If you’ve ever worked in industries where the stakes are high and the environment is harsh, then you’ve probably encountered the powerhouse material known as Inconel. This isn’t your everyday metal—it’s a family of nickel-chromium-based superalloys that thrive where other metals buckle under pressure, heat, and corrosion.

Inconel is a go-to solution when regular materials just don’t cut it—literally. It retains its strength and structure even when temperatures soar beyond 1300°F (700°C). Thanks to its incredible resistance to oxidation and corrosion, it’s a favorite in industries such as aerospace, marine, chemical processing, and nuclear energy.

But what really sets it apart is its ability to maintain its mechanical properties across a wide temperature range. Whether it’s a jet engine turbine blade or a deep-sea oil pipe, Inconel stands firm. The most commonly used grades like Inconel 600, 625, and 718 each bring unique attributes to the table—from weldability to creep resistance.

So, while Inconel is a beast to work with (as we’ll cover in detail), its strength, resilience, and adaptability make it indispensable for engineers and manufacturers who demand performance over convenience.

Why Inconel is a Popular Choice in High-Performance Industries

Inconel isn’t just another metal alloy—it’s the Ferrari of metals in high-stress, high-stakes industries. The demand for performance has never been higher, and materials like Inconel help companies meet—and often exceed—industry standards.

Let’s break down why it’s such a hot commodity:

Heat Resistance: Inconel maintains tensile strength and form even at extremely high temperatures, making it perfect for gas turbines, nuclear reactors, and jet engines.

Corrosion Resistance: Inconel shrugs off corrosive environments. From salty marine conditions to acidic chemical plants, it resists degradation where most metals would dissolve.

Mechanical Strength: With a high nickel content, Inconel offers unmatched durability, especially when under stress and tension. This makes it ideal for aerospace and submarine components.

Longevity: It’s tough, it lasts longer, and it doesn’t require constant replacement—saving money and headaches in the long run.

Industries that rely on Inconel are usually pushing limits. Inconel doesn’t just perform—it dominates in hostile environments, helping innovations soar higher, dive deeper, and last longer.

Understanding the Challenges of Machining Inconel

Is Inconel Difficult to Machine?

Yes—and that’s putting it mildly. If materials were students, Inconel would be the one who aces all exams but never cooperates during group projects. It’s notoriously difficult to machine due to its toughness, high heat resistance, and tendency to work harden in a flash.

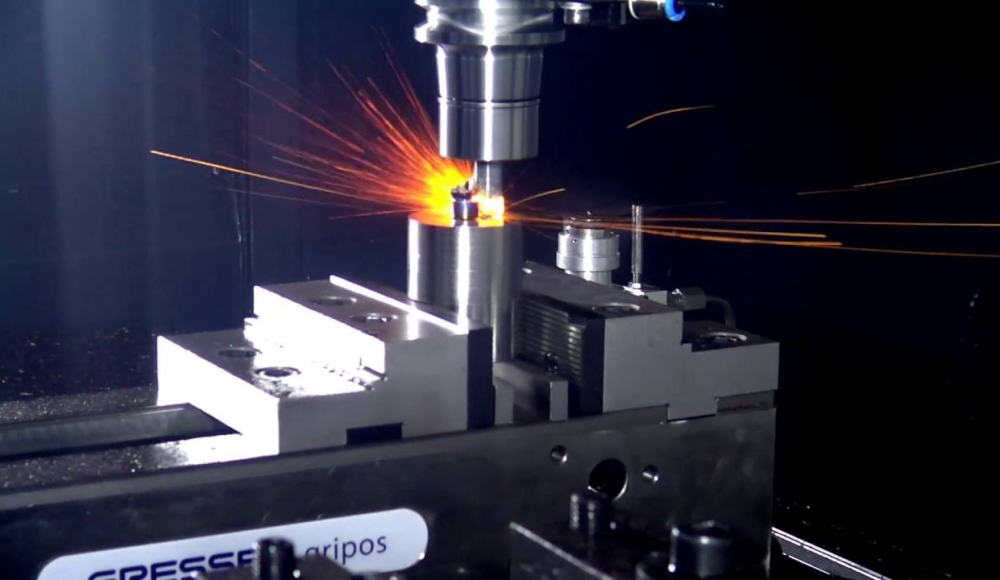

When you’re trying to shape something as resilient as Inconel, every cut becomes a battle. The cutting tools wear down fast, the heat builds up like a furnace, and if you don’t adjust your approach, you’ll find your expensive tools burning out before lunch.

The core issues?

Work Hardening: As soon as you cut it, Inconel starts getting harder. And then harder. And then harder. It’s like trying to carve steel that turns into diamond the moment you touch it.

Tool Wear: Expect your tools to degrade quickly unless you’re using the right combination of coatings, geometries, and cooling techniques.

Heat Generation: With its low thermal conductivity, Inconel holds onto heat. This stresses your tools and can even damage your part if not controlled.

Bottom line: machining Inconel is a challenge best handled by experienced machinists using specialized tools and fine-tuned parameters.

Machinability Rating of Inconel and What It Means

Inconel sits at about 12% on the AISI Machinability Index. To put that into context, carbon steel rates at 100%, and aluminum often clocks in over 300%. That means machining Inconel takes nearly ten times the effort of machining mild steel—and that’s on a good day.

Why such a low rating? The index takes into account things like:

Tool wear rate

Surface finish quality

Required horsepower

Metal removal rate

With Inconel, each of those metrics takes a hit. The tools wear down fast, the surface finish can be tricky, and even the feed rates need to be kept low to avoid catastrophic tool failure. All of this adds time, effort, and cost to your machining operation.

So, when we say Inconel has a 12% machinability rating, what we’re really saying is: it’s built like a tank, and it machines like one too.

What Makes Inconel Machining So Challenging?

Work Hardening Characteristics

The most infamous trait of Inconel is its ability to work harden faster than you can say “spindle speed.” Each cut makes the material tougher, which in turn makes the next cut even harder. It’s a vicious cycle. If your tool hesitates, skips, or rubs—boom, the workpiece just got harder.

How to manage this?

Consistent tool engagement is key.

Use sharp tools and constant feed rates.

Avoid dwelling the tool in one spot.

It’s like dealing with a stubborn knot—keep the pressure steady and don’t back off, or it’ll only get worse.

High Cutting Forces & Tool Wear

Machining Inconel is like cutting stone with scissors if you don’t have the right setup. The alloy’s high tensile strength means cutting forces are elevated, which translates to:

Increased power consumption

Greater vibration

Faster tool fatigue

Tool life goes downhill fast unless you’re equipped with premium carbide or ceramic tooling, ideally with heat-resistant coatings like TiAlN.

Expect to:

Change tools more often

Use low cutting speeds

Monitor inserts for micro-chipping

Heat Generation and Thermal Management

Since Inconel doesn’t conduct heat well, all that friction and cutting energy builds up fast. And where does that heat go? Right into your tool and the cutting zone.

That means:

Tools lose hardness quickly

Surface finish degrades

Workpieces might distort from thermal expansion

Effective coolant systems—especially high-pressure or cryogenic cooling—are essential. It’s not just about keeping the part cool. It’s about extending tool life, improving chip evacuation, and preserving dimensional accuracy.

Risk of Workpiece Deflection

Inconel is strong, but if you don’t secure it well, it can still flex under intense pressure. Combine that with high cutting forces and you’ve got a recipe for dimensional inaccuracy, or worse—scrap parts.

To prevent this:

Use rigid fixturing

Shorten the tool overhang

Choose machines with high spindle stiffness

Even a slight vibration can cause chatter, which ruins the surface finish and contributes to work hardening. So if you’re aiming for tight tolerances, rigidity is your best friend.

Essential Tools for Inconel Machining

Choosing the Right Cutting Tools

When it comes to Inconel, picking the right cutting tool is not optional—it’s essential. This alloy eats through tools like a hot knife through butter, especially if you’re using standard tooling. That’s why your weapon of choice needs to be specifically designed to handle the stress, heat, and toughness of this superalloy.

So, what’s the gold standard for Inconel cutting tools?

Carbide Tools: Your baseline tool for Inconel machining. These tools should feature a high positive rake angle, which reduces cutting force and helps chip flow smoothly. This reduces work hardening and prolongs tool life.

Coated Tools: Tools with TiAlN (Titanium Aluminum Nitride) or AlTiN coatings are your best bet for thermal resistance. These coatings act as a shield, letting your tool withstand the intense heat generated when cutting Inconel.

High-Speed Steel (HSS): Only good for roughing or light cuts. They wear out fast and are not ideal for sustained operations on tough alloys like Inconel.

Ceramic Tools: These are excellent for continuous cuts, especially at high temperatures. Their biggest strength? They don’t lose hardness when the going gets hot.

Geometry also matters—use tools with sharp cutting edges, optimal flute designs, and chip breakers that help prevent the chips from being recut. Think of your tool like a finely tuned blade—it needs to slice efficiently, not hack away.

The Role of Coolants

Coolants in Inconel machining aren’t just helpful—they’re mission-critical. Because Inconel is such a poor heat conductor, most of the heat generated during machining stays in the cutting zone. Without an effective coolant, you’ll burn up your tools and potentially damage your workpiece.

So, what kind of coolant setup should you use?

Emulsion Coolants: These are common and offer decent cooling properties. They’re a mix of water and oil, delivering moderate heat control and lubrication.

High-Pressure Coolants: These are the MVPs. They blast coolant directly into the cutting zone, ensuring chip evacuation and temperature control. This is especially helpful in deep-hole drilling or when you’re milling complex features.

Cryogenic Cooling: Using liquid nitrogen or CO₂, this method takes heat control to another level. It’s cutting-edge—literally—and helps reduce tool wear significantly.

Minimum Quantity Lubrication (MQL): Not recommended for Inconel. It can’t dissipate enough heat to keep up with the material’s thermal load.

Remember, coolant delivery is as important as the type. Use precision nozzles and make sure coolant reaches the cutting interface—where the real battle is happening.

Machining Parameters Optimization

Inconel doesn’t play nice with guesswork. You need to dial in your machining parameters with surgical precision to prevent tool damage, overheating, and poor surface finish. The three main variables to tweak are:

Cutting Speed

Go low and slow. Typical speeds range from 20 to 60 m/min, depending on the grade and tooling.

Too fast, and you’ll overheat your tool and workpiece.

Slower speeds reduce the risk of work hardening and tool wear.

Feed Rate

Keep it steady and moderate. Inconel punishes hesitation. If your tool skips or rubs instead of cutting, it’ll trigger rapid work hardening.

Choose feed rates that ensure constant engagement with the material.

Depth of Cut

Deep enough to remove material efficiently, but not so deep that you stress the tool.

Generally, stick to light-to-moderate cuts (0.5 mm–1.5 mm) unless your setup is extremely rigid.

These parameters should always be backed by real-time observation. Monitor the chips—long, shiny chips are bad news. Ideally, you want short, curled chips that indicate clean, efficient cutting.

Importance of Rigid Setups

If Inconel had a weakness, it would be vibration. And once it starts vibrating, all hell breaks loose—chatter marks, poor surface finish, dimensional errors, and accelerated tool wear. That’s why your setup needs to be as rigid as a rock.

Key rigidity strategies include:

Tool Holders: Use hydraulic chucks, shrink-fit holders, or heat-shrink tool systems. They grip the tool with high precision, reducing runout and vibration.

Workholding: Clamp your workpiece firmly. Use vise jaws, fixture plates, or custom clamps that don’t let the material move or flex.

Machine Choice: Machines with high-torque spindles, rigid columns, and damped tool paths are ideal. A cheap, wobbly CNC router won’t cut it—literally.

Reduce Overhang: Keep your tool’s stick-out as short as possible. The longer the reach, the more prone it is to deflection.

The goal is to create a stable machining environment. With Inconel, even the smallest flex or vibration can throw everything out of whack.

Advanced Machining Strategies for Inconel

Tool Wear Inspection and Maintenance

Tool wear with Inconel isn’t just probable—it’s inevitable. But that doesn’t mean you can’t get ahead of it. In fact, regular tool inspection and replacement can drastically improve your part quality and reduce overall costs.

How to stay on top of tool wear?

Inspect After Every Run: Especially for long jobs or when using smaller inserts. Look for wear at the tip and flanks of the tool.

Use a Microscope or Loupe: Visual inspection helps identify micro-cracks, chipping, or coating delamination.

Track Tool Life: Use software or manual logs to monitor how long each tool lasts under specific conditions. Replace them on schedule, not when they fail.

Regrind If Possible: Carbide tools can often be resharpened multiple times, which helps reduce long-term tool expenses.

Staying proactive with your tooling strategy means fewer surprises, smoother finishes, and higher yield on every job.

Post-Machining Processes for Inconel

Grinding, Honing, and Finishing Techniques

Once you’ve battled through the heat, stress, and wear of machining Inconel, you’re not done yet. In most high-spec industries, especially aerospace and energy, post-machining processes are critical to achieving the final part’s precision, surface quality, and compliance.

Let’s start with grinding. Inconel’s surface, after milling or turning, may still retain micro-burrs or surface inconsistencies. That’s where grinding shines. Using aluminum oxide or cubic boron nitride (CBN) wheels, you can reach tight tolerances and mirror finishes. But the key is controlling heat—just like during machining, thermal management is vital. Overheating during grinding can induce surface cracks or even alter the metallurgical properties of Inconel.

Next up, honing. This is used when you need to achieve super-precise internal diameters, such as in valve bodies or hydraulic cylinders. Honing removes small amounts of material and corrects geometry issues while polishing the internal surfaces to perfection.

There’s also lapping—ideal for achieving ultra-flat surfaces—and vibratory tumbling, useful for edge deburring and surface conditioning in batch processes.

Tips for better post-processing:

Always use coolants or lubricants designed for nickel alloys.

Keep the pressure consistent; too much force during grinding or honing can cause hardening.

Test surface finishes with precision gauges or profilometers.

In short, finishing Inconel is like fine-tuning a sports car engine—you’ve done the heavy lifting, now you make it shine.

Surface Treatments and Coatings

Machining Inconel is tough—but often, it’s just step one. In many cases, especially in aerospace, nuclear, or chemical processing applications, components require surface enhancements to improve performance, reduce friction, or resist wear even further.

Common treatments include:

Passivation: This chemical process removes free iron and other contaminants, enhancing Inconel’s already impressive corrosion resistance. It’s a must for medical and marine applications.

Shot Peening: Small metal or ceramic balls are blasted onto the surface to introduce compressive stress. This boosts fatigue strength and extends service life—especially valuable for aerospace engine parts.

Coatings (PVD/CVD): Applying a hard coating such as TiN (Titanium Nitride) or TiAlN through Physical Vapor Deposition (PVD) adds wear and thermal resistance. It’s great for moving parts or anything exposed to high stress.

Anodizing and Electroplating: While not as common for Inconel, they may be used for hybrid assemblies requiring mixed metal interfaces.

These treatments add significant value. They don’t just protect the component—they turn it into a precision-built, battle-ready asset for whatever demanding environment it’s going into.

Machining Different Grades of Inconel

Inconel 600 – Properties, Applications, and Tips

Inconel 600 is a workhorse of the Inconel family. It’s a nickel-chromium alloy with excellent oxidation resistance and the ability to handle a wide range of temperatures. That’s why it’s popular in chemical processing, nuclear reactors, and heat treatment equipment.

Key Features:

Great resistance to chloride-ion stress corrosion

Maintains strength at high temps (up to 2000°F)

Excellent formability and weldability

Machining Tips:

It work hardens less aggressively than Inconel 718, but don’t let your guard down.

Use sharp carbide inserts and keep feed rates consistent.

Opt for flood cooling or high-pressure coolant to manage heat and improve chip evacuation.

Inconel 600 may not be the toughest to machine in the family, but it still demands precision and attention to tool wear and heat.

Inconel 625 – Strength and Corrosion Resistance

Inconel 625 is often chosen when superior corrosion resistance and strength without heat treatment are top priorities. Its added molybdenum and niobium content make it ideal for marine environments, offshore oil rigs, and chemical plants.

Key Features:

High tensile and fatigue strength

Resistant to pitting and crevice corrosion

Operates up to 1800°F

Machining Tips:

This alloy is tougher than Inconel 600, so you’ll need tougher tools—think ceramic or coated carbide.

Keep cuts shallow but aggressive, avoiding light scraping that can lead to work hardening.

Drill with internal coolant-fed tools to extend tool life.

Inconel 625 is a machinist’s challenge but an engineer’s dream—what it lacks in ease of cutting, it makes up for in unbeatable performance under pressure.

Inconel 718 – Toughness and High-Temperature Machinability

Now we’re talking about the big boss of the Inconel family—Inconel 718. This alloy is known for its exceptional strength at elevated temperatures, as well as its creep resistance, fatigue life, and crack resistance. It’s the go-to for aerospace engines, spacecraft, and nuclear reactors.

Key Features:

Heat-resistant up to 1300°F

Precipitation-hardened with niobium and molybdenum

High yield and tensile strength

Machining Tips:

Inconel 718 will fight you every step of the way. Use only premium carbide or ceramic tooling.

Slow speeds, moderate feed, and rigid setups are non-negotiable.

Employ cryogenic cooling for high-volume production.

Inconel 718 machining is not for the faint-hearted, but once you master it, you’re working with one of the most advanced materials on the planet.

Awesome! Let’s complete the article with Step 4, covering the final sections 16–20 and wrapping up with a conclusion and FAQs.

Machining Benefits of Inconel 625 and 718

Durability in Extreme Environments

When the going gets tough, Inconel 625 and 718 get tougher. These two grades represent the pinnacle of what advanced nickel alloys can do when exposed to the harshest environments imaginable.

Why does this matter?

In applications like aerospace, nuclear, marine, and oil and gas, parts must endure:

Corrosive chemicals

Extreme pressures

Unforgiving temperatures

Long operating lifespans

Inconel 625 shines in corrosive and marine environments, while Inconel 718 dominates in high-temperature, high-stress scenarios. They resist deformation, cracking, oxidation, and fatigue, even under cyclic loads.

In a nutshell, these alloys bring military-grade durability to the commercial world. You can count on them to maintain integrity when other materials would fail catastrophically.

Long-Term Cost Efficiency Despite Upfront Challenges

Yes, Inconel is harder to machine and more expensive, but that initial investment pays off—big time. Here’s why:

Reduced Downtime: With higher corrosion and heat resistance, parts don’t need to be replaced as often.

Fewer Failures: Inconel components rarely fail under stress, reducing costly emergency repairs or replacements.

Better Performance: They help systems run more efficiently, especially in high-performance engines and pressure vessels.

It’s like buying a premium, rugged SUV that can handle off-road abuse and still drive smoothly for 300,000 miles. Over time, the durability and reliability of Inconel parts justify every penny of the machining challenge.

Industrial Applications of Machined Inconel

Aerospace and Defense

From jet engine blades to spacecraft shields, Inconel is a staple in the sky. It withstands:

High turbine temperatures

Rapid thermal cycling

Stress from constant movement

This makes it the metal of choice for rocket components, exhaust systems, and heat shields.

Oil & Gas and Power Generation

Inconel survives in sour gas and high-pressure underwater drilling zones. Components like:

Downhole tubing

Blowout preventers

Combustors and turbine vanes

…all rely on Inconel to resist corrosion and maintain safety in volatile conditions.

Automotive, Medical, and Marine Industries

Inconel also plays a critical role in:

High-performance race car exhaust systems

Dental and surgical tools

Naval submarines and marine propulsion motors

Wherever failure is not an option, Inconel is likely in play.

Cost Considerations in Inconel Machining

Factors Driving Up Costs

Several factors make Inconel more expensive to machine:

Tool wear is high, requiring frequent replacement of premium carbide or ceramic tools.

Machining time is long, as you must slow down speeds and feed rates to avoid damage.

Heat management systems, including coolants and advanced tool holders, add to the overhead.

Machines must be top-tier, able to handle intense cutting forces without flex.

Cost Comparison with Steel and Titanium

Here’s a quick comparison table:

| Material | Machinability Index | Tool Wear | Machining Speed | Overall Cost |

| Inconel | ~12% | Very High | Slow | High |

| Titanium | ~25% | High | Moderate | Moderate-High |

| Steel (Mild) | 100% | Low | Fast | Low |

Despite its high cost, Inconel’s performance over time makes it a smart investment for the right projects.

ROI and Performance Justification

Yes, machining Inconel requires more effort and budget upfront. But in mission-critical applications—aerospace, nuclear, deep-sea drilling—you can’t put a price on performance, safety, and reliability. You don’t want a part to fail 20,000 feet under the sea or 35,000 feet above ground.

Choosing the Right Inconel Machining Partner

What to Look for in a Machining Service Provider

Here’s your checklist for a qualified provider:

Advanced CNC capabilities (3-, 4-, or 5-axis)

Tight tolerance delivery (±0.01 mm)

Experience with nickel alloys

In-house inspection systems (CMM, XRF analyzers)

Flexible from prototyping to mass production

Ask about their past Inconel projects and demand real-world examples of parts delivered on time and on spec.

Case Study – Tops Precision as a Reliable Inconel Machining Provider

One standout in the field is Tops Precision. We’ve carved out a reputation for:

Rapid prototyping

Mass production (up to 100,000+ parts)

Inspection with HAAS machines, Hexagon CMM, and Olympus XRF

What sets them apart is speed. Many shops quote weeks—Tops Precision delivers in as little as 5 days. That’s a serious edge in fast-moving industries.

Conclusion

Machining Inconel is not for the faint of heart—it’s a grind, quite literally. But if your project calls for the ultimate in strength, heat resistance, and corrosion protection, then there’s no better material on the table. With the right tools, techniques, and mindset, you can turn this challenging superalloy into precision-engineered perfection.

Whether you’re crafting aerospace engine parts, marine hardware, or chemical reactor components, mastering Inconel machining opens doors to industries where performance and reliability are non-negotiable.

So gear up, tool up, and dive into the world of Inconel—where every cut counts and every part tells a story of endurance.

FAQs

1. Can Inconel Be Milled Effectively?

Absolutely. With the right high-performance carbide or ceramic tools, optimized parameters, and aggressive cooling strategies, Inconel can be milled with precision. The key is consistency—don’t let the tool rub or hesitate.

2. How Does Inconel Compare to Titanium in Machinability?

Inconel is significantly harder to machine. While both materials are tough, Inconel’s tendency to work harden and its low thermal conductivity make it more demanding than titanium.

3. What Coolants Work Best for Inconel Machining?

High-pressure water-soluble coolants or cryogenic coolants are ideal. They help evacuate heat from the cutting zone, protect tool edges, and improve surface finish.

4. Is CNC Machining Suitable for All Inconel Grades?

Yes, CNC machining can be used for Inconel 600, 625, 718, and others. Just make sure the machine is rigid, well-maintained, and equipped with premium tooling and monitoring systems.

5. How Can I Reduce Costs When Machining Inconel?

Use coated carbide tools, keep your setups rigid, monitor tool wear closely, and work with experienced machinists or shops like Tops Precision that specialize in nickel alloys. Efficient planning and expert execution are your best money-savers.

📸

🔗 Suggested External Links

To provide readers with additional resources, consider linking to the following:

*3ERP’s Inconel Machining Guide: Offers insights into challenges and applicatios.

Inconel Machining: Challenges, Applications & Grades

*Superior Steel Fabrication’s Overview: Discusses tips and considerations for Inconel machinig.

Inconel Machining – Overview and Tips

*Wikipedia on Inconel: Provides a comprehensive background on Inconel allos.