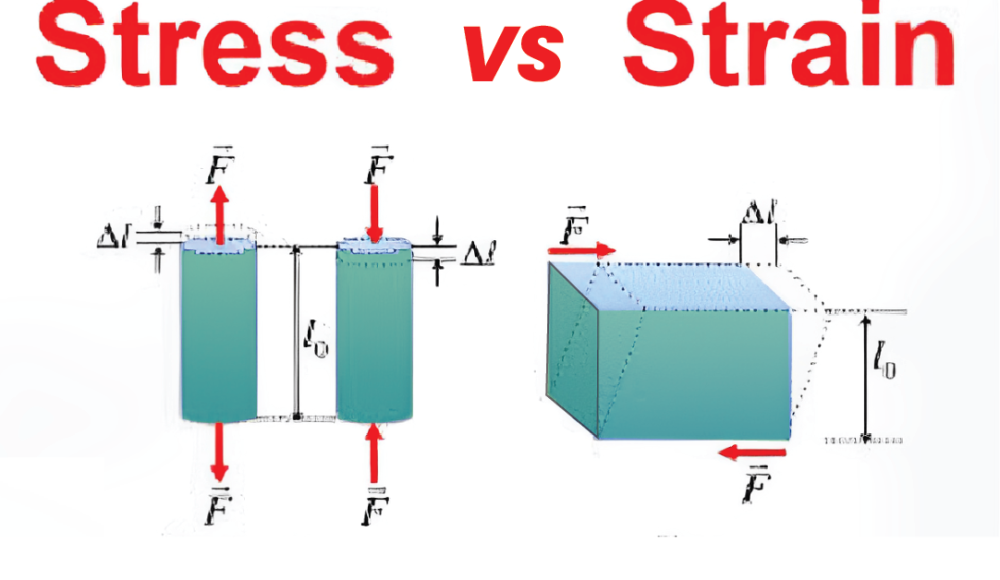

Stress and strain are the two related terms that measure the ability of a given material to accept the pressure from outside. Stress is the amount of force applied to any of the materials. On the other hand, when materials are forced to change their behavior, is called strain. Understanding how those forces behave makes it easier for engineers to develop secure and efficient materials for the structures. So, this article will further explore the basics of stress and strain and give the reader a general idea of the importance of these factors in practice.

How Would You Define Stress?

Stress is a force acting on the unit area of any material to get an estimate of the magnitude of internal forces acting on two neighboring particles. If we talk about its formula, stress is force per unit of area. It is usually measured in pascals (Pa) or newtons per square meter (N/m²). Its mathematical expression is:

σ=F/A

Here F is the applied force and A stands for the cross-sectional area of the channel.

Importance of Stress

Stress mainly refers to the force that we apply on an area of a material. Applying force to a material creates internal forces. Moreover, these forces extend throughout the material. The force acting on the area per unit area is described in what we term stress. Awareness of stress is useful in the identification of the way a material will behave under different loads without reaching its breaking point.

Different Types of Stress

Here are the other types of stress

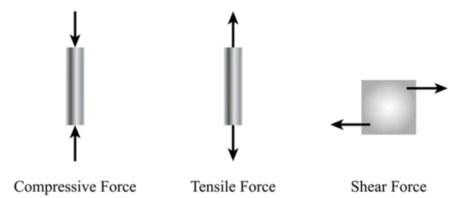

- Tensile Stress: It is normally experienced when stress force pulls the material to a new parallel length, i.e. the elongation. An example is when two ends of a rubber band get separated.

- Compressive stress: It occurs when a particular part of the material is pushed towards each other leading to a decrease in size. E.g. bow and bending low to take the bow and spring compression.

- Shear Stress: It occurs when the forces are parallel to a certain part of the material. Besides this, its layers of the material glide past one another. An example is scissors used in cutting papers.

- Bending stress: It generally happens due to deformation. It occurs when the material starts to bend due to the load with both the tension and the compression forces. An example is a beam sag under a load applied to its middle.

- Torsional stress: It is the direct stress occasioned by a twisting load leading to the shear stress in a material. An example is a metal rod that rotates using a torque at both ends.

Causes of Stress

The following are the major causes of stress;

1. External Forces

External loads acting on any structure apply forces directly on the material and cause stress. These forces can be tension, compression, and shear. The resultant forces are extremely high in a small region. Besides this, dynamic stress is the constant oscillating pressure. It is usually responsible for causing fatigue stress that gradually wears out the material.

2. Environmental Factors

Heat affects the dimensions of materials and increases or reduces their size. Besides this, a chemical attack weakens the material and generates internal stresses. Moisture and dampness cause swelling and degradation specifically in hygroscopic ones. Vibrations produce stress in materials by mechanically deforming them. Moreover, radiation like UV or gamma rays, causes atomic-level damage to the material.

How to Measure Stress?

Here are some possible ways to measure the stress appropriately;

- Load cells: They help convert mechanical force into electrical signals. Besides this, they give accurate and repetitive measurements in different scenarios.

- Strain gauges: They measure deformation by analyzing the changes in electrical resistance. Besides this, they provide accurate strain measurements to measure internal stress.

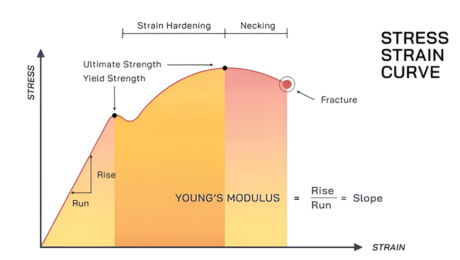

- Stress-strain curve: This curve helps in plotting stress against strain. It reveals elastic and plastic behavior along with key points, i.e. yield point (plastic deformation start), ultimate tensile strength (maximum stress), and fracture point (failure). , Moreover, this curve also helps in material choice and structural design.

- Other techniques: These can be photoelasticity for visual stress patterns. Besides this, they can be finite element analysis for computational stress simulation. Moreover, these techniques may include X-ray diffraction for residual stress measurement and acoustic emission. So, they can easily detect stress waves.

How Would You Define Strain?

Strain is a name of deformation that represents the displacement between particles in a material body. This displacement can be relative to a reference length. Besides this, strain estimates how much a material deforms under stress. Its general expression is

Strain = change in length / original length. or

strain (ε) ϵ=ΔL/ Lo

Importance of Strain

The strain has quite a significance in the construction field. It helps predict how materials will behave under different loading conditions. Besides this, it lets engineers consider whether a material will return to its original shape after removing the load (elastic behavior). So, the strain will help us in knowledge to ensure structural integrity and prevent material failure in engineering applications.

Causes of Strain

The following factors cause strain in different materials:

1. External Forces

Self-applied loads, i.e. tension, compression, shear force, bending force, and torque directly cause deformation in the materials. These forces change the shape or size of the material and result in strain.

2. Environmental Factors

Heat and cold affect the sizes of materials and hence the thermal stress arises. Some chemicals can cause deformation and deterioration in the material. Besides this, changes in the moisture content of some materials will force them to either expand or shrink. Radiation can cause a change in the lattice within the material at the atomic level resulting in strain.

How to Measure Strain?

Let’s discuss the strain measuring techniques in detail;

- Strain Gauges: Sensors that are used to quantify the level of distortion in a particular substance are known as strain gauges. In the process, however, they deform the material and alter electrical resistance.

- Extensometers: These devices measure the gauge change in length of a material sample when the load is being applied to it. These have wide applications in tensile tests.

- Digital Image Correlation (DIC):This is a comprehensible optical ascendancy control technique that uses digital images to observe the distortion of a material’s surface. It can measure total-field strain. Besides this, it is efficient in strain analysis that requires detailed information.

- Photoelasticity: It is a process of visualization of strain by using a Polarizing Microscope. Besides this, it uses the principle of Polarized light. They assist in determining areas of high stress and comprehending difficult strain patterns.

- Finite Element Analysis (FEA):It is one of the numerical methods for predicting the deformation of the material when different loads are acting on it. It processes specific strain information. This information is useful in determining the appropriate framework and design of materials and systems.

Key Differences Between Stress and Strain

Here is the table to give a better understanding of the key differences between stress vs strain.

| Stress | Strain |

| It can be defined as a force acting per unit area within a material. | It is a Deformation concerning the original length |

| This can be expressed as σ=F/A | It can be denoted as ϵ=ΔL/L0 |

| Units = Pascals (Pa) or Newtons per square meter (N/m²) | It is Dimensionless as it is the ratio of the same parameters |

| Stress gets the estimation of internal forces | It simply the measures change in shape or size |

| Caused by external forces and environmental factors | Caused by external forces and environmental factors |

| Types: Tensile, Compressive, Shear, Bending, Torsional | Types: Tensile, Compressive, Shear, Bending, Torsional |

| Indicates material’s force tolerance | Indicates material’s deformation under force |

| Measured with load cells, strain gauges, stress-strain curve, FEA | Measured with strain gauges, extensometers, DIC, FEA |

| Used in material selection, structural design, failure prediction | Used in performance analysis, deformation study, structural integrity |

How Does Stress and Strain Relate to Each Other?

Originally stress and strain are two concepts that have a close relationship in the field of material science. Stress is defined as the force per unit area that a material experiences, whereas strain is the change in the dimensions of the material as it experiences stress. Stress to strain correlation is usually represented in a stress–strain diagram which illustrates the behavior of a material when stressed. In the elastic region, the stress and strain are directly proportional and are governed by Hooke’s law, i.e. σ=Eϵ

How Would You Define the Stress vs Strain Curve?

Stress vs strain curve – a graphical representation of the amount of stress imposed on a material and the amount of strain it shows. So. here are its key regions and points on the curve include:

- Elastic Region: Region where the stress and strain relations are directly proportional as stated by Hook’s Law; i.e. σ=Eϵ. Here, the material regains its original form after the stress removal.

- Yield Point: The material starts to bend beyond its yield point and causes permanent deformation even when the stress is released.

- Plastic Region: At this point, the material gets permanently set beyond the yield stage.

- Ultimate Tensile Strength: The amount of stress that material can specifically tolerate to the point of necking.

- Fracture Point: It is also referred to as the true failure point, which is the position of the material’s breaking point.

The curve is also essential in explaining the properties of the material. Besides this, it helps in the process of choosing the right material in the engineering design process.

Conclusion

In conclusion, stress v. strain, stress and strain are basic concepts of materials science and engineering. It has a significant value in learning about material reactions resulting from various forces. Similar to stress which defines internal forces in a material, strain defines the deformity that comes with the forces. Stress-strain curves that represent their kind of relationship are very valuable in acquiring a general understanding of material characteristics and behavior. Thus, the mastering of these concepts by engineers and scientists will result in the development of safer and more efficient structures and materials. Contact us for more information.

3 thoughts on “Stress vs Strain: Understanding the Key Differences and Their Implications”