Choose a CNC machining process to make the precise parts in a shorter time than any other process. TOPS Precision Manufacture provides fast and accurate CNC prototyping service and the mechanical strength of the prototype part will be very high. Whether you require metal or plastic prototypes, our 3-axis and 5-axis milling and CNC turning technologies provide excellent outcomes for your project. We serve you with:

- Home

- Services

- CNC Machining

- Die Casting

- Mold Making

- Aluminum Die Casting

- Zinc Die Casting

- Magnesium Die Casting

- Die-cast Bracket Services

- Die-cast Enclosure Services

- Die-cast Housing Services

- Automotive Die Casting Services

- Gravity Die Casting Services

- Low-Pressure Die Casting Services

- China Die Casting Manufacturer

- High-Pressure Die Casting

- Prototype Die Casting Services

- High-Volume Die Casting Services

- Low-Volume Die Casting Services

- Structural Die Casting Services

- Thin-Wall Die Casting Services

- Squeeze Die Casting Services

- Vacuum Die Casting Services

- Sheet Metal Fabrication

- Plastic Injection Molding

- Contract Manufacturing

- Low Volume Manufacturing

- Massive Production

- Industries

- Automation

- Consumer Electronics

- Medical CNC Machining

- PCB Milling

- Aerospace Machining

- Automotive CNC Machining

- CNC Machined Bicycle Parts

- CNC Bottle Opener Machining

- CNC Camshaft Machining

- CNC Screw Machining

- CNC Machining Spare Parts

- CNC Piston Machining

- CNC Machined Gifts

- CNC Machined Fly Wheel

- CNC Machined Safety Razor

- CNC Machined Fidget Spinner

- CNC Machined Dice

- CNC Machined Chess Pieces

- Gallery

- Resources

- About Us

CNC Prototyping Services

- Tolerances for Metals: ±0.13 mm; Plastics: ±0.20 mm.

- Deal with a wide range of plastics and metals.

- Includes anodizing, polishing, powder coating, and more.

- 3-axis and 5-axis milling, CNC turning.

- 8-10 days for <50 parts.

Send Your Inquiry Today

What is CNC Prototyping?

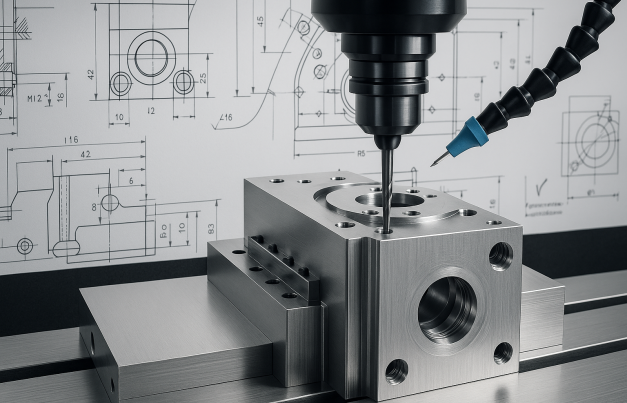

CNC Prototyping is a method of making functional prototypes using Computer Numerical Control or CNC machining. This type of manufacturing is done with the help of computer software. We operate tools and machinery to make precise cuts, drills, plastic milling, metal, or wood.

Key Aspects of CNC Prototyping

CNC prototyping is used to perform functional tests, design evaluation, and new product development in the automotive, aerospace, and electronics industries.

- Precision: Applications of CNC machines include creating intricate and superb quality parts that are well suited for developing prototypes that have to meet strict precision standards.

- Speed: CNC machining is fully automated, which helps save a lot of time on producing more components in less time, and to turn a prototype into reality.

- Scalability: CNC machining also allows for a simple transition from a prototype to regular production runs, making it a perfect solution for the initial production of a device.

Why Choose TOPS For CNC Prototyping?

Selecting TOPS for CNC prototyping is the decision to get the shortest time and highest accuracy in producing intricate parts. Clients can conveniently drop their CAD files to us without struggling through complicated procedures through the design-then-make approach with fast turnaround times.

- Precision and Speed: Utilize our state-of-the-art CNC solution to manufacture complex parts in minimum time. Through 3-axis and 5-axis CNC mills alongside CNC turning we can create accurate prototypes for a broad array of industries.

- Simple Process: Drop your CAD files here and share them with our engineers who will help you enhance them and move to production when complete. In TOPS Precision Manufacture, prototyping is hugely simplified and made very easy.

- Fast Turnaround: Our precision CNC machining services are perfect for low-volume to high-volume production runs. Order small quantities of your prototype parts and you can get your supplies in about 8-10 days.

TOPS Top-Notch CNC Machining Technologies

Our prototyping skills incorporate complex machining techniques such as CNC milling and CNC turning. These processes are for different geometries as seen from the above illustrations to allow us to cover multiple projects with high accuracy and quality. Our CNC prototyping services include;

CNC Milling

Ideal for complex and high-volume part work, with milling geometries of at least 3 axes, if not 5.

CNC Turning

It is more suitable with the geometries of cylindrical and round shapes with the help of an automatic lathe system.

Applications For CNC Prototypes

Used extensively across various manufacturing industries, including automotive, medical devices, aerospace, consumer electronics, and CNC prototypes. Our top-notch service defines our precision machining such that each prototype produced adequately delivers performance, durability, and accuracy, and is industry-specific.

Automotive Prototyping

The application of cnc machining for creating functional auto parts may include an engine part, a dashboard, and or brake component that is created with a high level of precision and durability.

Send Your Inquiry Today

Medical Devices

Surgical instruments, implants, and diagnosis tools, which are accurate replicas of those required medically.

Send Your Inquiry Today

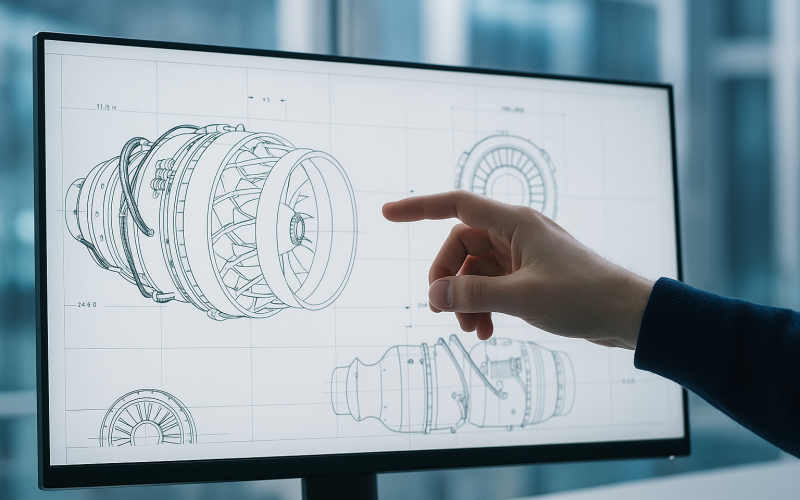

Aerospace Components

High-accuracy imperialism for specialized products like aerospace parts including turbine blades and other structural members where accuracy and strength are paramount.

Send Your Inquiry Today

Consumer Electronics

Manufacturing of casing and connectors for prototyping smartphones, tablet PCs, and wearable technology gadgets as well as fine parts

Send Your Inquiry Today

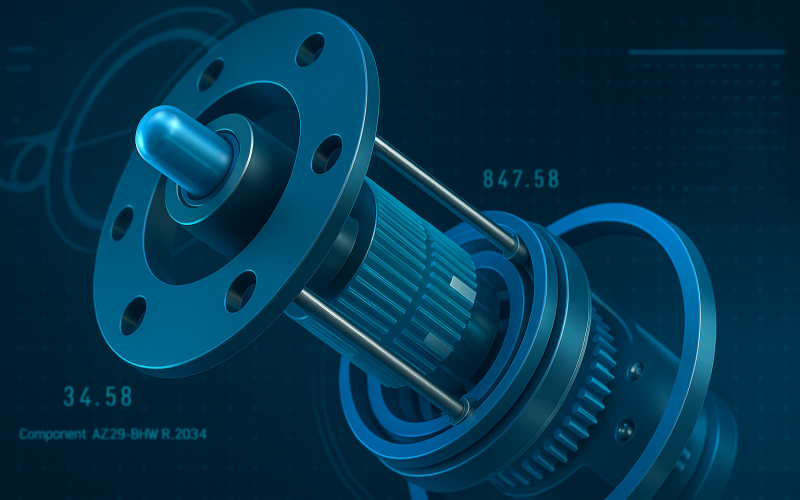

Robotics

Creating models of industrial robotic arms, their joints, and other components for mechanical equipment that must provide high strength for intricate movement.

Send Your Inquiry Today

Industrial Equipment

Customized gears, brackets, and machine parts used in construction equipment and manufacturing lines through Computer Numerical Control or CNC prototyping

Send Your Inquiry Today

Marine Engineering

Manufacturing and supplying of anti-corrosion components for marine engines, propellers, and underwater parts.

Send Your Inquiry Today

Custom Tooling

Custom molds are manufactured through the use of Computer Numerical Control for making molds and fixtures to be employed in different production procedures.

Send Your Inquiry Today

What’s the Significance of a Prototype with CNC Machining?

Here are some significance of having a prototype along with CNC machining:

- Design Potential: Exploit difficult geometries and angles with our 3-axis and 5-axis mills for the CNC prototype’s rapid accuracy.

- Virtual Iteration: Co-design with engineers on our Cloud Manufacturing Platform™ to pre-visualize as well as simulate your CNC prototype with potential designs before the manufacturing process.

- Fast Turnaround: CNC machining is a fast method of production that is also fast in producing a prototype and efficient in scaling up for further production.

- Versatility: Select different types (plastic and metal) and treatment methods of the CNC prototype to meet your product requirements appropriately.

Design Considerations for CNC Prototypes

Here are some of the important design considerations we follow to provide you with CNC Prototyping services.

Consideration | Details |

Max Part Size | 3-Axis: 1800x1000x500 mm (70.9×39.4×19.7 in) 5-Axis: 1000x900x600 mm (39.4×35.4×23.6 in) Turning: Ø 350×600 mm (Ø 13.8×23.6 in) |

Min Part Size | Milling: 12.7×12.7×12.7 mm (0.5×0.5×0.5 in) Turning: 6.4×6.4×6.4 mm (0.25×0.25×0.25 in) |

Min Feature Size | Ø 1 mm (Ø 0.039 in) |

Tolerances | Metals: ±0.13 mm (±0.005 in) Plastics: ±0.20 mm (±0.008 in) |

Lead Time | 8-10 days for <50 parts |

Materials | Plastics: ABS, Nylon, Acetal, PVC, PEEK, UHMW Metals: Aluminum, Steel, Brass, Copper, Titanium |

Finishing Options | As machined, anodizing, polishing, heat treating, powder coating, painting, engraving |

Range of Materials we use in CNC Machining

CNC machining services utilize materials like metals and plastics depending on the specific requirements. Our full line of materials ranges from aluminum to various forms of plastic. This may include PEEK, which allows your prototypes to meet the necessary performance standards.

Aluminum | Plastic | Other Steel | Stainless Steel | Other Metal |

| | | |  |

2024 | ABS | Mid Steel | 303 | Brass |

6061 | Nylon 6 | Alloy Steel | 304 | Copper |

6082 | Acetal (Delrin) | Tool Steel | 316 | Titanium |

7050 | Polycarbonate | 17-4 | Contact us for additional | |

7075 | PVC | 420 | metal machining options | |

HDPE | ||||

PTFE (Teflon) | ||||

PEEK | ||||

Nylon 30% GF | ||||

UHMW |

So, if you’re looking for high-precision CNC prototyping services, contact us today. We’ll work on your next CNC machining prototype, and watch as your creations come to life.

Send Your Inquiry Today

Frequently Asked Questions

We cope with different kinds of materials including metals like aluminum, titanium, steel, and brass; and plastics like ABS, nylon, PVC, and polyester PEEK.

For metal materials, our accuracy range is ±0.13mm(±0.005 inches), and for plastic materials it is ±0.20 mm (±0.008 inches). So, it allows the accurate fabrication of small and massive parts.

In 3-axis milling, the maximum size of the part to be machined is restricted to 1800 x 1000 x 500mm. For 5-axis milling, it is 1000x900x600mm, and for CNC turning it is parts up to Ø 350x600mm.

Indeed, we can provide prototypes in plastic and metal thus you can test and compare the characteristics of your project.

Yes, we have many finishing styles such as anodizing, bright polish, powder coating, painting, and branding depending on our clients’ directions on their projects.

Absolutely Yes! Our CNC machining capabilities avoid sharp differences between prototyping and actual production for mass products.