In the world of manufacturing, accuracy, and efficiency are essential factors when producing high-quality metal components. Likewise, die casting and investment casting: the two widely used techniques, have revolutionized the industry by offering distinct advantages in terms of material versatility, proficiency, and meticulousness. On one hand, die casting excels in high-volume production with flawless dimensional accuracy while on the other hand investment casting tends to stand out for its ability to generate complex designs with a wide range of metals. Overall, understanding the differences between these processes is crucial for manufacturers seeking to optimize their production strategies, such that exceptional results can be achieved.

What is Die Casting?

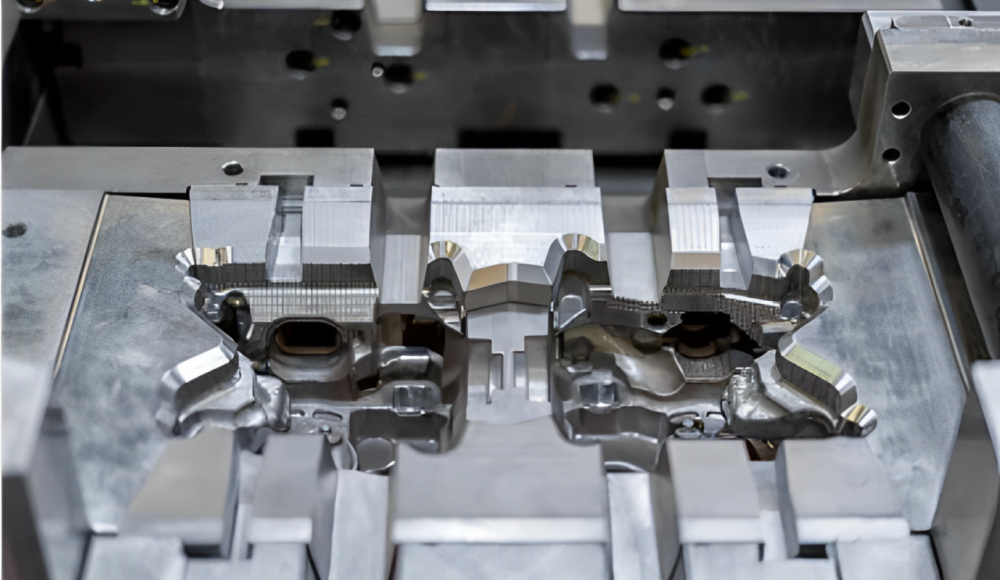

Die casting – a manufacturing process during which molten metal is infused in a steel mold under high pressure. This procedure allows speedy production of complex and explicit metal parts with high dimensional accuracy and seamless surface finishes. This method is commonly used with non-ferrous metals such as zinc and aluminum. Thus, overall die casting is ideal for achieving high-volume production, making it specifically popular in industries, i.e. electronics and automotive. Die casting is ideal due to its minimal machining requirements and precise results.

What is Investment Casting?

The lost-wax casting or ‘Investment casting’ consists of wax pattern production for the part. It is usually coated with a ceramic material to form a mold. Then the wax is allowed to melt. Once this is done, the molten metal is cast into form the mold. Here it gets the features and shapes of mold. Moreover, the investment casting method is quite simple as many metals may be used. Besides this, it gives a high degree of accuracy and surface finish of the parts. Investment casting is widely applied to low to moderate-production value parts of different industries, i.e. medical, aerospace, and artistic industries.

Complete Die Casting Process

Here the molten metal is injected into a steel mold under intense pressure. Later, the metal tends to fill the mold cavity quickly, taking the shape of the preferred segment. When the metal cools and solidifies in the die, the mold is carefully dismantled to release the finished component. Once it is expelled, the part is inspected for potential defects and even undergoes additional processes if necessary such as trimming to eliminate any excessive amount of material or flash.

Flash is the thin layer of metal that is sometimes formed around the edges. Moreover, quality control checks are also carried out to ensure the part meets stipulated tolerances and standards respectively. At last, the component is available for assembly or any further integration into the products if needed.

Complete Investment Casting Process

The investment casting process proceeds with the formation of a wax or resin pattern of the part, often by using injection molding. This pattern tends to imitate the details and shape of the final components. This wax pattern is then coated with a series of ceramic layers to create a resilient mold frame. It is ensured that each layer is hardened before applying the next. The coated pattern is then heated in an autoclave or furnace to melt and thus drain out the way, only leaving behind a hollow ceramic shell.

At this point, the ceramic mold tends to be hardened. Molten metal is then poured into this empty ceramic shell to fill the cavity left by the wax, thus taking the shape of the original pattern. Once it imitates its shape and solidifies, the ceramic shell is detached, revealing the cast metal part. The casting is then cleansed to extract any remaining ceramic material.

What is the Difference Between Die Casting vs. Investment Casting?

Let’s discuss a few aspects to differentiate Die casting from investment casting:

1. Process Type

Die casting is a process that includes the use of a steel mold in which molten metal is forced. It is known as die casting and is most appropriate for use in mass production. Investment casting or lost-wax casting is achieved using a wax model coated in ceramic to form a mold to achieve complex parts.

2. Material Compatibility

Here die casting technique is mainly employed on nonferrous materials including aluminum, zinc, and magnesium. Investment casting is more versatile and is capable of dealing with more variety of metals. These may include ferrous and non-ferrous alloys such as steel and titanium.

3. Production Volume

Die-casting is cheaper for large quantities so its application is well-suited for anything from thousands to millions of parts. Investment casting is ideal for low to medium-production runs and also for complex or detailed parts production.

4. Part Complexity

Die casting is good at intricate designs, especially for designs with thin sections. However, it cannot produce designs with high levels of complexity. Investment casting also performed well to produce complex and intricate shapes and designs with thin walls.

5. Surface Finish

Die casting offers good surface finishes and has to undergo polishing afterward. Investment casting also yields improved surface quality with extremely intricate patterns coming right from the mold. So, it rarely requires additional finishing.

6. Tooling Costs

Die casting however has high initial tooling costs because the molds are made of steel. It takes less time. In the case of investment casting, it is good for short runs or preliminary designs due to lesser tooling costs.

7. Lead Time

The lead time in die casting is comparatively long because of the time required to make the mold. Its actual production process is fast once the mold is available. Typically, investment casting has improved on the typical lead times depending on the volume of production required.

8. Applications

Some die-casting applications are used in automotive parts, consumer electronics, and engine parts which require large volumes and high strength. Investment casting is popular in aerospace structures, medical products, and items with tiny intricate designs, and more detailed functions.

The following table gives you a summary of the difference between Die-casting vs CNC Machining:

| Aspect | Die Casting | Investment Casting |

| Process Type | High-pressure metal injection into steel molds. | Wax model, ceramic mold, filled with molten metal. |

| Material Compatibility | Aluminum, zinc, and magnesium (non-ferrous metals). | Wide range, including steel, aluminum, and titanium. |

| Production Volume | High-volume (thousands to millions). | Low to medium volume (small batches). |

| Part Complexity | Complex shapes, limited fine detail. | Excellent for intricate, detailed parts. |

| Surface Finish | Good, may need finishing. | Superior finish, minimal finishing required. |

| Tooling Costs | High due to durable steel molds. | Lower, suited for smaller runs. |

| Lead Time | Longer for mold creation; fast production after. | Generally shorter, ideal for small batches. |

| Applications | Automotive, electronics, engine parts. | Aerospace, medical, jewelry, complex machinery. |

When to Choose Die Casting?

Here are some points where you can choose die-casting;

- High Production Volume: Die casting is quite an affordable option if you require hundreds of thousands or millions of similar components. You only need to serve over mold manufacturing.

- Material Requirements: Die casting is usually recommended if your project involves non-ferrous metals, such as aluminum, zinc, or magnesium.

- Durability and Strength: It leads to the formation of robust parts of several industries. They can be used in automotive industries, electronics, or other machinery.

- Cost Consideration: It’s worth knowing that although tooling is expensive at first, its cost per piece is relatively low with large production runs.

When to Choose Investment Casting?

The following are some points where you can opt investment casting process.

- Complex Designs: Although the wax master model is complex and costly. Besides this, investment casting offers better results where your part has fine features, thin walls, and intricate details.

- Material Versatility: Where your project demands a particular material, especially if it is high-performance alloys or ferrous metals. So, here it is beneficial to go with investment casting.

- Low to Medium Production Volume: Investment casting is cheap for small quantities or while generating prototypes. Besides this, it is closer to the requirement to change designs frequently.

- Superior Surface Finish: Another advantage of investment casting is that the production is done in this investment casting. So, it will enable the surface to be free from roughness, and frequently the final work will only require a marginal polish.

Conclusion

In conclusion, the choice between die casting and investment casting depends on various factors, i.e. production requirement, material type and specifications, the complexity of the part, and costs and additional factors. Based on the project demands against all these elements, you can make a decision that guarantees both the quality and the productivity of your manufacturing.

Contact us for more information.

Frequently Asked Questions

Q1. What are the differences in tooling costs between the two processes?

- Die Casting: Increased tooling cost due to the usage of durable steel material in the manufacturing of the molds.

- Investment Casting: It can afford cheaper wax patterns and ceramic shells being in a position to lower our tooling costs.

Q2. And which process is better for complex parts?

- Die Casting: Copes well with intricate forms but is not as good with details.

- Investment Casting: Perfect for detailed artwork and designs especially those requiring intricate work.

1 thought on “Die Casting Vs Investment Casting”