- Home

- Services

- Industries

- Automation

- Consumer Electronics

- Medical CNC Machining

- PCB Milling

- Aerospace Machining

- Automotive CNC Machining

- CNC Machined Bicycle Parts

- CNC Bottle Opener Machining

- CNC Camshaft Machining

- CNC Screw Machining

- CNC Machining Spare Parts

- CNC Piston Machining

- CNC Machined Gifts

- CNC Machined Fly Wheel

- CNC Machined Safety Razor

- CNC Machined Fidget Spinner

- CNC Machined Dice

- CNC Machined Chess Pieces

- Gallery

- Resources

- About Us

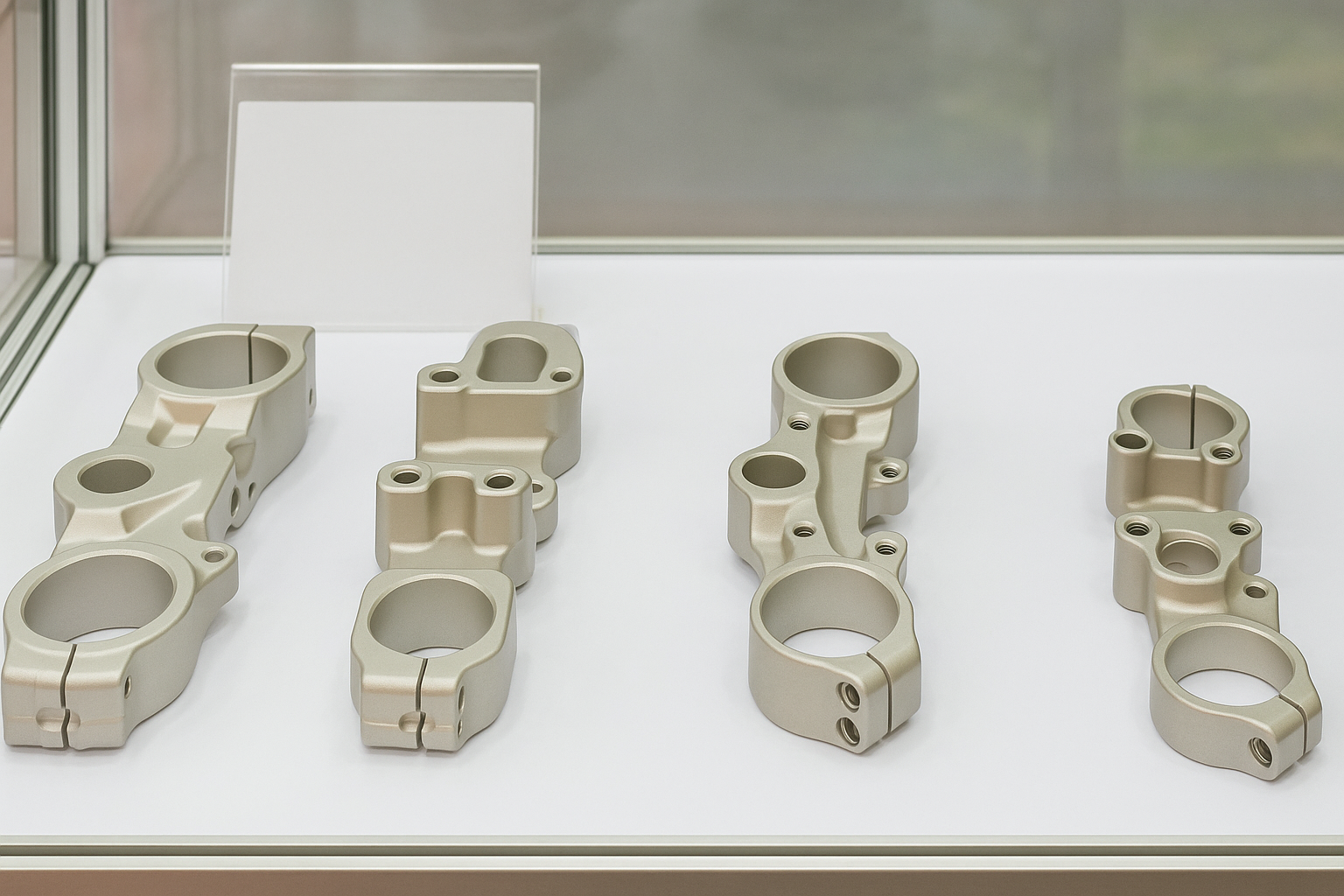

Aluminum Die Casting Services

At our company, we focus on aluminum die-casting services that produce top-quality parts with perfect specifications as soon as possible. With the aid of modern machinery and experienced human resources, we provide industries around the world with matching aptness and efficiency.

- Tolerance: ± 0.005” or 0.12 mm

- 24/7 Technical Support

- ISO 9001 & ISO 13485 Quality Management Systems

- Extensive OEM/ODM Options

Send Your Inquiry Today

TOPS – Your Complete Solution for Aluminum Die Casting

What is Aluminum Die Casting?

Aluminum die casting is the making of Aluminium parts by injecting molten aluminum at high pressure into an intricately fashioned die cavity. It is low density, corrosion resistance, and thermal conductivity make it suitable to offer good mechanical properties for use in the automobile industry and other industries to produce lightweight and durable components.

Why Aluminum Die Casting?

- Outstanding Precision:Aluminum die casting is a relatively easy process that enables the creation of designs with a small variation from the reference dimensions, which is suitable for highly detailed parts.

- Superior Surface Quality:The pre-coating process produces a smooth surface on the resultant parts rescue subsequent polishing. With low density and a high degree of recyclability, the material is both energy-saving and economical, particularly in high-volume manufacturing tight tolerances, making it ideal for complex parts.

- Superior Surface Quality:The resulting parts exhibit smooth finishes, often eliminating the need for further polishing.

- Cost-Effective for High Volumes:With low density and excellent recyclability, aluminum is energy-efficient and economical for mass production.

- Lightweight & Durable:The prominent characteristics of aluminum alloys may include strength & lightness, ideal for high-stress and low-weight usage.

- Eco-Friendly: Die casting is a sustainable manufacturing methodology because aluminum is very much recyclable.

Different Aluminum Die Casting Alloys: Properties and Applications

Although the specialty of TOPS Precision is production in stainless and carbon steel, the company offers different types of aluminum alloys to cater to various uses. Every alloy contains certain characteristics appropriate to various spheres — from repeatedly used, strong structural elements to hardly erodible casings. Here are some popular aluminum alloys used in die casting:

Alloy | Properties | Applications |

A380 | Excellent fluidity, corrosion resistance | Automotive parts, enclosures, and brackets |

A360 | High strength, good pressure tightness | Engine components, aircraft parts |

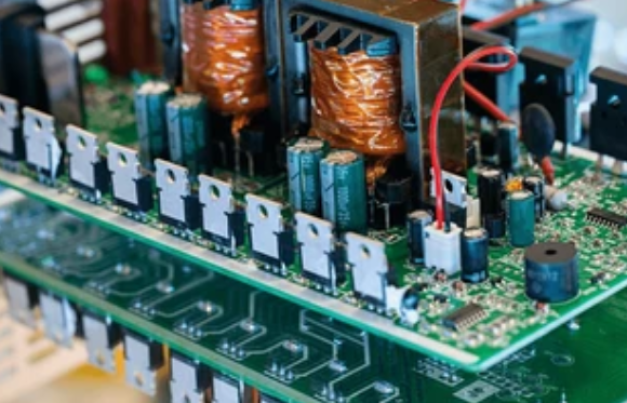

ADC12 | Superior castability, moderate strength | Electronics housing, motor housings |

A413 | High thermal conductivity, corrosion resistance | Lighting fixtures, heat sinks |

AlSi9Mg | High strength, good ductility | Precision instruments, frames |

A390 | Wear resistance, low thermal expansion | Hydraulic cylinders, piston engines |

518 | Lightweight, good for thin-walled parts | Aerospace, automotive |

Ensure Quality & Precision

TOPS Precision offers its clients aluminum die-casting solutions that fulfill the highest quality requirements. All our facilities have installed proper technology to make sure there is full process transparency and quality assurance is there.

Send Your Inquiry Today

Why TOP Precision for Aluminum Die Casting?

Wide Range of Options

We provide different grades of aluminum alloys, different surfacecoatings, and tight dimensions. We ensure that our professionalteam will handle all the work without any deviations.

State-of-the-Art Facility

Our workers and equipment are highly trained to offer efficientproduction on all scales ranging from small scale to large orders. Weoffer die casting out of aluminum alloy to intricate details to a variety ofindustries.

Certified Quality Assurance

TOPS Precision has its Quality Department which makes the company lS0 9001&1S0 13485 compliant. The stages of productionare well-watched to ensure accuracy and efficiency are achieved.

Customer Support

We also have an automatic and efficient quote generator so thecustomers can get their quotes in the shortest time possible, and as forthe orders they place, customers can always track what is being done tothem at any given time.

Uses of Aluminum Die Casting

Aluminum die casting is ideal for manufacturing lightweight yet strong parts used across various sectors, including:

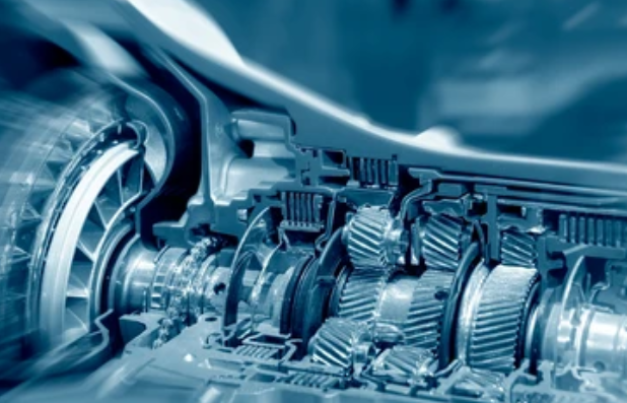

Automotive Components

Electrical Enclosures

Consumer Electronics

Industrial Machinery

Medical Devices

For more details on the high-precision aluminum die-casting services offered by our company, you can talk to us or visit TOPS Precision to speak to us about your unique requirements.

Send Your Inquiry Today

Frequently Asked Questions

Aluminium provides high strength-to-weight ratios, resists corrosion, good thermal conductivity, and a high degree of durability, thus making it ideal for lightweight strength members.

Our assembly and drawing tolerances are within ± 0.1mm to guarantee the accuracy of our parts to your requirements.

Yes; we offer both OEM and ODM agreements for die casting in accordance with the client’s design and functional specifications.

Check out the quality and industry compliance of our facility; we have ISO 9001 and ISO 13485 certifications.

Our standard lead time is 10 days for most products, but it may take longer if the order and its quantity are more complicated.

We deal with different types of aluminum alloys such as A380, A360, and ADC12 each having unique characteristics like mechanical strength, heat dissipation, and corrosion protection respectively.

Our equipment is capable of working on specific aluminum parts not exceeding a certain weight, with the size, they’re designed for intricate and highly accurate applications.

Of course Yes, there are several types of protective coatings, namely powder coating, anodizing, and polishing. They all contribute to augmenting durability and appearance, as well as preventing corrosion.