En el mundo de fabricación de rápido movimiento, La demanda de materiales que entregan resistencia sin exceso de peso es mayor que nunca. Los metales livianos están a la vanguardia de esta tendencia, haciendo posible diseñar productos que sean más eficientes en combustible, consciente de la energía, y más fácil de fabricar. Desde componentes aeroespaciales hasta electrónica de consumo, Estos materiales están dando forma a la forma en que los ingenieros y fabricantes piensan en el diseño de productos..

Esta guía explora cuáles son los metales livianos, sus diferentes tipos, beneficios clave, desafíos, y aplicaciones industriales.

¿Cuáles son los diferentes tipos de metales livianos??

Los metales livianos generalmente se definen como metales con baja densidad pero suficiente fortaleza, durabilidad, y resistencia servir en entornos exigentes. A continuación se muestran las opciones más utilizadas.

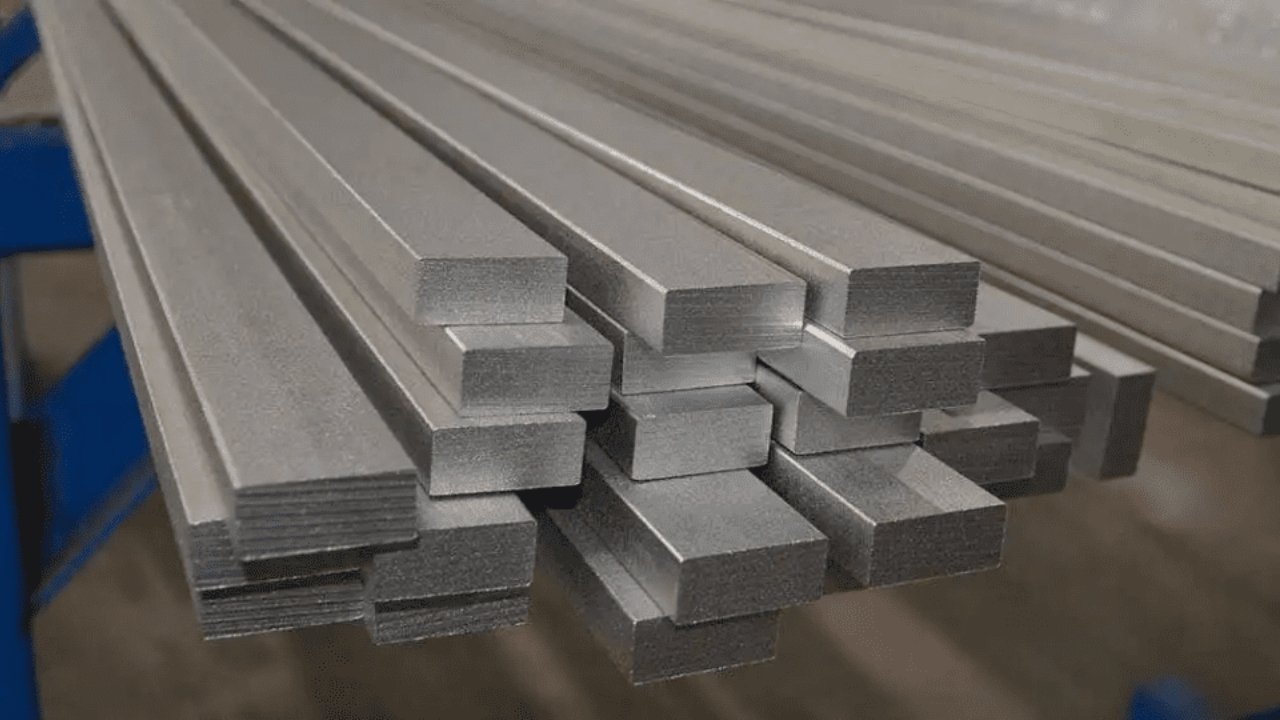

1. Aluminio y sus aleaciones

Densidad: ~ 2.7 g/cm³ (aproximadamente un tercio que el de acero).

Propiedades clave: Alta resistencia a la corrosión, Excelente maquinabilidad, conductividad térmica y eléctrica.

Aleaciones:

6061 aluminio (magnesio + silicio) → Fuerte, dúctil, resistente a la corrosión.

7075 aluminio (basado en zinc) → muy fuerte, a menudo utilizado en aeroespacial y defensa.

Métodos de fabricación: Fundición, extrusión, laminación, y mecanizado.

Aplicaciones: Fuselajes de aviones, piezas automotrices, intercambiadores de calor, latas de bebidas, y materiales de construcción.

Por qué aluminio?

Ofrece un gran equilibrio entre el costo, reducción de peso, y versatilidad. También es altamente reciclable, haciéndolo tanto económico como sostenible.

2. Aleaciones de magnesio

Densidad: ~ 1.7–1.8 g/cm³ (el metal estructural más ligero).

Propiedades clave: Muy baja densidad, fuerza moderada, Excelente amortiguación de vibración, alta maquinabilidad.

Limitaciones:

Puede corroerse si no está protegido.

Produce chips y polvo combustibles durante el mecanizado, requiriendo cuidadosos controles de seguridad.

Aplicaciones:

Automotriz → bloques de motor, carcasas de transmision, ruedas.

Bienes de consumo → computadoras portátiles, cámaras, marcos de bicicleta, artículos deportivos.

Por qué magnesio?

Es el metal estructural más ligero, haciéndolo ideal donde se necesita una reducción de peso extrema. Sin embargo, A menudo se necesitan recubrimientos o aleaciones adicionales para mejorar su resistencia a la corrosión y durabilidad.

3. Titanio y sus aleaciones

Densidad: ~ 4.5 g/cm³ (más pesado que el aluminio, Pero mucho más fuerte).

Propiedades clave:

Resistencia de corrosión excepcional (especialmente en ambientes marinos y químicos).

Alta relación resistencia-peso.

Excelente rendimiento a temperaturas elevadas (retiene la resistencia de hasta ~ 550 ° C).

Desafíos:

Difícil y costoso de la máquina debido a la dureza y la baja conductividad térmica.

Alto costo de materia prima.

Aplicaciones:

Aeroespacial → motores a reacción, tren de aterrizaje, fuselaje.

Médicos → Implantes, instrumentos quirúrgicos.

Marine → Estructuras en alta mar, componentes de buques.

Por qué titanio?

Aunque más pesado que el aluminio, La resistencia superior y la resistencia a la corrosión del titanio lo convierten en una opción superior para la crítica, Aplicaciones de alto rendimiento donde la seguridad y la durabilidad son esenciales.

Comparación de metales livianos

| Propiedad / Característica | Aluminio | Magnesio | Titanio |

| Densidad (gramos/cm³) | ~ 2.7 | ~ 1.7–1.8 | ~ 4.5 |

| Peso relativo | Medio (más ligero que el acero) | Metal estructural más ligero | Más pesado que el aluminio, más ligero que el acero |

| Relación fuerza-peso | Bien | Moderado | Excelente |

| Resistencia a la corrosión | Alto (Especialmente con recubrimientos) | Bajo a moderado (Necesita protección) | muy alto (especialmente en ambientes marinos y químicos) |

| maquinabilidad | Bien, pero necesita enfriamiento para la conductividad térmica | Fácil de mecanizar, Pero el polvo es inflamable | Difícil, Requiere herramientas especiales y enfriamiento |

| Conductividad térmica | Alto | Moderado | Bajo |

| Reciclabilidad | Excelente | Bien | Limitado (intensivo en energía para reciclar) |

| Costo (Relativo) | Bajo (de presupuesto) | Moderado a alto | Alto (el más caro) |

| Aplicaciones comunes | Automotor, aeroespacial, construcción, electrónica | Piezas de automóviles, equipo deportivo, carcasas para electrónica | Aeroespacial, implantes medicos, marina, defensa |

| Ventaja clave | Rentable y versátil | Más liviano | Metal liviano más fuerte y duradero |

Por qué elegir metales livianos para sus proyectos?

Los metales livianos no se tratan solo de reducir el peso; Ofrecen una amplia gama de ventajas funcionales.

Resistencia a la corrosión

Ejemplo: El titanio se resiste a la corrosión del agua de mar, haciéndolo indispensable en ingeniería marina.

Durabilidad y resistencia

A pesar del bajo peso, Los metales como el magnesio y el titanio pueden soportar cargas pesadas y condiciones de servicio duras.

Alta relación resistencia-peso

Esta propiedad permite a los diseñadores reducir la masa mientras mantienen o incluso mejorando la fuerza.

En diseño automotriz, Los metales más ligeros reducen el consumo de combustible y las emisiones.

Reciclabilidad

El aluminio y el magnesio se pueden reciclar con una pérdida mínima de propiedades, Apoyo a la fabricación circular y la reducción de la huella ambiental.

Propiedades térmicas

El aluminio tiene una excelente conductividad térmica → útil en intercambiadores de calor y refrigeración electrónica.

La baja expansión térmica ayuda a mantener la estabilidad dimensional en aplicaciones de alta temperatura.

Consideraciones importantes al seleccionar metales livianos

Elegir el metal liviano correcto depende de múltiples factores:

Propiedades mecánicas y térmicas

Aluminio → buena maquinabilidad, alta conductividad.

Magnesio → extremadamente ligero, pero requiere recubrimientos protectores.

Titanio → más fuerte y duradero, Ideal para entornos de alto estrés y alta temperatura.

Sostenibilidad e impacto ambiental

Considere la reciclabilidad y la huella de carbono.

El magnesio y el aluminio son altamente reciclables; El titanio es intensivo de energía para producir.

Restricciones presupuestarias

Aluminio es generalmente la opción más rentable.

Magnesio es liviano pero más caro de procesar de manera segura.

Titanio es el más caro pero ofrece un rendimiento inigualable en aplicaciones especializadas..

Requisitos de solicitud

Aeroespacial → priorizar la resistencia y la resistencia a la fatiga (titanio, aluminio de alta resistencia).

Automotriz → Balance entre costo y reducción de peso (aluminio, magnesio).

Electrónica → Ligero y conductor (aluminio, aleaciones de magnesio).

Desafíos de usar metales livianos

Mientras que los metales livianos proporcionan ventajas claras, Los fabricantes deben administrar varios desafíos:

Desperdicio de materiales: Sin mecanizado de precisión, La chatarra excesiva puede aumentar los costos.

Dificultad de mecanizado:

Titanium requiere herramientas especiales y sistemas de enfriamiento.

El mecanizado de magnesio debe tener en cuenta los riesgos de incendio.

El aluminio requiere un manejo térmico debido a la alta conductividad.

Altos costos de materia prima: Las aleaciones de titanio y magnesio pueden aumentar significativamente los presupuestos generales del proyecto.

Necesidades de procesamiento especiales: Recubrimientos, tratamientos térmicos, y las capas protectoras agregan complejidad y costo.

Aplicaciones de metales livianos

Los metales livianos son indispensables en todas las industrias:

Aeroespacial: Fuselajes de aviones, tren de aterrizaje, piezas de motor de reacción.

Automotor: Paneles de cuerpo, ruedas, Componentes del motor para mejorar la eficiencia del combustible.

Médico: Implantes quirúrgicos, prótesis, y dispositivos médicos.

Equipo deportivo: Trefetas, bicicletas, cascos, equipo de rendimiento.

Electrónica de consumo & 3C Productos C: portátiles, teléfonos inteligentes, cámaras, y trípodes.

Construcción: Marcos de ventana, paredes de cortina, materiales para techos.

Eléctrico & Energía: Líneas de transmisión (aluminio), carcasa de la batería, marcos solares.

Marina: Plataformas de petróleo en alta mar, buque piezas, componentes resistentes a la corrosión.

Futuro de los materiales livianos

El futuro parece muy brillante para los metales y materiales livianos.. Como industrias como el aeroespacial, automotor, y la electrónica continúa creciendo, El empuje para el encendedor, más fuerte, y más materiales ecológicos solo se fortalecerán.

Ya estamos viendo grandes cambios:

Autos eléctricos Necesita marcos livianos y carcajadas de baterías para ir más lejos con una sola carga.

Aviones están utilizando aluminio más avanzado, magnesio, y aleaciones de titanio para ahorrar combustible y reducir las emisiones.

Electrónica de consumo Al igual que los teléfonos inteligentes y las computadoras portátiles se están volviendo cada vez más delgados sin perder fuerza, Gracias a nuevos diseños de materiales.

Otra tendencia emocionante es el surgimiento de materiales compuestos (Mezclas de metales con fibra de carbono, cerámica, o polímeros). Estos a menudo ofrecen un rendimiento aún mejor que los metales solo.

encima de eso, La tecnología de reciclaje está mejorando. En el futuro, será más fácil y más barato reutilizar aluminio, magnesio, e incluso titanio. Esto significa menos desperdicio, costos más bajos, y producción más verde.

En términos simples, El futuro de los materiales livianos se trata de:

Volviendo más ligero (Para una mejor eficiencia).

Fortaleciéndose (para manejar condiciones difíciles).

Volviéndose más verde (a través de reciclaje y producción sostenible).

Entonces, Ya sea que esté diseñando autos, aviones, o incluso dispositivos médicos, Los metales y los materiales livianos van a desempeñar un papel muy importante en la que los productos sean más inteligentes, más rápido, y mejor para el planeta.

Conclusión

Los metales livianos son fundamentales para la ingeniería moderna, ofreciendo una combinación de baja densidad, fortaleza, y durabilidad que los hace invaluables en todas las industrias. Si el objetivo es reducir el consumo de combustible en el transporte, Extender la durabilidad en entornos duros, o mejorar el rendimiento en productos de consumo, Los metales livianos proporcionan una ventaja competitiva.

La elección entre aluminio, magnesio, y el titanio depende de presupuesto, requisitos de rendimiento, y objetivos de sostenibilidad. Mientras existen desafíos como las dificultades de mecanizado y los altos costos, Las ventajas de los metales livianos superan con creces sus limitaciones.

Preguntas frecuentes

- ¿De qué manera pueden los metales livianos afectar el diseño de su parte??

Permiten un uso reducido de material, geometrías más complejas, y mejor flexibilidad de diseño, todo mientras mantiene la integridad estructural. - Que es más ligero: aluminio o titanio?

El aluminio es más ligero. El titanio es casi el doble de denso pero ofrece una fuerza superior. - ¿Qué metal liviano es el más barato y liviano para la fabricación??

El aluminio es el metal liviano más asequible, mientras que el magnesio es el metal estructural más ligero.

Leer más:

Enlace a nuestro Servicios de mecanizado CNC

Consejos de diseño de fundición de die

Formulario de molienda esencial, tu guía práctica