EDM began gaining commercial traction in the mid-20th century, originally used to remove broken drills and taps from hard metals. Over time, engineers realized the potential of this non-traditional machining method and refined it into two dominant processes: Sinker EDM and Wire EDM.

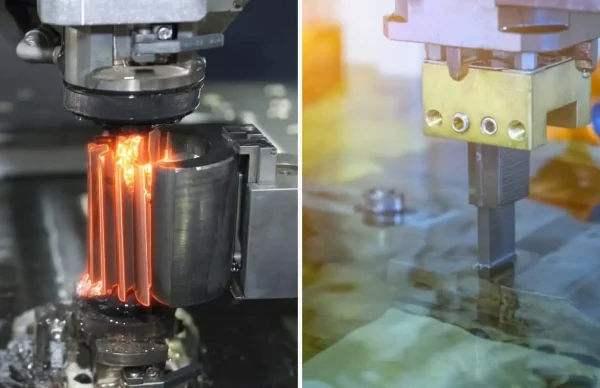

Sinker EDM, the older sibling, uses shaped electrodes to “sink” into the workpiece, forming detailed cavities. Meanwhile, Wire EDM came later and offered something unique—fine wire could be used to slice through thick, tough metals with pinpoint accuracy, making it ideal for 2D profiles and intricate parts.

Today, both technologies continue to evolve with CNC automation, advanced CAD/CAM integration, and improved dielectric fluids, ensuring higher speeds, better finishes, and reduced costs. Each method has carved its own niche in industries where precision is not just important—it’s critical.

What is Sinker EDM?

How Sinker EDM Works

Sinker EDM, also called ram EDM or cavity-type EDM, is a machining process that uses a pre-shaped electrode to burn a specific shape into a conductive workpiece. Picture this: if you want to create a mold cavity shaped like a complex gear, you first fabricate a solid electrode that mirrors the gear’s outline. This electrode is then “sunk” into the workpiece using controlled electrical discharges to recreate that shape with incredible accuracy.

This process is carried out in a dielectric fluid—typically hydrocarbon oil—which not only cools the system but also flushes away eroded particles. The setup involves the electrode (usually made from copper, graphite, or tungsten) and the workpiece submerged in this fluid. The machine pulses voltage across the spark gap between the electrode and the workpiece, causing electrical discharges that melt and vaporize the material.

Unlike traditional cutting methods, there’s no physical contact. That means less mechanical stress on the part, and it’s especially helpful when machining thin walls, sharp internal corners, or fragile structures.

Sinker EDM is also very programmable through CNC, so it’s not just accurate but repeatable—ideal for complex tooling like dies, molds, and aerospace components.

Common Applications of Sinker EDM

Sinker EDM is the go-to solution when your parts require precision cavities and intricate shapes that are either impossible or too costly to produce through conventional methods. Its ability to reproduce sharp internal features and complex geometries makes it indispensable in several high-tech industries.

Some common applications include:

Injection molds and die-casting tools: Perfect for creating cavities with complex internal geometries.

Medical device manufacturing: Used for shaping titanium implants and other components with fine details.

Aerospace components: Especially useful for creating turbine blades and intricate cooling channels.

Jewelry making: Machining detailed patterns in precious metals.

Blind keyways and internal splines: Tasks that traditional machining struggles to handle.

Its unmatched accuracy and flexibility make it a favorite for low-volume, high-complexity production where tolerances are tight and quality is non-negotiable.

Benefits of Sinker EDM

Sinker EDM stands out in the world of precision manufacturing for several good reasons. First off, it’s an incredibly versatile machining method. Whether you’re cutting titanium, carbide, or hardened steel, sinker EDM handles the job with grace.

Here are the standout benefits:

No Contact = No Stress: The non-contact process means no mechanical stress or distortion on the part, which is critical for fragile or thin-walled components.

Intricate Detail: Able to create complex cavities, cross-sections, and thin ribs that traditional tools just can’t manage.

Hard Material Capability: It’s excellent for cutting through the hardest materials like tool steel, Inconel, and tungsten carbide.

Repeatability and Accuracy: Excellent for high-precision tooling that demands tight tolerances and consistency.

Minimal Tool Wear: Electrodes degrade, but much slower than cutting tools used in conventional machining.

These perks make sinker EDM the weapon of choice in mold making, aerospace, medical devices, and anywhere high-precision cavities are a must.

Limitations of Sinker EDM

Despite its numerous strengths, sinker EDM isn’t a one-size-fits-all solution. It comes with its own set of challenges and constraints that you should be aware of before committing to the process.

Here are some limitations:

Only Works on Conductive Materials: Sinker EDM can’t cut ceramics, plastics, or composites unless they are metal-coated.

High Cost and Time: Making custom electrodes takes time and money, making it less ideal for rapid prototyping or small-batch runs.

Power Intensive: The process requires substantial electrical energy to generate the necessary spark erosion.

Tooling Wear: Though it’s gradual, electrode wear affects precision over long production cycles, especially in deep cavities.

Surface Finish: While decent, it often requires secondary finishing processes to achieve mirror-like smoothness.

So, while sinker EDM is amazing for specific tasks, it’s best used when the design complexity justifies the added cost and setup time.

What is Wire EDM?

How Wire EDM Works

Wire EDM, short for Wire Electrical Discharge Machining, offers a radically different take on spark erosion. Imagine a super-fine, electrically charged wire slicing through a block of metal—not by cutting but by vaporizing the material through tiny sparks. That’s the magic of wire EDM.

Here’s how it works: A thin wire (often made of brass or coated with zinc) is strung between two guides. This wire moves precisely along programmed CNC paths while a voltage is pulsed through it. Like sinker EDM, it uses dielectric fluid—typically deionized water—to cool the part and carry away debris. But instead of plunging into the part like a sinker electrode, the wire cuts from the edge inward, making it ideal for through-cuts and profiles.

The machine’s X-Y motion controls, combined with upper head movement in U and V directions, allow for tapered cuts, intricate contours, and even 3D profiles. That level of flexibility, combined with high-speed automation, makes wire EDM perfect for producing ultra-precise parts in demanding industries.

Typical Uses of Wire EDM

Wire EDM is particularly favored in industries where precision, burr-free cuts, and minimal material distortion are essential. The process can handle extremely hard materials that would destroy traditional cutting tools. It’s often used for detailed cuts in hardened steel, titanium, tungsten, and conductive alloys—materials that are notoriously difficult to machine.

Here are some standout applications:

Aerospace components: Used to machine turbine discs, nozzles, and precise internal shapes.

Medical and dental tools: Produces surgical instruments and orthopedic implants with high tolerances.

Tool and die industries: Perfect for blanking punches, extrusion dies, and precision tool parts.

Automotive sector: Machining fuel system parts, transmission components, and engine blocks.

Electronics and semiconductors: Wire EDM is ideal for cutting heat sinks, shielding parts, and connectors.

Beyond these, it’s also excellent for prototype creation where accuracy is paramount but machining stress must be avoided.

Advantages of Wire EDM

Wire EDM has carved out a critical role in modern manufacturing thanks to its unique advantages. From the ability to achieve extreme precision to its non-deforming, stress-free nature, wire EDM is a workhorse in the fabrication of tight-tolerance components.

Let’s look at its biggest strengths:

Extreme Precision: Capable of achieving tolerances within ±0.0001 inches. Perfect for complex, detailed parts.

No Burrs or Tool Marks: Since there’s no mechanical contact, edges come out clean, sharp, and burr-free.

Cuts Very Hard Materials: From tungsten to Inconel, wire EDM can handle metals that conventional tools can’t.

Minimal Distortion: The non-contact process means there’s virtually no thermal or mechanical deformation.

Flexible Tooling: No need for custom dies or molds. Just program the part and go—great for low- to mid-volume production.

It’s also a highly repeatable and automated process, often running unattended, which can be a huge time-saver for manufacturers aiming for consistent, scalable output.

Drawbacks of Wire EDM

As amazing as wire EDM is, it’s not without its drawbacks. Like any specialized tool, it shines in the right application but may fall short in others. Understanding its limitations can help you avoid costly misapplications.

Here are some of the trade-offs:

Only Works with Conductive Materials: Non-conductive materials like plastic, glass, or ceramic? Wire EDM can’t help unless coated with conductive layers.

Higher Setup and Maintenance Costs: EDM machines are complex, requiring skilled operators, regular maintenance, and costly wires and guides.

Slow Material Removal Rate: Compared to conventional milling or laser cutting, wire EDM is relatively slow, especially for thicker materials.

Edge Start Required: Since it can’t start a cut from the middle of a part, it always requires a pre-drilled hole or starting point from the edge.

Post-Processing May Be Needed: For certain surface finishes or dimensional accuracy, secondary machining or polishing might be required.

Despite these limitations, its high-precision cutting capabilities make it indispensable for specific, high-value applications.

Key Differences Between Sinker EDM and Wire EDM

Even though both sinker and wire EDM share the same fundamental principle—removing material through electrical discharges—they are fundamentally different in their design, execution, and application scope. Think of them as siblings with the same roots but very different personalities.

Cutting Mechanism Comparison

The cutting method is the most obvious and important distinction. In Sinker EDM, a solid-shaped electrode is machined to mirror the final desired geometry and then sunk into the workpiece to form a matching cavity. The electrode doesn’t actually touch the part—it’s the electric sparks that erode the material.

Wire EDM, on the other hand, uses a continuously fed, thin wire as the electrode to cut from one side of the workpiece to another, much like a band saw. This wire creates sparks along its path, slicing through the metal with extreme accuracy.

Key takeaway? Sinker EDM is excellent for internal cavities, while wire EDM excels at profile cuts and intricate outlines.

Precision and Tolerance Levels

When it comes to dimensional accuracy, both processes are outstanding, but wire EDM generally offers better precision. Thanks to its thin wire and finely controlled CNC movements, it can achieve ultra-tight tolerances and mirror-smooth finishes.

Sinker EDM is still precise but typically has a slightly lower resolution due to electrode wear and spark gap limitations. It’s more suited for mold cavities and complex internal geometries where ultra-fine tolerances aren’t critical.

So, if your part demands sub-micron precision, wire EDM is your go-to.

Speed and Efficiency

Speed is another major point of difference. Wire EDM is usually faster because it doesn’t require custom electrode fabrication. Once you’ve programmed the design, you can get cutting immediately. For simple profile cuts or through-holes, wire EDM is a breeze.

By contrast, sinker EDM requires additional time to design and machine the electrode, which can extend the setup phase significantly. However, for repeated mold-making or die-sinking operations, that upfront time can pay off over multiple production runs.

In short: Wire EDM is faster for quick turnaround jobs, while sinker EDM is better for high-detail, repetitive production.

Design Flexibility and Capabilities

This is where the two processes diverge significantly. Sinker EDM can machine complex 3D geometries, including undercuts, deep cavities, blind holes, and intricate mold features. It’s especially useful for designs that require material removal in confined or hidden areas.

Wire EDM, however, is generally limited to 2D or slightly contoured 3D profiles. It can’t make blind holes or internal features without a start hole. But it shines in tasks requiring narrow kerfs, sharp internal corners, and minimal part deformation.

Bottom line? Choose sinker EDM for cavities and internal geometries, wire EDM for external shapes and outlines.

Starting Points for Cutting

This may seem minor, but it can drastically influence your choice of process. Sinker EDM can begin cutting anywhere on the surface of the material since it doesn’t require an entry point—making it ideal for enclosed cavities.

Wire EDM must start from an edge or a pre-drilled hole, as the wire needs to pass through the workpiece to begin cutting. This makes it slightly less flexible for certain internal cuts or isolated features.

Choosing Between Sinker and Wire EDM

Selecting the ideal EDM process is not just about technical capabilities—it’s about matching the right method to your specific manufacturing needs. Whether you’re producing complex aerospace components, intricate medical tools, or precision dies, understanding the practical considerations of both Sinker and Wire EDM will save time, money, and resources.

Considerations Based on Part Geometry

One of the most important factors in choosing between sinker EDM and wire EDM is part geometry. If your component requires internal cavities, detailed ribs, blind holes, or sharp internal corners, sinker EDM is your best option. This method allows machining from any angle on the surface, making it highly versatile for 3D features.

On the other hand, if your part features 2D profiles, external outlines, or through-holes, wire EDM excels. It provides ultra-fine cuts with minimal kerf width, which is ideal for parts that demand intricate outer shapes, like stamping dies, surgical blades, or engine parts.

So, when comparing sinker EDM vs wire EDM for geometry needs:

Use sinker EDM for deep cavities, mold bases, and internal detail.

Use wire EDM for contour cutting, external precision parts, and tooling outlines.

Material Compatibility

Both EDM methods are limited to electrically conductive materials, but their performance differs based on material hardness and thickness.

Sinker EDM performs excellently on hard-to-machine materials like titanium, tungsten, Inconel, and hardened steel. It can erode thick, dense metal blocks and is commonly used in die and mold fabrication. Its versatility also allows for machining soft metals like copper and brass, especially when fine finishes are necessary.

Wire EDM, while also compatible with a wide range of materials, works best on thinner, flatter workpieces. It’s perfect for slicing sheets or blocks of materials such as:

Hardened tool steels

Aluminum alloys

Graphite

Carbides

If you’re dealing with very thick parts, sinker EDM is usually the better fit. If you’re machining high-precision, thin parts, wire EDM takes the crown.

Surface Finish Requirements

Another point of differentiation is the surface quality each process delivers. Wire EDM typically provides a smoother and finer finish, especially on the cut edges. Since it uses a thin wire and minimal spark gap, there’s less roughness and fewer surface irregularities. For industries like aerospace, electronics, and medical devices, where a fine finish is crucial, wire EDM is ideal.

Sinker EDM, while still capable of good surface quality, often produces slightly rougher surfaces, especially if the electrode wears down during the process. However, modern sinker EDM machines with advanced flushing and servo controls can achieve surface finishes comparable to wire EDM with proper process control.

Conclusion for finishing:

Choose wire EDM for ultra-smooth edges and minimal post-processing.

Choose sinker EDM for internal features where finishing isn’t critical or when polishing is possible afterward.

Production Volume and Cost

Wire EDM shines in environments where fast, accurate, and low-cost prototyping or small batch production is needed. Since it doesn’t require tooling or custom electrodes, it’s quicker to set up and more cost-effective for short runs. It’s also highly automated, reducing labor costs and allowing for unattended machining.

Sinker EDM, in contrast, requires custom electrodes, which increases setup costs and lead time. However, for long production runs—especially in mold and die-making—the investment pays off. Once the electrode is fabricated, it can be reused across multiple identical parts with exceptional repeatability.

From a budget perspective:

Go with wire EDM for short runs, prototypes, or budget-conscious jobs.

Opt for sinker EDM for long-term, high-volume production of complex tooling.

Manufacturing Costs

While both methods can be cost-effective when applied correctly, there’s a distinct difference in initial investment and operating costs.

Wire EDM machines generally cost more upfront and require maintenance for wire feed systems and dielectric systems. However, because there’s no need for tooling and electrodes, the per-part cost is often lower for small batches.

Sinker EDM, despite being slower and more labor-intensive upfront, becomes more economical with higher-volume jobs due to the reuse of electrodes. But it’s worth noting the cost of electrode wear, time for fabrication, and higher energy consumption.

Summary:

Wire EDM = Lower setup cost, higher precision, ideal for quick turnarounds.

Sinker EDM = Higher setup cost, better for mass production of complex cavities.

Industry Applications of EDM Technologies

EDM technologies are not confined to niche applications. Their broad versatility and extreme precision make them indispensable across various industries. Whether you’re in aerospace, medical, electronics, or mold-making, understanding which EDM process best fits your industry can boost efficiency and performance.

Aerospace and Automotive Sectors

In aerospace and automotive, precision and durability are paramount. Wire EDM is used extensively for producing engine components, gears, turbine blades, and fuel system parts with tight tolerances and stress-free edges.

Sinker EDM comes into play when manufacturing turbine components, mold inserts for carbon fiber parts, or internal cavities in complex aerospace assemblies.

Both processes are also vital in:

Prototyping and R&D: Quickly create functional prototypes for design validation.

Tooling and Fixture Creation: Manufacture durable, high-precision tools for assembly and testing.

Medical and Dental Industries

The medical sector demands absolute precision and sterilization-ready finishes, both of which EDM can deliver. Wire EDM is used for making surgical blades, orthopedic implants, and dental components that require flawless surfaces.

Sinker EDM is used for creating medical molds, implant cavities, and fine internal structures like those found in bone screws or prosthetics.

Key advantages include:

Biocompatible material compatibility (like titanium and stainless steel)

Repeatable high precision for regulatory compliance

Micro-machining for miniature tools and components

Tooling, Die, and Mold Manufacturing

This is perhaps the most traditional and widespread use of both EDM techniques. Sinker EDM dominates mold and die making, as it can burn cavities, contours, and detailed features directly into hardened steel blocks.

Wire EDM complements this by cutting the mold inserts, forming punches, and trimming dies with incredible edge accuracy. Tooling engineers rely on EDM to:

Maintain part uniformity

Eliminate burrs

Minimize post-machining processes

Together, wire and sinker EDM create a robust, end-to-end solution for tooling requirements across high-demand manufacturing industries.

Future Trends in EDM Technologies

As industries evolve, Electrical Discharge Machining (EDM) continues to advance with new technologies, improved automation, and sustainable innovations. These trends are not just enhancing precision and performance—they’re also making EDM more cost-effective and environmentally friendly. Understanding these upcoming developments helps manufacturers stay competitive and efficient in an ever-changing production landscape.

Advancements in EDM Automation

One of the most significant future trends is the integration of automation and robotics into EDM systems. Newer wire and sinker EDM machines come with robotic arms for part loading/unloading, automated tool changers, and smart sensors for real-time monitoring.

Key benefits include:

Unattended operation: Machines can run 24/7, reducing labor costs and increasing output.

Increased productivity: Automated EDM cells can handle multiple setups without human intervention.

Consistency and precision: Advanced monitoring ensures consistent spark generation, reducing variation in cut quality.

Incorporating AI-driven diagnostics is also on the rise. Machines can now predict tool wear, adjust discharge parameters, and even optimize cutting paths on the fly—all without operator input.

Integration with CAD/CAM Systems

The future of EDM is tightly linked with seamless CAD/CAM integration. Designers can now send 3D models directly to EDM machines with minimal conversion. This eliminates errors in interpretation, shortens lead times, and makes custom jobs much easier.

Some exciting developments include:

Real-time simulation: See how the EDM process will behave before machining begins.

Automatic toolpath generation: CAM software customizes paths for better efficiency and reduced wear.

Cloud-based control: Manage and monitor multiple EDM units remotely using IoT and cloud computing platforms.

This level of digital integration ensures that EDM keeps pace with the demands of Industry 4.0 and smart manufacturing.

Sustainable Practices in EDM

With environmental concerns growing across all industries, green manufacturing practices are becoming essential—even in EDM. While EDM is known for being energy-intensive and reliant on dielectric fluids, emerging technologies aim to reduce its environmental footprint.

Key sustainability efforts include:

Eco-friendly dielectrics: Using water-based or biodegradable fluids instead of petroleum-based oils.

Energy optimization software: Helps machines use only the power needed, minimizing waste.

Material efficiency: Precise cuts reduce scrap rates, especially with expensive metals like titanium and tungsten.

By focusing on cleaner, more efficient machining, EDM remains relevant in the push toward more sustainable and responsible manufacturing.

Conclusion

Sinker EDM vs Wire EDM is more than a comparison of tools—it’s about choosing the right technology for the job. Both techniques are built on the same principle of spark erosion, yet they diverge in terms of application, accuracy, material compatibility, and process efficiency.

Sinker EDM excels in machining deep cavities, intricate mold details, and complex internal geometries. It’s perfect for die-making, tool creation, and high-detail component production where custom electrodes can be justified.

Wire EDM, meanwhile, is the go-to for precision cutting of profiles, tight tolerances, and burr-free finishes. Its ability to slice through hardened materials with extreme accuracy makes it a staple in aerospace, medical, and high-end manufacturing.

In short:

Choose Sinker EDM when you need internal complexity and 3D features.

Choose Wire EDM when you want fast, clean, accurate external cuts.

Both play vital roles in modern manufacturing, and knowing when and how to use each gives you a clear edge in engineering excellence.

Frequently Asked Questions (FAQs)

1. What is the main difference between sinker and wire EDM?

The main difference lies in their cutting approach. Sinker EDM uses a solid electrode to shape cavities into a workpiece, while Wire EDM uses a thin wire to cut through materials in a profile or outline, typically from the edge.

2. Can EDM cut non-conductive materials?

No, EDM can only cut electrically conductive materials. Both sinker and wire EDM require the workpiece to conduct electricity to generate the spark discharge necessary for erosion.

3. Which EDM type is better for complex shapes?

It depends on the complexity. For internal 3D cavities and blind holes, sinker EDM is more suitable. For detailed external shapes or tight tolerances, wire EDM is generally better.

4. Is EDM expensive compared to CNC machining?

EDM can be more costly upfront due to the slower cutting speed and, in the case of sinker EDM, custom electrode production. However, for hard materials or intricate parts, EDM can be more cost-effective over time due to reduced tool wear and minimal part distortion.

5. What industries benefit most from EDM?

Industries that require high-precision, stress-free machining benefit the most, including:

Aerospace

Medical and dental

Automotive

Tool and die making

Electronics and semiconductor

Relevant External Links

Wikipedia – Electrical Discharge Machining

Comprehensive overview of EDM processes, including history, types, and applications.

https://en.wikipedia.org/wiki/Electrical_discharge_machining

Xometry – All About Wire EDM Machining

Detailed insights into Wire EDM processes, advantages, and suitable materials.

https://www.xometry.com/resources/machining/wire-edm-machining/

Fictiv – Electrical Discharge Machining Services

Information on both Sinker and Wire EDM services, including capabilities and material compatibilities.

https://www.fictiv.com/cnc-machining-service/electrical-discharge-machining

Makino – Wire EDM Machine Centers Tutorial

Technical tutorial on Wire EDM machine centers, focusing on capabilities and applications.

https://www.makino.com/resources/content-library/article/archive/edm-wire-tutorial/198

EDMIS – Micro Manufacturing with Wire and Sinker EDM

Exploration of micro-manufacturing capabilities using both Wire and Sinker EDM technologies.

https://www.edmdept.com/manufacturing-services/micro-manufacturing/

1 thought on “Sinker EDM vs Wire EDM: Exploring Their Differences”