Injection molding is one of the most widely used manufacturing processes for producing plastic components in large quantities with high precision. From consumer electronics and automotive parts to medical devices and packaging, injection molding enables cost-efficient production at scale.

A key factor that determines the success of this process is the type of injection mold used. Different mold categories—based on feeding system, number of cavities, mold plates, and special mechanisms like unscrewing—directly influence production speed, product quality, material efficiency, and tooling costs.

This article provides a comprehensive guide to the types of injection molds, their components, beneficios, y aplicaciones industriales, helping engineers and manufacturers make informed decisions when selecting mold tooling.

What Are Plastic Injection Molds?

Plastic injection molds are precision-engineered tools used to shape molten plastic into desired parts during the injection molding process. These molds are typically made from hardened acero o aluminio, depending on the required durability, volumen de producción, y presupuesto.

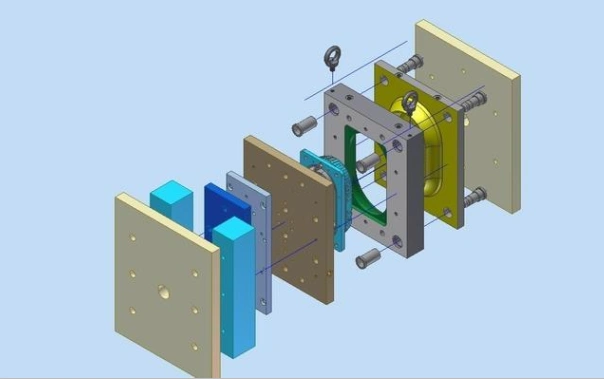

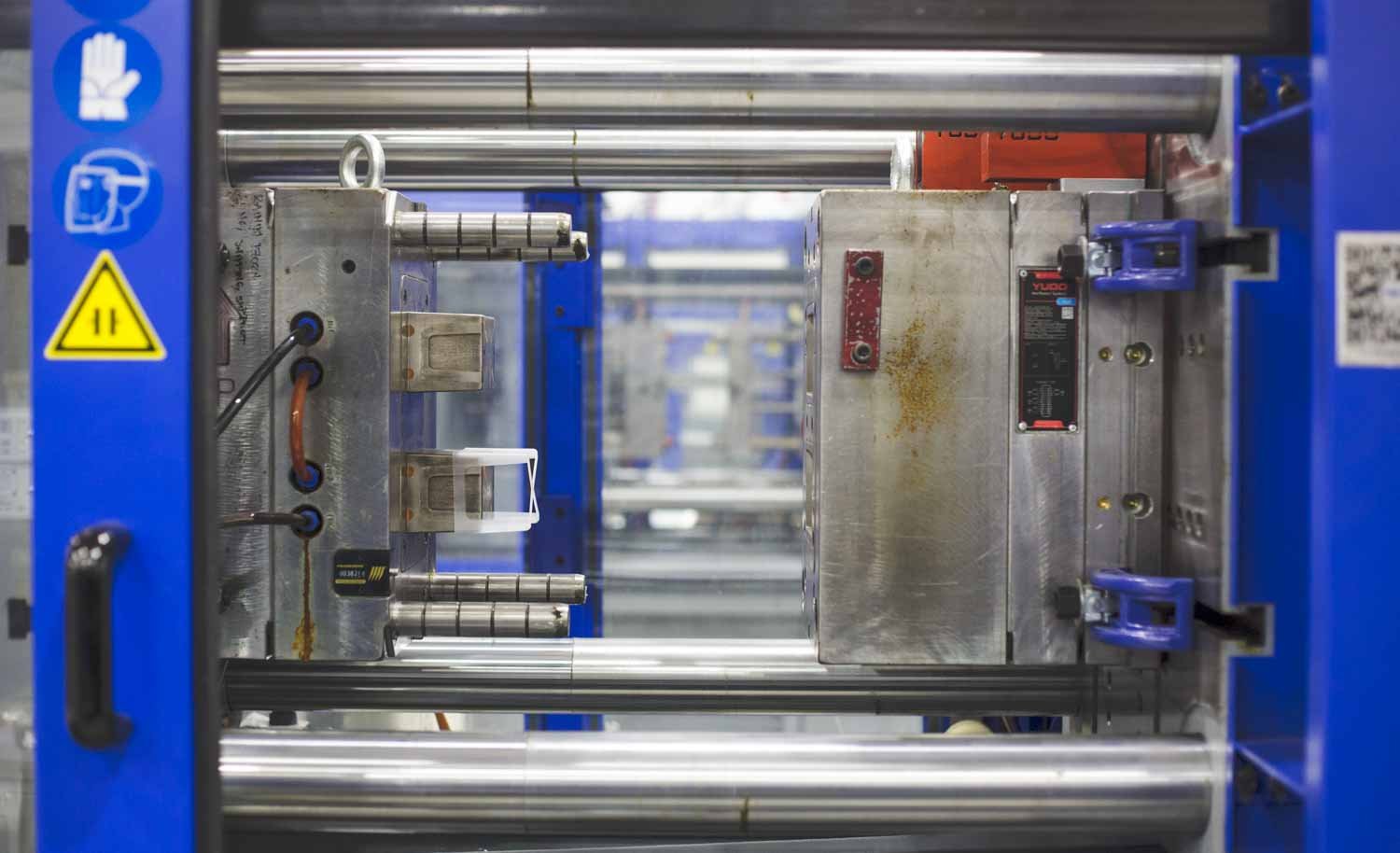

Each mold consists of two halves:

Fixed mold (stationary half): Mounted on the stationary platen of the molding machine.

Moving mold (dynamic half): Mounted on the movable platen, enabling mold opening and part ejection.

When the two halves close, they form a cavity into which molten plastic is injected under high pressure. Once cooled and solidified, the mold opens, releasing the finished product.

Components of Plastic Injection Tooling

The design of an injection mold is complex, with each component serving a specific role in ensuring smooth production and consistent quality.

Guide Pins and Bushings: Maintain precise alignment between mold halves during opening and closing cycles.

Sprue and Runner System: Channels that deliver molten plastic from the machine nozzle to the mold cavities.

Puerta: The entry point where plastic flows into the cavity. Common gate types include:

Edge Gate – Best for flat parts and two-plate molds.

Sub Gate – Automatically trimmed and flexible in placement.

Hot Tip Gate – Ideal for conical or round shapes requiring uniform flow.

Direct/Sprue Gate – Used in single-cavity molds for strength and simplicity.

Locating Ring: Ensures proper mold alignment with the machine nozzle.

Mold Cavity and Core: The negative shape of the final product; multiple cavities allow higher productivity.

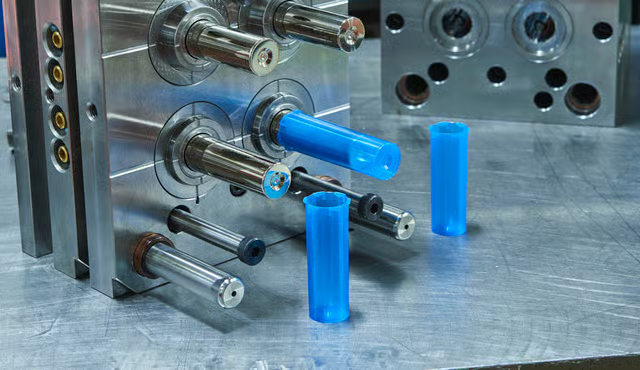

Ejector Pins and Ejector Plate: Push finished parts out of the mold after cooling.

Shot Volume: The precise amount of molten plastic required to fill the cavity.

Clamping Plates: Secure the mold to the injection molding machine.

Understanding these elements is critical, as even small deviations in design can lead to molding defects such as warping, sink marks, o imprecisiones dimensionales.

Types of Injection Mold Classification

A. Based on Feeding System

The feeding system defines how molten plastic flows from the machine nozzle into the cavity.

Hot Runner Injection Mold

Uses heated runners to keep plastic molten within the manifold.

Ventajas: Faster cycles, desperdicio mínimo, no need for regrinding runners, excellent for high-volume production.

Desventajas: High tooling and maintenance costs, complex cleaning, difficulties with color/material changes, risk of degradation for heat-sensitive plastics.

Aplicaciones: De alta precisión, multi-cavity production such as medical components, embalaje, y electrónica de consumo.

Cold Runner Injection Mold

Runners are unheated, and excess material solidifies with each cycle.

Ventajas: Lower tooling cost, easy maintenance, versatile material compatibility, easier color changes.

Desventajas: Higher material waste, need for regrinding runners, slower production speed.

Aplicaciones: Suitable for lower-cost production and prototyping.

Insulated Runner Mold

Combines features of cold runner molds with partial heating to keep plastic molten.

Ventajas: Less expensive than hot runners, allows quicker material changes, simpler control system.

Desventajas: Limited to certain materials, not suitable for high-performance plastics.

Aplicaciones: Medium-volume production requiring balance between cost and efficiency.

B. Based on the Number of Cavities

Single-Cavity Injection Mold

Produces one part per cycle.

Ventajas: Lower tooling cost, easier process control, reliable for low-volume runs.

Contras: Tasa de producción más lenta, higher per-unit cost.

Use Cases: Creación de prototipos, small-scale manufacturing, precision parts.

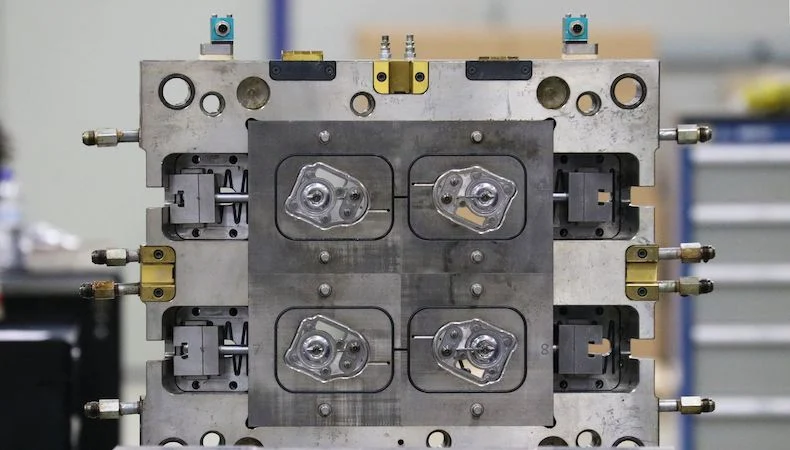

Multi-Cavity Injection Mold

Produces multiple identical parts in each cycle.

Ventajas: Mayor eficiencia, reduced per-unit cost, faster mass production.

Contras: Higher initial tooling investment, requires advanced machine capacity.

Use Cases: Piezas de automóviles, bienes de consumo, packaging items.

Family Injection Mold

Multiple cavities designed to produce different but related parts in one cycle.

Ventajas: Reduces total production time and cost, useful for assemblies.

Contras: Limited to parts made from the same material and color, higher complexity.

Use Cases: Left-right components, product assemblies like casings with matching lids.

C. Based on Mold Plate

Two-Plate Injection Mold

Simplest and most common design with one parting line.

Ventajas: Low tooling cost, straightforward construction.

Contras: Manual runner removal required in cold runner setups.

Use Cases: Small-scale, general-purpose molding.

Three-Plate Injection Mold

Includes an additional stripper plate, creating two parting lines.

Ventajas: Automatic separation of runner and molded part, higher efficiency.

Contras: More expensive tooling, limited to cold runner systems.

Use Cases: Multi-cavity cold runner molds for high-volume parts.

Stack Injection Mold

Multiple levels of cavities arranged vertically.

Ventajas: Increases productivity without requiring larger machines, reduces clamp tonnage.

Contras: High manufacturing complexity and initial cost.

Use Cases: embalaje (bottle caps, contenedores), medical disposables, bienes de consumo.

D. Based on Unscrewing Injection Mold

Specialized molds for producing threaded parts.

Equipped with mecánico, eléctrico, or hydraulic drive systems that rotate to unscrew the part during ejection.

Ventajas: Automates the production of threaded components, reduces damage risk, supports high-volume manufacturing.

Aplicaciones: Bottle caps, threaded closures, cojones, pernos, cosmetic packaging, automotive fasteners.

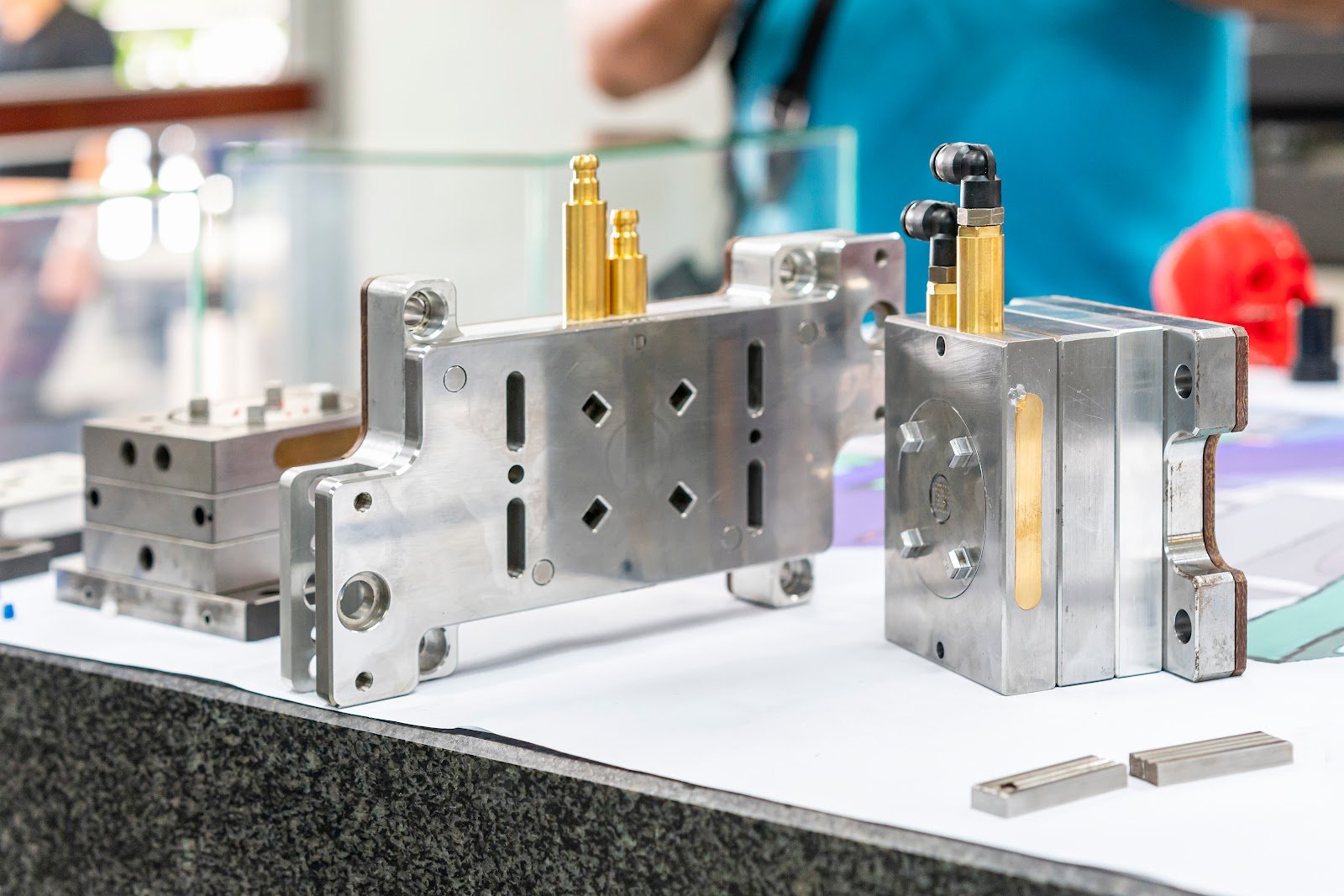

Injection Mold Tooling Materials: What Are Molds Made Of?

When we talk about injection molds, one big question is: what are they actually made of? The choice of material for the mold is really important because it affects cost, durabilidad, and how many parts the mold can produce before wearing out.

Here are the most common tooling materials:

Steel Molds

Steel is the go-to material for high-volume production. Está duro, de larga duración, and can handle millions of molding cycles without losing accuracy. Steel molds are more expensive to make at first, but they pay off when you need to run large batches over time.

Aluminum Molds

Aluminum molds are lighter, más fácil de mecanizar, and usually cost less than steel. They’re great for prototyping or low- to medium-volume production. The downside is that aluminum wears out faster, so it’s not the best choice if you plan to make millions of parts.

Beryllium-Copper Inserts

Sometimes molds use beryllium-copper in certain areas. This material is excellent at conducting heat, which helps the mold cool faster and shortens cycle times. It’s not usually used for the whole mold but rather for sections where fast cooling is needed.

What’s the Difference Between Hard and Soft Injection Mold Tooling?

Soft Tooling

Soft tooling usually means the mold is made from aluminio or another softer material. These molds are quicker and cheaper to make, which makes them great for prototipos, pruebas, or small production runs. The downside is they don’t last as long—after a certain number of cycles, the mold wears out and can’t produce accurate parts anymore.

Hard Tooling

Hard tooling means the mold is made from acero endurecido. These molds take longer and cost more to manufacture, but they can handle hundreds of thousands to millions of cycles without breaking down. That makes them perfect for producción en masa where you need consistent quality over a long period.

Simple Way to Think About It

Soft tooling = faster and cheaper upfront, but limited lifespan.

Hard tooling = expensive upfront, but lasts much longer and is more cost-effective for large-scale production.

Entonces, if you’re testing a new design or making only a few thousand parts, soft tooling is usually the smarter choice. But if you know you’ll be running big batches for years, investing in hard tooling will save you money in the long run.

How Do Tooling Complexity and Tight Tolerances Work Together in Injection Molding?

En moldeo por inyección, two things really affect how tricky a mold is to design and build: complejidad y tolerancias. Let’s break it down in simple terms.

Tooling Complexity

This means how complicated the mold is. Por ejemplo, does the mold need moving parts like slides or lifters to release undercuts? Does it have multiple cavities or threaded sections that need unscrewing? The more features you add, the more complex (and expensive) the mold becomes.

Tolerancias estrictas

Tolerances are about how close the final part needs to be to the exact design size. A tight tolerance means very little room for error—think of medical devices or aerospace parts where every millimeter matters. Wider tolerances mean there’s more “wiggle room,” which makes the mold easier to build and maintain.

How They Interact

Here’s where it gets interesting: el more complex the mold is, the harder it becomes to maintain tight tolerances. Every moving piece, every extra cavity, and every special feature adds a chance for tiny errors. encima de eso, tight tolerances often require:

More precise machining of the mold.

Better-quality materials (like hardened steel instead of aluminum).

Extra quality checks during production.

A Real-World Example

If you’re making something simple like a plastic toy, you don’t need ultra-tight tolerances, and the mold design can stay pretty straightforward. But if you’re making a medical syringe or an aerospace connector, Necesitarás both a complex mold and very tight tolerances—which means more time, costos más altos, and a need for expert mold makers.

The Takeaway

High complexity + tight tolerances = more expensive, more time-consuming, but higher-quality parts.

Low complexity + wider tolerances = cheaper and faster, Pero menos preciso.

That’s why it’s always a balance: design engineers and mold makers need to work closely together to decide what level of complexity and tolerance is truly necessary for the part’s function.

How Does Material Flow Affect Tooling in Injection Molding?

When plastic is injected into a mold, it doesn’t just sit still—it flows like liquid before cooling down into a solid part. The way this material flows has a huge impact on how the tooling (el molde) is designed and built.

Flow Paths Matter

Think of the molten plastic like water running through a maze. If the “maze” (el molde) is designed poorly, the plastic might not reach every corner evenly. This can cause defects like short shots (incomplete parts), air pockets, or uneven thickness.

Colocación de la puerta

The gates are the entry points where plastic flows into the mold. If they’re placed in the wrong spot, the flow might not fill the mold properly, or you might see visible marks on the finished part. Tooling designers spend a lot of time figuring out the best gate locations to balance flow and appearance.

tipo de material

Different plastics flow differently. Por ejemplo, ABS flows smoothly, mientras glass-filled nylon is stiffer and more abrasive. This means the tooling has to be designed (and sometimes hardened) to handle the material’s flow behavior.

Cooling and Warpage

If the material doesn’t flow evenly, some areas might cool faster than others, leading to warping or shrinkage. Toolmakers often adjust the cooling channels inside the mold to keep things even.

Simple Way to Think About It

Material flow is like traffic in a city.

If the roads (mold channels) are designed well, traffic (plástico) moves smoothly.

Si no, you get traffic jams, dead ends, and frustrated drivers—except in this case, you get defective parts and worn-out tooling.

Why Are Injection Molds Necessary?

Limitless Design Possibilities: Supports a wide range of industries, from medical devices to aerospace.

Material Selection Flexibility: Each mold can be tailored to handle specific plastic properties, shrinkage rates, and thermal behaviors.

High Product Consistency: Automation reduces human error and ensures uniform part quality.

Efficiency and Cost Control: The right mold design minimizes waste, reduces cycle times, and lowers per-unit costs in mass production.

What Are the Common Issues in Injection Molding Tooling and How Can You Fix Them?

Even with the best-designed molds, injection molding doesn’t always go perfectly. Tooling issues can pop up during production, and knowing how to spot and fix them quickly can save a lot of time and money. Let’s look at some of the most common problems and what you can do about them.

1. Destello (Extra Thin Plastic on Edges)

que es: Extra plastic that seeps out where the mold halves meet.

Why it happens: Poor mold clamping, worn mold edges, or high injection pressure.

How to fix: Tighten the clamping force, repair worn mold surfaces, or reduce injection pressure.

2. Short Shots (Incomplete Filling)

que es: The part doesn’t fill completely, leaving gaps or missing sections.

Why it happens: Not enough injection pressure, poor material flow, or blocked gates.

How to fix: Increase pressure or temperature, improve venting, or redesign gates and runners.

3. Pandeo (Parts Bending or Twisting)

que es: The part cools unevenly and loses its intended shape.

Why it happens: Uneven cooling, poor material flow, or wrong wall thickness design.

How to fix: Adjust cooling channels, change wall thickness, or tweak processing parameters.

4. Sink Marks (Dents on the Surface)

que es: Small depressions or dents on the part’s surface.

Why it happens: Thick sections cool slower, causing uneven shrinkage.

How to fix: Adjust cooling, reduce wall thickness, or add proper rib designs to support the surface.

5. Weld Lines (Visible Lines Where Flows Meet)

que es: Lines on the part where two plastic flows meet but don’t fully bond.

Why it happens: Poor gate placement, low melt temperature, or uneven flow.

How to fix: Change gate locations, increase melt or mold temperature, or adjust flow paths.

6. Desgaste y daños de las herramientas

que es: The mold itself wears down or gets damaged after repeated use.

Why it happens: Abrasive materials (like glass-filled plastics), high clamping force, or poor maintenance.

How to fix: Use hardened steel, apply surface coatings, and schedule regular maintenance.

How to Optimize Costs in Injection Molding Tooling?

Injection molds can be one of the biggest investments in manufacturing, especialmente para la producción de alto volumen. But the good news is—there are smart ways to cut costs without cutting corners. Let’s break down some practical strategies.

1. Choose the Right Tooling Material

Aluminum molds are cheaper and faster to make, great for prototypes or low-volume runs.

Steel molds cost more upfront but last much longer, making them the better choice for large-scale production.

👉 Picking the right material based on your production needs can save a ton in the long run.

2. Simplify the Mold Design

The more complex the mold (extra cavities, lifters, toboganes, hilos), the more expensive it gets. If some features aren’t absolutely necessary, simplifying the design can lower costs while still getting the job done.

3. Optimizar el diseño de piezas

A veces, small changes in the part design can make the tooling easier and cheaper. Por ejemplo:

Keeping wall thickness uniform.

Avoiding deep undercuts.

Adding draft angles for easy ejection.

These tweaks help reduce tooling wear and speed up production.

4. Balance Cavities and Production Volume

A multi-cavity mold makes more parts per cycle, but it’s also more expensive to build. If your order size is small, a single-cavity mold may be more cost-effective. For big production runs, multi-cavity molds save money in the long term by cutting cycle times.

5. Plan de mantenimiento

Neglecting mold care can lead to expensive repairs or even full replacements. Regular cleaning, lubricación, and inspection extend the life of the mold and prevent costly downtime.

6. Work Closely with the Toolmaker

A skilled toolmaker can suggest design improvements, material choices, and cooling layouts that reduce costs. Early collaboration helps avoid expensive redesigns later.

Para llevar

Optimizing tooling costs is all about finding the right balance: don’t just go for the cheapest option, but also don’t over-engineer the mold. By making smart choices in materials, diseño, y mantenimiento, you can lower upfront expenses y save more over the mold’s lifetime.

Choosing a Reliable Injection Molding Partner

Injection mold design is a technical, precision-driven task that requires deep expertise in tooling, materiales, and process optimization. Partnering with an experienced injection molding service provider ensures:

Professional mold design and manufacturing

Diseño para la fabricación (DFM) analysis to prevent defects

High-quality plastic parts optimized for strength, exactitud, and cost-efficiency

Conclusión

Injection molding is an indispensable manufacturing method for modern industries, but the choice of mold type plays a decisive role in production success. Whether classified by feeding system, cavity number, mold plate, or unscrewing mechanisms, each mold offers unique benefits and limitations.

Understanding these categories empowers engineers to select the right mold for their projects, ensuring higher efficiency, costos más bajos, and better product quality.

Preguntas frecuentes

What type of injection mold is most commonly used?

Three-plate multi-cavity molds are widely used because they support high-speed, high-volume production with automated runner separation.

What are the most common materials for injection molding?

abdominales, policarbonato (ordenador personal), polipropileno (PÁGINAS), polietileno (EDUCACIÓN FÍSICA), poliestireno (PD), nylon (Pensilvania), and acrylic.

Do different plastics require different molds?

Sí. Plastics have varying shrinkage rates, flow characteristics, and temperature tolerances. Mold design must account for these properties to maintain dimensional accuracy.

Leer más:

Injection molding vs. Mecanizado CNC

Todo el proceso de fabricación de moho

¿Qué es la fabricación asistida por computadora? (LEVA)?