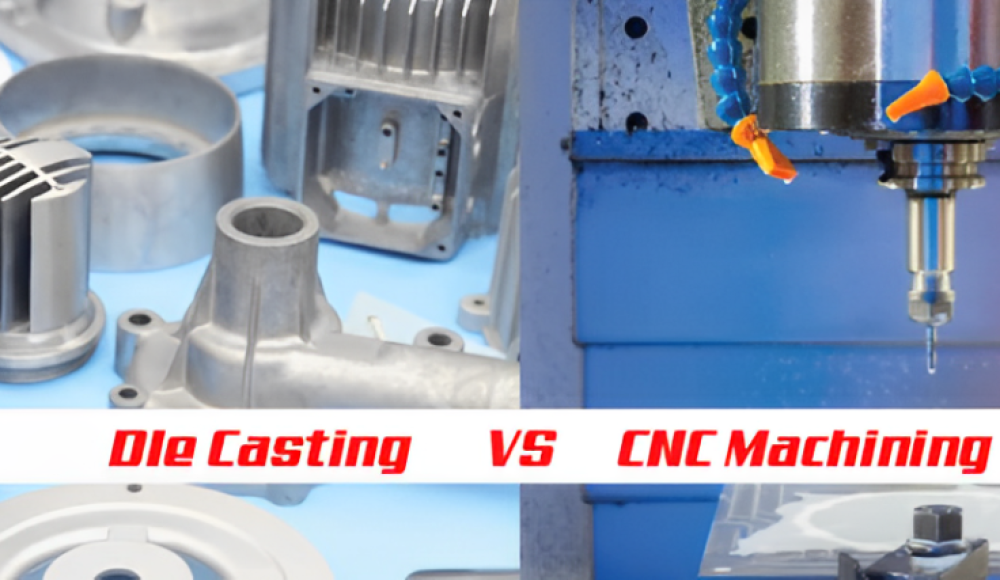

In producing complex parts, both CNC machining and die-casting processes present some value propositions. However, consider certain aspects in selecting a suitable process for the project. These may be the material requirements, production rate, and cost, among others. So, this guide will also aim to provide an overview on the major differences between die-casting vs CNC machining. It will also discuss their advantages and disadvantages, and what needs to be considered when choosing between CNC machining and die casting.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a form of production known as subtractive manufacturing, i.e. the elimination of material from a block of metal. This elimination is generally called a piece to form a finished part with specific geometry. It includes cutting materials into the desired shape with the help of computer-controlled machines. These machines can be Mills, Lathes, and routers. CNC or computer numerical control machining is highly valued for its accuracy, versatility, and versatility in material choice, including metals, plastics, and composites.

What is Die Casting?

The die-casting process involves injecting fluid material into a mold cavity through applying high pressure. The mold generally fabricated from steel, enabling the formation of parts that are intricate in form and with excellent features. After the metal has cooled down and has gained its solidity, the part is then expelled from the mold. It is used where large quantities of the same metal part like nonferrous metals are being manufactured. These materials can be aluminum, zinc, and magnesium.

Material Considerations: Which Process Suits Your Needs?

Choosing the right material for your project is a major factor when deciding between CNC machining and die casting.

CNC Machining: A Broad Material Selection

✅ Works with a variety of materials, including:

- Metals: Aluminum, stainless steel, titanium, brass, copper, magnesium, etc.

- Plastics: ABS, PEEK, Nylon, Polycarbonate, Acrylic, etc.

- Composites and even wood.

💡 Best for:

- High-strength, high-performance materials.

- Specialized applications requiring specific properties (e.g., corrosion resistance, heat resistance).

- Prototyping and small batch production with material flexibility.

Die Casting: Limited to Non-Ferrous Metals

✅ Common die-casting materials include:

- Aluminum(lightweight, corrosion-resistant, used in aerospace and automotive).

- Zinc(high precision, good for small parts).

- Magnesium(strong, lightweight).

💡 Best for:

- High-volume production of metal parts.

- Cost-effective solutions for aluminum, zinc, or magnesium products.

- When high thermal conductivity or electrical properties are needed.

🔴 Limitations:

- Does not support plastic or composite materials.

- Less material flexibility compared to CNC machining.

Precision and Complexity: Comparing Tolerances and Design Capabilities

CNC Machining: Unmatched Precision and Complexity

✅ CNC machining is ideal for high-precision and complex designs, with tolerances as tight as:

🔹 ±0.0005 inches (±0.0127 mm)

💡 Best for:

- Aerospace, medical, and automotive parts requiring extreme accuracy.

- Components with intricate details, deep cavities, sharp edges, and complex geometries.

Die Casting: Consistency in Simpler Geometries

✅ Die casting produces uniform parts with tolerances typically between:

🔹 ±0.002 inches (±0.05 mm) to ±0.005 inches (±0.13 mm)

💡 Best for:

- Mass production of parts with consistent shapes and smooth surfaces.

- Designs that don’t require extreme precision or intricate details.

🔴 Limitations:

- Not ideal for ultra-complex designs.

- Shrinkage and porosity can occur, requiring post-machining in some cases.

Production Volume: Scalability and Cost-Effectiveness

CNC Machining: Best for Low to Medium Volumes

✅ Suitable for:

- Prototyping and small batch production

- Custom and one-off parts

- High-mix, low-volume manufacturing

💲 Cost Factor:

- Higher cost per part than die casting.

- No mold required, so initial setup costs are lower.

Die Casting: Best for High-Volume Production

✅ Suitable for:

- Mass production (thousands to millions of units).

- Consumer electronics, automotive, and hardware parts.

💲 Cost Factor:

- High initial mold cost, but low per-unit production cost.

- The more parts you produce, the more cost-effective die casting becomes.

🔴 Limitations:

- Not cost-effective for low-volume production due to high mold costs.

- Design changes require a new mold, adding to expenses.

Surface Finish and Aesthetics

CNC Machining: Superior Surface Finishes

✅ Produces smoother, high-quality finishes right out of the machine.

✅ Additional finishing options: polishing, anodizing, bead blasting, painting.

💡 Best for:

- Products requiring a premium, polished appearance.

- Medical, luxury, and high-performance applications.

Die Casting: Uniform but May Require Post-Processing

✅ Good surface finish but often requires sanding, powder coating, or polishing.

✅ Can integrate textures, logos, and markings directly into the mold.

💡 Best for:

- Mass production where aesthetic consistency is important.

🔴 Limitations:

- May show small imperfections, porosity, or surface shrinkage.

Durability and Strength: Which Process Offers More?

CNC Machining: High-Strength, Durable Parts

✅ Stronger parts due to solid billet material (no porosity or weak points).

✅ Customizable reinforcements for stress-prone areas.

💡 Best for:

- High-stress applications in aerospace, medical, and industrial machinery.

Die Casting: Durable but Limited to Casting Materials

✅ Strong, lightweight metal parts with good dimensional stability.

✅ Thinner walls possible, making parts lighter than machined ones.

🔴 Limitations:

- Weaker than machined parts due to porosity and material limitations.

- Not suitable for extreme loads or impact resistance.

Customization and Flexibility: Which Process Adapts Better?

CNC Machining: Highly Customizable

✅ Easily modified designs (just update the software, no tooling required).

✅ Ideal for prototypes and iterative designs.

💡 Best for:

- Custom one-off parts, R&D, and industries requiring frequent modifications.

Die Casting: Best for Fixed, High-Volume Production

✅ Molds last for thousands/millions of units.

✅ Consistent parts with tight process control.

🔴 Limitations:

- Expensive to modify molds(not ideal for flexible design needs).

Cost Comparison: CNC Machining vs. Die Casting

| Factor | CNC Machining | Die Casting |

| Precision | ±0.0005 inches | ±0.002 to 0.005 inches |

| Material Choices | Metals, plastics, composites | Aluminum, zinc, magnesium |

| Production Volume | Low to medium | High-volume |

| Setup Cost | Low | High (molds are expensive) |

| Per-Part Cost | Higher | Lower for large batches |

| Customization | Very flexible | Limited once mold is made |

| Strength | Stronger, no porosity | Can be weaker with porosity |

| Surface Finish | Excellent | Good, may need post-processing |

Advantages and Disadvantages of CNC Machining

The following are the pros and cons of CNC Machining. These will help us understand how CNC machining is better for our projects and its limitations.

Pros:

- High precision and accuracy.

- It can be used with many different materials and many colors.

- Applicable for firms that produce moderate levels of units with low to medium variability.

- Faster time to deploy and lower lead time.

- Flexibility in design modifications.

Cons:

- This process consumes a lot of materials to arrive at the final product. Therefore, it leads to wastage.

- Different cost structures for mass production are based on the total cost per part in a mass-production operation. This cost is higher for a large number of operations performed.

- Of course, working extra hours on complicated parts is another critical issue to consider in machining.

- If the tool is only used and the technique is not implemented in the existing machines. It is limited to the tool’s mobility.

- Geometries that involve hatchings and other such structures, may need several operations to be completed.

Advantages and Disadvantages of Die Casting

The following are the pros and cons of die-casting:

Pros:

- Cost-effective for high-volume production.

- High detail and the possibility to make complicated forms, due to thin walls.

- No need for re-shaping which reduces the use of more material than required.

- It lengthened the life of cast parts making it possible to achieve high strength.

- High and uniform dimension accuracy, along with fabrication accuracy.

Cons:

- High initial tooling costs.

- These limitations apply only to several metals and alloys.

- Therefore, longer lead times are expected to be inevitable when it comes to the development of tooling.

- Not very useful for small-batch production.

- Some features of the castings that may be attained with sand casting method: Potential for porosity and other casting defects.

Which Process is More Appropriate for My Project?

For a given project, you can choose between CNC machining and die casting depending on what will suit the project best. If you require high precision parts, low volumes, or require materials that cannot be used in die casting. So, you can opt for CNC machining as it is suitable for use. On the other hand, if you are making large iron machined parts with small features. Then die casting can prove to be more economical and effective.

Applications of CNC Machining

- Aerospace components

- Automotive parts

- Medical devices

- Precision tools

- Electronics housings

- Custom prototypes

- Industrial machinery parts

Applications of Die Casting

- Automotive engine components

- Consumer electronics casings

- Hardware tools

- Household appliance parts

- Telecommunications equipment

- Lighting fixtures

- Industrial machinery components

Conclusion

In conclusion, CNC machining and die casting are two distinct manufacturing procedures. They both need to be compared based on certain factors including material type, parts quantity that you want to produce, complexity of the part, and price. Besides this, each of the two processes has its strengths and weaknesses. So, we know these will help determine which method to adopt in the manufacturing process.

Frequently Asked Questions

Q1. What can be fabricated in CNC?

CNC machining can manipulate a lot of materials such as metal, plastic, composite, and even wood.

Q2. Is die casting appropriate for making small quantities of parts?

Absolutely yes. Die casting is more suitable for large production since it requires high initial costs for tool preparation.

Q3. Is it possible to create parts with complicated shapes using CNC machining?

Yes, the machining done with the use of a computer can create such small designs. But it may require more than one process.

Q4. What are the main benefits of die-casting?

It is suitable to manufacture parts in a large number of pieces. These pieces have uniform quality and small intricate features.

Q5. What is the difference between lead times for cnc machining and die casting?

CNC machining normally takes a shorter time than die casting. Therefore, it is preferable for prototype runs and limited production quantities.

2 thoughts on “A Complete Guide on Die Casting Vs CNC Machining”