В развиващия се пейзаж на напредналото производство, Компютърно цифрово управление (ЦПУ) машини са се превърнали в незаменими инструменти, които предлагат автоматизация, точност, и ефективност. Тези програмируеми машини се използват в почти всяка индустрия - от аерокосмическото пространство и автомобила до електрониката и прототипирането. Тази статия изследва 12 Основни видове CNC машини, как работят, и където те обикновено се използват.

Какво е CNC машина?

А CNC машина е автоматизиран машинен инструмент, контролиран от компютърен софтуер и интегриран хардуер. Обработката на ЦПУ е a Извличащ процес, което означава, че премахва материал от детайл (или празно) За да създадете желана форма. въпреки това, Някои системи на ЦПУ, като 3D принтери, употреба Добавно производство Методи за изграждане на части слой по слой.

Независимо дали премахнете материал или го добавяте, Системите с ЦПУ разчитат CAD (Компютърно проектиране) и CAM (Компютърно подпомагано производство) Софтуер за конвертиране на цифрови дизайни в прецизни физически компоненти.

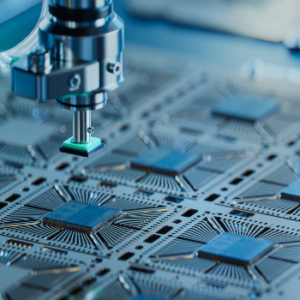

1. Изберете и поставете машина

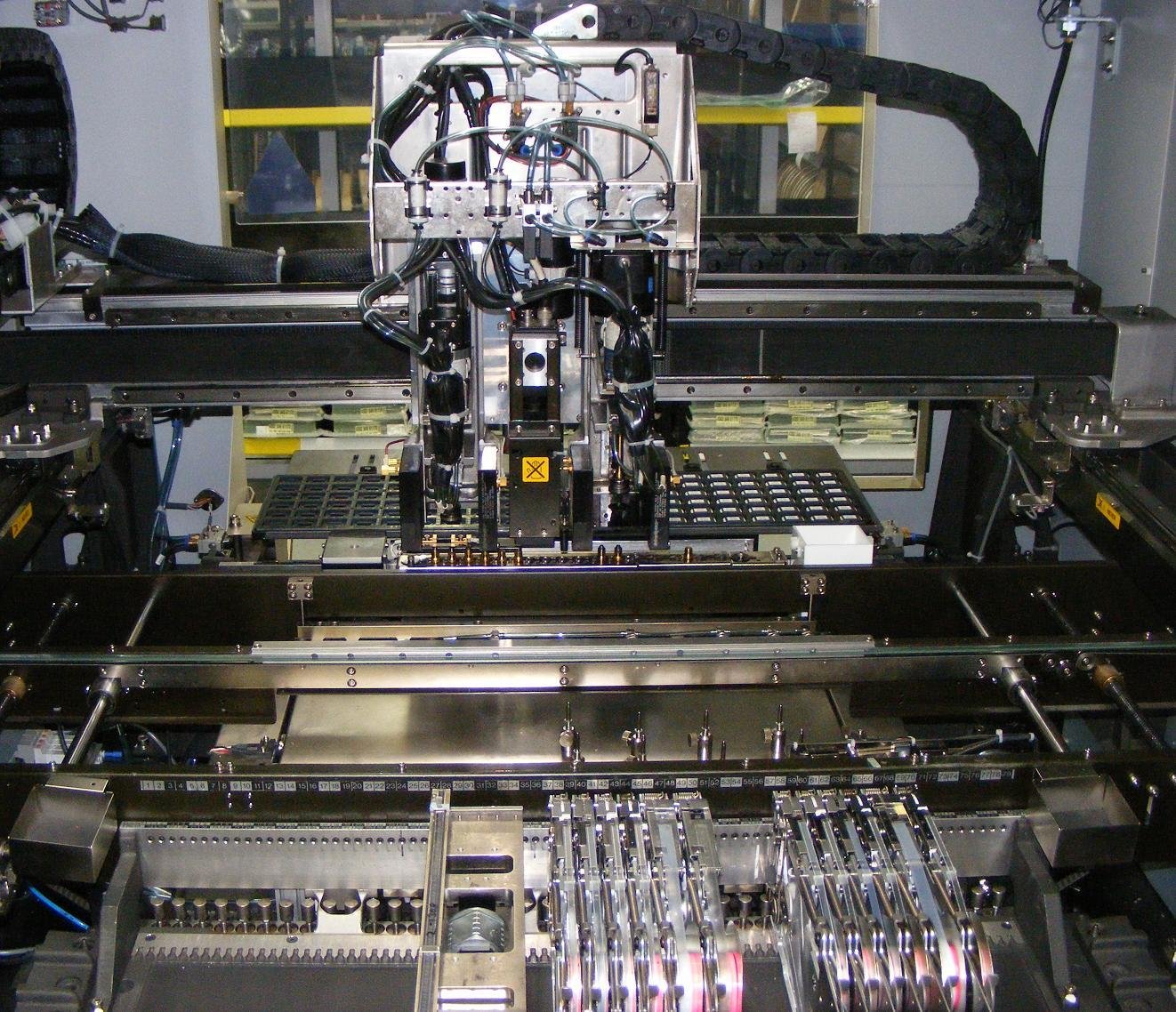

Изберете и поставете CNC машини се използват широко в производството на електроника. Тези машини имат множество роботизирани дюзи, които автоматично взимат малки компоненти като резистори, Ics, или кондензатори и ги позиционирайте точно върху печатни платки (PCBS).

Общи приложения:

Мобилен телефон и сглобяване на таблети

Производство на компютърна дънна платка

Високоскоростно производство на електроника

2. CNC 3D принтер

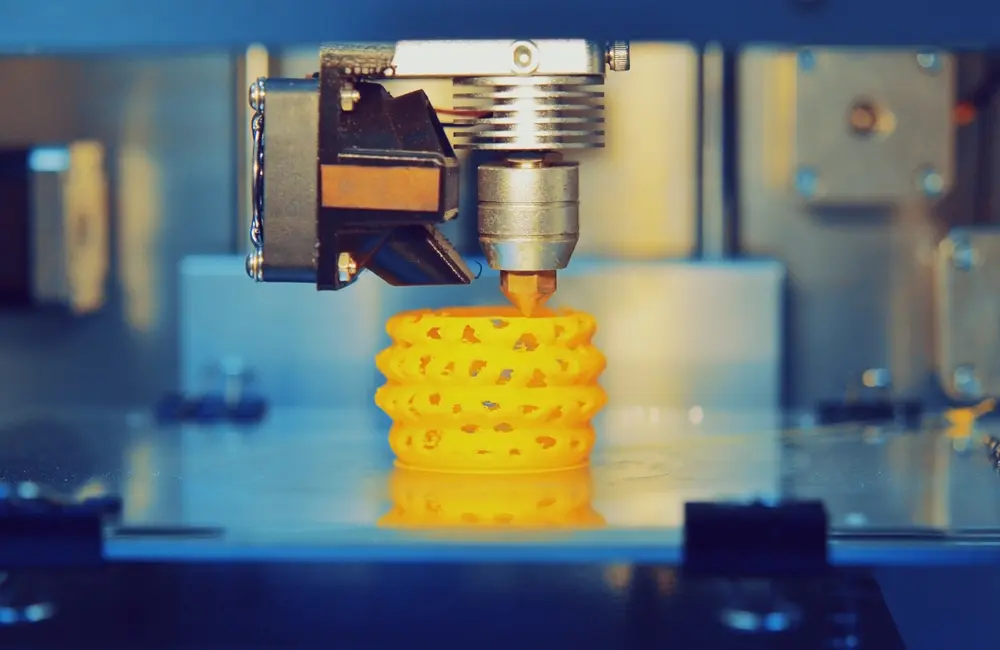

Докато повечето машини за ЦПУ са изваждащи, CNC 3D принтери следвайте Добавно производство подход. Тези машини екструдират или лекуват материал - обикновено пластмаса, смола, или метални прахове - слой по слой, за да образуват пълен обект от цифров модел.

Характеристики:

Свобода с висок дизайн

Отличен за бързо прототипиране

Съвместим с PLA, коремни мускули, смоли, и метални нишки

Индустрии:

Аерокосмическо и автомобилно прототипиране

Медицински импланти

Разработване на потребителски продукти

3. CNC рутер

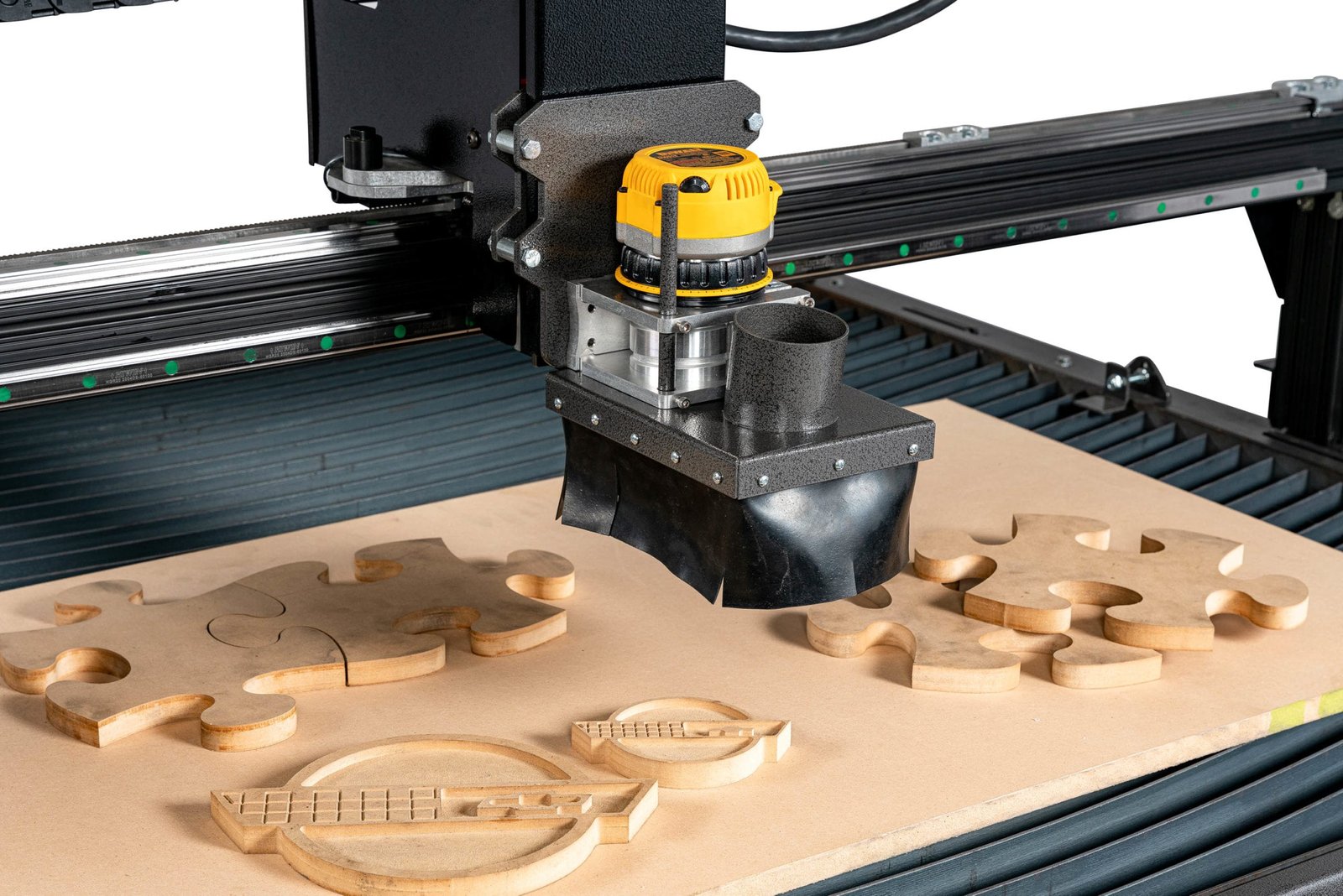

CNC рутери са идеални за рязане и издълбаване на меки материали. За разлика от мелниците, които обикновено се използват за метал, рутери са по -често срещани за дървообработването, пластмаси, и пени. Рутери работят на три оси и могат да произвеждат подробни гравюри, модели, или разфасовки.

Материали:

дърво, MDF, пластмаси

Алуминий и меки композити

Предимства:

Високоскоростна работа

Рентабилни за меки материали

По -голяма работна площ в сравнение с типичните мелници

4. CNC пробивна машина

Машини за пробиване на ЦПУ Автоматизирайте процеса на създаване на дупки в метал, дърво, или композитни материали. Тези машини използват различни свредла и могат да извършват операции като Peck Drilling, пробиване, или потупване.

Видове битове:

Twist тренировки

Забелязване на тренировки

Пробивки на винтове

Шапендира рейдъри

Типични употреби:

Блокове за производство на двигатели

Метално изработка

Подготовка на дупка на монтажната линия

5. Машина за стругови стругове

CNC стругове извършват операции за завъртане, Премахване на материали от въртящ се детайл с помощта на инструмент за рязане с една точка. Тези машини могат да изпълняват сложни задачи като резба, блъскане, и обърнато към една настройка.

Видове:

Двигател на двигателя

Курет струг

Швейцарски тип струг

Центрове за завиване на многооси

Приложения:

Производство на вал и щифтове

Аерокосмически крепежни елементи

Автомобилни втулки

6. 5-Машина на Axis CNC

5-Машини на Axis CNC Подобрете традиционната 3-осе система, като добавите две допълнителни въртящи се оси. Това позволява на режещия инструмент да се приближи до детайла от почти всяка посока без ръчно препозициониране.

Основни предимства:

Машина пет страни на част от една настройка

Идеален за сложни геометрии и извити повърхности

Подобрява точността и намалява времето за олово

Общи употреби:

Аерокосмически структурни части

Медицинска протеза

Сложно изработка на плесен

7. CNC фреза

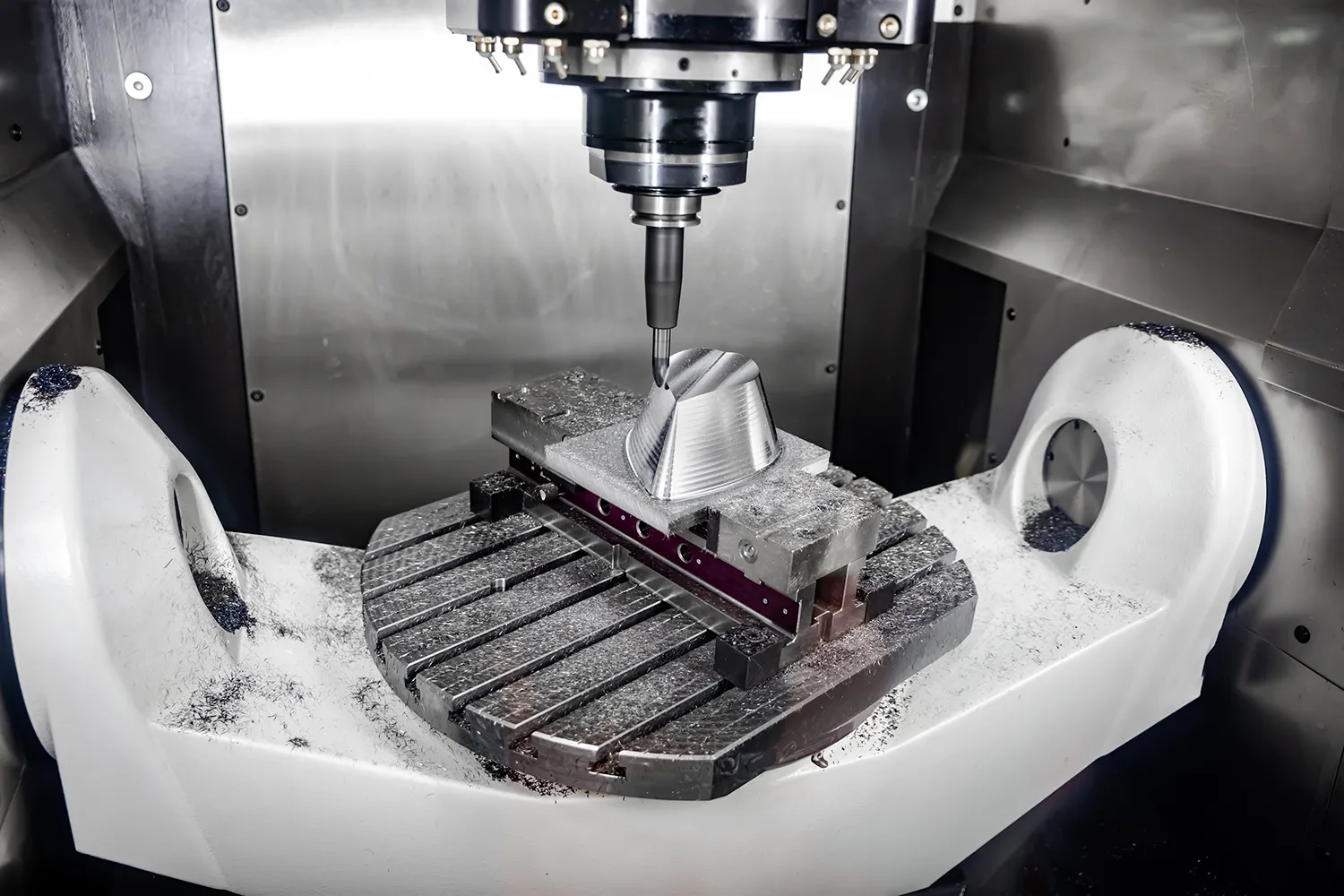

CNC фрезови машини Използвайте въртящи се многоточкови резачки, за да оформите детайла. Те са много гъвкави и способни да произвеждат сложни контури и кухини. CNC Mills могат да работят на 3, 4, или дори 5 оси.

Типове резачи:

Крайни мелници

Лицеви мелници

Фамилни мелници

Резачи за нос на топка

Приложения:

Компоненти за прецизна плесен

Автомобилни скоби

Персонализирани механични части

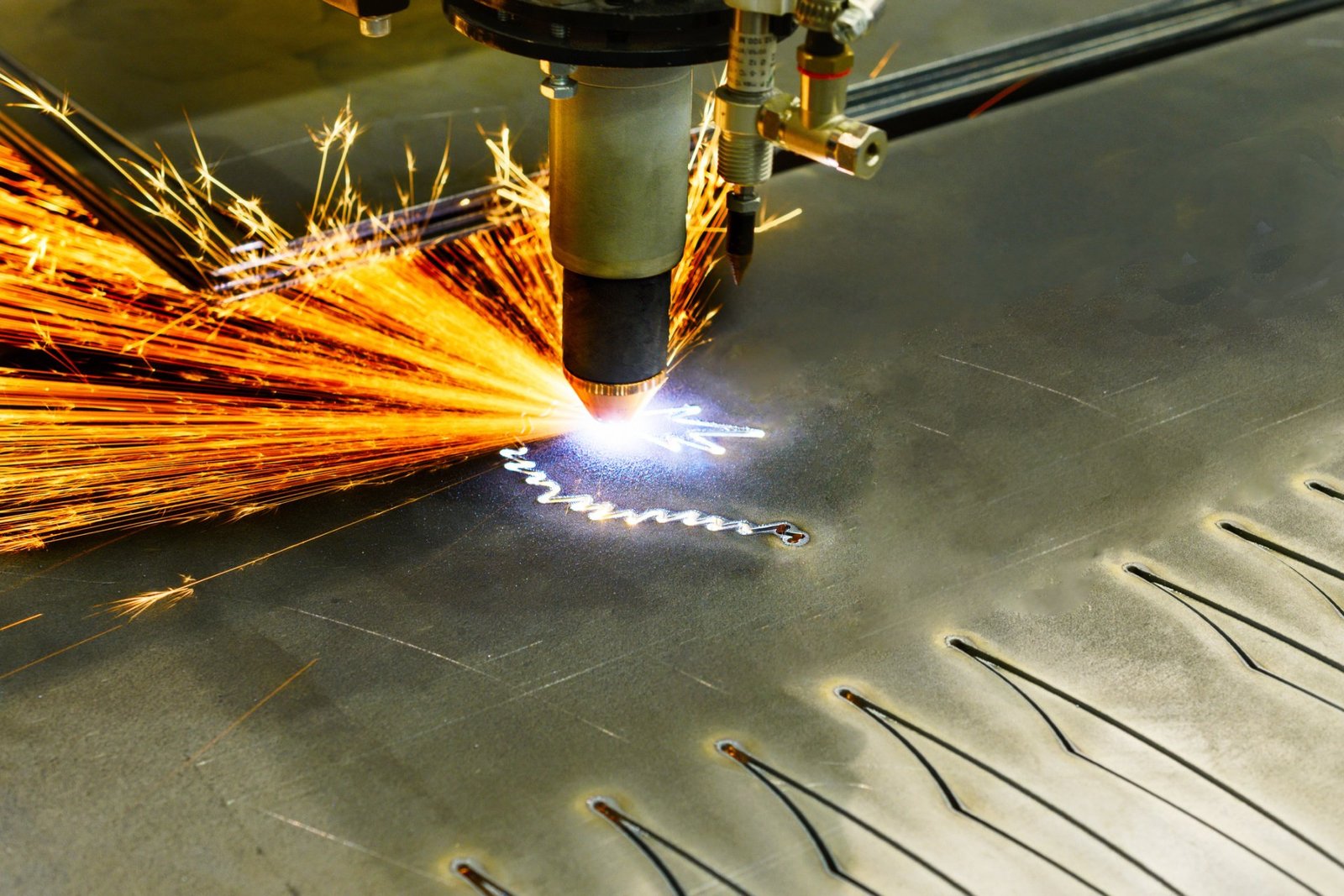

8. CNC плазмена машина за рязане

Плазмено рязане на CNC машини Използвайте йонизирана газова факла, за да прорежете електрически проводими материали. Плазмената струя достига температури до 30 000 ° F, рязане на метали с висока точност и скорост.

Подходящи материали:

Въглеродна стомана

Неръждаема стомана

Алуминий

Месинг и мед

Характеристики:

Високоскоростно рязане

Ниски оперативни разходи

Идеален за ламарина

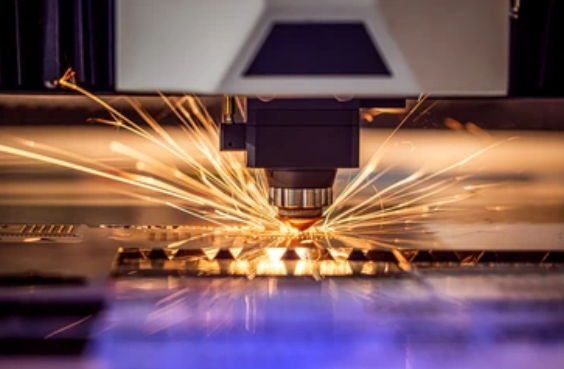

9. CNC лазерна машина за рязане

Машините за лазерно рязане използват фокусирана светлинна енергия за изпаряване или стопилка. Тези системи от ЦПУ могат да постигнат изключително строги допустими отклонения и се използват както за рязане, така и за гравиране.

Лазерни типове:

Съвместните лазери (неметали, гравиране)

Лазери от влакна (метали, високоскоростно рязане)

Nd:Яг лазери (Прецизно рязане на метали)

Приложения:

Табели и дисплеи

Изработка на медицински изделия

Автомобилно интериорно подрязване

Медна облицовка и други архитектурни продукти

10. CNC машина за електрическа разряда (EDM)

EDM машини Използвайте високочестотни електрически изхвърляния (искри) между електрод и детайл за отстраняване на материала. Той е особено полезен за обработка на твърди метали или сложни геометрии.

Видове:

Телен EDM

Синкер EDM

Предимства:

Точни вътрешни кухини

Няма механични сили за рязане

Работи върху много твърди материали

11. CNC шлифовъчна машина

CNC шлифовъчни машини Използвайте абразивни колела, за да завършите повърхностите с много тесни допустими отклонения. Те са от съществено значение за приложенията, при които високото качество на повърхността и прецизността на размерите са от решаващо значение.

Приложения:

Касапитни валове и коляновите валове

Производство на зъбни колела

Повърхностно завършване на втвърдени компоненти

Видове:

Повърхностно смилане

Цилиндрично смилане

Безцелно шлифоване

12. CNC машина с автоматичен смяна на инструменти (ATC)

CNC машини с автоматични смяна на инструменти Може ли да разменя инструменти за рязане по време на обработка без ръчна намеса. Това значително подобрява времето на цикъла и поддържа части за многооперация в една настройка.

Ползи:

Повишена ефективност на обработка

Намалено участие на оператора

Идеален за производство с голям обем

Как да изберете правилната CNC машина

Избирането на правилната машина за ЦПУ може да се почувства завладяващо в началото, Особено с толкова много видове там. Но не се притеснявайте - ако го разбиете, Всичко е в това да разберете какво искате да прави машината, С какви материали ще работите, И колко често ще го използвате. Ето няколко лесни съвета, които ще ви помогнат да направите правилния избор:

С какъв материал работите?

Започнете, като се запитате: Какви неща ще режа или оформям?

Ако е така дърво, пяна, или пластмаса, а CNC рутер Може да е перфектно.

Ако е така метал, Вероятно ще ви трябва нещо по -трудно като CNC Mill, струг, или Плазмена резачка.

За сложни форми или твърди материали, an EDM машина или 5-Мелница на ос може да е най -подходящият.

Колко големи са вашите части?

Уверете се, че машината е Достатъчно голям За най -голямата ви част. Винаги избирайте машина, която има малко по -голяма работна зона от най -големия ви проект. Това ви дава повече гъвкавост по линията.

Какви функции ви трябват?

Помислете:

Скорост: Колко бързо се нуждаете от машината, за да работи?

Промяна на инструмента: Ще използвате ли много различни инструменти? Машина с Автоматичен смяна на инструменти (ATC) Може да спести много време.

Оси: Имате ли нужда от 3-ос движение, или повече? Колкото повече оси, по -сложните форми можете да направите.

Лесно ли е да се поддържа и ремонтира?

Като всяка машина, CNC машините могат да се износват или да се пробият с течение на времето. Отидете за добре известен модел и има добра подкрепа- Ще бъде много по -лесно да намерите резервни части или да получите помощ, когато нещо се обърка.

Изисквания за захранване

CNC машините използват много електричество. Преди да купите, Проверете нужди от енергия на машината и се уверете, че вашата работилница или фабрика могат да се справят. Някои по -големи машини може да се нуждаят от специални настройки на мощността.

Какъв е вашият бюджет?

разбира се, пари има значение. Някои машини за ЦПУ са по -достъпни, но може да имат по -малко функции. Други струват повече, но спестяват време и дават по -добри резултати. Помислете колко можете да похарчите сега и колко време или пари може да се направи машината Запазете ви по -късно.

Заключение

CNC машини революционизират производството, като доставят ненадминат прецизност, последователност, и производителност. От изваждане на методи като фрезоване и смилане до адитивни подходи като 3D печат, Всеки тип CNC машина изпълнява отлична роля в производството.

Разбирането на силните страни и възможностите на всяка машина помага на производителите и инженерите да изберат най -ефективното решение за техните нужди.

Прочетете повече:

Магазинът за машини CNC: Пълно ръководство

Видове EDM обработка & Техните приложения

2 мисли за "12 Видове машини с ЦПУ и техните приложения в съвременното производство”