メーカー向け, エンジニア, そしてデザイナー, 理解 プラスチック射出成形 不可欠です. 製品設計に影響を与える, 費用対効果, 持続可能性, そして将来のイノベーションさえも. 記事上で, 私たちは通り抜けます プラスチック射出成形について知っておくべき 5 つの重要な側面, 基本をカバーする, 設計上の考慮事項, 利点と課題, 環境への影響, そして新たなトレンド.

1. プラスチック射出成形の基礎

プラスチック射出成形の基礎

射出成形とは?

その中心に, プラスチック射出成形は、プラスチックペレットを完成部品に変えるプロセスです. プロセスは次のように動作します:

プラスチックペレット ホッパーを通って機械に供給されます.

ペレットは、 加熱されて溶けた ヒーターと回転スクリューによりバレル内で.

溶けたプラスチックは、 高圧で注入される 金型キャビティに.

プラスチック 冷えて固まる, 型の正確な形状を取得する.

型が開きます, そして 完成した部品が排出される, 必要に応じて二次仕上げの準備ができています.

このプロセスは速いです, 繰り返し可能, 何百万もの同一のアイテムの生産に適しています.

一般的に使用される材料

製品が異なれば、要求されるプラスチックの特性も異なります, だからこそ素材の選択が重要です:

熱可塑性科学 (ポリエチレンのような, ポリプロピレン, ABS, ポリスチレン): 再加熱・再成形可能, 多用途かつリサイクル可能にする. 梱包に使用, おもちゃ, 自動車部品, そしてエレクトロニクス.

熱硬化性プラスチック (エポキシ樹脂やフェノール樹脂など): 設定したら, 再溶解することはできません. 高い耐熱性が要求される用途に使用されます。, 電気絶縁材や調理器具のハンドルなど.

適切な材料の選択は、機械的強度などの要素に依存します。, 柔軟性, 温度抵抗, 化学的耐久性, そしてコスト.

射出成形機の主要コンポーネント

射出成形機にはいくつかの重要な部品があります:

ホッパー: 生プラスチックペレットの入口ポイント.

加熱バレル & スクリュー: ペレットを溶かし、溶けたプラスチックを金型に注入します。.

型: 形状を定義するカスタムメイドのスチールまたはアルミニウムツール, サイズ, 部品の表面仕上げ.

クランピングユニット: 射出および冷却中に金型を高い力で閉じた状態に保持します。.

排出システム: 冷却されたものを押し出す, 硬化した部分を型から取り出します.

これらのコンポーネントがどのように連携するかを理解することは、欠陥のトラブルシューティングと生産効率の向上に役立ちます。.

2. 設計上の考慮事項とプロトタイピング

設計上の考慮事項とプロトタイピング

デザインの重要性

デザインは見た目の美しさだけを意味するものではありません。部品の成形の容易さや製造コストに直接影響します。. 良いデザイン:

反りなどの製造不良を防止します。, ヒケ, そして不完全な充填.

材料の使用量とサイクルタイムを削減.

最終製品が機能的かつ視覚的に魅力的であることを保証します.

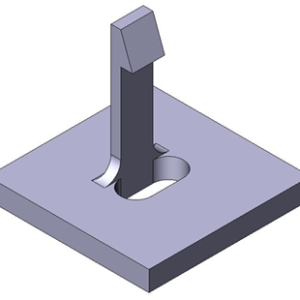

射出成形の主要な設計ガイドライン

均一な肉厚: 一貫した冷却を確保し、反りを防ぎます.

抜き勾配角度: 垂直壁の小さなテーパーにより、金型から部品を取り出しやすくなります。.

リブとガセット: 厚みを増やさずに強度を高める, ただし、収縮を避けるために慎重に設計する必要があります.

ゲートの位置: 溶融プラスチックがどのように金型に流れ込むかを決定します, 表面仕上げと構造の完全性に影響を与える.

丸い角: 応力集中を軽減し、塑性流動を改善します。.

収縮代: プラスチックが冷えると収縮するという事実を考慮したもの.

プロトタイピングと 3D プリンティングの役割

高価な金型に投資する前に, プロトタイピングは不可欠です. 3D プリンティングやその他のラピッド プロトタイピング手法により、デザイナーは:

機能モデルの適合性をテストする, 人間工学, そして強さ.

設計上の欠陥を早期に特定する.

物理サンプルをクライアントや関係者に提示してフィードバックを求める.

このステップにより、生産後のコストのかかる修正が削減され、市場投入までの時間が短縮されます。.

3. 利点と制限事項

射出成形の利点

高い効率とスピード: 型を作った後, 本番稼働は非常に高速になる可能性があります, 1 日に何千もの部品を生産する.

一貫性と精度: 厳しい公差で同一の部品を製造します.

素材の柔軟性: 幅広い種類のプラスチックが使用可能, フィラー, 強度を高めるための添加剤, UV抵抗, 難燃性, または色.

複雑な形状も可能: 他のプロセスでは困難または不可能な複雑な形状や細部の成形が可能.

スケーラビリティ: スケールメリットにより部品あたりのコストが大幅に削減される大量生産に最適.

制限と課題

初期費用が高い: 金型の設計と加工には多額の先行投資が必要です.

設計上の制限: 一部の機能は成形が難しい場合があります, 複雑な金型設計が必要となり、コストが増加する.

材料の制約: プラスチックの種類ごとに制限があります, 耐熱性や脆性など.

生産量要件: コスト効率が良いのは大量生産の場合のみです, 金型コストは多くの部品に分散する必要があるため、.

4. 環境への影響と持続可能性

プラスチック廃棄物の課題

プラスチック射出成形に対する最大の批判の 1 つは環境負荷です。:

プラスチック廃棄物 欠陥のある部品や使い捨て品が埋め立てや海洋汚染の原因となる.

エネルギー集約型の生産, 特に加熱とクランプ, 温室効果ガスの排出量が増加する.

化石燃料への依存, プラスチックのほとんどは石油由来なので、.

サステナビリティへの取り組み

業界はより環境に優しい実践を積極的に追求しています:

リサイクルと再研磨: 廃プラスチックは再粉砕して再利用できます, 無駄を減らす.

生分解性プラスチックおよびバイオベースプラスチック: 植物由来の素材や自然分解するように設計された素材が人気を集めています.

エネルギー効率の高い機械: 最新の電動射出成形機は、古い油圧システムよりも消費エネルギーが少なくなります。.

クローズドループ製造: スクラップを最小限に抑え、材料の使用を最適化する監視システム.

サステナビリティはもはやオプションではなく、より厳しい規制や消費者の期待に応えるために必須のものになりつつあります。.

5. イノベーションと将来のトレンド

イノベーションと将来のトレンド

現在の技術の進歩

自動化とロボット工学: ロボットが部品の取り外しを処理するようになりました, 組み立て, そして品質チェック, 人件費と人的ミスの削減.

スマートモールド: 埋め込みセンサーが圧力を追跡, 温度, リアルタイムの冷却速度, 一貫性の向上.

3D 金型への印刷: 積層造形により迅速な製造が可能, 複雑な形状の金型をコスト効率よく作成.

業界 4.0 統合: IoTとAIで射出成形機はよりスマートに, 予知保全とプロセスの最適化を可能にする.

今後の方向性

持続可能性へのさらなる注目: 再生プラスチックや生分解性プラスチックの幅広い利用が期待される.

新素材開発: 機械的特性と環境特性が改善された先進的なポリマー.

現地生産: より分散化された, 自動化された工場でサプライチェーンへの依存を軽減.

データ駆動型の製造: 欠陥削減のための AI 主導の予測分析, より短いサイクル時間, 適応型プロセス制御.

結論

プラスチック射出成形は、現代においても最も重要な製造プロセスの 1 つです。. 比類のない効率を実現します, スケーラビリティ, および汎用性, 消費財から航空宇宙まで幅広い産業の根幹となっている.

しかし, 課題がないわけではありません。特に環境への懸念や初期の工具コストの高さに関して言えば、. ありがたいことに, 素材の革新, オートメーション, そして持続可能性の実践がこれらの問題に対処しています.

エンジニア向け, デザイナー, およびメーカー, プラスチック射出成形の基礎とそのプロセスをマスターする, デザインルール, 利点, 制限事項, と将来の方向性 - 製品開発と現代の製造業の成功には不可欠です.

続きを読む: