Ecco cosa include il nostro servizio e cosa ci distingue:

- ISO 9001:2015 lavorazione CNC certificata per parti di biciclette OEM;

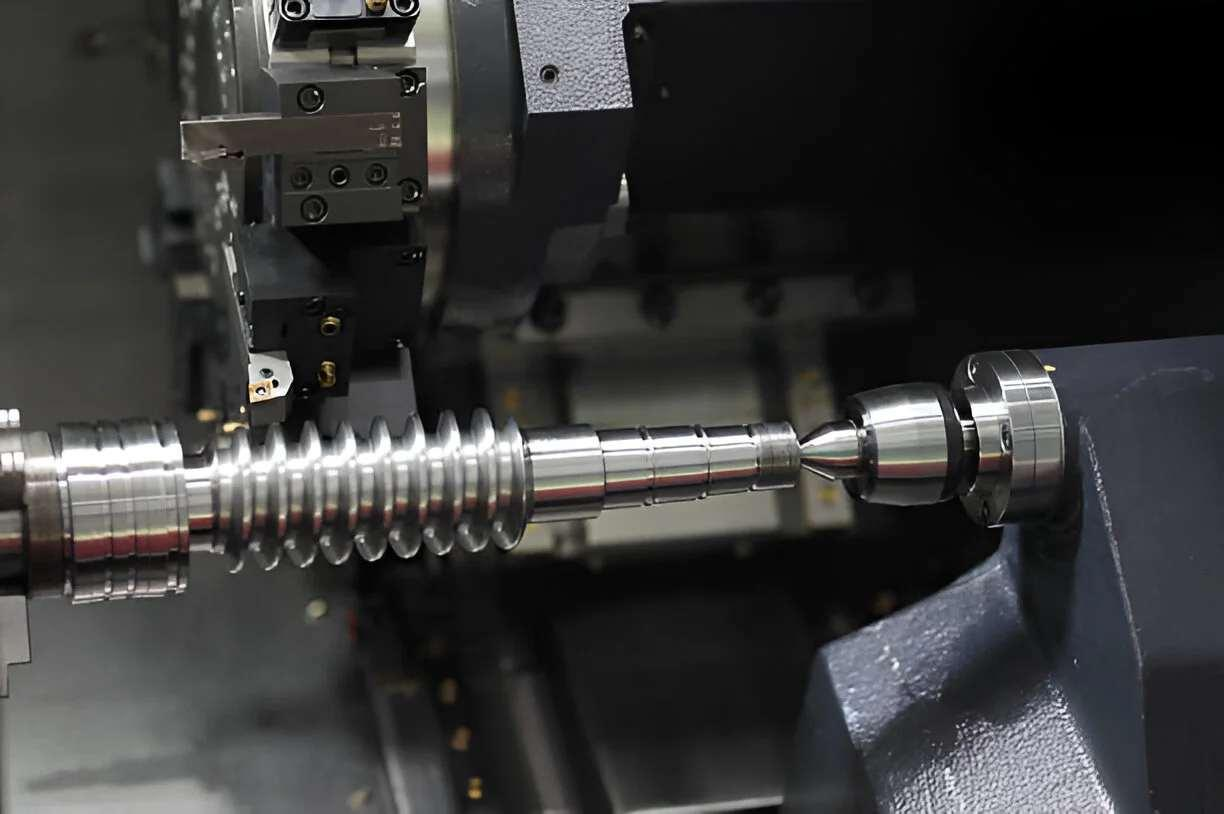

- Avanzato 3, 4, e macchine CNC a 5 assi per parti precise e complesse;

- Supporta biciclette di tutti i tipi, dai modelli fuoristrada ai modelli ad alte prestazioni;

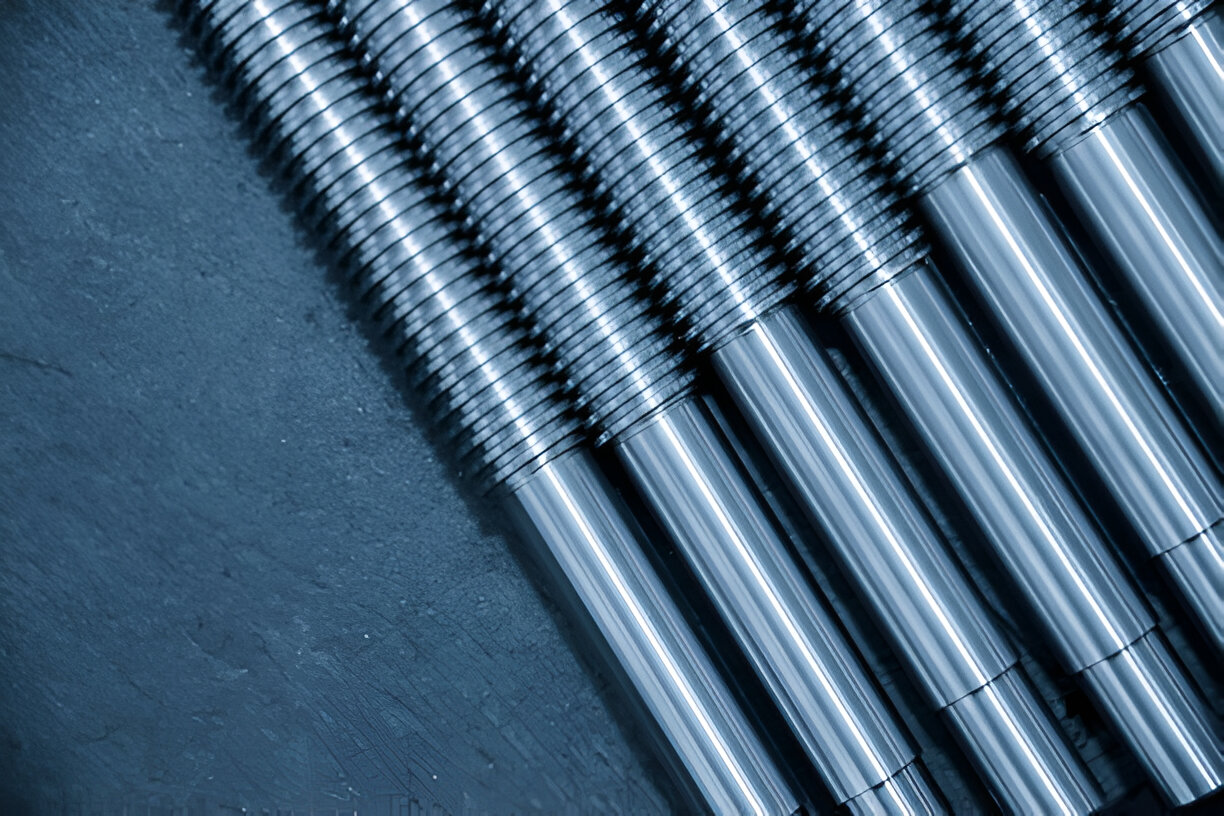

- Possibilità di lavorazione per materiali tipo alluminio, acciaio inossidabile, acciaio, titanio, ottone, bronzo, rame, zinco, addominali, acrilico, PTFE ecc.;

- Fresatura e tornitura CNC con tolleranze strette fino a ±0,400 mm;

- Lavorazioni per pezzi fino a 90 di dimensioni mm;

- Macinazione orizzontale per parti fino a 18 X 22 X 12 pollici, e disegni personalizzati;

- Tornitura di pezzi con diametro fino a 13 pollici.

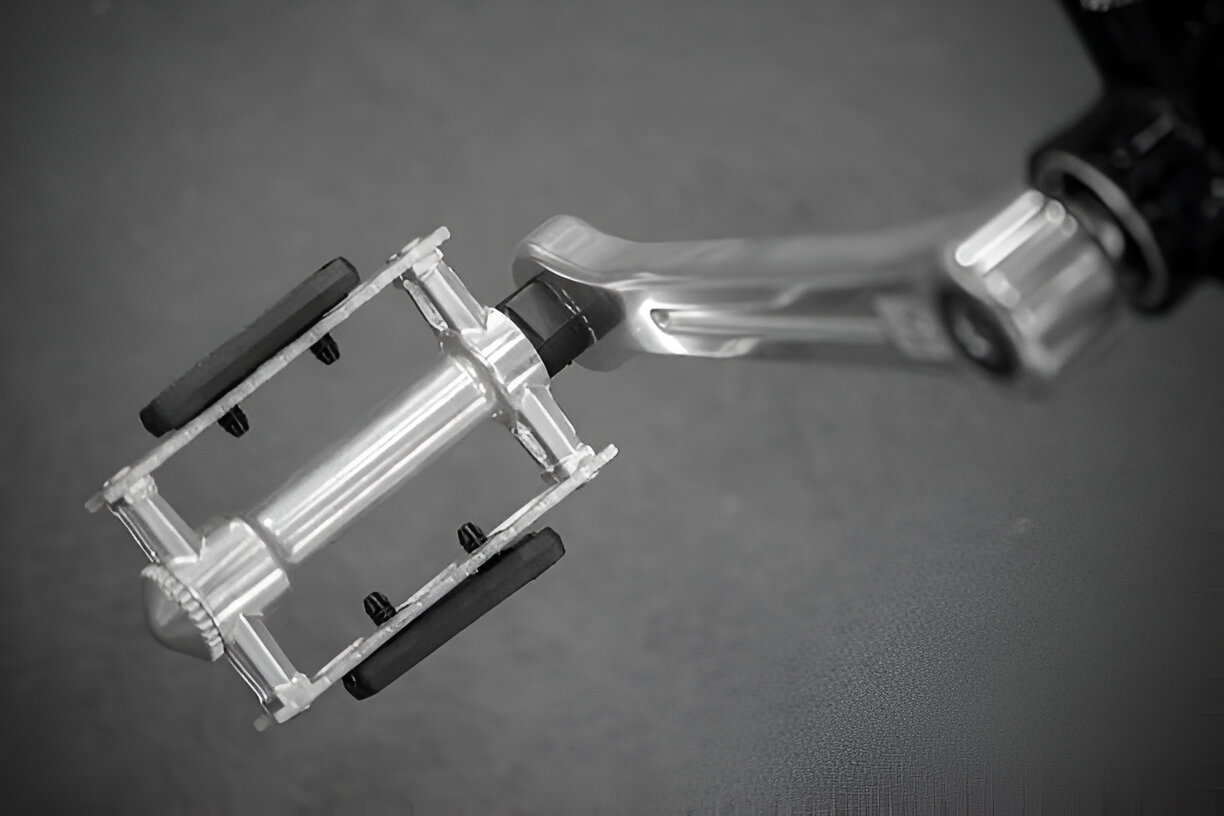

Realizziamo di tutto, da attacchi manubrio e mozzi leggeri a forcellini e distanziali personalizzati. Ogni parte è realizzata con cura meticolosa, e non compromettiamo la qualità.

Invia la tua richiesta oggi

Perché la prototipazione e la lavorazione CNC veloce sono importanti per le parti di biciclette

Nello sviluppo di parti di motociclette e biciclette, la prototipazione e la produzione rapida svolgono un ruolo importante. La lavorazione CNC presso Tops Precision converte i tuoi disegni CAD in parti funzionanti in brevi tempi di consegna. Ottieni campioni accurati, può testare l'idoneità, e fattibilità in anticipo, e procedere con fiducia.

Il nostro team ti aiuta a evitare lunghe ore e a ridurre i tempi di consegna, risolvere problemi di progettazione in breve tempo, ed eliminando i costosi requisiti di attrezzature. Ciò è particolarmente utile con le cornici personalizzate, parti della sospensione, parentesi, o raccordi. Non devi aspettare settimane; Infatti, ricevi parti in pochi giorni. oltre a questo, il processo di prototipazione fa risparmiare tempo e mantiene il tuo progetto nei tempi previsti quando è veloce, precisione, e il feedback sono indispensabili.

Perché la prototipazione è importante nelle fasi iniziali dello sviluppo

I prototipi iniziali ti aiutano a verificare l'idoneità, funzionamento, e geometria. Ti consente di verificare la funzionalità della parte prima di passare alla produzione completa. Quando qualcosa non va nel design, diventa semplice farlo bene e fare diversi tentativi.

Massima precisione, lavoriamo le tue parti direttamente dai tuoi file CAD. Hai campioni funzionanti delle stesse dimensioni e materiale del finale. Nessuna stampa 3D o supposizione: solo parti reali da testare. Ciò è utile con componenti come i dropout, supporti del disco, o collegamenti dove conta la precisione fino al millimetro.

Come la produzione rapida accelera la produzione

Non sempre hai il tempo di aspettare fino all'attrezzatura completa. La rapida produzione CNC ti mantiene sulla buona strada. Può essere utilizzato in tirature brevi, un campione di pre-produzione, o una sostituzione di emergenza.

Non ritardiamo lotti di volume medio-basso. Bisogno 5 nasce la prossima settimana? O 10 supporti freno da testare? Possiamo fornire soluzioni rapide senza alterare il vostro design. Ciò mantiene la sequenza temporale fluida e riduce il rischio al momento del lancio.

Migliore controllo su revisioni e piccole modifiche

I progetti sono soggetti a test successivi. La nostra lavorazione rapida è in grado di aggiornarsi rapidamente. Mantieni il controllo della parte, la vestibilità, e il finale.

Tops Precision sincronizza i tuoi file e crea la versione successiva senza lentezza. Non passi molto tempo avanti e indietro o riorganizzando.

Invia la tua richiesta oggi

Eccellenti parti di biciclette lavorate a CNC che produciamo

Massima precisione, produciamo una vasta gamma di parti di biciclette di precisione lavorate a CNC. Ogni parte è realizzata con cura per soddisfare le vostre specifiche e misure esatte. Ci concentriamo sulla forza, adatto, e durata per aiutare la tua bicicletta a funzionare al meglio.

Ecco alcune delle parti chiave che lavoriamo con particolare attenzione ai dettagli.