Алуминий е един от най -универсалните инженерни материали благодарение на неговите Лека сила, устойчивост на корозия, и висока проводимост. Той се използва широко в аерокосмическото пространство, автомобилен, потребителска електроника, медицински изделия, и архитектура. въпреки това, Суровите или обработените алуминиеви повърхности често изискват повърхностна обработка За подобряване на производителността, издръжливост, и визуална привлекателност.

Повърхностното довършване не е само за естетика. Това може драстично да подобри устойчивостта на алуминия срещу корозия, абразия, и химическа атака, като същевременно гарантирате, че компонентите отговарят Тесни допустими отклонения и функционални изисквания. Независимо дали имате нужда от огледален алуминиев панел, аерокосмическа част, устойчива на корозия, или устойчив корпус на потребителския продукт, Правилният метод на довършителни работи е критичен.

Това ръководство изследва Защо алуминиевата повърхностно покритие има значение, на 10 Най -често срещаните методи за довършителни работи, различни повърхностни ефекти и стилове, И как да изберете правилния за вашето заявление.

Защо алуминиевите продукти се нуждаят от повърхностно завършване?

Повърхностното довършване на алуминий обслужва и двете функционални и естетически цели. По -долу са основните причини, че е от съществено значение:

Устойчивост на корозия: Алуминият естествено образува тънък оксиден филм, Но в тежки среди, Допълнително завършване (напр., Анодизиране или химичен филм) осигурява дългосрочна защита.

Устойчивост на износване: Много алуминиеви части са изложени на триене или механично напрежение. Твърдите покрития подобряват устойчивостта на драскотината и издръжливостта.

Електрически и термични свойства: Някои завършвания повишават проводимостта (напр., Chem Film), Докато други подобряват изолацията (напр., анодиране).

Намалено триене & Замърсяване: Гладки завършвания с по -ниско триене и предотвратяване на натрупването на мръсотия или влага.

Естетична привлекателност: Завършвания като полиране, четкане, и праховото покритие осигуряват разнообразни стилове, От огледален блясък до сатен или матови текстури.

Накратко, Алуминиевият довършител пряко влияе върху продукта живот, изпълнение, и стойност на марката.

10 Общи видове алуминиеви облицовки

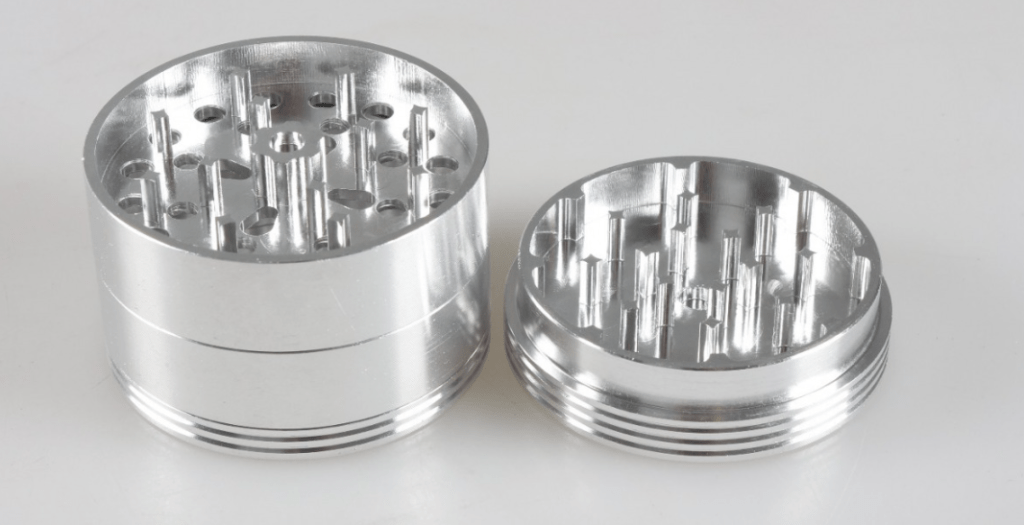

1. Ас-Обработното покритие

Процес: Част е оставена в своята сурова, обработено състояние.

Грапавост на повърхността: Обикновено ra 0.2 – 3.2 μm, В зависимост от параметрите на обработка.

плюсове: Ниска цена, поддържани точни допустими отклонения.

минуси: Видими марки инструменти, Ограничена защита от корозия.

Приложения: Вътрешни компоненти, прототипи, не-декоративни части.

2. Анодиране

Процес: Електрохимична обработка, която образува контролиран оксиден слой.

Дебелина: 5–25 μm за декоративно, до 50 μm за твърдо анодизиране.

Ползи:

Отлична корозия и устойчивост на износване.

Широка гама от цветови опции.

Непроводима повърхност за електрическа изолация.

Приложения: Аерокосмически панели, потребителска електроника, медицински изделия.

3. Прахово боядисване

Процес: Електростатично пръскане на прахови частици, излекувано под топлина.

Повърхност: Защитен, декоративни, Леко текстурирано покритие.

Ползи:

Без разтворители → Екологични.

Отличен цветен сорт.

Силна адхезия и издръжливост.

Приложения: Автомобилни колела, мебели, Външни заграждения.

4. Алодин (Chem Film)

Процес: Потапяне в химическа баня, която образува покритие за преобразуване.

Ползи:

Рентабилна устойчивост на корозия.

Поддържа електропроводимост (За разлика от анодизирането).

Идеален за части, които изискват боядисване след това.

Приложения: Аерокосмически структури, електронни корпуси.

5. Бластиране на мъниста

Процес: Абразивни стъклени или стоманени мъниста, взривени под налягане.

Повърхност: Гладка, Текстура, подобна на сатен.

Ползи:

Почиства примеси.

Създава равномерен матов вид.

Приложения: Потребителски стоки, Декоративен хардуер, Автомобилни интериори.

6. Галванопластика

Процес: Отлагане на метали като никел, злато, сребро, или хром на алуминий чрез електролиза.

Ползи:

Подобрена проводимост, устойчивост на износване, и отразяваща способност.

Добавя луксозна естетика (злато/сребърно покритие).

Приложения: електроника, Аерокосмически конектори, луксозни потребителски продукти.

7. Полиране

Процес: Механично или химическо полиране за отразяваща повърхност.

Ползи:

Подобрява яркостта и естетиката.

Намалява окисляването чрез изглаждане на порите.

Приложения: Декоративни панели, медицинско оборудване, Показване на части.

8. Четкане

Процес: Абразивните четки създават фини, Линейна текстура.

Повърхност: Сатен или метален вид, намалява видимите драскотини.

Приложения: Кухненски уреди, Автомобилни тапицерии, Архитектурни панели.

9. Лазерно офорт

Процес: Фокусирани лазерни лъчи гравира постоянни марки или текст.

Ползи:

Висока точност и повторяемост.

Постоянна идентификация или брандиране.

Приложения: Аерокосмически компоненти, медицински изделия, индустриални инструменти.

10. Ярко потапяне

Процес: Химическо потапяне в киселина за огледален блясък.

Ползи:

Създава силно отразяващ, лъскава повърхност.

Идеален за декоративни части.

Ограничения: Не е съвместим с всички сплави (Най -добре с 6463).

Приложения: храна & оборудване за напитки, Декоративни профили.

Различни повърхностни ефекти & Стилове за алуминиеви облицовки

Довършването не е само за защита - това също определя как изглежда и се чувства алуминий.

Висок блясък (Лъскав, Светлоотразителни): Постигнати чрез полиране, Ярко потапяне, или анодизиране с гланц. Често срещани в електрониката, Автомобилни тапицерии, и луксозни предмети.

Сатен (Мек блясък, 72 GU блясък): Постигнати чрез четка или взривяване на мъниста. Балансира естетиката и издръжливостта, крие несъвършенствата.

Матово (Нерефлективни, 30 GU блясък): Постигнати чрез анодизиращо или прахово покритие. Устойчив на пръстови отпечатъци и ниска поддръжка.

Металик (Луксозен външен вид): Постигнати чрез анодизиране, четкане, или електроплаване. Може да имитира месинг, мед, злато, или облицовки от неръждаема стомана.

Фактори, които трябва да се вземат предвид при избора на алуминиево покритие на повърхността

При избора на правилния завършек, Инженерите и дизайнерите трябва да обмислят:

Среда за приложение: Вътрешен срещу. Използване на открито, UV експозиция, Корозивни химикали, или абразия.

Естетически изисквания: Цвят, гланц, текстура, консистенция на брандиране.

цена: Първоначална разходи за обработка + Дългосрочни разходи за поддръжка или подмяна.

Издръжливост: Очакван живот на финала, устойчивост на износване и изветряне.

Функционалност: Проводимост срещу. изолация, съображения за тегло, повърхностно триене.

Промишлени приложения на алуминиеви облицовки

Алуминиевите облицовки не са само за правенето на метала добре - те също правят частите по -силни, по-дълготрайни, и по -надеждни в трудна среда. В зависимост от финала, Алуминият може да се използва почти навсякъде, От самолети до смартфони.

Космонавтика

Частите на самолета трябва да се справят с висок стрес, температурни промени, и излагане на влага. Завършва като анодиране и Chem Film (Алодин) се използват широко, защото подобряват устойчивостта на корозия, без да добавят твърде голяма тежест. Лазерното офорт също е често срещано за маркиране на постоянна част, което е важно за безопасността и проследяването.

Автомобилна

автомобили, Камиони, и мотоциклите разчитат на алуминиеви завършвания и за двете защита и стил. Прахово покритие и анодизиране се използват на колела, тапицерии, и части от двигателя, за да се предпазят от пътна сол, топлина, и износване. Полирани и четкани облицовки също са популярни за даване на превозни средства елегантни, Модерен външен вид.

Потребителска електроника

Гладкото, лъскав корпус на вашия смартфон или лаптоп често идва от анодизиране или взривяване на мъниста. Тези завършвания правят устройството да изглежда премиум, като същевременно го предпазва от драскотини и пръстови отпечатъци.

Медицински устройства

В здравеопазването, Материалите трябва да са безопасно, лесен за почистване, и устойчив на корозия. Анодизирани и полирани алуминиеви части често се използват в хирургични инструменти, болнично оборудване, и дори компоненти на имплантирането. Тези покрития поддържат повърхностите гладки, стерилен, и издръжлив.

Архитектура и строителство

от рамки за прозорци за изграждане на фасади, Алуминият е навсякъде в съвременната архитектура. Праховото покритие е особено популярно тук, защото може да осигури трайна защита и широка гама от цветове, които да съответстват на дизайнерските нужди. Четкани или метални облицовки също добавят висок вид към интериорни елементи като мебели и осветителни тела.

Индустриални машини

Тежките машини често използват анодизирани или електропластирани алуминиеви компоненти за допълнителна устойчивост на износване и по-добри електрически характеристики. Това гарантира, че частите могат да се справят с трудна среда, без да се разпадат бързо.

Заключение

Алуминиевото завършване е решаваща стъпка за гарантиране, че частите отговарят на двете функционални и естетически изисквания. С опции, вариращи от рентабилен химически филм до декоративно ярко потапяне и високоефективно анодизиране, Всеки завършек предлага уникални предимства за различни приложения.

Като внимателно обмисляте среда за приложение, нуждите на издръжливостта, цена, и желания външен вид, Производителите могат да изберат правилното покритие на повърхността на алуминия, за да подобрят и двете Изпълнение и живот на техните продукти.

Често задавани въпроси

- Кое е най -трайният алуминиев завършек?

Анодизиране - особено твърдо анодизиране - по -превъзходно износване и устойчивост на корозия, което го прави един от най -трайните финиши. - Който завършва най -добре, предотвратява корозията?

Анодизирането и алодинът са ефективни, С анодизиране на предлагането на по-добра дългосрочна съпротива. - Коя е най-рентабилната обработка на повърхността на алуминиевата повърхност?

Chem Film (Алодин) е сравнително евтин, като все още осигурява силна устойчивост на корозия и прилепване на боя.