Постобработката се отнася до всяка вторична операция, извършена върху пластмасова шприцована част, след като е била извадена от кухината на формата. Докато леене под налягане is a highly efficient manufacturing process, it has limitations, and parts rarely emerge fully ready for their intended end-use.

The primary function of post-processing is two-fold: to execute corrective actions that remove unwanted material or surface defects, and to perform secondary functional or decorative processes that the molding machine cannot achieve efficiently or at all.

This stage is crucial because it often represents a cost-benefit trade-off. например, achieving a specific color or intricate graphic through post-processing might be significantly cheaper than investing in expensive pigmented resins, complex in-mold labeling, or highly sophisticated tooling designs. By adding these steps, manufacturers can utilize less expensive base materials and simpler molds, mitigating high upfront costs.

This guide details the six most common and critical post-processing techniques used in the plastic injection molding industry:

Gate Trimming

Рисуване

Лазерно маркиране

Тампонен печат

Heat Staking

Ultrasonic Welding

Common Post-Processing Activities

1. Gate Trimming

Gate Trimming

Gates are the critical connection points where molten plastic flows from the runner system into the mold cavity. Even with optimal tool design, a small protrusion of solidified material remains at this point, often referred to as a “gate vestige.” Flash, a thin layer of excess material forced into the mold’s parting line or around ejector pins, is another common defect.

Цел: The primary goal of gate trimming (or degating) and flash removal is to ensure the part is aesthetically pleasing, fits correctly during assembly, and functions as intended (especially for sealing surfaces).

Методи:

Manual Trimming: For smaller, по -прости части, this involves using hand tools like sharp snips, ножове, or specialized cutters. This is the most labor-intensive and quality-variable method.

Automated Trimming: For high-volume or complex parts, приспособления, cutting tools integrated into the molding machine, or robotic arms are used to ensure consistency and speed.

In-Mold Degating: Highly engineered tools (like those for submarine or hot runner gates) are designed to shear the gate vestige cleanly преди the part is ejected, minimizing or eliminating the need for secondary trimming.

2. Рисуване

Рисуване

While colored plastics are available, painting is a preferred post-process for achieving specific colors, specialized finishes (like metallics or textures), or providing protective functional layers (such as EMI shielding).

Pre-Painting Preparation: Successful adhesion is paramount. Plastics are chemically diverse, and some, like Polyethylene (PE) and Polypropylene (ПП), have low surface energy, causing liquids to bead up rather than spread.

Cleaning/Sanding: Required to remove mold release agents, прах, and oils.

Plasma Treatment: This highly effective process uses gas plasma to increase the surface energy of non-polar polymers, introducing polar functional groups that create a stronger molecular attraction between the plastic and the paint.

Painting Methods:

Spray Painting: The most common method. It can be applied in single or multiple layers. Paints can be self-curing (air-dry) or chemically cured. UV-curing paints are fast, ефикасен, and minimize volatile organic compound (VOC) emissions.

Прахово боядисване: A dry finishing process where finely ground plastic powder is electrostatically charged and sprayed onto the part. The part is then heated (UV or oven curing) to melt the powder into a smooth, трайно покритие. It offers excellent chip resistance.

Silk Screening (Печат на екрана): Used for applying patterns, лога, или текст, often in two or more colors. A porous woven mesh (screen) is used to support an ink-blocking stencil, leaving open areas through which ink is forced onto the substrate.

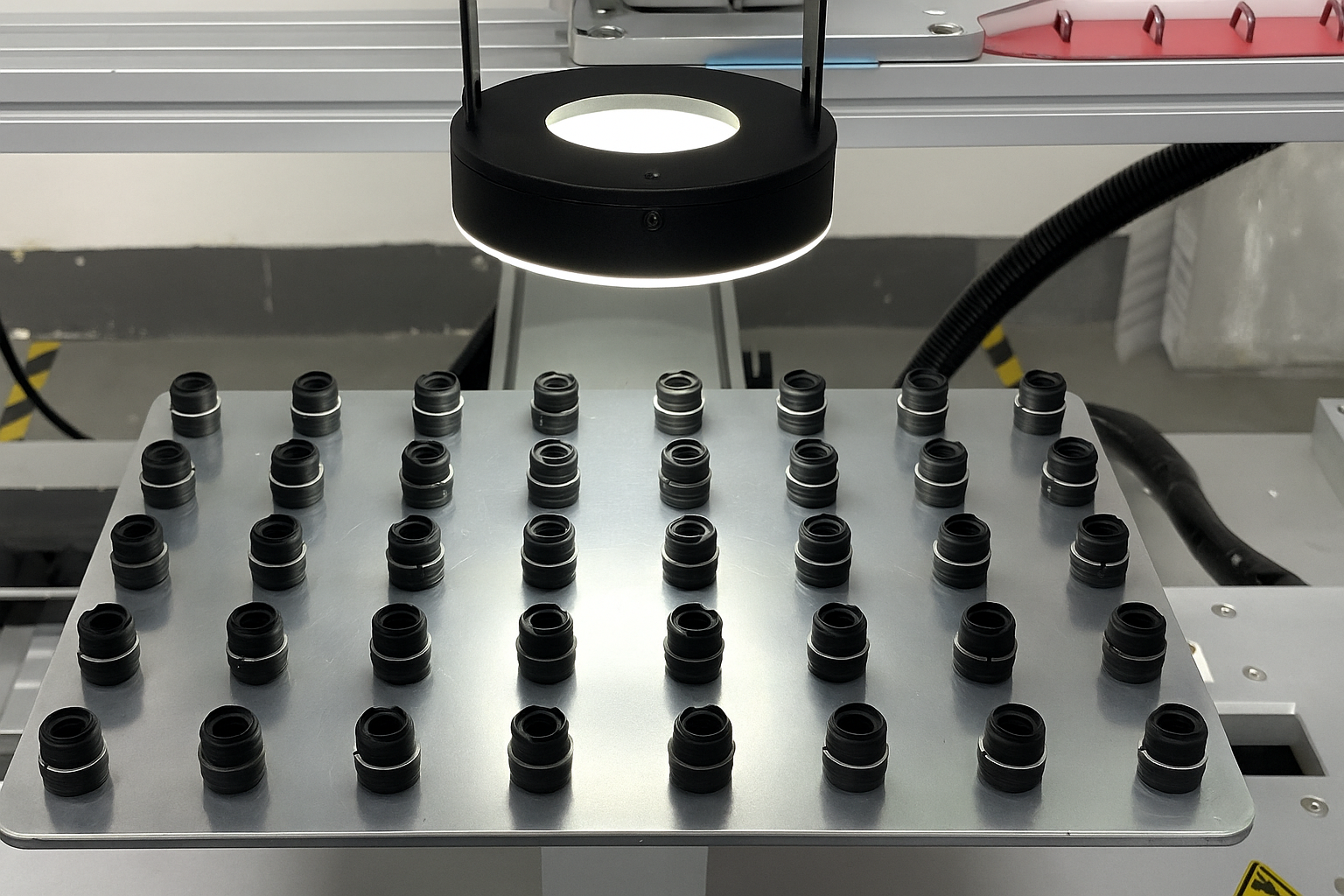

3. Лазерно маркиране

Лазерно маркиране

Laser marking is a non-contact, tool-less, and highly precise method for applying permanent graphics, alphanumeric characters, or unique identifiers to parts.

Principle: The solid-state pulsed laser delivers energy with a wavelength specifically chosen for the molded plastic. The plastic absorbs this energy, resulting in a localized surface change.

Key Mechanisms:

Color Change (Carbonization): The laser heat causes chemical changes within the material, often darkening the surface to black or gray. This requires specific material additives.

Foaming: The laser locally melts the plastic, causing tiny gas bubbles to form just below the surface, which appear as a raised, lighter mark.

Ablation (Гравиране): The laser removes a thin layer of surface material. If the underlying plastic is a different color, it exposes the contrasting layer for a clear mark.

Приложения: Due to its high resolution and permanence, laser marking is essential for parts requiring проследяване or regulatory compliance, such as medical implants, serializing electronics, or automotive components.

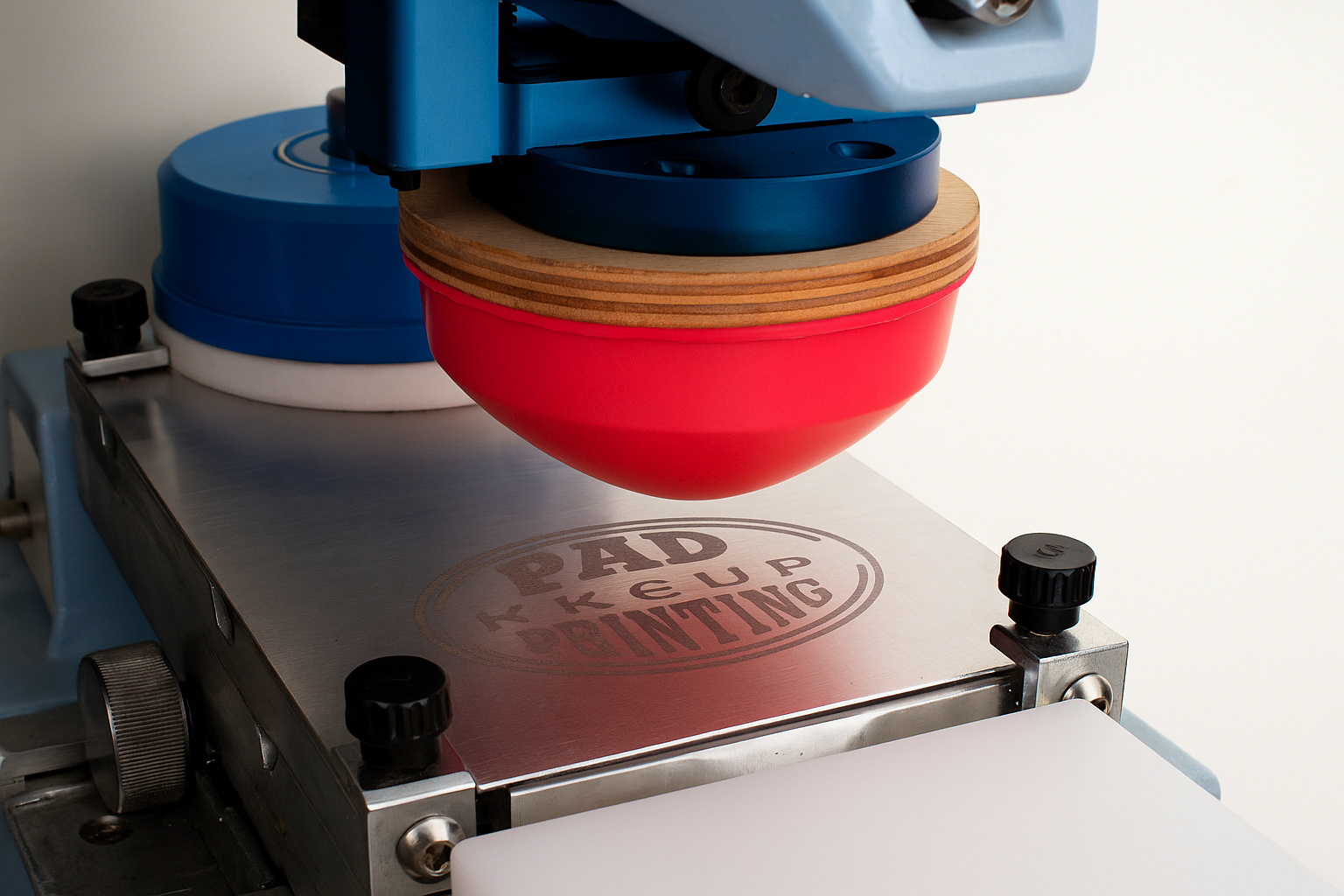

4. Тампонен печат

Тампонен печат

Pad printing is a unique offset printing process designed to transfer a 2D image onto a 3D object, often with complex or non-uniform surfaces.

Компоненти на процесите:

Cliché (Plate): An etched plate holds the ink for the desired image.

Ink Cup: The cup slides over the cliché, filling the etched area with quick-drying ink while wiping the rest of the plate clean.

Transfer Pad: A silicone rubber pad is pressed onto the cliché, picking up the inked image.

Transfer: The pad then deforms as it presses onto the 3D part surface, transferring the image cleanly.

Предимства: Pad printing excels where conventional methods fail, especially on concave, изпъкнал, spherical, or irregular surfaces. The use of quick-drying inks minimizes the risk of smearing, making it ideal for high-volume consumer goods, спортни стоки, and appliance housings where detailed, multi-color graphics are needed.

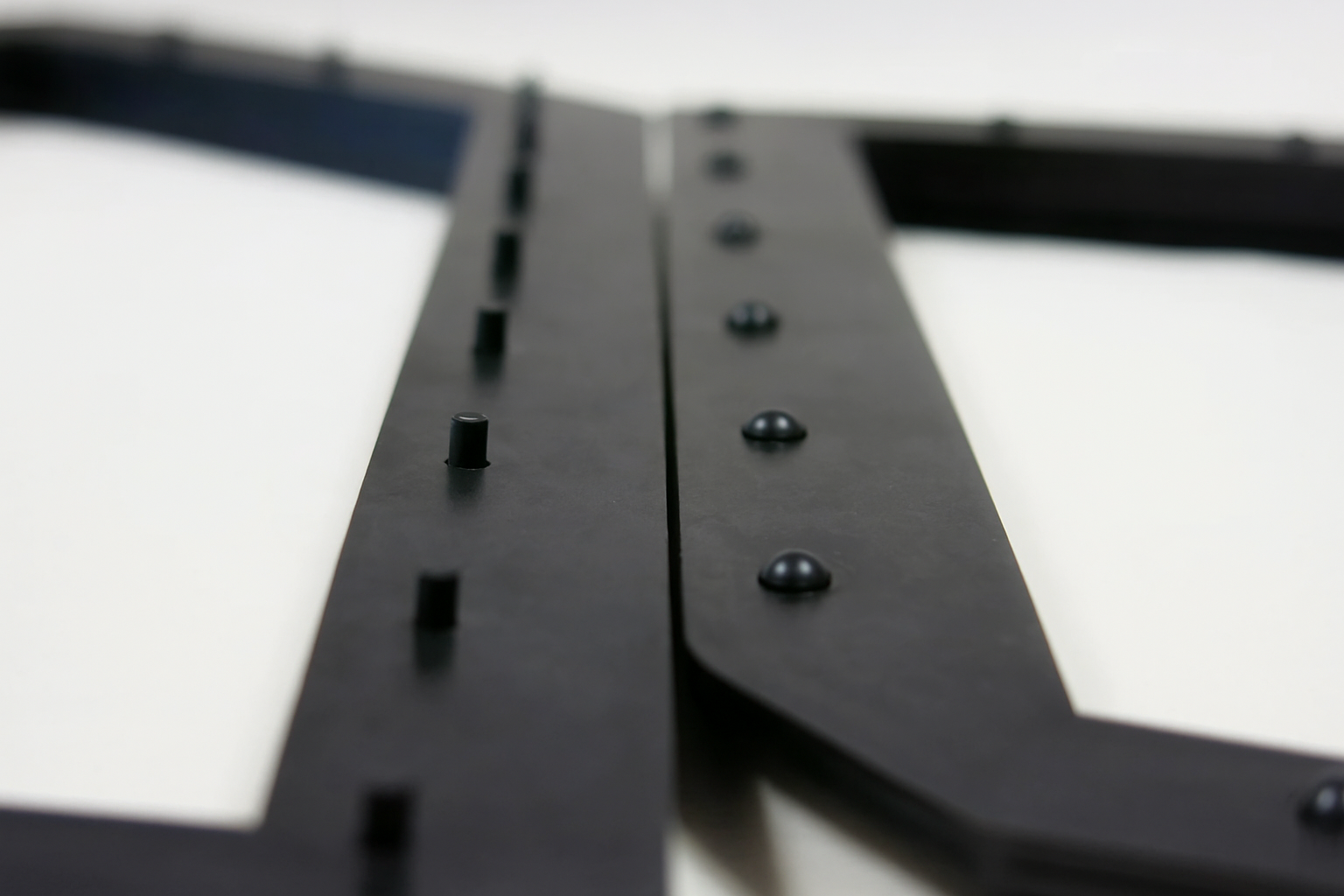

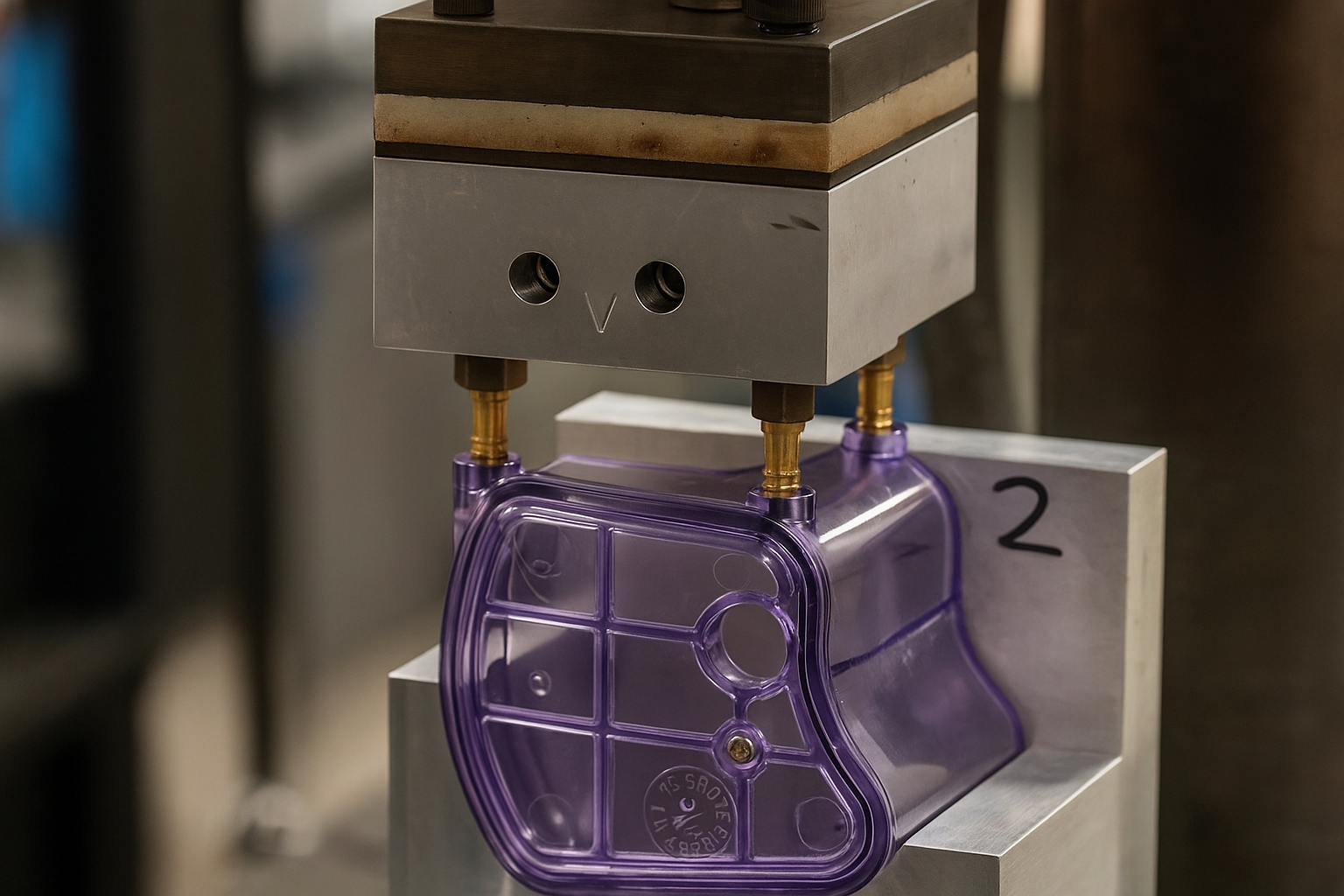

5. Heat Staking

Heat Staking

Heat staking, or thermoplastic staking, is a joining technique used to securely fasten two or more parts together, typically to permanently install a non-plastic component (like a metal insert or a PCB) into a plastic component.

Механизъм: A heated tool or metal insert is pressed against a plastic stud or boss. The heat causes the localized melting and plastic reflow of the stud’s tip. The tool then shapes the softened plastic material into a defined head (like a dome or flare) that captures the non-plastic part.

Ползи & Приложения:

It creates strong, permanent mechanical joints.

It is vital for installing threaded metal inserts (напр., hex nuts or standoffs) into plastic bosses, ensuring screws can be used repeatedly during product assembly.

Its low insertion force prevents stress and potential cracking in thin-walled or delicate plastic features.

6. Ultrasonic Welding

Ultrasonic Welding

Ultrasonic welding is a rapid and clean process that permanently joins two compatible thermoplastic components using high-frequency acoustic vibrations.

Механизъм: An ultrasonic horn (sonotrode) vibrates between 20 да се 40 kHz. This vibration is transmitted to the parts being joined, specifically concentrated at a designed interface feature called an energy director. The mechanical vibration generates intense frictional heat at this point, causing the plastic to melt and intermix. Once vibration stops, a clamping force is maintained for a specific hold time to allow the molten plastic to cool and resolidify, creating a permanent, solid-state weld.

Предимства:

Скорост: Welding cycles are typically measured in seconds.

Чистота: It requires no chemical solvents, лепила, or fasteners.

Биосъвместимост: This feature makes it highly favored in the assembly of медицински изделия and sterile packaging where chemical residues are unacceptable.

Preparing for Post-Processing: Early Planning is Key

Preparing for Post-Processing

It is a common mistake to treat post-processing as an afterthought. Waiting until a part is fully designed and molded before considering secondary operations is inefficient and costly.

Design Integration: You should actively discuss your post-processing requirements—whether it’s the need for a scratch-resistant powder coat, the exact size of a heat-staked insert, or the location of an energy director for welding—with your manufacturing partner early in the design phase.

By factoring in post-processing from the start, you can modify part geometry, choose the optimal resin, and select the most cost-effective solution, ultimately saving both time and money on your next injection molding project.

Често задавани въпроси

Q1: Does post-processing always increase the final part cost?

да, post-processing adds an additional step and labor (manual or automated) to the manufacturing flow, which increases the unit cost compared to a “straight from the mold” part. въпреки това, it’s a strategic cost. например, painting a part might increase the labor cost, but the overall project cost might be lower than using a high-cost specialty colored resin in the molding machine, or paying for more complex tooling designed to eliminate flash.

Q2: How do I choose between painting and coloring the plastic directly?

Coloring Plastic (Pigmented Resin): Ideal for parts requiring color uniformity throughout the material (if the surface gets scratched, the color remains) or for high-volume parts where consistency is critical. It’s often cheaper for simple, solid colors.

Рисуване: Ideal for achieving special effects (metallics, high gloss, soft-touch), providing functional coatings (EMI shielding), or covering defects. It offers more control over the final finish and can be cost-effective for achieving multiple colors on a single part.

Q3: What is the main difference between heat staking and ultrasonic welding?

Both are joining methods, but their mechanism differs:

Heat Staking: Употреби conductive heat from a heated tool or insert to melt and reshape a plastic stud or boss, locking a component in place. It’s generally slower than ultrasonic welding.

Ultrasonic Welding: Употреби frictional heat generated by high-frequency vibrations to melt the plastic surfaces at the joint interface. It is much faster and creates a permanent, solid-state bond directly between two plastic components.

Q4: Can all types of plastic be laser marked?

не. Successful laser marking depends heavily on the plastic’s ability to absorb the laser’s wavelength. While many common thermoplastics can be marked, some transparent or highly reflective plastics require specific additives (often black or white pigments) to facilitate the necessary chemical reaction and create a visible contrast. Consultation with a laser marking specialist is essential.

Q5: Why is surface preparation (like plasma treatment) so important for painting?

Proper paint adhesion requires high surface energy on the plastic. Many common commodity plastics (PE, ПП) are non-polar and have low surface energy. If the surface energy is too low, the paint will not wet the surface properly and will easily chip or flake off, severely compromising the finish and durability. Plasma treatment temporarily increases this surface energy, ensuring a strong, molecular-level bond between the paint and the plastic.

Q6: Can pad printing be used for highly curved surfaces?

да, this is one of pad printing’s main advantages. The silicone transfer pad is highly flexible and can deform to conform to curved, spherical, or irregular three-dimensional surfaces, allowing a crisp, flat image from the cliché (plate) to be transferred accurately onto complex geometry.