Have you ever noticed how some metals look shiny and slick, like the chrome on your motorcar gold in your jewelry, or a smooth visceral on your kitchenware? This sorcery doesn’t occur by chance—it’s because of plating! But what is plating? and why do we use it?

So, in this article, we’re going to run over exactly what plating is, the plating process, what it’s used for, and why you need it. If you’re in manufacturing, jewelry making, or just want to know, the answers are here.

What Is Plating?

This means that plated is the application of a thin cover of material (often metal) on a surface to improve its characteristics or look. In other words, it’s a protective coating of sorts — a shiny, stylish sheen, if you will, on an individual piece.

This can be done for durability, corrosion resistance, appearance, etc. Whether you want to add a hint of gold to an ornament or make a part more corrosion-resistant, plating is a well-established method.

How Does Plating Work?

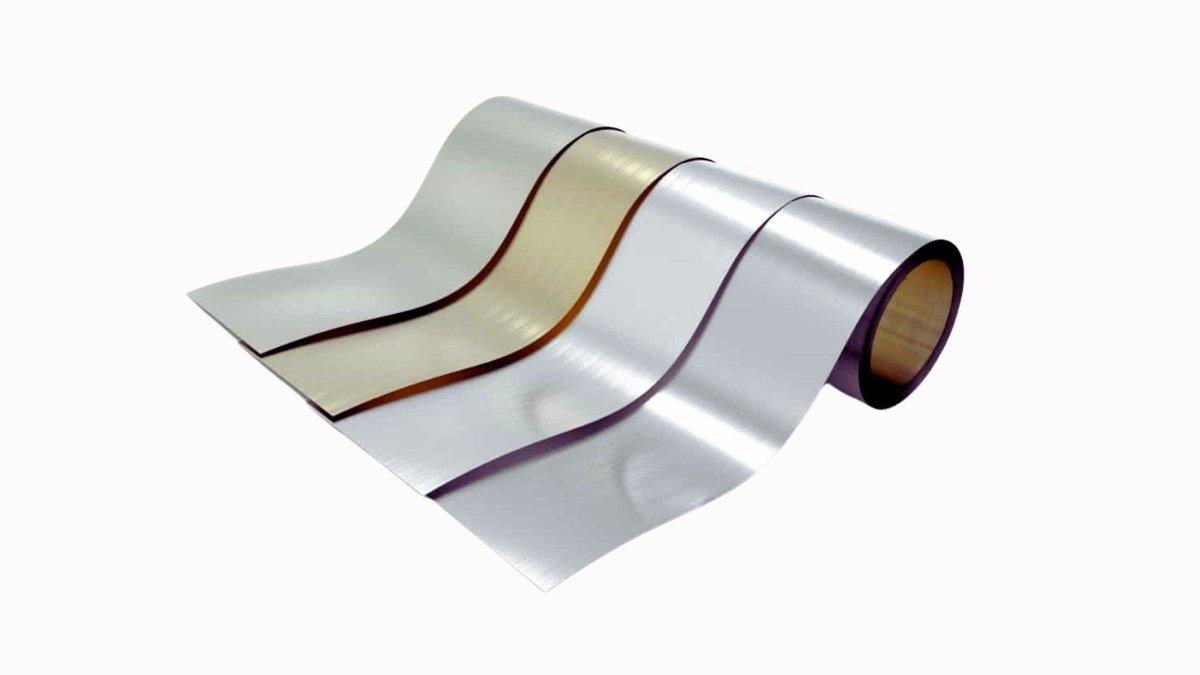

Plating usually involves the deposition of a layer of metal (or other material) onto a substrate using several different techniques. Those are only two types of plating methods, you may have heard of electroplating or electroless plating. There are various pros and cons to each approach and choices depend on the material and the result you want to achieve.

Electroplating

One of the most utilized application techniques for plating is electroplating. The process entails electroplating a metal coating to an item. Here’s how it goes:

Step 1: The object that will be plated (referred to as the “substrate” during the process) is first cleaned for dirt and/or oil.

Step 2: The substrate is placed in a Metal Ion Solution.

Step 3: An electric current runs through the solution. This prompts the metal ions to migrate and deposit onto the substrate’s surface, creating a thin metallic film.

You’ve probably witnessed this for chrome plating on car bumpers or gold plating for jewelry.

Electroless Plating

No electricity is required for this method. Rather, it uses a chemical reaction to deposit the metal. One of the main differences here is that electroless plating does a more uniform job of plating and can coat non-metals like plastics. The technique is commonly used in coating products such as connectors in electronics, where uniformity is important.

Why Is Plating Used?

There are certain reasons to opt for plating:

Aesthetic Appeal

Probably one of the most used reasons for plating is aesthetic appeal. Think shiny gold-plated rings, or a mirror finish chrome bumper, RS on, of a car. They are quite appealing and can easily grab attention. These are used because of their glamorous and beautiful high-quality finishing on products like Gold, Silver, Chrome, etc.

Increased Durability

Plating adds an extra protective layer and further enhances a part’s durability. For example, chrome plating is commonly applied to automotive parts and hand tools to inhibit rust and corrosion. The plated layer serves as a barrier against wear and tear, preserving the integrity of the underlying substrate.

Corrosion Resistance

Iron and steel are metals that rust readily when exposed to moisture and air. Oxidation is prevented by plating with metals such as nickel or chrome. It’s a practice commonly followed in sectors where parts need to endure extreme environmental conditions, such as automotive and aerospace.

Electrical Conductivity

For example, plating is used to increase conductivity in electronics. Gold is a common material for plating items like connectors, as it’s a great conductor of electricity and resists corrosion. It guarantees the proper progression of electrical currents within the system.

Wear and Tear Resistance

Plating isn’t simply cosmetic—it can also keep parts from wearing out. Nickel plating, for instance, is a popular option for reducing friction in mechanical parts and helping to prolong the life span of the machinery.

Different Types of Plating

Plating is not a one-size-fits-all process. Different materials and different goals call for different techniques. Now, let’s look at some of the most common plats:

Chrome Plating

Chrome Plating is applied to parts for both aesthetic reasons providing a smooth and shiny/reflective finish, which adds some corrosion resistance. You can find it commonly on car bumpers, motorcycle parts, and faucets. It is a type of plating that is used to fine-tune appearance and provide durable surfaces.

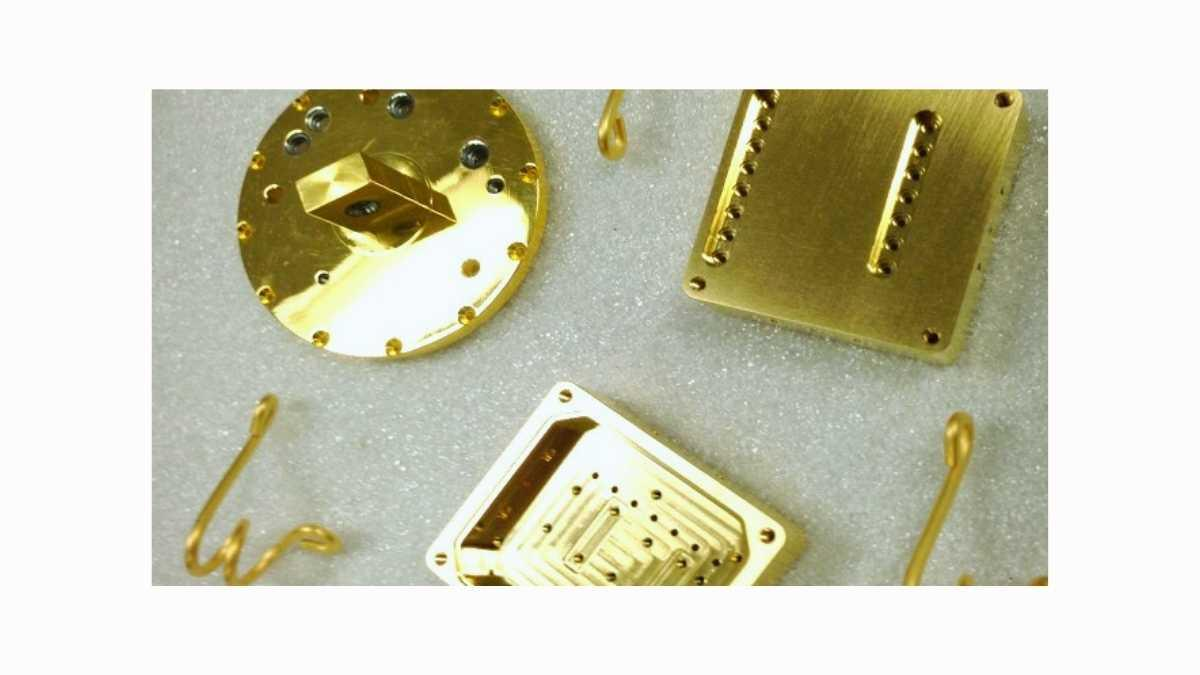

Gold Plating

Over the years, gold plating has become a common practice in jewelry, electronics, and even medical devices. It makes an item look luxurious and also offers high corrosion resistance. Gold is also a very good conductor, which is why it’s often used in electronics.

Silver Plating

Typical Uses of Silver Plating Silver plating is used in flatware, jewelry, and electrical components. Silver is less durable than gold or chrome but offers a lustrous finish and excellent electrical conductivity. An example is jewelry designed with silver, which often can be cheaper than solid silver (because is silver-plated) and is a cheaper option.

Nickel Plating

For what applications Nickel plating are used? It is strong, durable, and corrosion-resistant. Nickel also gives a smooth finish, which is often used to increase the wear and tear resistance of metal parts.

Tin Plating

Tin plating is often used for food packages, electrical elements, and soldering material production. This makes tin less prone to rusting, an important feature for items that should remain functional in a wide variety of environments.

Common Applications of Plating

At the moment, this is mostly used for a variety of industries and a plethora of applications. The most common applications are the following:

Jewelry

Gold, silver, and platinum plating are some of the most commonly used in jewelry. It gives jewelry makers a bright, shiny finish while protecting the underlying material from wear. It also renders costly metals like gold more readily available by covering cheap metals in a layer of gold.

Automotive Industry

In cars, plating protects parts such as exhaust systems, bumpers, and engine components from rust. Chrome plating, known for its shiny surface and robustness, is especially common. And it gives cars that slick, shimmery appearance that’s hard to miss.

Electronics

“In an era of rapid technological change, the demand for high-quality electronic components will not be satiated. Plating in electronics is critical to preserving conductivity and ensuring longevity in devices such as smartphones, computers, and other home appliances. As an example, gold-plated connectors aid with signal transmission and reduce the chances of corrosion.

Aerospace

Aerospace components need to be strong, withstand extreme heat, and remain durable over time. Plating ensures these tools are doing their work. Nickel and cadmium plating have been widely used in the aerospace industry to protect parts from exposure to heat, moisture, and mechanical wear.

Food Packaging

Food packaging is tin-plated, such as cans, to prevent rusting and preserve the contents. In addition to use alone as a coating, tin is often plated to another material to help serve as a barrier for food in a container.

Advantages of Plating

Plating protects items, making them last longer and work better. Plating helps products withstand the test of time — whether by preventing corrosion or reducing friction.

Aesthetic Appeal

Sometimes, how a product looks can be just as important as how it functions. Plating offers a shiny, aesthetically pleasing appearance that improves the look of products such as jewelry, consumer goods, and automotive components.

Cost-Effective

Instead of having to manufacture an entire part out of rare or expensive metals, you can plate a cheaper material with the desired metal. Plating to give one a very similar appearance and functionality at an affordable price.

Disadvantages of Plating

While plating has lots of benefits, it also comes with a few disadvantages:

Thickness Control

Plating has to be precise. If the coating is too thick, it can warp the part; if too thin, it may not provide enough protection. Consistency is key!

Environmental Concerns

Certain processes in plating, such as those involving cadmium or chromium chemicals, can be eco-unfriendly. Reducing the environmental impact would require appropriate disposal of chemicals and waste.

Conclusion

Plating is a general process involved in manufacturing, as well as the production of jewelry, automotive, electronics, etc. From corrosion resistance to wear prevention, electrical conductivity and even enhancing a product’s aesthetics, plating can have a significant impact on performance and life. Knowing how plating works, what its various types are, and where it’s used, you’re in a better position to appreciate the value of this process in everyday life and industry. Contact us for more information.

1 thought on “What Is Plating? All Details Explained”