CNC обработка, или компютърна обработка на цифрово управление, се е превърнал в крайъгълен камък на съвременното производство. От автомобилни и аерокосмически до медицински изделия, Индустриите разчитат на обработката на ЦПУ за точност, скорост, и последователност. все пак, Много потенциални учащи се чудят: Трудно ли е обработката на CNC? Тази статия разглежда този общ въпрос, Разсейва погрешни схващания, и осигурява ясен път за всеки, който се интересува от овладяване на обработката на ЦПУ.

Какво е CNC обработка?

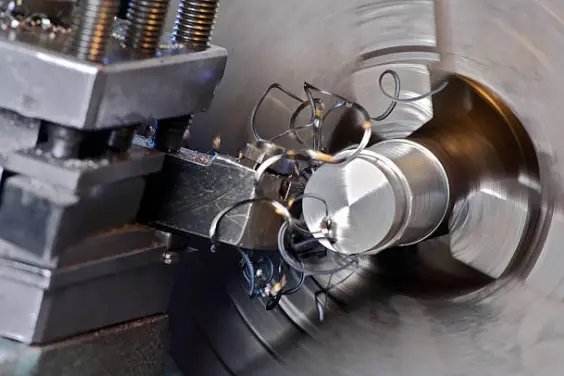

Обработката на ЦПУ е производствен процес, при който компютърно контролирани машини точно оформят материали като метал, пластмаса, или дърво. За разлика от ръчната обработка, Обработката на ЦПУ разчита на автоматизация и софтуер като G-код инструкции за работа на машини като:

Мелници

Стругове

Рутери

Мелници

Тази технология дава възможност за постоянно производство на комплекс, Части с висока точност, значително намаляване на човешките грешки и времето за производство.

Трудно ли е обработката на CNC?

Когато хората за първи път погледнат в обработката на CNC, Те често се чудят: „Наистина ли е трудно да се научим?” добре, Истината е, Обработката на ЦПУ може да изглежда малко сложна в началото, Особено, ако сте нови в производствените или техническите полета. Има какво да разбера, Като как да пускате различни машини, Разбиране на специални кодове (като G-код), и да се научим да избирате правилните инструменти.

Но ето добрата новина: Въпреки че определено има крива на обучение, Това е Абсолютно изпълним. Точно като шофиране на кола или научаване да свирите на нов инструмент, Обработката на ЦПУ става по -лесна, колкото повече практикувате. Не е нужно да знаете всичко за една нощ - да започнете малки, Практикувайте редовно, И постепенно поемането на по -напреднали задачи ще ви помогне да се почувствате уверени и квалифицирани с течение на времето.

Често срещани погрешни схващания относно обучението на ЦПУ

Няколко погрешни схващания могат да възпрепятстват начинаещите да изследват обработката на ЦПУ:

Всички машинисти от ЦПУ вършат една и съща работа:

Има множество нива на умения, В диапазона от основни оператори, управляващи прости настройки до високо специализирани машинисти програмиране на сложни компоненти.

CNC програмиране (G-код) е изключително трудно:

Докато е предизвикателство в началото, Ученето на G-код е подобно на изучаването на всеки език-практиката и повторението опростяват процеса.

Не всеки може да успее в обработката на ЦПУ:

Обработката на ЦПУ изисква внимание към детайлите и решаването на проблеми, Но тези умения могат да бъдат развити от всеки посветен и мотивиран.

Можете бързо да овладеете CNC:

Въпреки че основните умения за експлоатация могат да се спечелят след месеци, Истинската експертиза обикновено отнема години на практически опит и непрекъснато обучение.

Основни умения за овладяване на обработката на ЦПУ

Да успее в обработката на ЦПУ, Ще ви трябва комбинация от технически знания и лични черти:

Лични черти:

Любопитство и независимост: Готовност за изследване на нови методи и самообучение.

Внимание към детайлите: Внимателно планиране и прецизно изпълнение на задачите.

Мислене за решаване на проблеми: Бързо вземане на решения и способности за отстраняване на неизправности.

Технически умения:

Работа на машината: Разбиране как работят CNC машините.

Знания за инструменти: Избор на подходящи инструменти и техните специфични приложения.

Знания за материали: Познаване на свойствата и обработваемостта на различните материали.

Умения за програмиране: Писане и отстраняване на грешки G-код, и използване на софтуер CAM.

Умения за поддръжка: Рутинни проверки, Отстраняване на неизправности, и ремонти.

Прецизно измерване: Точно измерване, за да се гарантира качеството на части и допустимите отклонения.

Знания за програмиране: Софтуер G-код и CAM

G-код и камера (Компютърно подпомагано производство) Софтуерът са основополагащи инструменти в обработката на ЦПУ:

G-код насочва CNC машини чрез определяне на движения и операции.

CAM софтуер Преобразува CAD моделите в G-код автоматично.

Популярните програми на CAM включват:

Mastercam: Разнообразен, широко използван софтуер за фрезоване, обръщане, и EDM.

Сливане 360: Потребителски, Облачна платформа за дизайн и производство.

SolidWorks Cam: Интегриран в CAD системата SolidWorks, Рационализиране на работни процеси за проектиране към производство.

Ръководство срещу програмиране на CAM:

Ръчно програмиране: Осигурява гъвкавост и контрол; полезно за персонализирани задачи.

CAM програмиране: Стриймбиране на програмиране, намалява грешките, и повишава ефективността.

Математически и аналитични умения в обработката на ЦПУ

Основните математически и аналитични умения са жизненоважни за задачите за обработка на ЦПУ, включително изчисляване на скоростите на фураж, скорости, Пътеки на инструмента, и размери. въпреки това, Съвременният софтуер на CAM значително опростява тези изчисления, позволявайки на машинистите да се съсредоточат върху практическото изпълнение.

Как можете да започнете да изучавате обработката на ЦПУ?

Можете да избирате сред няколко образователни пътя въз основа на вашите кариерни цели и предпочитан стил на обучение:

Образователни пътеки:

Програми за професионално обучение: Практически практически курсове.

Онлайн курсове: Гъвкави графици чрез платформи като Coursera, Удеми, LinkedIn Learning.

Университетски програми: Изчерпателни програми в областта на инженерството или производствената технология.

Чиракуване: Печелете, докато натрупвате практически опит.

Ресурси за самоукарване: Уроци, YouTube канали, учебници, онлайн форуми.

Направи си сам обучение срещу официално образование:

Направи си сам учене:

плюсове: Рентабилно, гъвкав, специализирани теми.

минуси: Изисква силна самодисциплина, Ограничен практически опит.

Официално образование:

плюсове: Структурирано обучение, практическо обучение, Професионални мрежи.

минуси: По-скъпи, Фиксирани графици.

Препоръчителни онлайн ресурси:

Coursera: Курсове на CNC на ниво университет.

Удеми: Достъпни, Практически видео уроци.

YouTube канали: Безплатно, Изчерпателни уроци.

Уебсайтове на производителя: Специфични насоки за експлоатационно оборудване.

Избор на правилната програма за обучение на CNC

При избора на програма за обучение на ЦПУ, помислете:

Акредитация: Проверете признаването на индустрията.

Качество на оборудването: Достъп до съвременни машини за ЦПУ.

Практическо обучение: Възможности за практическа работа на машината.

Топ препоръчани програми:

Центрове за обучение на NTMA: Практически умения за незабавно влизане в работната сила.

Програма на CNC на университета Goodwin: Изчерпателно обучение на ниво сертификат.

Универсален технически институт (Uti): Широка учебна програма, включително разширени концепции за ЦПУ.

Истински предизвикателства при изучаването на обработката на ЦПУ

Общите предизвикателства включват:

Овладяване на основополагащите умения (чертежи, инструменти, Основи за програмиране).

Преодоляване на първоначалното самосъмнение и придобиване на увереност.

Постепенно излагане на задачи за усъвършенствана обработка.

Разработване на устойчивост и ефективни стратегии за решаване на проблеми.

Преодоляване на кривата на обучение за програмиране на CNC

Стратегиите за успех включват:

Основни основи първо: Разберете чертежите, инструментална екипировка, и прости команди G-код.

Постепенно обучение: Изградете знанията прогресивно от основни до напреднали умения.

Симулационен софтуер: Използвайте софтуер като MasterCam, за да визуализирате и тествате програми безопасно.

Практически опит: Работете директно върху машини с ЦПУ под професионален надзор.

Грешки като уроци: Възприемете конструктивен подход за учене от грешки.

Колко време отнема да стане оператор на ЦПУ?

Типично, Основно владеене на оператора на ЦПУ приема една до две години, в зависимост от предишния опит и сложността на програмата. Напреднали умения, като програмиране на сложни машини, може да отнеме повече време.

Роля и отговорности на CNC Machinist

CNC машините се справят:

Настройка и програмиране на машини.

Осигуряване на точност и качество на частта.

Рутинна поддръжка и отстраняване на неизправности.

Сътрудничество с инженери и производствени екипи.

Възможности за кариера за машинисти от ЦПУ

CNC машините имат различни кариерни пътеки:

CNC оператор: Управлява основни операции за обработка.

CNC програмист: Разработва G-код за производствена ефективност.

Специалист по контрол на качеството: Гарантира, че части отговарят на необходимите стандарти.

Мениджър на продукцията: Наблюдава операциите и екипите на CNC.

Индустриите често наемат автомобили, космическото пространство, медицинско производство, бързо прототипиране, и персонализирано производство.

Как да подобрите вашите умения за обработка на ЦПУ

Непрекъснато подобряването на вашите умения за ЦПУ е от решаващо значение за развитието на кариерата:

Усъвършенствано обучение и сертифициране:

Преследвайте специализирани сертификати (напр., Сертифициране на NIMS).

Участвайте в програми за чиракуване.

Учене от експерти от индустрията:

Посетете индустриални конференции и семинари.

Присъединете се към програми за менторство или професионални асоциации като NTMA.

Да останеш актуализиран с иновации:

Редовно обучение в нов софтуер на CAM.

Абониране за индустриални списания (Модерен машинен магазин).

Работа в мрежа чрез професионални групи и събития в индустрията.

Заключение

Ученето на обработката на ЦПУ може първоначално да се почувства обезсърчително, Но със структурирано обучение, практически опит, и всеотдайност, тя става достъпна и силно възнаграждаваща. Обработката на ЦПУ предлага множество възможности за кариера и е основно умение в съвременното производство. Чрез систематично развитие на вашите умения и възприемане на непрекъснато обучение, Ще се позиционирате за дългосрочен успех в тази вълнуваща индустрия.

Често задавани въпроси

Е стресираща ли CNC?

Това може да бъде взискателно поради високите изисквания за точност, но е управляем с обучение и опит.

Лесно ли е програмирането на CNC?

Първоначално предизвикателство, става по -лесно чрез последователна практика и структурирано обучение.

Работи ли е трудно с CNC машина?

Първоначално сложен, Но уменията бързо се придобиват чрез обучение и практическа практика.

Прочетете повече:

Разбиране на CNC програмните езици с помощта на G и M кодове

CNC завой и фрезоване - Бързо ръководство за разбиране на техните различия

Разбиране на SFM (Повърхностни крака в минута): Основни прозрения и приложения в обработката

Всичко, което трябва да знаете за чертежите за обработка на обработката на ЦПУ

10 Най-добрите предимства на обработката с ЦПУ