The TOPS Machining team has more than 10 years of overseas customer service experience, and the people working with you are extremely professional. All walks of life are involved in the field of service, aerospace, automation equipment, medical equipment, communication equipment, high precision products, products also include: aviation seats, Baling machine, Intercom housing, Drones and so on. We believe we can serve you well.

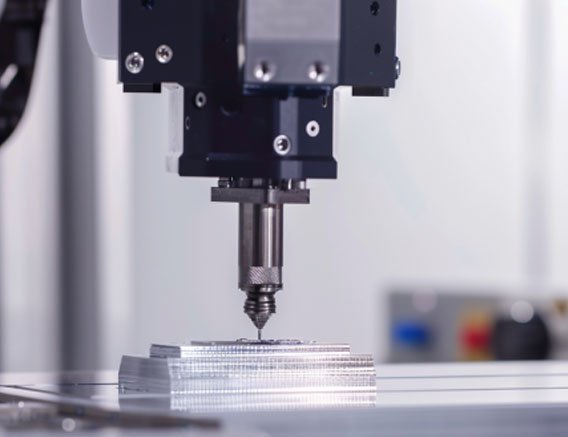

CNC Machining Services

TOPS can provide you with 3 axis, 4 axis, 5 axis machining services, we are using the industry's top equipment, in addition, we have the following advantages

Guarantee Rapid Turnaround - 1 day

Provide Tolerance With a Range of 0.01mm

Send Your Inquiry Today

Why Choose TOPS for CNC Needs?

Submit Your Request

The first stage is, submitting the request and explaining everything about your projects. We would appreciate it if you share your technical drawings with us. But, if in case they are not available, you can ask for assistance. Our team will help you in makings these drawings with high precision.

Send You Quotation

Our team will overview your details and will connect with you within 24 hours. TOPS guarantees a quick response to your CNC machining requirements. Besides this, we will provide you with custom machining services. And also will thoroughly review your request with the provision of a comprehensive quotation.

Start Working on Project

After finalizing your quotation, we will initiate your project. Here we will collect all the required CNC machining tools and designs. So, our engineers and other technical staff can meet the specifications smoothly and with high efficiency.

Delivery

Now in the last stage, you will receive your CNC-machined products. Here we guarantee that your product will be carefully packed and labeled. After this, our team will ship it directly to your place with safety and security.

TOPS Always Guarantee Quick Turnaround

Send Your Inquiry Today

Checkout Our Best Options for CNC Machining Services

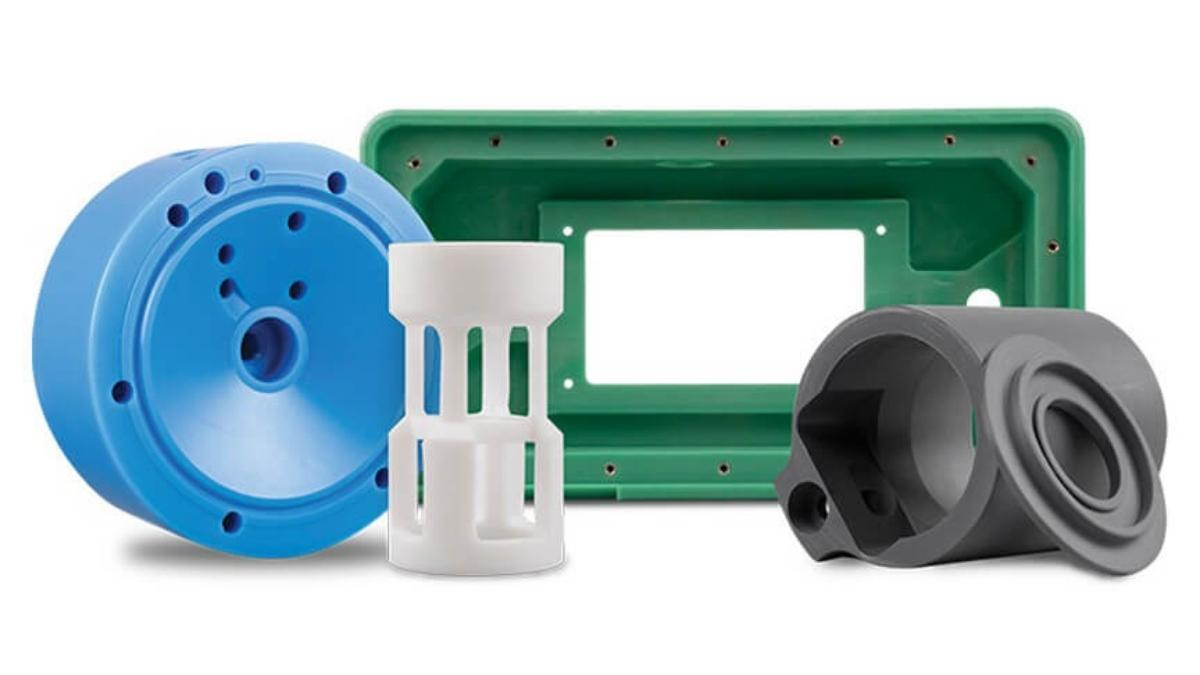

At TOPS, we are covering the two main types of custom CNC Processing services.

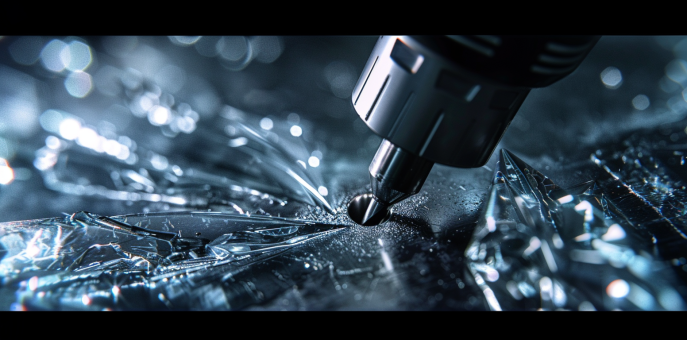

Highly Accurate CNC Milling Service

TOPS is an expert in producing complex geometries and precise components through our CNC milling process. This technique is the best fit for manufacturing components, i.e. engine parts, frames, and enclosures. Moreover, our team of experts will serve you with the most advanced milling machines. with high accuracy and surface finish. So, your product can meet the market standards.

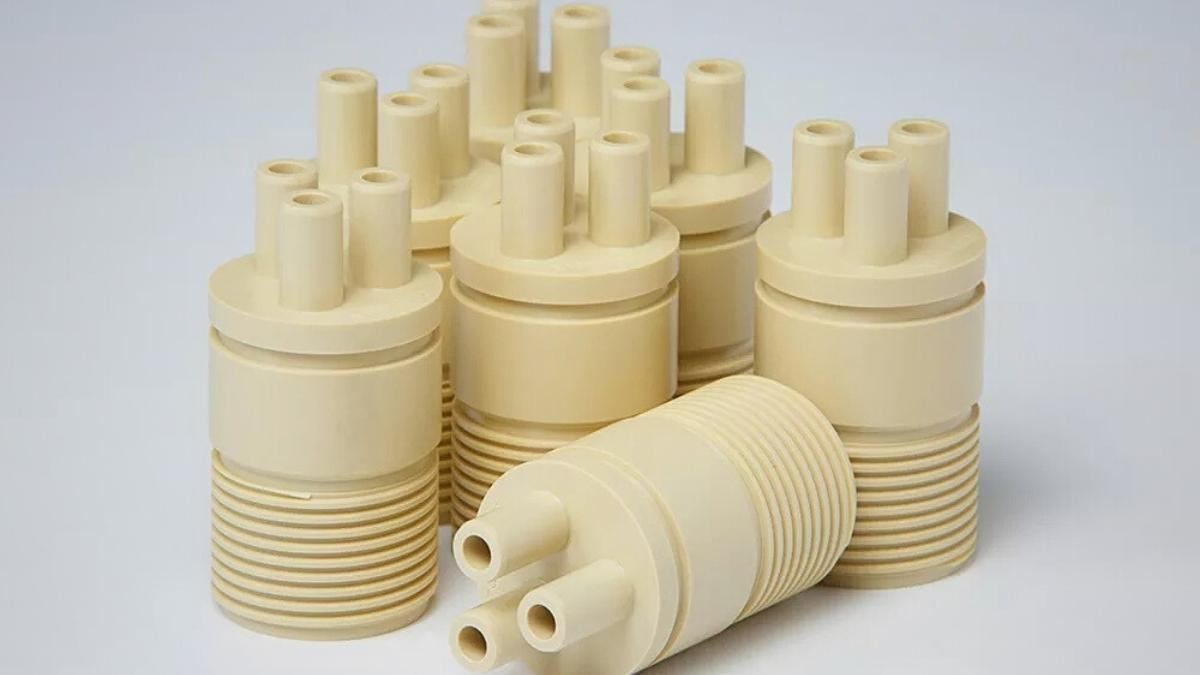

Best CNC Turning Service

TOPS’s CNC turning services will ultimately help you with manufacturing the cylindrical parts. These mainly include shafts, rods, and bushings. Besides this, our CNC turning process guarantees exceptional precision and surface integrity. Our turning centers excel at processing various materials. Additionally, we are experts in crafting parts with tight tolerances and flawless finishes.

100+ Materials Available for Selection

Choose the Ideal Option by Understanding Their Unique Properties

Aluminum

Lightweight, corrosion-resistant metal known for its excellent strength-to-weight ratio and versatility in manufacturing.

Brass

Corrosion-resistant alloy of copper and zinc, excellent machinability, attractive gold-like appearance, good electrical conductivity.

Stainless Steel

Strong corrosion-resistant alloy, durability, sleek appearance, and excellent performance in demanding environments.

Steel

Versatile and durable alloy of iron and carbon, high strength, toughness, and wide range of industrial applications.

Copper

Highly conductive, excellent electrical and thermal performance, as well as its resistance to corrosion.

Cast Iron

Excellent abrasion resistance, low cost, ideal for high-load components.

Bronze

Durable copper alloy with added tin, great wear resistance, low friction, and a rich, antique appearance.

Magnesium

Exceptionally lightweight, moderately durable, combustible in ribbon or powder form.

Tool Steel

High-strength alloy, withstand high heat and wear, ideal for cutting, molding, and machining tools.

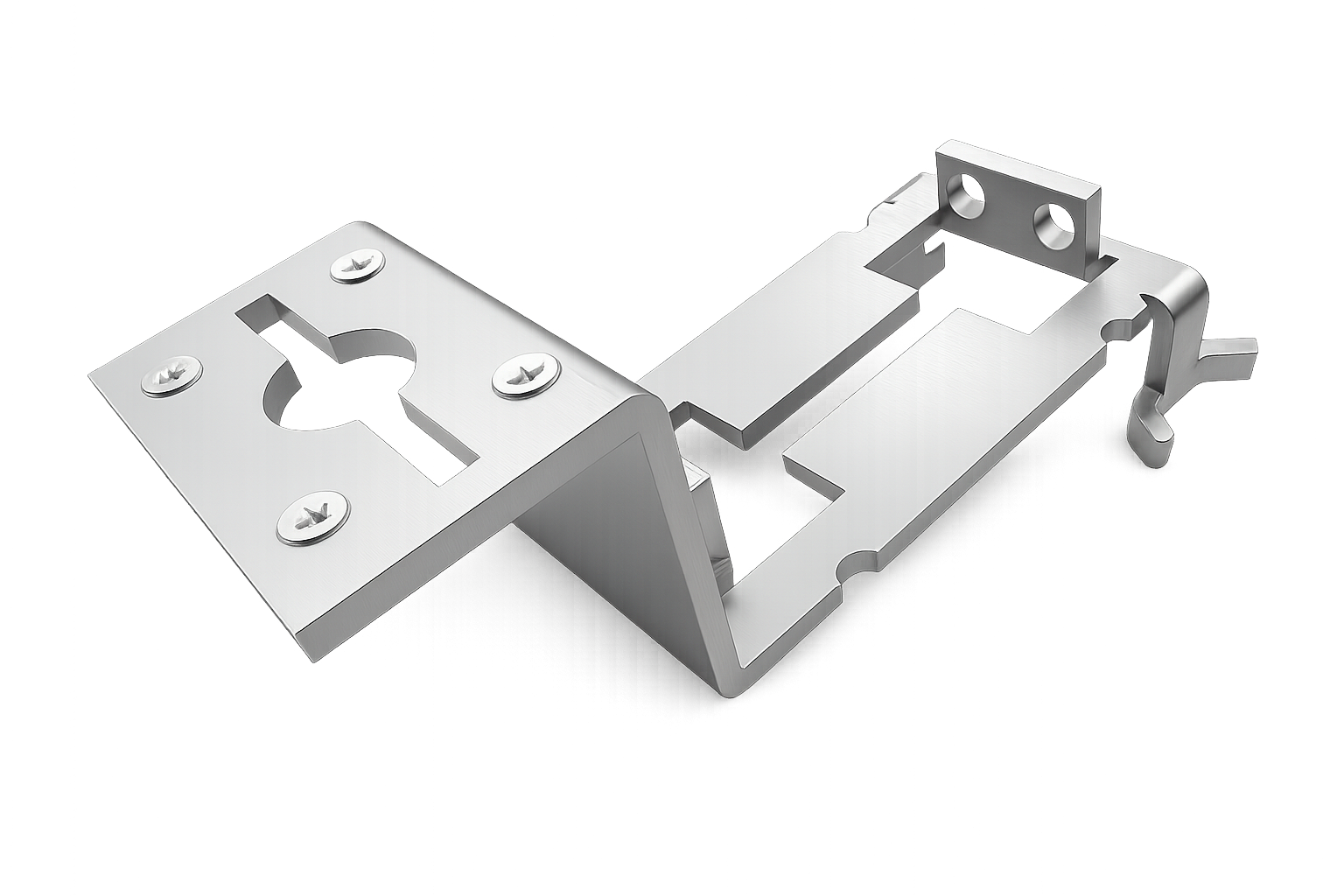

Sheet Metal

High strength-to-weight ratios. Easily formable, ideal for cutting, bending, and fabrication in various industries.

Titanium

Lightweight, high-strength metal, exceptional corrosion resistance, commonly used in aerospace, medical, and high-performance applications.

Understanding Each Material’s Unique Properties Can Greatly Improve Project Success

Delrin(POM)

Strong, low-friction engineering plastic, excellent dimensional stability and wear resistance.

ABS

Tough, impact-resistant plastic commonly used for durable consumer products and electronic housings.

Acrylic(PMMA)

Transparent plastic, glass-like clarity, weather resistance, and ease of fabrication.

Nylon(PA)

Strong, flexible plastic, excellent abrasion resistance and good chemical stability, ideal for mechanical parts.

Peek

High-performance thermoplastic, strength, chemical resistance, and ability to withstand high temperatures.

HDPE

Strong, lightweight, and durable thermoplastic known for its excellent resistance to impact, moisture, and chemicals.

PTFE(Teflon)

Non-stick, chemical-resistant plastic, very low coefficient of friction, widely used in sealing and insulation applications.

Garolite

Excellent electrical insulation properties. Strong, lightweight, and resistant to moisture, chemicals, and wear.

PVC

Versatile, cost-effective plastic, good chemical resistance and rigidity, commonly used in piping and construction.

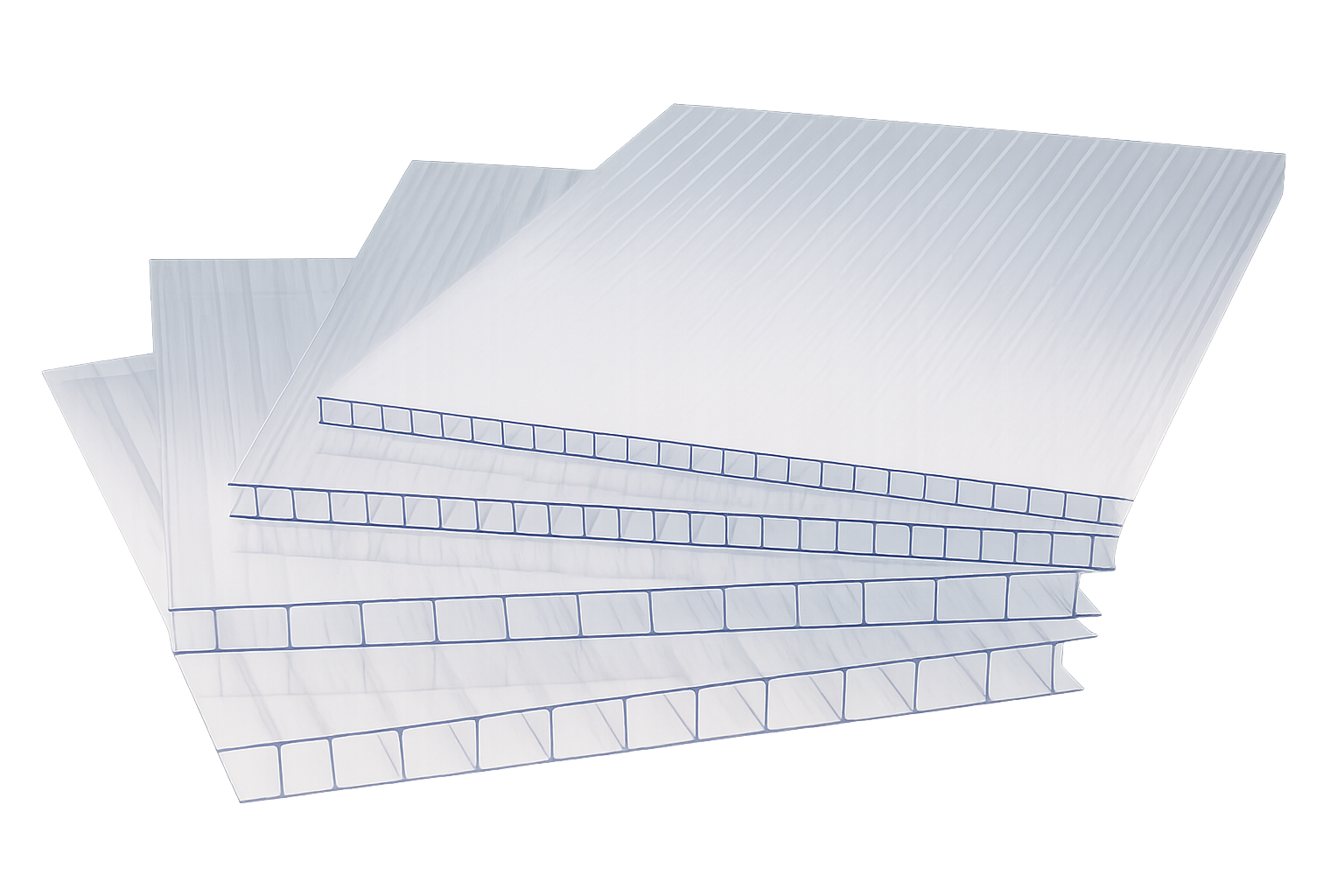

Polycarbonate

Good heat resistance and is commonly used in safety equipment, lenses, and enclosures.

PEI(Ultem)

High-strength, heat-resistant plastic, excellent flame and chemical resistance, often used in aerospace, medical.

UHMW

Low friction coefficient and excellent impact strength, making it ideal for high-wear applications.

Other Materials

So, besides metals and plastics, there is a third scope we also cover, i.e. Alloys. TOPS is a master in dealing with different alloys of zinc, copper, aluminum, etc.

If in case you want to deal with multiple materials, you can connect with us, TOPS team will assist you with different materials as well. Order a free quote today!

Send Your Inquiry Today

Industries We Serve

With two decades of machining experience, we’ve served a wide range of industries—medical, robotics, consumer products, automotive, aerospace, defense, marine, green energy, industrial, and more. What truly sets us apart is our in-depth knowledge of each sector’s specific applications, standards, and unique needs—delivering real value to our customers.

If your desired material is not listed above, contact us and order a free quote today!

Send Your Inquiry Today

Tolerance Ranges We Support for CNC Machining

TOPS is an expert in delivering exceptional CNC Milling Services Besides this, we also provide accurate and precisely tight milling with tolerances of 0.01 – 0.05mm. But this range varies with material type and the geometry of the part. You can consider the following chart for more information:

Tolerance Level | <<3, >0.5 | <<6, >3 (these values are in ±) | <<30, >6 (these values are in ±) | <<120, >30 (these values are in ±) | <<400, >120 (these values are in ±) | <<1000, >400 (these values are in ±) | <<2000, >1000 (these values are in ±) |

F | 0.05 | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 0.5 |

M | 0.1 | 0.1 | 0.2 | 0.3 | 0.5 | 0.8 | 1.2 |

C | 0.2 | 0.3 | 0.5 | 0.8 | 1.2 | 2 | 3 |

V | – | 0.5 | ±1 | 1.5 | 2.5 | 4 | 6 |

Surface Finishes Available for CNC Machined Parts

Surface finishing is an essential part of our precision CNC machining services. It helps us get the final flawless product. At TOPS, we are experts in giving an array of modern surface treatment solutions. They guarantee that every CNC-fabricated part will meet the most strict standards of quality and visual appeal. So, we are using the following techniques:

As machined (Ra 3.2μm / Ra 126μin),

Bead blasted + Anodized type II (Matte),

Bead blasted + Anodized type II (Matte),

Smooth machining (Ra 1.6μm / Ra 63μin),

Brushed + Electropolished (Ra 0.8μm / Ra 32μin,

Powder coated,

Polishing (Ra 0.8μm / Ra 32μin),

Fine machining (Ra 0.8μm / Ra 32μin),

Brushed + Electropolished (Ra 0.8μm / Ra 32μin, etc.

Explore More About Our CNC Machining Applications

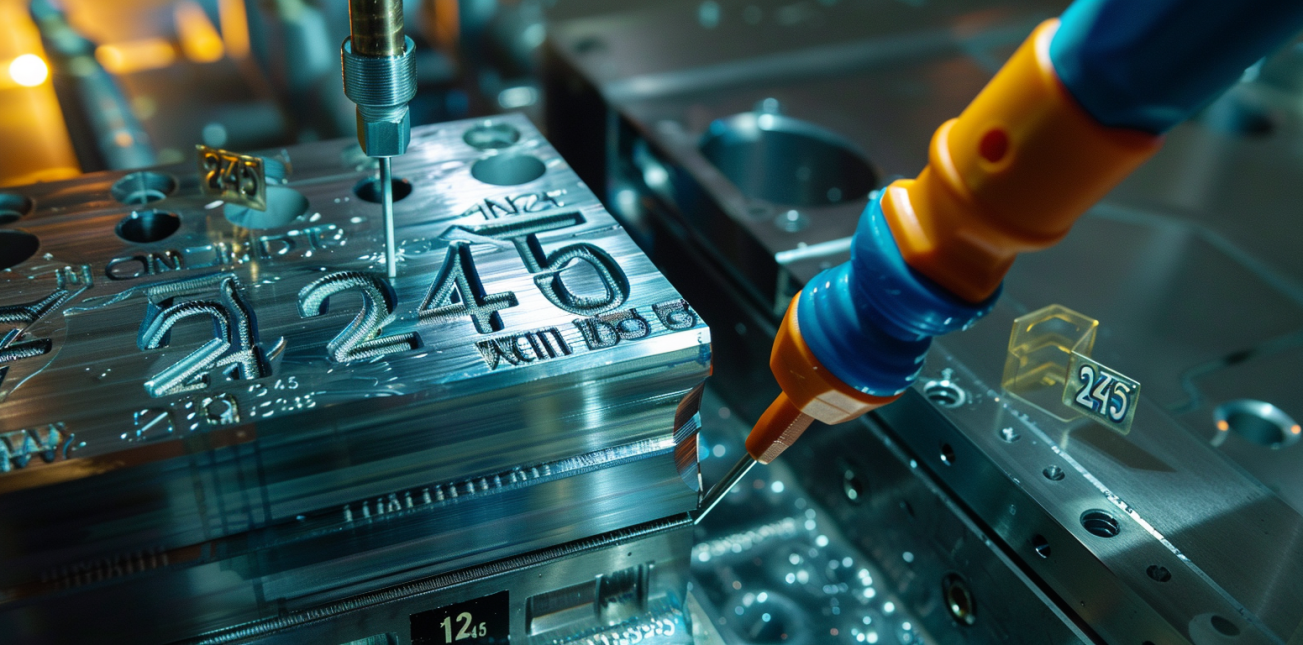

Mold and Die Manufacturing

We use several techniques, i.e. plastic injection molds, high-pressure die-cast molds, two-shot molds, 2-plate molds, and 3-plate molds, just to make dies. TOPS has expertise in cutting molds in special designs and shapes. So, they can be used in several complex tooling requirements. Because they are perfectly aligned with the demands of rapid manufacturing.

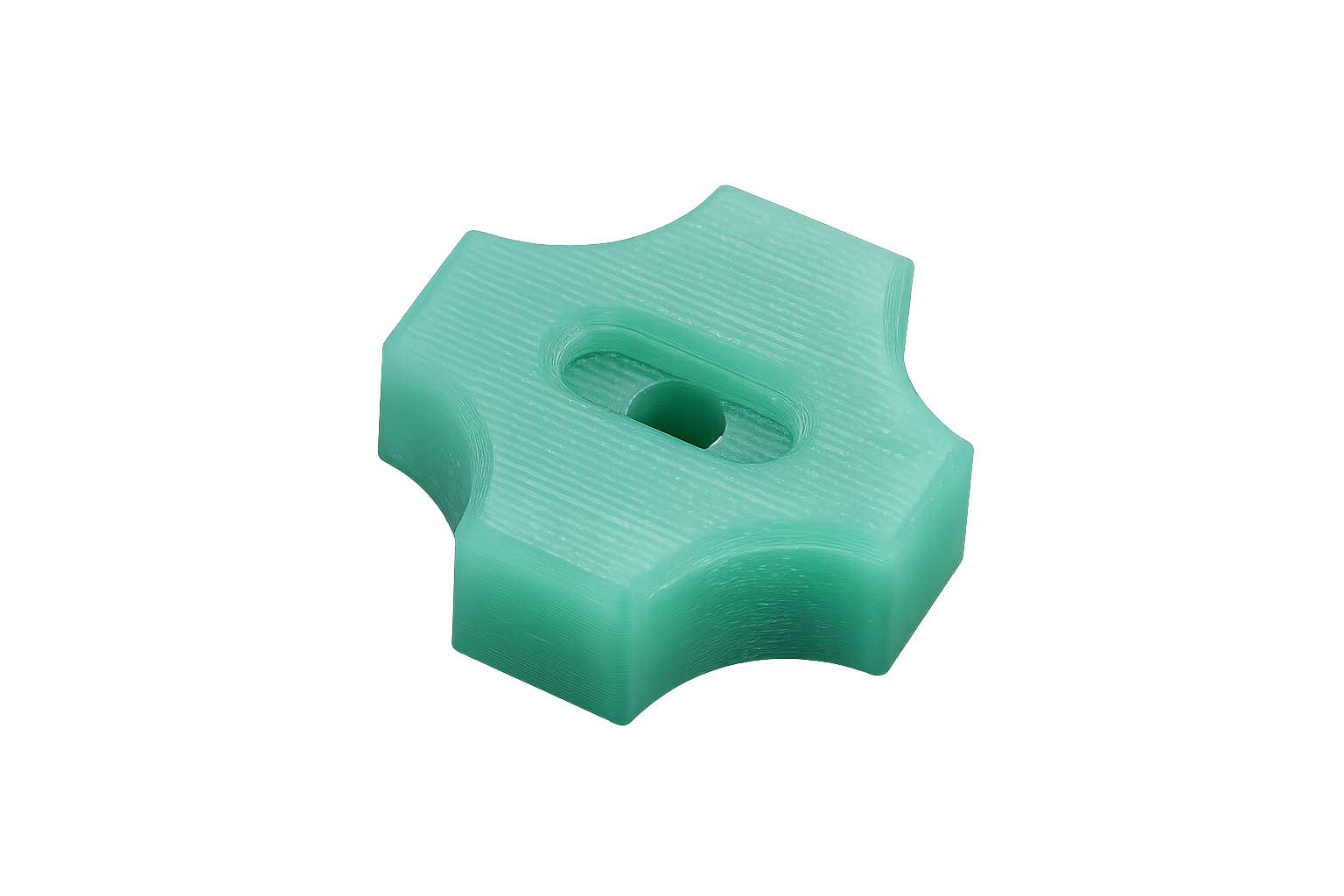

Custom Prototype Development

TOPS is an expert in making custom prototypes. These can be complex automotive parts, i.e. engine components, intricate medical devices, and consumer electronics, like smartphone cases. Besides this, our precision machining guarantees that our prototypes are accurate like the final products. So, our CNC machining services serve in this process and also ensure cost-effectiveness and high efficiency.

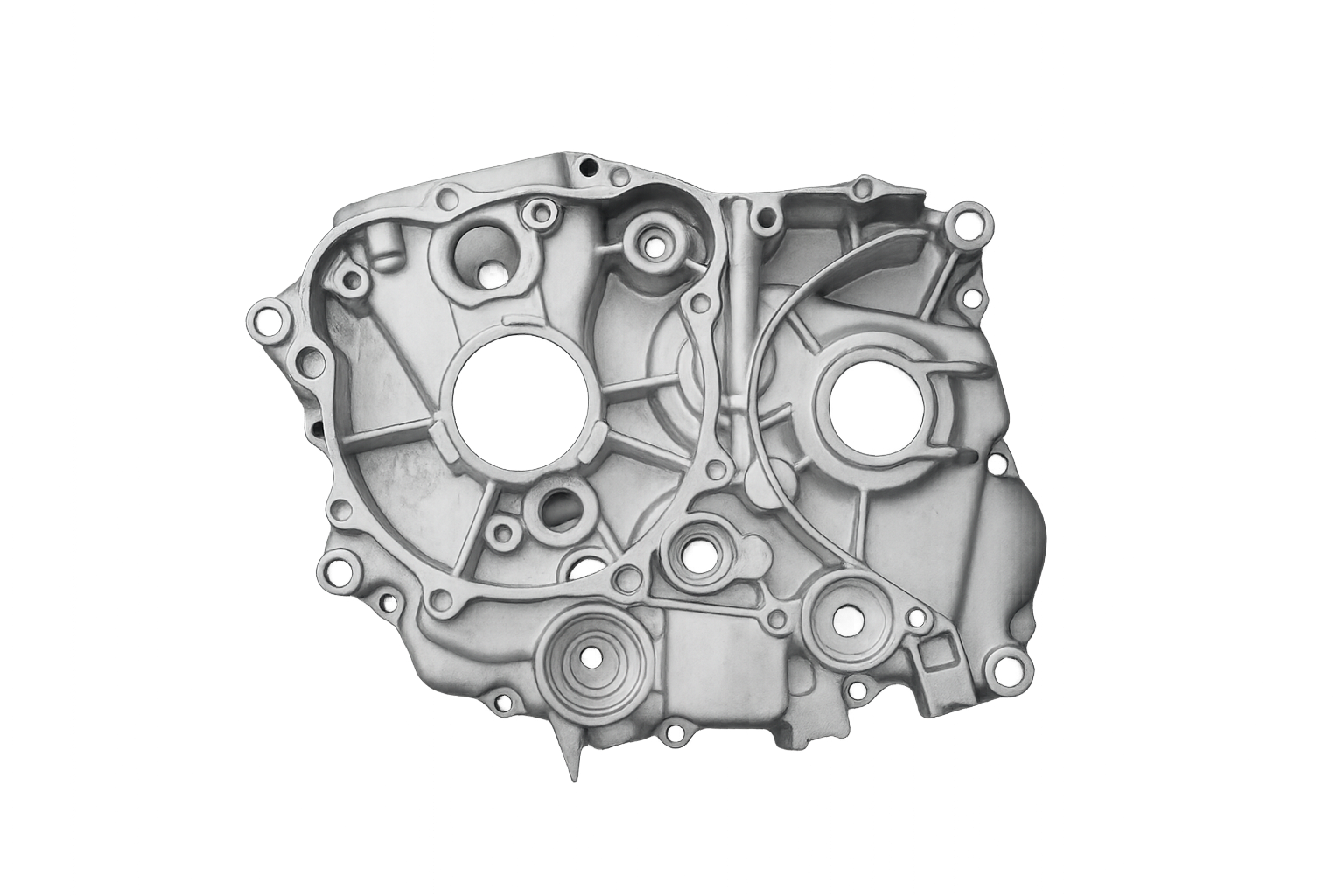

Aerospace Components Manufacturing

We’re experts

TOPS specializes in making different aerospace parts like turbine blades, engine mounts, gear parts, aircraft structural, and many more. We are using advanced machining toolings to make both simple and complex parts, control system components, and aerofoil sections. So, each part meets the high standards of the aerospace sector. Besides this, they guarantee effective performance and safety in every application.

Automotive Parts Making

TOPS parts have found their applications in

automotive sector. This mainly includes engine blocks, transmission gears, suspension systems, and steering mechanisms. Besides this, our precision machining services make different parts, i.e. exhaust systems, brake components, and complex valve assemblies.

TOPS guarantees that each part is highly accurate and precise.

Medical Device Manufacturing

We are not limited to the aerospace and automotive sectors. TOPS also deals with the manufacturing of medical equipment, i.e. orthopedic implants, surgical instruments, and diagnostic equipment casings. TOPS is also an expert in machining complex parts, i.e. medical imaging devices, dental tools, and custom prosthetics. We make every part with care and the utmost precision. Besides this, we strictly adhere to medical standards.

Production of Consumer Products

When it comes to consumer goods, TOPS always comes first. We provide services to manufacture various goods like household appliances, sports equipment, and musical instrument pieces. Moreover, we also specialize in making personal gadgets, luxury items, toys, kitchenware, and even custom furniture fittings. Besides this, each product is produced with precision and quality and sticks to the compliances.

Send Your Inquiry Today

A Comprehensive Overview of CNC Machining

If You're New To CNC Machining Services, Here's A Brief Introduction To Help You Get Started

How Would You Define CNC Machining?

It is a process of cutting the materials using computerized controls. Here, the engineers set the specifications of parts on the computer and the computer-controlled machine starts to cut the material accordingly.

- CNC machining is very accurate due to automation

- It is quite fast and also suitable for cutting the cross-sections.

- Highly suitable for making parts for cars, medical, or aerospace sectors.

How CNC Machining Works?

- Planning: Here, before cutting the material, we first completely analyze the design specifications.

- Set Up the Machine: It must be understood that client instructions must be fed to the machine in a way that enables it to be programmed correctly.

- Machining: The specific function of the tool is to carve and form the metal.

- Check Quality: So, we make sure that every single part of it is as perfect as one can get.

Rely on Us for Your CNC Machining Needs

You can choose us for the following reasons, such as:

- High Accuracy: Our CNC machining services are highly accurate. So, it has high demand in different industries i.e. aerospace and medical devices.

- High Speed and Versatile: TOPS guarantees CNC machining service delivery at a fast rate. Besides this, we can work on almost any complex design.

- Safety and Reliability: It also eliminates human intervention. So, it ultimately reduces the chances of completing work that may be substandard or even hazardous.

- Wide Material Compatibility: Our CNC machining has various options. Because it is versatile, takes into account the requirements of various industries, and successfully works with various types of materials.