Selecting an appropriate steel alloy often presents numerous challenges. Because the choice of the wrong material can lead to compromises in structural integrity and overall quality. Luckily there is always a way to make a decision easier if you know of distinguishing aspects of materials. Let’s take a look at the mechanical properties and applications of 4140 contre 4130 steel alloys with the intention of understanding, why these steels are highly appreciated in the manufacturing of sophisticated parts or products. This understanding will help you make decisions in your business.

Understanding Steel Grades in Rapid Prototyping

Selecting the right steel grade is critical to the success of a project in rapid prototyping. Engineering professionals often encounter difficulty in choosing the right material which can cause setbacks and or failure.

The steel grade 4130 is a chromium-molybdenum steel with a carbon content of between 0.28% et 0.33%. It provides good weldability and formability and is hence optimal for complex shapes prototypes in the automotive and aerospace industries. En outre, it has good machinability and its response to heat treatment makes it suitable for use in rapid prototyping.

En comparaison, 4140 acier contains a carbon between 0.38% à 0.43%. The high carbon content makes it stronger and harder as compared to the other steel types. 4140 is central for high-stress applications for instance for shaping gears and shafts. The wear resistance acquired through heat treatment is even better, contributing to the unit’s effectiveness in high-strain applications.

4140 Alloy Steel at a Glance?

4140 alloy steel is a typical chromium-molybdenum alloy. It features multiple mechanical properties, benefiting several sectors. Steel alloy 4140 is most frequently employed where high strength and toughness are major concerns. It’s widely used where parts are produced that are to be subjected to heavy loads like gears, arbres, et essieux.

Composition of Alloy 4140:

4140 steel typically contains:

- Carbone (C): 0.38% – 0.43%

- Chrome (Cr): 0.8% – 1.1%

- Molybdène (Mo): 0.15% – 0.25%

The presence of these components usually helps in improving general hardness and resistance during exposure to abrasive wear.

Propriétés

Force:

- High tensile strength or up to 100000 psi.

- This characteristic ensures it has a high yield strength hence ideal for carrying heavy loads.

Dureté:

- Gains high hardness by heat treatment processes such as quenching and tempering.

- The material shall remain hard even in applications where it is subjected to high loads.

Ductilité:

- Good ductility means that shaping will not cause the material to break.

- Used in machining and forming applications.

Soudabilité:

- Can be welded but care must be taken to avoid cracking, otherwise preheating may be required.

Dureté:

- Has high impact strength, which is suitable for applications with a lot of movement.

Applications

4140 alloy steel is used in various applications, y compris:

- Automobile: Blocs de moteur, connecting rods, pistons, arbres à cames, valves and springs, engrenages de transmission, differentials, driveshafts, axels, roues, and suspensions.

- Aérospatial: Landing gear; pièces de moteur; et pièces de structure.

- Fabrication: Ils comprennent; Machine tools, Dies, and Jigs.

- Pétrole et Gaz: Drill rods and pressure vessels are the two main parts of the gear.

Traitement thermique

4140 steel can accommodate multiple heat treatment processes including:

- Recuit: Annealing yields to enhanced ability to machine as well as a reduction in hardness.

- Trempe: This makes it even more resilient and strong after heating.

- Trempe: It helps to decrease brittleness while increasing the strength correspondingly.

4130 Steel at a Glance?

4130 steel is a low alloy chromium-molybdenum steel. These alloys are often used in the aerospace, automobile, et les secteurs du bâtiment. Steel alloy 4130 is prized for its great weldability, ductilité, et la force. It can be used for both structural and mechanical purposes due to its flexibility.

Composition of 4130 Acier:

4130 steel typically consists of:

- Teneur en carbone: 0.28% – 0.33%

- (Cr) contenu: 0.8% – 1.1%

- Molybdène (Mo): 0.15% – 0.25%

Propriétés

Force:

- Has an excellent combination of strength and hardness.

- The tensile strength can go up to approx. 90,000 psi.

Ductilité:

- Demonstrates good ductility which makes it possible for it to be bent, rolled, etc..

- Promotes activities such as forming and cutting.

Soudabilité:

- Very easy to weld and thus it can be fabricated.

- The thicker sections may require pre-heating to avoid crack formation during the cooling process.

Usinabilité:

- The material exhibits good machinability when in the annealed condition.

Traitement thermique:

- May be heat treated for improvement of strength and hardness.

- Some of the well-known treatments comprise annealing, trempe, and tempering.

Applications

4130 steel is used in a variety of applications, y compris:

- Automobile: Body shells, structural members, et composants de suspension.

- Aérospatial: Aerospace structural parts and airframe assemblies.

- Pétrole et Gaz: Such as; drill pipes, and pressure vessels.

- General Engineering: Gabarits, luminaires, et outillage.

Traitement thermique

De la même manière, 4130 steel is compatible with several heat-treating methods given by:

- Recuit: Softens and enhances the ability to process metal with a machine tool.

- Trempe: Enhances strength and rigidity when submerged in cold water so that it cools very fast.

- Trempe: It balances strength and toughness by minimizing the possibility of making it brittle.

4130 Vs 4140 Acier: Comparative Analysis

The table below highlights the key differences and properties of each steel grade, ensuring clarity and technical accuracy.

| Propriété | 4130 acier | 4140 acier |

| Composition | Soufre: 0.040% (maximum) | Soufre: 0.040% (maximum) |

| Silicium: 0.15%-0.35% | Silicium: 0.15%-0.35% | |

| Molybdène: 0.15%-0.25% | Molybdène: 0.15%-0.25% | |

| Traitement thermique | Normalized and tempered | Quenched and tempered |

| Heated to 1600°F-1700°F for normalizing | Heated to 1600°F-1650°F for hardening | |

| Cooled in air | Quenched in oil or water | |

| Propriétés mécaniques | Résistance à la traction: 560-725 MPa | Résistance à la traction: 655-979 MPa |

| Limite d'élasticité: ~460 MPa | Limite d'élasticité: ~415 MPa | |

| Dureté: 15-23 CRH | Dureté: 28-32 CRH (endurci) | |

| Usinabilité | Easier to machine due to lower carbon | Requires careful machining to avoid cracking |

| Soudabilité | Superior weldability | Requires preheating and post-welding treatment |

| Suitable for standard welding methods | May require specialized techniques | |

| Material Forms | Commonly available in tube and sheet | Available in bar and plate form |

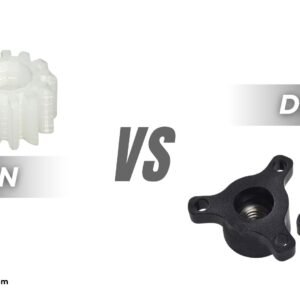

| Applications | Used for gears, perceuses, et pièces automobiles | Ideal for high-stress components like crankshafts and sprockets |

4130 contre. 4140 Acier: Considerations For Selecting The Right Grade

The strength and toughness are relatively impressive for both of the steel materials. Although they are not identical. Knowing their differences is important in arriving at the right decision in choosing the appropriate steel for your construction needs.

Compare The Chemical Composition of Both Steels

Le 4140 steel has risen to 0.40% carbon and corresponding 0.90% chromium compared to plain carbon steel. Alors que 4130 steel contains a lower carbon. Stakeholders should consider key constituents like the carbon, manganèse, silicium, soufre, and molybdenum of both alloys to seek the optimum balance.

Mechanical Properties Understanding

When a project demands high hardness, 4140 is a preferred choice for demanding applications. En plus, it has a high carbon and manganese content with good resistance to heat treatment practices including quenching and tempering. 4130 acier, offers adequate tensile and yield strength and presents good formability. Both steels should have their mechanical characteristics analyzed and compared, so you can decide which one matches your project requirements.

Understand Your Machinability Need

Advantages such as easy machinability make 4130 steel suitable for applications requiring high machinability. The high shear strength makes it more desirable because of the machining ease. Par conséquent, it often leads to a smooth process by reducing chips and wearing down the cutting force during manufacturing. Cependant, if the strength is an essential requirement, then opt for 4140. Bien que, it may present challenges of slow chip-removal, and high cutting forces. Donc, It’s always necessary to assess your machining needs to identify the appropriate steel to take on your production process.

Evaluate Heat Treatment Requirements

- Premièrement, you should find out what specific heat treatment is necessary for your case.

- If your project needs specific hardening, then it is very useful that 4140 can be tempered.

- Look at the behavior of both the steels in different heat treatment processes.

- This assessment will help you to choose the material that meets your requirements.

Evaluate the Cost

The cost of 4130 contre 4140 steel generally depends on supplier price and quantity. Généralement, 4140 steel is costlier than other similar grades. This is so because the material has higher strength and hardness, properties that are important for demanding use. Fluctuations in prices among the suppliers are also common. One must always take some time to assess the project requirements of your project. This will assist you in determining the right steel that is cheapest to purchase while at the same time maintaining high quality.

Tops Precision Offers Best 4140 et 4130 Steel Turning Services

Machining of steel often presents certain challenges. Different grades of steel are employed depending on specific requirements, but the selection of the grade could be daunting mainly by considering each grade’s characteristics.

À Précision au sommet, our professional staff takes full control of all your steel machining services. We also provide high-quality surface coatings to make your steel parts look as good as new. Contact our support center now for your free quote and let us turn your vision into reality.

Conclusion

Low-alloy steel’s 4140 et 4130 grades are recognized by their high strength and satisfactory ductility. Due to their excellent corrosion properties, these materials find use in a variety of manufacturing industries. Néanmoins, differences are evident between the two grades. Donc, one must understand all these differences in a bid to choose the right steel for an intended project.