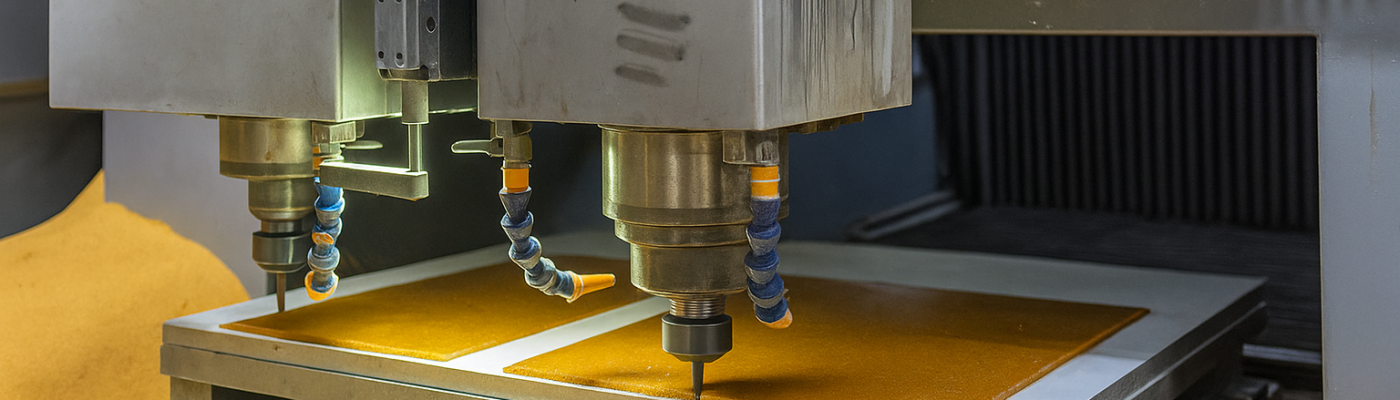

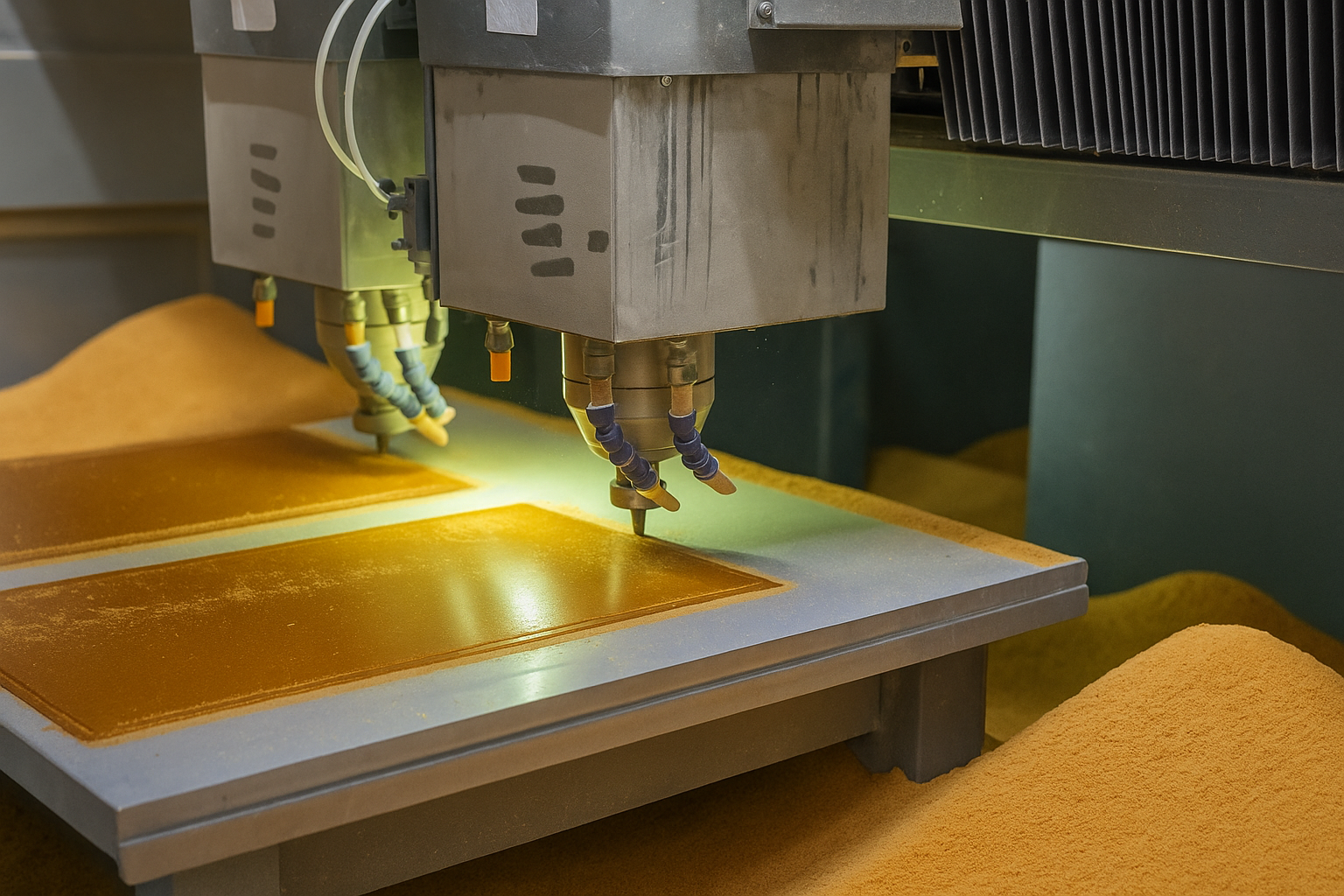

What is the Process of Machining Bakelite?

Bakelite is brittle and thermoset, which means that machining requires a well-controlled, high-speed, low-heat CNC process. Bakelite has the incapability of melting or reforming and must hence be shaped on brushes that are abrasive resistant, with appropriate feed speeds, and with the control of cooling.