Jigs and fixtures play a crucial role in modern manufacturing by improving accuracy, efficiency, and repeatability. Though these terms are often used interchangeably, they serve distinct purposes. Jigs guide cutting tools during machining operations, while fixtures securely hold workpieces in place for various machining and assembly tasks. These tools enhance productivity, reduce manual errors, and streamline automation in industries such as aerospace, automotive, and medical device manufacturing.

This article provides an in-depth look at jigs and fixtures, their types, benefits, and design principles, as well as essential features that contribute to their effectiveness in machining and manufacturing.

Introduction

Jigs and fixtures are essential tools in manufacturing, used to ensure precision, consistency, and efficiency. Both are designed to improve machining operations, but their functions differ:

- Jigs are used to guide tools during machining operations like drilling and tapping.

- Fixtures hold workpieces in a fixed position to support operations such as milling, turning, and grinding.

These tools help eliminate human error, reduce cycle times, and enhance the quality of machined parts. With advancements in CNC machining, many tasks have been automated, but jigs and fixtures remain valuable in manual machining, high-precision assembly, and inspection processes.

What is a Jig?

Definition and Purpose

A jig is a work-holding device designed to guide a cutting tool into a precise position. Jigs provide alignment and positioning assistance, ensuring accuracy in drilling, tapping, or other machining operations.

Common Applications

Jigs are used in:

- Drilling– Ensuring holes are placed accurately and consistently.

- Reaming– Enlarging holes with precision.

- Counterboring and Countersinking– Preparing holes for fasteners.

- Tapping– Creating internal threads in a hole.

Examples of Jigs

- Drill Bushings: Guide drill bits through workpieces for accuracy.

- Template Jigs: Use templates to guide cutting tools.

- Angle Plate Jigs: Hold workpieces at a specific angle for machining.

Jigs in CNC Machining

With CNC technology, many tool paths are digitally programmed, reducing the need for jigs in automated machining. However, jigs remain useful in custom manufacturing and manual operations where automation is not feasible.

What is a Fixture?

Definition and Function

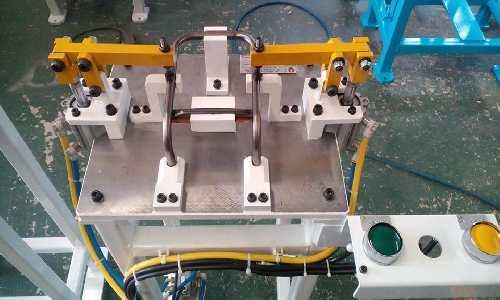

A fixture is a device used to hold, locate, and support a workpiece during machining or assembly operations. Unlike jigs, fixtures do not guide cutting tools but ensure that the workpiece remains secure and correctly positioned.

Common Applications

Fixtures are widely used in:

- Milling– Holding workpieces steady during cutting.

- Turning– Securing parts in lathes for precision shaping.

- Grinding– Ensuring uniform material removal.

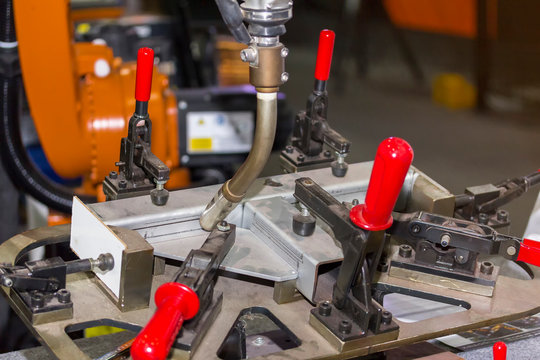

- Automotive Assembly Lines– Holding car parts in place during welding and assembly.

Examples of Fixtures

- Vise Jaw Fixtures: Used in milling and grinding machines.

- Indexing Fixtures: Rotate workpieces for multi-sided machining.

- Chucks and Collets: Secure cylindrical parts in lathes.

Role of Fixtures in Automation

Fixtures are crucial in robotic assembly lines and automated inspection systems, ensuring accurate alignment and reducing manual handling.

Types of Jigs and Fixtures

Jigs and fixtures come in many shapes and sizes, each designed to hold parts steady, improve accuracy, and make machining easier. Whether you’re drilling, milling, or assembling, using the right jig or fixture can save time, reduce mistakes, and boost efficiency. Let’s break down the different types and how they are used.

Types of Jigs – Helping Guide the Cutting Tool

Jigs are mainly used to guide drills, reamers, or other cutting tools into the right position. They make sure every hole or cut is placed exactly where it needs to be.

Plate Jig – Simple but Effective

- A flat plate with holes that guide a drill or cutting tool.

- Best for repetitive drilling jobs where accuracy is key.

Template Jig – Great for Mass Production

- Uses a template to position the tool in the right spot.

- Common in woodworking and sheet metal fabrication.

Box Jig – Holds the Workpiece from All Sides

- Completely encloses the part for extra stability.

- Used when a workpiece needs to be drilled or machined from multiple angles.

Indexing Jig – Perfect for Multi-Step Machining

- Rotates or moves the workpiece for precise cuts at different points.

- Helps create gears, wheels, and other complex parts.

Sandwich Jig – Compact and Lightweight

- Holds the part between two plates like a sandwich.

- Ideal for smaller, thinner parts that need precision drilling.

Channel Jig – U-Shaped for Extra Support

- Wraps around the workpiece, keeping it secure while machining.

- Used in both manual and CNC machining.

Types of Fixtures – Keeping the Workpiece Locked in Place

Fixtures are used to secure workpieces firmly during milling, turning, grinding, and assembly. Unlike jigs, they don’t guide the cutting tool but make sure the part stays in the right position.

Plate Fixture – Flat and Reliable

- A simple flat plate with clamps or screws to hold the part.

- Often used in CNC milling and drilling operations.

Vise Jaw Fixture – Secure Grip for Small Parts

- A vise with specially designed jaws that hold parts securely.

- Used in both manual and CNC machining.

Multi-Station Fixture – Perfect for High-Volume Production

- Holds multiple workpieces at the same time.

- Speeds up machining and reduces downtime.

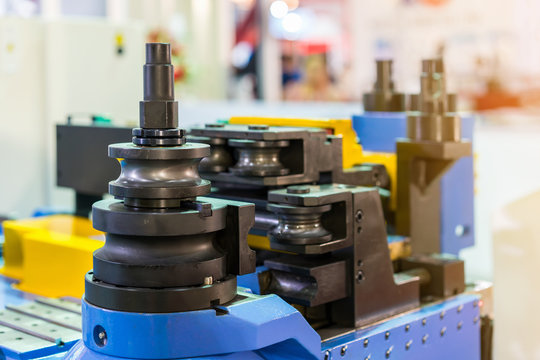

Indexing Fixture – Helps with Rotational Machining

- Allows the workpiece to rotate and lock into position for multi-step machining.

- Common in gear cutting and turbine blade production.

Chucks and Collets – Best for Round or Cylindrical Parts

- Used in lathes and CNC turning machines.

- Provide a strong grip without damaging the workpiece.

Angle Plate Fixture – Holds Workpieces at an Angle

- Used when machining parts that need angled cuts or holes.

- Helps achieve precise positioning without complex machine adjustments.

Choosing the Right Jig or Fixture

Picking the right jig or fixture depends on the type of machining, the material, and the level of precision needed.

- If you need precise hole placement, go for a drill jig like a plate jig or template jig.

- If you need to hold a part steady while cutting, a fixture like a vise or plate fixture works best.

- For high-volume production, multi-station fixtures can save time and increase efficiency.

Using the right jig or fixture not only makes machining easier but also improves quality, reduces errors, and boosts productivity. Whether you’re working with metal, wood, or plastic, there’s always a jig or fixture to make the job simpler and more precise!

Workholding Methods in Jigs and Fixtures

One of the most important parts of machining and assembly is making sure the workpiece stays in place. If it moves, even a little, the whole process can go wrong. That’s where workholding methods in jigs and fixtures come in. These methods keep parts steady, allowing for accurate, repeatable, and safe machining. Here are some common ways to secure workpieces:

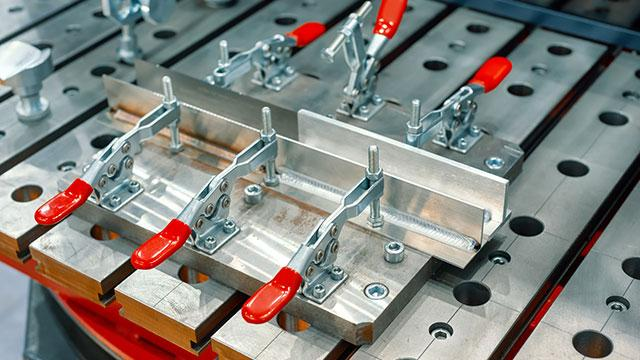

T-Slot Plates – The Classic and Reliable Option

T-slot plates are built into milling tables and are one of the simplest ways to secure workpieces. These slots allow machinists to attach vises, clamps, and other holding tools. Pros: Strong and durable. Cons: Hard to place workpieces in the exact same spot every time, which can add extra setup work.

Fixture Plates – A Faster, More Precise Alternative

Fixture plates (also called tooling plates) sit on top of T-slot tables and come with a pre-drilled grid of holes. This makes it easier to position workpieces the same way every time, reducing setup time and mistakes. They also allow for quick swaps between different fixtures, making them ideal for high-production environments.

Modular Workholding – Flexible and Adjustable

This method uses interchangeable components like clamps, stops, and pins that can be adjusted depending on the job. It’s perfect for handling different-sized parts without needing a completely new fixture each time.

Vises and Clamps – Secure and Simple

Vises are great for gripping smaller parts, while clamps can hold larger or oddly shaped workpieces. These are common in both milling and drilling operations, making them one of the most widely used workholding methods.

Vacuum Workholding – No Clamps Needed

For thin or delicate materials, vacuum workholding uses suction to hold the part in place. This method is ideal for soft metals, plastics, and composites where traditional clamping could cause distortion or damage.

Magnetic Workholding – Great for Metal Parts

Magnetic chucks use powerful magnets to secure ferrous (iron-containing) materials during machining. They eliminate the need for mechanical clamps, allowing for full access to the workpiece.

Using the right workholding method makes machining easier, faster, and more precise. Whether you need a simple clamp or a high-tech vacuum system, choosing the right setup ensures better efficiency, improved accuracy, and safer operations.

Locating and Positioning Components

Precise alignment is crucial in workholding. Common components include:

- Locating Pins: Ensure consistent part placement.

- Spring Plungers: Provide retractable locating points.

- Alignment Bushings: Guide workpieces into position.

- Fixture Keys: Align fixtures on slotted machine tables.

Benefits of Using Jigs and Fixtures

Jigs and fixtures are game changers in manufacturing, helping businesses save time, reduce errors, and produce high-quality parts consistently. Whether you’re working in a small workshop or a large production facility, these tools simplify machining and assembly, making processes smoother and more reliable. Here’s why they are so valuable:

- Boosts Productivity– Cuts down setup time, speeds up machining, and reduces the need for frequent adjustments.

- Improves Accuracy and Consistency– Ensures every part is made to the same specifications, eliminating variation.

- Reduces Skill Requirements– Allows less experienced workers to handle machining and assembly with confidence.

- Lowers Production Costs– Minimizes waste prevents rework, and increases overall efficiency.

- Enhances Workplace Safety– Holds parts securely, reducing the risk of accidents and tool mishaps.

Design Basics for Jigs and Fixtures

Key Design Considerations

- Locating Points: Ensures easy workpiece placement.

- Error-Proofing: Prevents incorrect positioning.

- Weight Management: Should be easy to handle without sacrificing strength.

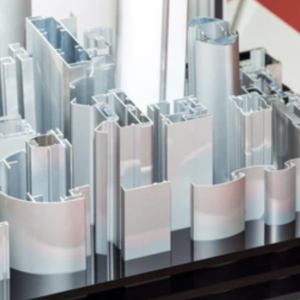

- Material Choice: Steel, aluminum, or cast iron for durability.

Additional Design Considerations

- Cleanliness: Designs should allow easy chip removal.

- Replaceable Parts: Components should be standardized and interchangeable.

- Cooling and Chip Management: Features should enable coolant flow.

- Hardened Surfaces: Prevent wear and extend tool life.

- Ejecting Devices: Should allow easy removal of workpieces.

Summary

Jigs and fixtures are vital for improving machining efficiency, accuracy, and safety. Jigs guide tools for precision hole-making, while fixtures hold workpieces securely for machining and assembly.

Key Takeaways:

- Jigs are mainly used for drilling, reaming, and tapping.

- Fixtures are used for milling, grinding, turning, and assembly.

- High-volume manufacturing depends on precise workholding solutions.

- Jigs and fixtures increase accuracy, simplify work, and reduce costs.

Industries such as automotive, aerospace, and medical device manufacturing rely heavily on these tools for high-precision production.

FAQs

1. What is the primary difference between jigs and fixtures?

Jigs guide the cutting tool, while fixtures hold the workpiece in place.

2. What are common types of jigs?

Plate jigs, template jigs, indexing jigs, and box jigs are frequently used.

3. Where are fixtures commonly used?

Fixtures are widely used in milling, grinding, turning, and assembly processes.

4. How do fixture plates improve accuracy?

Fixture plates provide precise, repeatable workpiece positioning compared to T-slot plates.

5. What industries benefit most from jigs and fixtures?

Automotive, aerospace, medical, and heavy machinery manufacturing use them extensively.

2 thoughts on “Jigs and Fixtures: Everything You Need to Know”