PPS Materials for Machining

We can deal with all the materials.

PS Material Type | Explanation | Key Properties | Best Suited Applications |

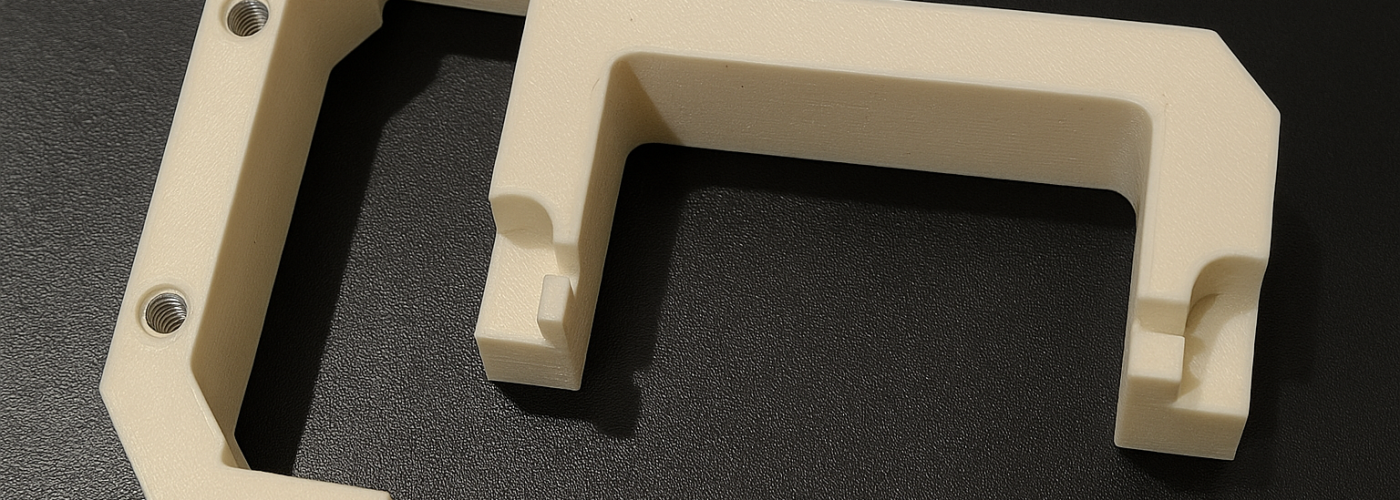

Unfilled PPS | Pure PPS without fillers | High electrical insulation, good machinability | Insulators, seals, and general components |

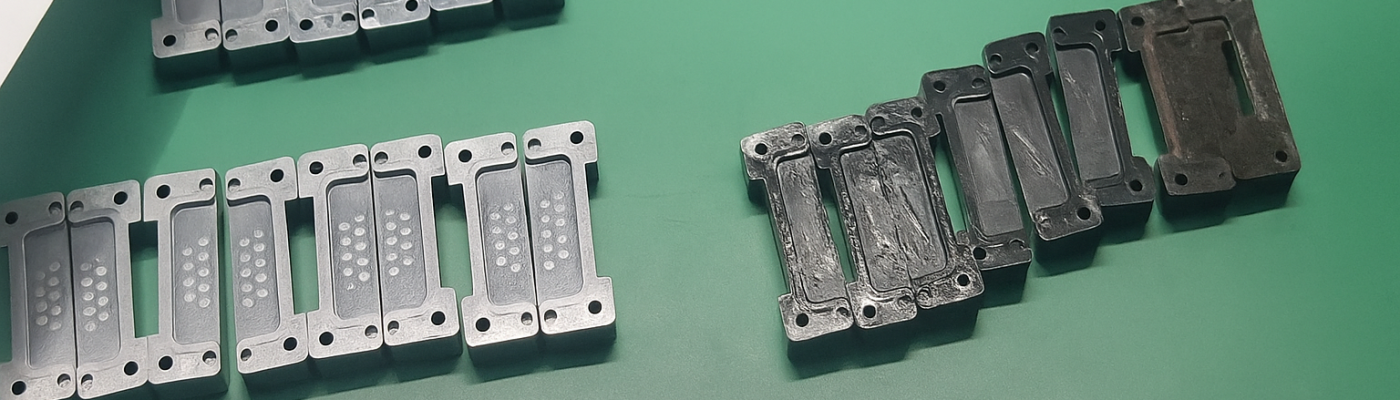

30% Glass-Filled PPS | Reinforced with glass fibers | Improved stiffness, high heat, and dimensional stability | Automotive, pumps, mechanical housings |

40% Glass-Filled PPS | Higher glass loading | Even greater rigidity and dimensional accuracy | Valve parts, structural components |

Carbon-Filled PPS | Filled with carbon fibers | High strength, wear resistance, and conductive properties | Gears, bushings, electronics |

Lubricated PPS | PPS with internal lubricants (e.g., PTFE) | Low friction, enhanced wear properties | Sliding parts, bearings, and moving assemblies |

Mineral-Filled PPS | Enhanced with mineral reinforcements | Thermal stability, reduced cost | Electrical components, automotive |

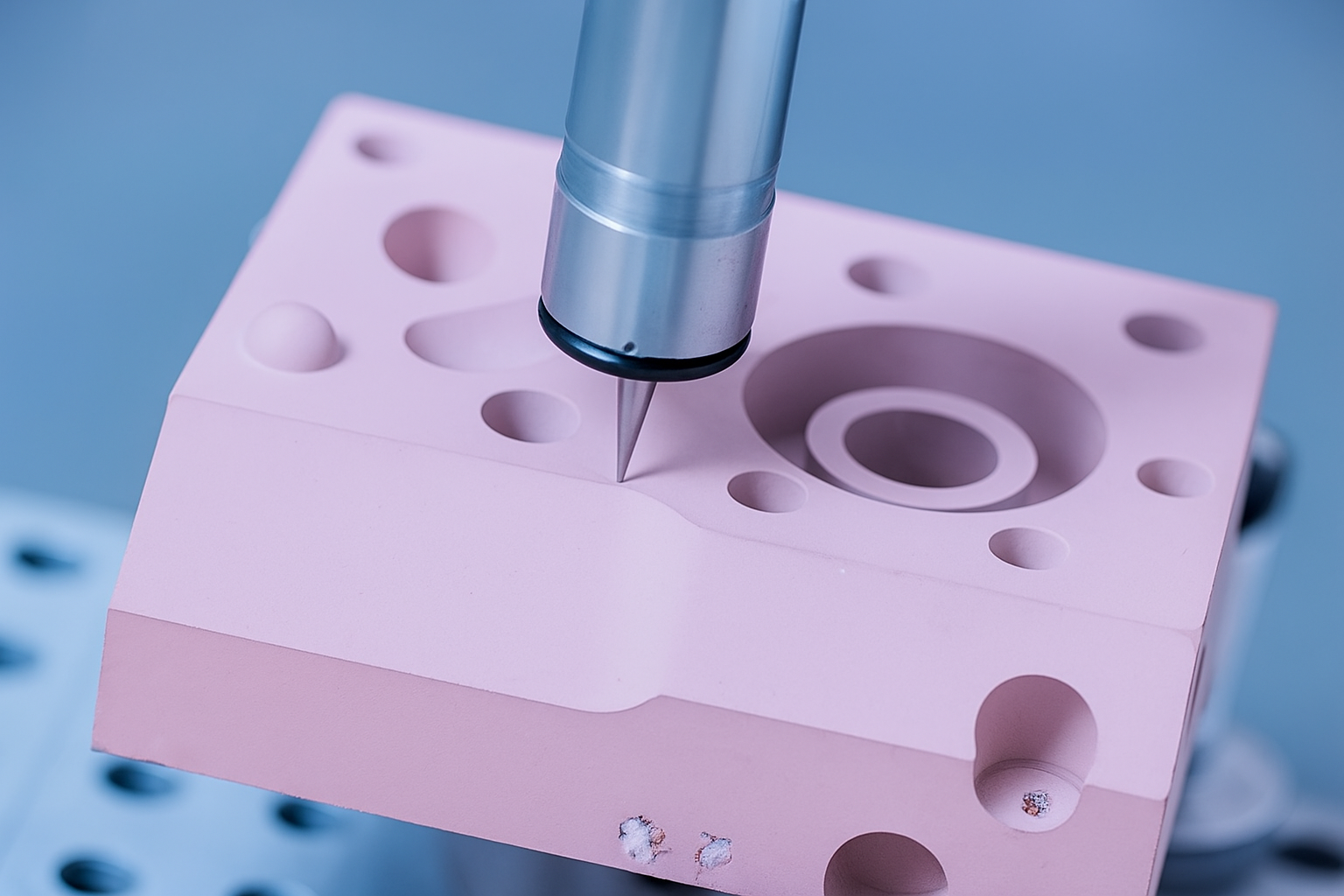

PPS Film/Sheet/Rod | Stock shapes used for machining | Versatile, easy to shape | Prototypes, custom-machined parts |