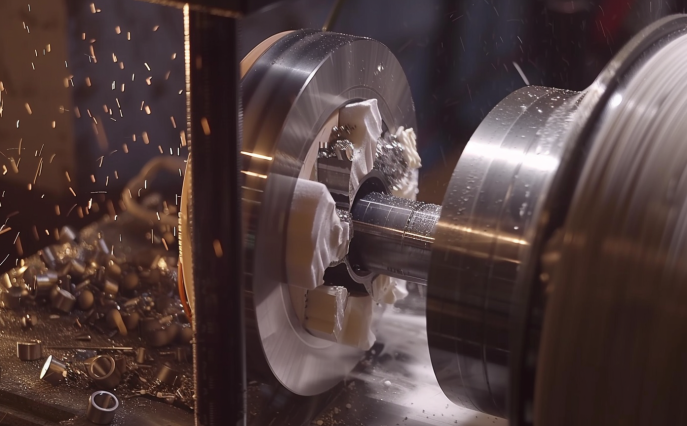

Trust TOPS for CNC turning services. So, you can get trusted metal and plastic parts quickly. We have a team of experts to offer cutting services for your project. At TOPS, we combine ultra-modern equipment and human capital to produce world-standard custom prototypes as well as final production units. Our highly accurate CNC turning provides accurately machined parts. So, no matter the intricacy, we give various parts ranging from flat surfaces to radial and axial openings, notches, and channels. We make sure to provide you with all these within a quick turnaround - single day.

Services for CNC Turning

Discover Our Commitment to Providing the Best CNC Turning Products

- Lead times down to one day.

- Customer centricity

- Best for Small Batch Manufacturing Or Scale Production

Send Your Inquiry Today

Reasons to Select Our CNC Turning Services

Accuracy and Excellence

TOPS the CNC turning services extend superior accuracy in the machining of components. We provide the first-rate quality of each produced element. Our expertise is essential in the production of parts that require minor differences in their thickness. These small differences are quite significant for the performance of the final product.

Swiftness and Performance

TOPS opts for computer-numerically controlled turning for part production is much faster than other traditional methods. Our services lead to much shorter lead times. It’s our capability that facilitates the advancement of prototypes and the acceleration of production timeframe. Additionally, at TOPS, our performance helps your projects remain on schedule.

Diverse Range of Materials and Intricacy

We have capabilities in offering CNC turning solutions in finding workable solutions for many types of projects and materials. These may include metals, plastics, and composites. We can easily make more intricate models and layouts through technical management. So, you can get flexibility in the manufacturing process.

Low and High Volume Cost Efficiency

We offer cost-effective CNC turning services for both small batches and mass production. Although the initial tooling costs are much higher, it is quite quick and also provides high speed and efficiency in the process. So, it makes it a feasible choice for projects of all sizes. Additionally, CNC turning is highly scalable and guarantees that as your project's scope grows. Besides this, it helps in unit cost can potentially decrease, providing economic advantages.

Send Your Inquiry Today

Instructions for Utilizing Our Rotation Services

Seek a Quotation

Get a free and no-obligation quote for our accurate and efficient CNC turning solutions today. Kindly share with us the specifications of your product, including the detailed description and any technical diagrams so that we can evaluate its technical aspects well. No technical drawings? Oh no, worry no more because here in our firm we have professional engineers who can reverse engineer your product samples.

DFM Review and Cost Estimation

Within the next 24 hours, you will receive a report with a Design for Manufacturability Assessment and a specific quotation on our CNC turning solutions.

CNC Turning Initiates

Once you agree to the quote you give us and make a deposit, work begins at once. This way, every single aspect of the car is designed with the highest level of effort to achieve precision in manufacturing.

Expedient Shipment

Once completed, CNC-machined parts undergo careful packaging, labeling, and shipping to you, to make the delivery time-conscious. Our CNC turning is the best way to go – you will be sure that your project is in the right hands and moving at the right pace.

We Offer Top Services In Industry

Reach Out To Us Today For A Complimentary Quote On Getting Your Workpieces Turned.

Send Your Inquiry Today

Explore Our Extensive Selection of CNC-turning Solutions

CNC Turning is used for the mass production of complex and accurate parts with a special focus on prototypes and end products. It is also essential for large-scale manufacturing, supporting a wide range of processes such as It is also essential for large-scale manufacturing, supporting a wide range of processes such as:

Standard CNC Turning

CNC turning is useful to make precise turns and is used for a wide range of parts from simple to a bit complex ones in high-volume production turned parts as well as single/double, light to moderate complex prototyping turned parts with the flexibility of turning metals, and other materials.

CNC Turning with Multiple Axes

An example of an improving feature is Multi-Axis CNC Turning which gives us better control to produce complex forms and fine varieties involving multiple operations all at once on parts where turning from more than one direction is required.

CNC Turning with Live Tooling

Incorporating elements of conventional turning, TOPS Live Tooling CNC Turning also allows for on-turn lathe vertical and horizontal milling for faster rates of manufacture, a variety of designs of curvature surfaces, and multi-level facets.

Hard Turning

Hard Turning is used in many industries that require high tolerances on hardened steels, its advantage is that it is an economical and faster method than grinding. This is ideal for mass production, creating strong parts, with closely defined accuracy of shape and size.

Explore the Variety of Materials We Employ in Our CNC Turning Services

At our CNC turning division, the variety of used materials permits us to satisfy the peculiarities of various projects and customers. This is possible because of the versatility that enables the manufacture of parts for different uses, ranging from industrial products to small gadgets for use in homes. Here are the materials we commonly use: Here are the materials we commonly use:

Plastics

CNC turning is especially good at machining prototypes from plastics and allows you to see the external and internal rough in every aspect and evaluate the product.

Metals

In metalworking, no other process can match CNC turning with varieties of metals used in the cutting process for prototype and finished parts making; therefore each part is accurately and strongly made. The post In metal machining, CNC turning is unmatched, using a variety of metals to produce both prototypes and final parts, ensuring each component’s precision and durability

Other Materials

We also have MSC capability for turning with various alloys and specialized materials to meet your project needs.

Plastics That Are Frequently Used in Our Work

ABS, ABS+PC, Polycarbonate (PC), Polypropylene (PP), PEEK, Polyoxymethylene (POM), Acrylic (PMMA), Teflon, Polystyrene (PS), High-Density Polyethylene (HDPE), Polyphenylene Sulfide (PPS), Low-Density Polyethylene (LDPE), Nylon (PA6, PA66), Polyetherimide (PEI), PVC, PET, PTFE

Metals We Regularly Utilize

Aluminum, Brass, Copper, Magnesium, Titanium, Stainless Steel, Tin, Zinc

Non-standard materials Please contact us or request a quotation.

Send Your Inquiry Today

Tolerance Standards

CNC turning service at our firm offers optimal and satisfactory results to its customers in terms of machining. However, for more accurate product requirements, wider achievable tolerances vary based on the material utilized and the form of the part. For detailed information, please refer to the following chart: For detailed information, please refer to the following chart:

Tolerance Lever | Overall Dimension Range | ||||||

Specifications | <<3, >0.5 | <<6, >3 | <<30, >6 | <<120, >30 | <<400, >120 | <<1000, >400 | <<2000, >1000 |

Tolerance Standard | |||||||

F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

M | ±0.1 | ±0.1 | ±0.2 | ±10.3 | ±0.5 | ±0.8 | ±1.2 |

C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

Surface Coatings

Once your part has been turned with exceptional accuracy and precision, we move on to the surface finishing stage. We will provide a variety of options to meet different requirements. Just after your part has been through the rotation and has been turned with exceptional accuracy and precession, we proceed to surface finished, ranging from:

- As machined (Ra 3. 2μm / Ra 126μin)

- The workpieces manufactured herein have a surface roughness of Ra 1. 6μm / Ra 63μin with smooth machining.

- The surface finish of the machined surface is received as Ra 0. 8μm and Ra 32μin separately known as fine machining.

- Polishing, Ra 0. 8μm / Ra 32μin

- Bead blasted

- Brushed + Anodized type II (Glossy)

- Form as machined + Anodized type II

- Chromate Conversion Coating

- Black oxide

- Electroless Nickel Plating

- Bead blasted + Anodized – type II (fine texture)

- Bead Blasted + Anodized, Type II, GLine (Glossy).

- Brushed + Electropolished (Surface roughness, 0, 8μm / Surface roughness, 32μin)

- As machined + Anodized type III (Hardcoat)

- Surface finish of brush (Ra 1. 2μm / Ra 47μin)

- Powder coated