What exactly is Delrin? Delrin, or acetal, is a tough high-performance thermoplastic. It’s known to be strong, stiff, and wear-resistant. When precise performance combined with durability is required, you will find machining Delrin in action. Delrin is your material for machining if you are looking for things such as low friction, high impact resistance, and dimensional stability.

Why Do People Love Delrin?

- Strength: It is durable and can withstand a great deal of stress.

- Minimal Friction: Ideal for movable components.

- Stable: Holds shape under fluctuating temperatures.

- Chemical Resistance: It is resistant to many chemicals, which means it is ideal for tough environments.

Why Machine Delrin?

For a reliable, easy-to-work material, Delrin’s a solid pick. It is very machinable, meaning that you can easily cut, drill, and mill it into parts with very specific definitions. It’s used in industries that require high-quality, durable components, such as automotive, aerospace, medical, and more.

Why is Delrin a Great Material for CNC Machining?

When it comes to CNC machining, Delrin is relatively easy to work with. It’s easier to work with than most plastics and metals, and you can get tight tolerances and smooth finishes. Delrin has low thermal expansion, so it won’t warp as it is machined. It is important when you require accuracy in your components.

Tips for Machining Delrin

So now let’s discuss how to achieve the best results when machining Delrin. There are a handful of things you’ll want to consider to promise that you won’t face issues like chipping, melting, or rough edges.

Pick the Right Tools

Using proper tools is crucial for machining Delrin. Your best bet is high-speed steel (HSS) and carbide tools. Carbide tools, specifically, are useful for high-speed machining as they maintain their cutting edge longer, making cuts more efficient and with improved results.

Speeds and Feeds Are Important

You need to determine a sweet spot for the cutting speeds and feed rates. If you drive too fast, the matter will melt or can get a rough finish. Too slow, and you might grind down your tools faster. Over the broad range, however, generally, 500-700 SFM (surface feet per minute) is where this works best.

Don’t Forget the Coolant

Delrin does not require a lot of coolant like metal but using a light mist of coolant can make things run smooth. This reduces friction, prevents overheating, and gives a cleaner cut.

Avoid Chatter

Chatter is a bitch, and can ruin your machining work. To prevent any hiccups, ensure that your CNC is solid and well-clamped. The correct cutter size is; therefore, also crucial in the reduction of vibrations and the stabilization of the machinery.

Watch Out for Dust

When machined, Delrin creates fine dust, and that dust can ruin your project. It can jam up your machine and destroy the surface finish on your part. That’s why you should have a dust collection system to keep your workspace clear and safe.

Benefits of Machining Delrin

So why is machining Delrin so amazing? Here are the top benefits of using Delrin for your projects.

High Strength and Durability

Strength-wise, Delrin is no slouch. Like, it can take a beating and will not break down the same way that composite materials will, and that’s why we use it in areas of the vehicle that have a lot of mechanical stress.” Won’t hurt, and it’s good for the long-haul components.

Wear Resistance

Delrin is so loved because it resists wear and tear. It has a low friction coefficient, meaning it wears longer without breaking down. That makes it a prime candidate for applications such as gears, bearings, and bushings.

Self-lubrication and Friction

The low friction property of Delrin changes the game. It can be self-lubricating, meaning it does not require additional lubricants to keep things moving smoothly. That’s a big plus for maintenance and part-life.

Dimensional Stability

It is very stable in shape, even with different temperatures and humidity. So Delrin won’t fail you when it comes to tight tolerances and precision measurements.

Chemical Resistance

Delrin is resistant to many chemicals, such as oils and solvents. So, if you are functioning in an environment where chemicals are present, Delrin can hold up when the rest of the field fails.

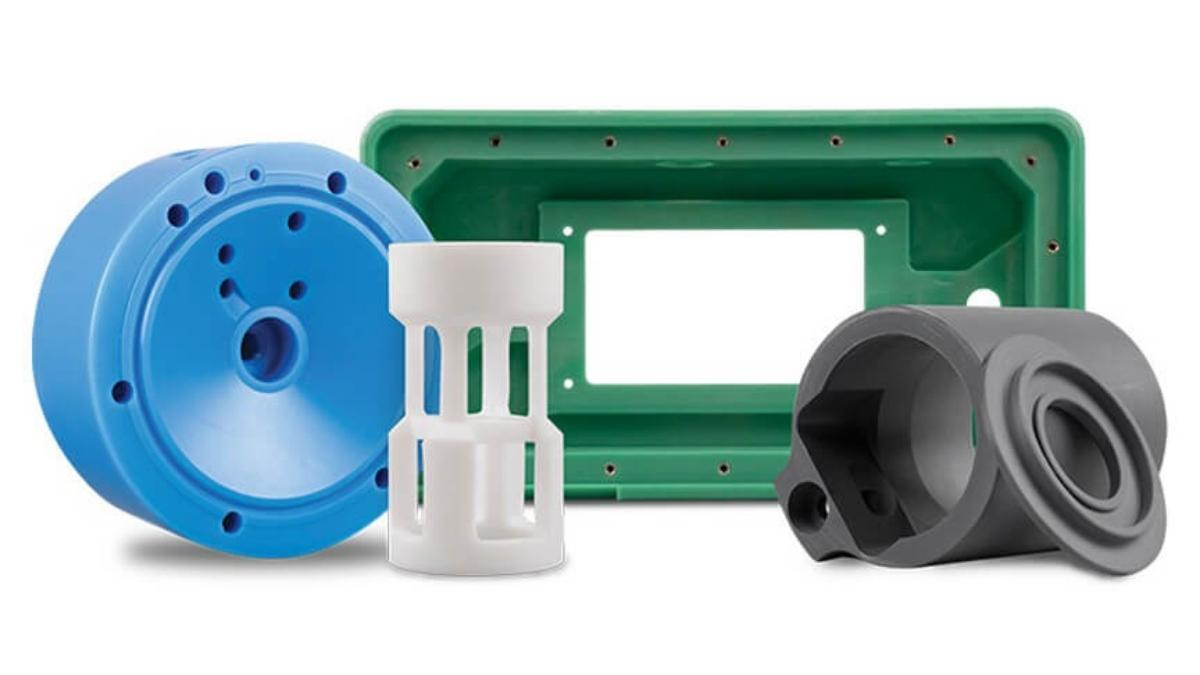

Applications of Delrin

Delrin is unique in its properties and can be seen in use near you, from machines to medical Devices. Let’s take a look at where it truly excels.

Automotive Components

Delrin is used all over the automotive world, particularly in gears, bushings, and trim. It has the toughness to withstand the industry’s high-performance demands, and its heat resistance also makes it ideal for engine parts.

Aerospace Parts

Delrin is also adored by aerospace companies. It’s employed in components such as actuators and bushings, where weight savings and strength are both essential. Its strength makes it ideal for parts that should be able to perform under extreme conditions.

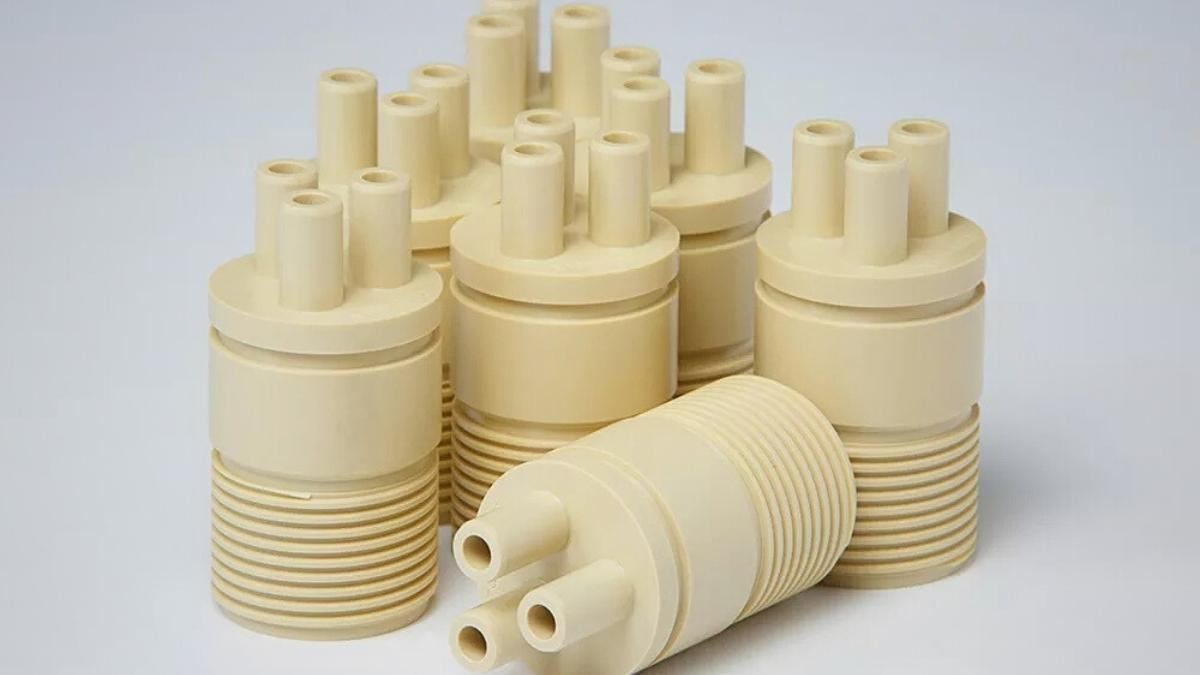

Medical Devices

Delrin can be found in the medical field on surgical instruments or medical device housings. It is biocompatible and withstands the sterilization process, which also makes it safe for medical applications.

Consumer Electronics

In consumer electronics, Delrin can be used for connectors, gears, housings, etc. (That is, its accuracy, strength, and resistance to wear make it suitable for devices such as printers, computers, and mobile phones.)

Industrial Applications

Delrin in industrial machinery And ever heard of Delrin? It’s used for machine parts, seals, and conveyor systems. Its low friction and wear-resisting properties make it ideal for moving parts in machinery that work under a constant stressing load.

The Challenges of Machining Delrin

Delrin is a great material but there are a few challenges to watch out for when machining.

Risk of Melting

If you’re not careful, Delrin can melt during machining, especially if you’re cutting too quickly. That’s why it’s good to adhere to the proper speeds and feed rates and use coolant to keep the thing cool.

Chipping or Cracking

Delrin can chip or crack, if machined too aggressively or with the wrong tools. To avoid that, ensure that you’re using sharp, quality cutters and that your feed rates are not excessive.

Cost

It is relatively more expensive than other types of plastic, making it less cost-effective for all applications. But when you are looking for something strong, durable, and precise, the investment is usually justified.

Delrin For Prototype Manufacturing

CNC machining Delrin is also excellent for prototyping. It is relatively inexpensive, easy to handle, and powerful enough to prototype new designs.

Why Use Delrin for Prototyping?

Another great thing about Delrin is that it’s super easy to machine, making it an excellent prototyping material. You can scout a design’s fit, function, and feel long before signing off on it for mass production. It’s a quick and reliable way to achieve working and durable prototypes.

Conclusion

If you need something strong durable, and easy to machine, then Delrin is an excellent choice. Ideal for those places where performance and accuracy are important. With the right tools and techniques, high-quality parts able to resist wear, stress, and temperature changes can be manufactured. Delrin works wonders for automotive components, medical devices, and industrial parts alike. contact us for your project now!