Le moulage de matrices est un processus de fabrication essentiel largement utilisé dans des industries telles que l'automobile, aérospatial, électronique, et biens de consommation. Le fondement de la coulée de matrice de haute qualité réside dans des outils optimisés - les moules utilisés pour façonner le métal fondu en parties complexes. L'outillage supérieur influence directement les tolérances des produits, durée de vie de la moisissure, efficacité de production, et le retour sur investissement du projet global (Retour de retour).

Comprendre l'outillage moulé Die

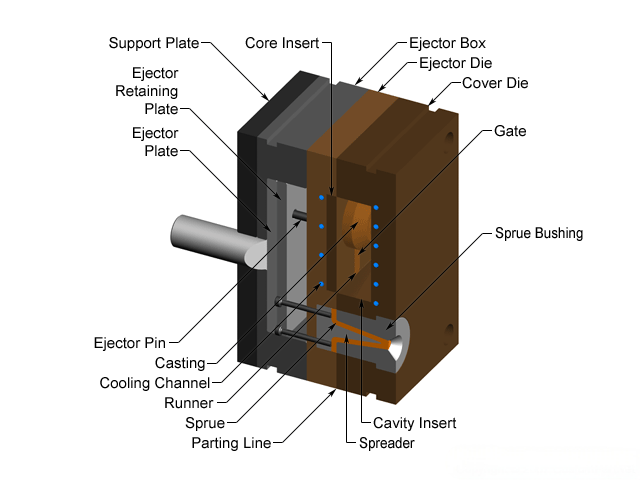

Outillage moulé, ou moules moulés, Comprend des moules en acier artisanaux conçus pour résister aux injections à haute pression de métal fondu. Au refroidissement, Le métal se solidifie dans la forme prévue, offrir des composants cohérents et précis. Les moules se composent généralement de deux pièces ou plus, permettant une extraction facile de la coulée finie.

Les types de moisissures de moulage communs incluent:

Prototyping Dies: Utilisé pour les tests et la validation initiaux.

Dies unit: Convient à la production à plus petite échelle et adaptable à divers composants.

Dies à outils rapides: Activer le revirement rapide pour les tests de produits rapides.

TRAPIER: Moules spécialisés pour couper l'excès de matériau à partir de pièces coulées.

Dies de production: Conçu pour un volume élevé, Runs de fabrication à long terme.

Processus de conception de moule à moulage

Le processus de conception de moisissure pour la coulée de la matrice implique une planification méticuleuse et plusieurs étapes cruciales:

Phase préliminaire: Évaluation initiale des produits, analyse de faisabilité, et détermination des spécifications.

Déterminer le nombre de cavités: Décider du nombre de pièces le moule devrait produire par cycle d'injection en fonction du volume de production.

Évaluation de la zone de projection: Évaluation des considérations de taille et de pression du moule requises.

Analyse du volume et de la forme: Assurer la compatibilité de la conception avec les objectifs de production et les performances de moisissure.

Simulation semi-empirique: Simulation assistée par ordinateur pour identifier les problèmes de coulée potentiels, comme les poches d'air, irrégularités de flux, et incohérences thermiques.

Analyse de fabrication, en particulier en utilisant un logiciel avancé, Aide à anticiper les problèmes avec le flux métallique, taux de refroidissement, et les points de stress, Permettre des ajustements proactifs aux conceptions de moisissures avant le début de la production.

Conception de moisissure pour la fabrication (DFM)

Conception de la fabrication (DFM) intègre des pratiques d'ingénierie et de conception qui rationalisent la production de moisissures, réduire les coûts, et améliorer la durabilité et les performances globales des moisissures.

Les paramètres clés de la moule de moulage DFM incluent:

Angles de projet: Angles suffisants pour le retrait facile des pièces coulées, Réduire l'usure des moisissures.

Rayons et filets: Lisse des bords internes et externes pour éviter les concentrations de contraintes et améliorer le débit métallique.

Patrons et côtes: Renforcements structurels pour améliorer l'intégrité et la résistance de la coulée sans utilisation excessive de matériaux.

Lignes de séparation: Placement approprié pour minimiser le flash et faciliter l'extraction de pièces faciles.

DFM efficace garantit moins de révisions de conception, Réduction des retards de production, et amélioration de la qualité du produit.

Care et entretien des moisissures

L'entretien régulier est essentiel pour maximiser la durée de vie des moisissures et assurer une qualité de produit cohérente. Les moules de coulée de dédale perdurent des cycles répétés de chauffage et de refroidissement, conduisant à des problèmes potentiels tels que:

Tenue de base: Érosion progressive des caractéristiques de moisissures critiques.

Érosion de la porte: Porter à des points où le métal pénètre dans le moule.

Les stratégies de maintenance comprennent:

Inspections planifiées et entretien préventif.

Nettoyer des moules régulièrement pour éviter l'accumulation qui peut avoir un impact sur la qualité.

Réparer ou rénover les zones usées rapidement.

Par exemple, Les moules de zinc multi-glissières résistent généralement à environ un million de coups, tandis que les moules en aluminium gérent approximativement 200,000 coups de feu. Des pratiques de maintenance appropriées peuvent prolonger considérablement ces durées de vie.

Maximiser le retour sur investissement à partir de l'optimisation des moisissures de moulage de la matrice

L'investissement dans des moules de haute qualité se traduit directement par des économies à long terme substantielles. Alors que les coûts initiaux peuvent être plus élevés, L'outillage optimisé réduit les besoins de maintenance fréquents, Minimise les temps d'arrêt de la production, et diminue considérablement.

Les stratégies pour maximiser le retour sur investissement comprennent:

Angles de projet flexibles: Permettre des angles légèrement plus grands dans les zones non critiques améliore la durabilité des moisissures.

Tolérances sur mesure: Évitez les tolérances trop étroites sauf si vous avez absolument nécessaire, Réduire la complexité et le coût.

Collaboration précoce des fournisseurs: Engager les fournisseurs de moisissures et les ingénieurs au début de la phase de conception pour identifier les problèmes et solutions potentiels avant la production de moisissure.

Conclusion et appel à l'action

L'optimisation des moules de moulage de mat, efficacité, et rentabilité dans votre processus de fabrication. Collaborer avec des professionnels expérimentés assure le développement de robustes, Moules durables adaptés à vos besoins spécifiques.

Tops Precision propose des services d'experts d'optimisation de moule à moulage de moules, soutenu par une vaste expérience, technologie de pointe, et pratiques de maintenance rigoureuses. Contactez-nous dès aujourd'hui pour discuter de la façon dont nous pouvons soutenir votre prochain projet avec de haute qualité, Solutions d'outillage optimisées.

En savoir plus:

Services de moulage par dépérisation par Tops Precision

1 réfléchi à "Optimisation du moule de moulage de la matrice: Un guide complet”