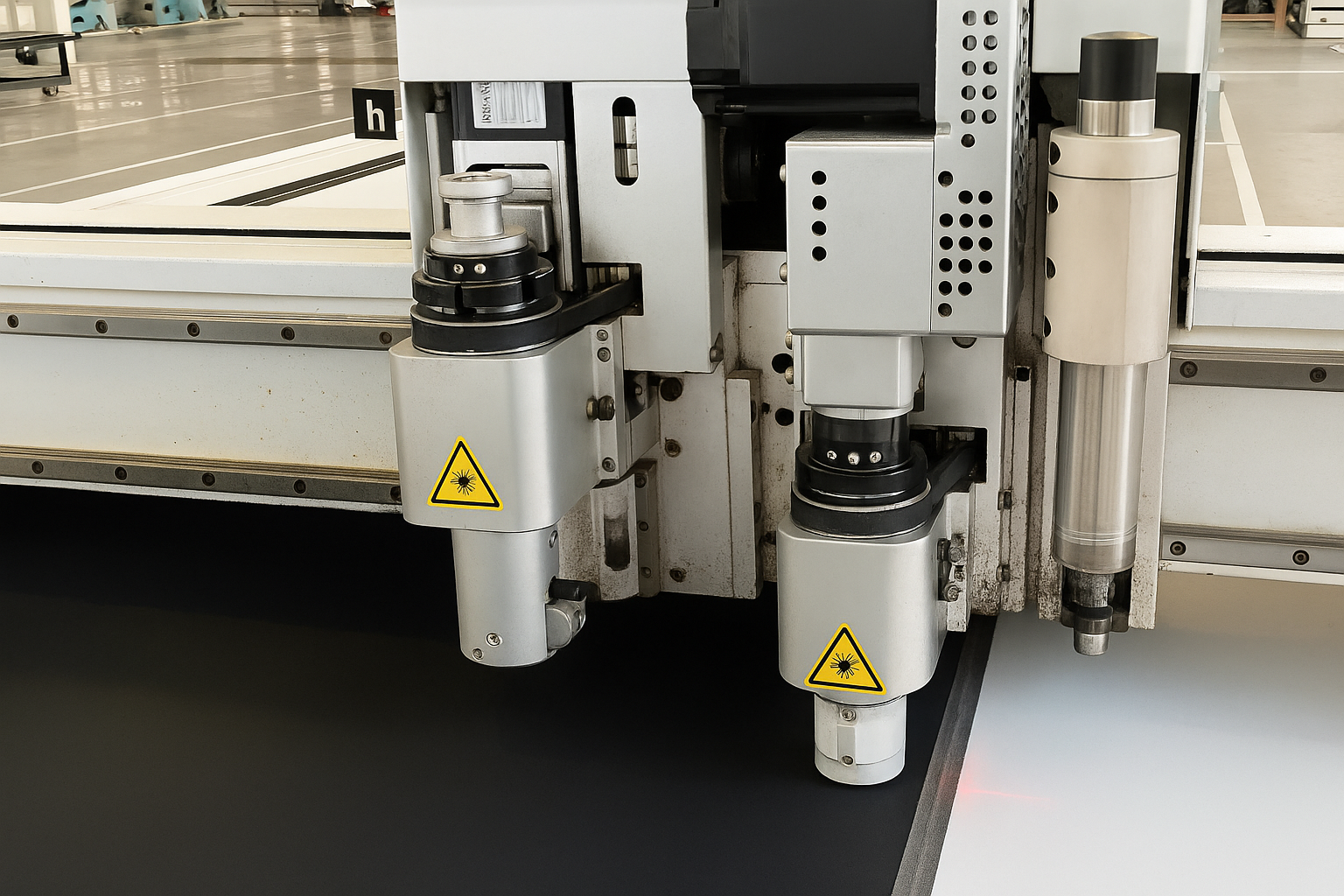

2. Configuración de CNC

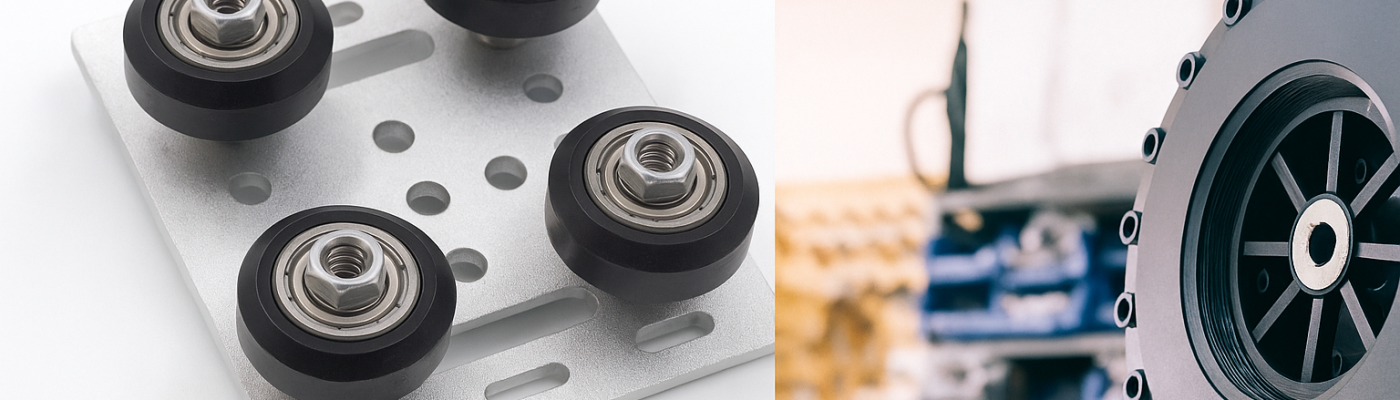

Our machines use soft jaws, custom tooling, and vibration-dampening mounts to hold flexible rubber securely and prevent distortion during machining.

3. Ejecución de corte

With sharp HSS and carbide tools, Nos casamos, doblar, and groove rubber parts like O-rings and gaskets. Optimized feeds ensure clean cuts without tearing or deformation.

4. Eliminación de virutas / Enfriamiento

Rubber chips are evacuated using vacuum and air—no liquid coolants—preserving elasticity and material purity.

5. Inspección y acabado

All parts are inspected for tight tolerances. Post-processing includes deburring and thermal conditioning to restore strength and flexibility.

Diferentes propiedades de caucho

Entonces, Las siguientes son las diferentes propiedades del caucho:

1. Elasticidad

Ideal for seals and dampers, our rubber parts maintain flexibility with high dimensional accuracy.

2. Resistencia a la tracción

We machine strong rubbers like NBR to handle dynamic loads without tearing.

3. Resistencia a la lágrima

Our components resist ripping and flex fatigue, ensuring longer service life.

4. Resistencia a la abrasión

We produce wear-resistant rollers and pads using tough compounds like neoprene and PU.

5. Resistencia química

EPDM, VITON, and other rubbers are precisely machined for harsh chemical environments.

6. Estabilidad térmica

Silicone and FKM parts withstand up to 250°C, perfect for high-heat applications.

7. Aislamiento electrico

We machine dielectric rubbers for safe, accurate parts in electronic and moisture-prone systems.

8. Clima & Resistencia a ozono

EPDM parts are UV-, ozone-, and moisture-resistant—ideal for outdoor and HVAC use.

9. Resistencia al conjunto de compresión

Our seals retain shape and function under long-term pressure and heat.