4140 steel is one of the most widely used low-alloy steels due to its high strength, toughness, and wear resistance. From automotive axles to aircraft landing gears, it’s a go-to material in high-performance industries.

This guide covers everything you need to know about 4140 steel, including its composition, mechanical properties, machining characteristics, and comparisons with other steel types.

What Makes 4140 Steel So Special?

Unlike regular carbon steel, 4140 contains chromium and molybdenum, which:

✅ Increase Strength – Handles heavy loads without deforming.

✅ Improve Toughness – Withstands impact without cracking.

✅ Enhance Wear Resistance – Ideal for gears, shafts, and high-stress parts.

📌 Common Applications of 4140 Steel

✔ Automotive: Drive shafts, axles, and suspension parts

✔ Aerospace: Landing gears, engine components

✔ Defense: Firearm barrels, bolts, military vehicle components

✔ Industrial Machinery: Hydraulic cylinders, spindles, gears

Manufacturing and Processing of 4140 Alloy Steel

Here are the complete steps for the manufacturing and processing of 4140 Alloy Steel.

1. Heat Treatment

The mechanical properties of 4140 alloy steel are the most important consideration. Besides this, heat treatment is important to obtain the right composition. The primary heat treatment processes include:

- Annealing: This process includes heating the steel to a range of between 1550F and 843C and then tempering it. Annealing improves the ability to machine the material and reduces internal stress in it.

- Quenching: The steel is heated up to 1550°F (843°C) and is instantly quenched in water or oil. Steeling overserves to increase the relative hardness of the steel. But may do this to the detriment of toughness.

- Tempering: After quenching, we undergo reheating to a lower temperature (between 400-1200°F or 204-649°C) and then cooling. Normalizing is also known as tempering. It has the function of minimizing the brittleness levels while increasing the toughness.

2. Forging and Machining

Due to the good forgeability and machinability, 4140 steel is applicable for different parts. The forging process helps shape steel at high temperatures. It improves the silicon mechanical properties as well as the grain structure. Finishing is used to get the required dimensions and surface finish. Besides this machining helps make accurate dimensions and good surface finishes.

3. Welding and Joining

It is possible to weld 4140 alloy steel, although the material must usually be preheated and welded. It may require heat treatment subsequently. Some of the methods applied for welding include gas tungsten arc welding (GTAW) and shielded metal arc welding (SMAW).

What Are the Properties of 4140 Alloy Steel?

| Property | Description |

| Strength | Excellent strength, capable of handling high stress without deformation or breakage. |

| Toughness | High toughness, meaning it absorbs impact without cracking, ideal for heavy-duty applications. |

| Hardness | High hardness when heat-treated, suitable for wear-resistant applications such as gears and shafts. |

| Machinability | Can be easily machined, especially in its annealed state, which makes it convenient for creating detailed parts. |

| Corrosion Resistance | Moderate resistance to corrosion, improved by its chromium and molybdenum content. |

Mechanical Properties of 4140 Steel

| Property | Value | Why It Matters |

| Tensile Strength | 95,000 – 115,000 psi | Withstands high stress before breaking |

| Yield Strength | 60,000 – 70,000 psi | Resists deformation under load |

| Hardness (HRC) | 22 – 30 (Rockwell) | Provides excellent wear resistance |

| Impact Toughness | 54 – 61 Joules | Absorbs impact energy, reducing fracture risk |

💡 Key Takeaway:

4140 steel is stronger than 1045 steel and tougher than 4130 steel, making it a perfect choice for high-load components.

Chemical Composition of 4140 Alloy Steel

The chemical makeup of 4140 steel is what gives it its unique properties.

| Element | Composition (%) | Purpose |

| Carbon (C) | 0.38 – 0.43 | Adds hardness and strength |

| Chromium (Cr) | 0.80 – 1.10 | Increases wear resistance |

| Molybdenum (Mo) | 0.15 – 0.25 | Boosts toughness & heat resistance |

| Manganese (Mn) | 0.75 – 1.00 | Helps hardenability |

| Silicon (Si) | 0.15 – 0.30 | Improves strength & oxidation resistance |

🔎 Did You Know?

The chromium content in 4140 helps improve corrosion resistance, but it still needs coatings for long-term outdoor use.

Machinability Rating of 4140 Alloy Steel

| Aspect | Details |

| Machinability Rating | 65% machinability (compared to 1212 steel), meaning it is moderately easy to machine but requires more effort than highly machinable steels. |

| Heat Treatment | Annealing improves machinability by reducing hardness and stress, making 4140 easier to machine. |

| Tools Required | High-speed steel (HSS) or carbide tools are recommended for machining 4140 due to its strength and hardness. |

| Cutting Speeds | – HSS tools: 70-110 surface feet per minute (SFM) – Carbide tools: 150-250 SFM |

| Coolants and Lubricants | Essential for maintaining low temperatures and preventing excessive wear on tools during the machining process. |

| Cutting Depth & Feed Rate | Moderate depths of cut and feed rates are ideal to prevent tool wear, chatter, and poor finishes. |

| Work Hardening | 4140 can work-harden during machining, making it tougher as it’s cut. Using the right speed and technique can minimize work-hardening effects. |

| Typical Applications | Automotive components (crankshafts, gears, axles), aerospace parts (landing gear, engine components), heavy machinery parts (shafts, spindles, gears). |

Common Forms of 4140 Alloy Steel

4140 alloy steel is available in a variety of forms, each suited for different manufacturing and machining processes. Below are the most common forms:

Sheets:

4140 steel is available in sheet form, typically between 1 to 10 mm thick. It is often used when customers require flat, precision-cut parts made from the alloy.

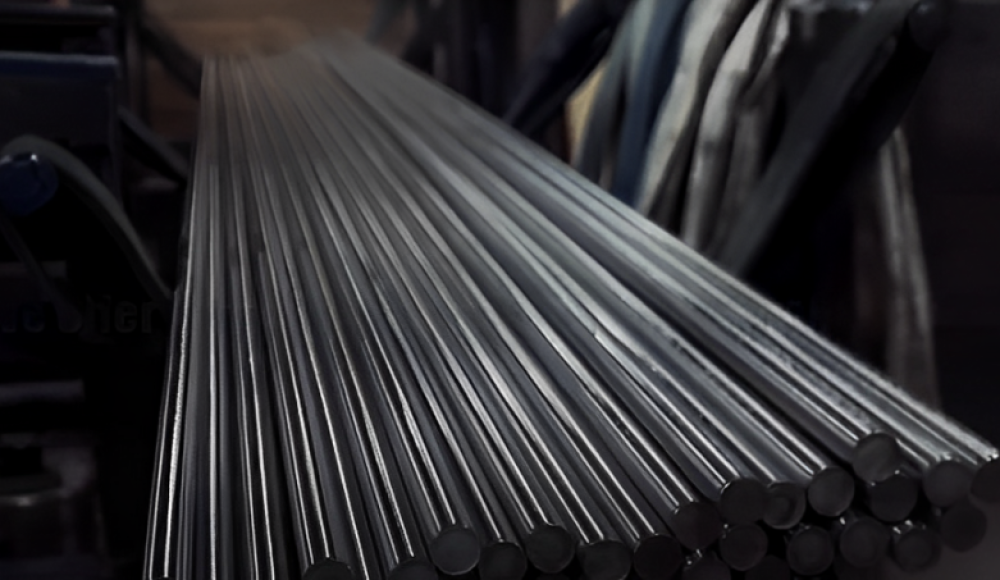

Bars:

Bars of 4140 steel are available in various cross-sections, including round, square, and flat shapes. Bar sizes can range from 6 mm to 120 mm in diameter, making it a preferred choice for CNC machining applications.

Plates:

4140 alloy steel can also be found in plate form, with thicknesses ranging from 20 mm to 120 mm, and sometimes even up to 300 mm. These plates can be heat-treated, polished, or coated depending on the application.

Hot Rolled vs Cold Drawn:

- Hot Rolled: Typically used for larger parts, hot-rolled 4140 alloy steel is treated through hot working, which shapes the steel at high temperatures. It is less strong than cold-rolled types but ideal for general applications.

- Cold Drawn: Cold-drawn 4140 steel bars are produced through a process that strengthens the steel and refines its shape, improving its machinability.

4140 Alloy Steel Equivalents

4140 alloy steel is known by different names in different countries, and each has its own national standard. Below are some international equivalents:

| Country Standard | Equivalent Grade |

| China GB/T 3077 | 42CrMo |

| Germany DIN 17200 | 1.7225/42crmo4 |

| Great Britain BS 970 | 42CrMo4 |

| Japan JIS G4105 | SCM440 |

| USA ASTM A29 | 4140 |

4140 Alloy Steel—Advantages and Disadvantages

Advantages:

- High Strength: 4140 alloy steel offers exceptional tensile, fatigue, and torsional strength, making it ideal for heavy-duty applications.

- Wear Resistance: Its chromium and molybdenum content provide enhanced wear and corrosion resistance.

- Heat Treatable: It can be heat-treated to further enhance its strength and hardness.

- Machinability: It has a machinability rating of 65%, making it easier to machine than many other high-strength alloys.

Disadvantages:

- Difficult to Weld: The welding of 4140 steel is challenging due to its carbon content. Proper preheating and post-welding heat treatment are required to avoid cracks and ensure a durable weld.

- Requires Heat Treatment: Without the right heat treatment, 4140 can be less effective in certain applications.

How to Check the Quality of a 4140 Alloy Steel Plate?

Ensuring the quality of a 4140 alloy steel plate is crucial for its performance and longevity in various applications. Whether you’re using steel in automotive, aerospace, or heavy-duty machinery, it’s essential that the material meets the required standards and performs as expected under stress. So, how can you check the quality of 4140 steel before it’s used in your project?

Tensile Testing

Tensile testing is one of the most reliable ways to evaluate the strength and ductility of 4140 steel. In this test, a sample of the steel is stretched until it breaks, and the amount of force it can withstand before failure is measured.

How It Works:

- A sample of the steel is shaped into a “dog-bone” form to ensure uniform stretching.

- The specimen is pulled under a controlled force until it stretches and eventually breaks.

- The strength and ductility of the steel are measured by recording the yield strength(the point at which it starts to deform) and the ultimate tensile strength (the maximum stress it can withstand before breaking).

Why It’s Important:

- Tensile testing provides crucial information on how the steel will perform under tension and stress.

- For 4140 steel, typical yield strength ranges from 415 MPa, with tensile strength between 850-1000 MPa.

Tensile Testing Example:

- Industry Application: Aerospace components that need to withstand high forces without failure, ensuring the material’s ability to maintain integrity under extreme conditions.

Hardness Testing

Hardness testing helps determine the material’s resistance to surface deformation, giving a good indication of its wear resistance. It’s a quick and non-destructive way to assess the material’s ability to endure abrasion and impact.

How It Works:

- The Rockwell and Brinell methods are commonly used for hardness testing.

- In the Rockwell test, a diamond cone is pressed into the material under a specific load, and the depth of the indentation is measured.

- The Brinell test uses a larger steel ball pressed into the material, measuring the size of the indentation.

Why It’s Important:

- Harder steel generally offers better resistance to wear and tear, making it suitable for high-stress applications such as gears and shafts.

- 4140 steel typically falls between 22 to 30 HRCin Rockwell hardness, depending on heat treatment.

Hardness Testing Example:

- Industry Application: In the automotive industry, parts like crankshafts or gears made from 4140 steel need to have a high level of hardness to withstand wear from continuous rotation.

Fatigue Testing

Fatigue testing evaluates how well the material can withstand repeated or cyclic loads over time. This test is particularly important for components that will be subjected to constant movement, such as drive shafts or gears.

How It Works:

- A sample is subjected to a series of loading and unloading cycles, usually at different levels of stress, until it fails.

- The number of cycles the steel can endure before failure is counted, and the fatigue limit(the stress level below which the material can endure an infinite number of cycles without failing) is determined.

Why It’s Important:

- Fatigue testing reveals how long the material can last under conditions where it experiences fluctuating stresses.

- 4140 steel is known for its fatigue strength, with a typical fatigue strength of about 310 MPa at 10^7 cycles, making it ideal for high-stress, cyclic environments.

Fatigue Testing Example:

- Industry Application: In aerospace, parts such as turbine blades and landing gears are subject to cyclic loads during every flight, so knowing the fatigue strength of the steel used is critical for safety.

Impact Testing

Impact testing assesses the toughness of a material, or its ability to absorb energy during sudden shocks or impacts. It’s particularly relevant for parts that might be exposed to sudden forces, like heavy machinery components or vehicle parts.

How It Works:

- The Charpy V-notch test is commonly used for impact testing. A notched sample is struck with a hammer, and the energy absorbed by the material is measured.

- The size of the notch determines how much impact the steel can handle before cracking or breaking.

Why It’s Important:

- Impact testing helps determine how well 4140 steel will perform in dynamic and high-impact environments.

- For 4140 steel, a typical impact value is between 54-61 J at room temperature, ensuring it can handle sudden, high-force impacts without breaking.

Impact Testing Example:

- Industry Application: For construction machinery, such as excavators or bulldozers, that often experience shocks and high-impact forces, impact testing ensures the material can withstand harsh conditions.

Surface Quality and Visual Inspection

While testing the mechanical properties is crucial, the overall surface quality of the 4140 steel plate is also an important factor. Any surface imperfections such as cracks, pitting, or scale can negatively affect the steel’s performance.

How It Works:

- Visual inspection involves examining the steel for any surface imperfections.

- Non-destructive testing (NDT) methods like ultrasonic testing or magnetic particle inspection can be used to detect internal flaws or surface cracks that are not visible to the naked eye.

Why It’s Important:

- Even minor surface defects can affect the integrity of a part, especially under high-stress conditions.

- A smooth, defect-free surface ensures better performance, especially for parts that need to be heat-treated or machined further.

Surface Quality Inspection Example:

- Industry Application: In the aerospace industry, any small defect in the steel used for critical components like landing gear could have serious consequences. Visual inspection and NDT are essential in ensuring safety.

Here’s a detailed, user-friendly, and clear comparison of the three steel types: 4140 Alloy Steel, 8620 Steel, 1045 Steel, and 4130 Steel. The information is presented in tables for easy understanding.

Differentiate Between 4140 Alloy Steel with 4340 and 1045 Steel

So, here is a detailed table for comparing 4140 alloy steel with 4340 and 1045 steel.

| Property | 4140 Alloy Steel | 4340 Alloy Steel | 1045 Carbon Steel |

| Composition | Chromium, Molybdenum | Chromium, Molybdenum, Nickel | Carbon |

| Hardness | Medium to High (28-32 HRC) | High (40-45 HRC) | Medium (12-17 HRC) |

| Tensile Strength | Up to 100 ksi | Up to 120 ksi | Up to 80 ksi |

| Yield Strength | 70-90 ksi | 90-100 ksi | 45-50 ksi |

| Impact Toughness | Good | Very Good | Moderate |

| Wear Resistance | Good | Excellent | Moderate |

| Machinability | Moderate | Moderate | Good |

| Weldability | Moderate (requires pre/post-treatment) | Moderate (requires pre/post-treatment) | Good |

| Cost | Moderate | High | Low |

| Typical Applications | Automotive components, machinery parts | Aerospace components, high-stress parts | General machinery, structural parts |

Summary

4140 alloy steel is one of the most reliable and versatile materials available, offering excellent strength, toughness, and wear resistance. It is used across many industries that require durable and high-performance components, including aerospace, automotive, military, and construction. The alloy’s ability to withstand high stress and strain makes it an ideal choice for rotating components like gears and drive shafts, as well as load-bearing components like bolts and chains.

In addition to its superior mechanical properties, 4140 alloy steel is cost-effective and available in various forms such as bars, sheets, and plates. Whether you’re looking for precision-machined parts or high-strength industrial components, 4140 steel offers unmatched performance for a wide range of applications.

FAQs

Q1. Is it possible to weld 4140 alloy steel?

Yes, it is possible to forge a joint of 4140 steel. It depends on the thickness of the component to be welded. For thick sections preheat and post-weld heat treatment must be done to obtain sound weld.

Q2. How hard is 4140 alloy steel?

Its hardness is usually between 28-32 HRC in the heat-treated condition. However, this hardness is heat-treatable dependent on certain fine heat treatment procedures.

Q3. What is the relationship between 4140 to 1045 carbon steel?

In comparison with 1045 carbon steel; 4140 alloy steel has better mechanical properties i.e. higher strength, hardness, and wear resistance. But is more difficult to process and somewhat expensive.

Q4. Is 4140 alloy steel self-corrosive?

4140 alloy steel has reasonable corrosion resistance. However, it means it needs a protective coating or any protective treatments in highly corrosive environments.

Contact us for more information.

1 thought on “A Complete Guide to 4140 Alloy Steel. Its Composition, Properties and Applications”