La distinción más importante en las máquinas de fresado se reduce a la orientación del huso—La parte que contiene y gira la herramienta de corte. Basado en este factor, Las máquinas generalmente se clasifican en máquinas de fresado vertical y máquinas de fresado horizontal. Cada uno tiene fortalezas y debilidades únicas, haciéndolos más adecuados para diferentes aplicaciones.

Para pequeños talleres y prototipos, Las máquinas verticales son la opción común debido a su asequibilidad y simplicidad. Por otro lado, Las operaciones de fabricación a gran escala a menudo favorecen las máquinas horizontales debido a su mayor productividad y capacidad para manejar más pesado, cortes más complejos.

Este artículo analiza de cerca ambos tipos de máquinas., explica brevemente cómo funcionan, y luego entra en profundidad en su diferencias clave. Al final, Tendrá una imagen clara de qué configuración puede ser adecuada para Tus necesidades de mecanizado.

Un vistazo rápido a las máquinas de fresado vertical

Principio de funcionamiento

Se diseña una máquina de fresado vertical para que el huso que sostiene la herramienta de corte esté orientada verticalmente, perpendicular a la pieza de trabajo. Esta configuración permite que la herramienta de corte se mueva hacia abajo hacia el material.. La pieza de trabajo en sí permanece estacionaria, sujetado de forma segura a la mesa de la máquina, mientras que la herramienta de corte se escapa gradualmente.

Las fábricas verticales son favorecidas para trabajo de precisión. El huso vertical permite una mejor visibilidad del área de corte, lo que significa que los operadores pueden monitorear directamente el proceso y hacer ajustes rápidos. Esto hace que las máquinas verticales sean extremadamente populares en las salas de herramientas, talleres de creación de prototipos, y fabricación a pequeña escala.

Otra ventaja es su versatilidad para operaciones a nivel de superficie como ranura, perforación, frente a, y contornear. Sin embargo, Cuando se trata de cortes profundos o trabajando con partes muy grandes., Las máquinas de fresado vertical comienzan a mostrar sus limitaciones.

Tipos comunes (enjuagar & Molienda de cama)

Las máquinas de fresado vertical generalmente vienen en dos diseños principales: molino y fábrica de cama.

Máquinas de fresado de torreta:

Los molinos de torret son compactos y están diseñados para piezas más pequeñas. El eje permanece fijo en su lugar, Pero la cabeza de la torreta puede girar y la mesa puede moverse en múltiples direcciones (Hachas x e y). Este diseño hace que las torretas estén excelentes para trabajos y piezas de servicio ligero que necesitan detalles finos. Piense en ellos como el "caballos de batalla" para la precisión, mecanizado de bajo volumen.

Fresadoras de bancada:

Los molinos de cama son más grandes y más robustos. En este diseño, el huso puede moverse verticalmente, Mientras la mesa se mueve horizontalmente a lo largo de la cama. Esta configuración proporciona más rigidez y soporte para piezas más pesadas.. Las fábricas de cama son más comunes en los talleres de máquinas tradicionales porque logran un equilibrio entre la precisión y la capacidad de manejar componentes medianos.

En resumen, Las fábricas verticales son más simples, Más fácil de aprender, y menos costoso. Son un punto de entrada natural para muchos maquinistas y siguen siendo ampliamente utilizados en todas las industrias para mecanizado a pequeña escala o precisión..

Un vistazo rápido a las máquinas de fresadoras horizontales

Principio de funcionamiento

Las máquinas de fresado horizontal funcionan con el mismo principio fundamental que las máquinas verticales: Una herramienta de corte giratoria elimina el material de una pieza de trabajo fija. Sin embargo, La distinción clave es la orientación horizontal del huso. Este cambio altera dramáticamente cómo funciona la máquina.

En lugar de cortar hacia abajo, La herramienta montada horizontalmente atraviesa el material. Este diseño hace que las máquinas horizontales sean particularmente efectivas para cortes más pesados y profundos, Como la herramienta es más corta y gruesa que su contraparte vertical. La geometría de herramienta más fuerte reduce la vibración, Permitir que la máquina maneje operaciones más exigentes con facilidad.

Las máquinas de fresado horizontal se usan comúnmente para carreras de producción a gran escala, mecanizado de piezas de gran tamaño, y trabajos que requieren tasas agresivas de eliminación de materiales. Industrias como la aeroespacial, energía, y la fabricación de equipos pesados depende en gran medida de las configuraciones horizontales para su capacidad para entregar Alta productividad y rendimiento robusto.

Capacidades especiales (Evacuación de chips & Manejo de ángulo)

Dos de las mayores ventajas de las máquinas de fresadoras horizontales son evacuación de chips y manejo de ángulo.

Evacuación de chips:

Durante la molienda, papas fritas (pequeñas piezas de material eliminado) acumular alrededor del área de corte. En máquinas verticales, La gravedad a menudo hace que las papas fritas se acumulen en la pieza de trabajo, conduciendo a fallas superficiales, calentamiento excesivo, o la necesidad de una limpieza adicional. Máquinas horizontales, por otro lado, Naturalmente, expulse las papas fritas del área de corte gracias a su orientación del huso. Esto no solo mejora el acabado superficial, sino que también reduce el tiempo de inactividad para la limpieza..

Manejo de ángulo:

Las máquinas horizontales a menudo están equipadas con una mesa universal, que permite que la pieza de trabajo se gire e incline. Esta capacidad significa que el cortador puede acercarse a la pieza de trabajo desde múltiples direcciones, haciendo que sea más fácil mecanizar geometrías y características complejas. Máquinas verticales, en contraste, están restringidos a trabajar en un solo avión.

En esencia, Mientras que las fábricas horizontales requieren una mayor inversión inicial, Traen ventajas únicas que las hacen indispensables en alto volumen, entornos de mecanizado complejos.

Ventajas y desventajas en breve

Máquinas de fresado vertical - Pros & Contras

Ventajas: Asequible, ampliamente disponible, Más fácil de operar, Genial para el trabajo de precisión, bajo mantenimiento.

Contras: Profundidad de corte limitada, tasa de eliminación de material más lenta, menos efectivo para grandes partes.

Máquinas de fresadoras horizontales - Pros & Contras

Ventajas: Mayor productividad, mejor evacuación de chips, Capacidad para cortar en los ángulos, Excelente para cortes profundos y grandes partes.

Contras: Caro de comprar y mantener, Más difícil de encontrar operadores calificados, menos adecuado para pequeños talleres.

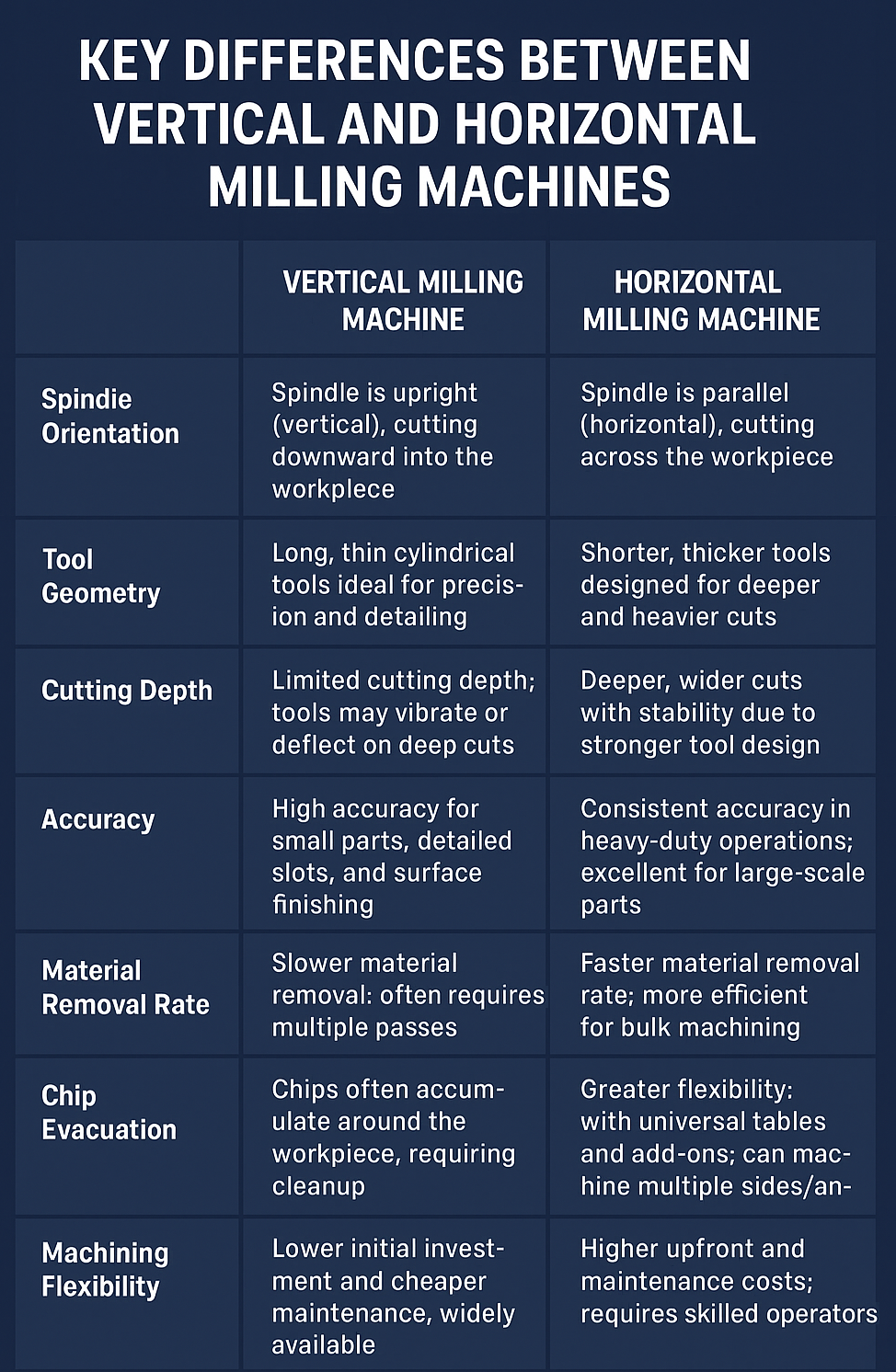

Diferencias clave entre las fresadoras verticales y horizontales

Orientación del huso

La diferencia más obvia entre las máquinas de fresado vertical y horizontal se encuentra en la orientación del huso. En fresado vertical, El eje se coloca en posición vertical, perpendicular a la pieza de trabajo. Esto permite que la herramienta de corte se mueva hacia abajo, presionando el material. La configuración facilita que los operadores monitoreen visualmente el proceso y se ajuste en tiempo real., que es especialmente valioso para el trabajo de precisión, creación de prototipos, y proyectos más pequeños.

A diferencia de, Las máquinas de fresado horizontal colocan el huso paralelo a la pieza de trabajo. Esta configuración horizontal significa que la herramienta se mueve a través del material en lugar de hacia abajo en él. El resultado es un más fuerte, proceso de corte más estable, especialmente para cortes más profundos y piezas de trabajo más grandes. Porque la herramienta es más corta y resistente, Resiste flexión o tambaleándose bajo cargas pesadas, Algo de las herramientas verticales a menudo lucha.

La elección entre las dos orientaciones afecta no solo el rendimiento, sino también los tipos de piezas que puede producir. Los husos verticales son mejores para detallados, mecanizado a nivel de superficie donde la precisión es más importante, mientras que los husillos horizontales brillan en escenarios que requieren energía, velocidad, y durabilidad. Por ejemplo, Hacer moldes o surcos precisos se maneja mejor por una configuración vertical, Mientras que cortar una carcasa de caja de cambios pesada sería más eficiente en una máquina horizontal.

En breve, La orientación del huso prepara el escenario de cómo funciona cada tipo de máquina, influir directamente en la estabilidad, profundidad de corte, y la complejidad de las piezas que puede fabricar.

Geometría y diseño de herramientas

Otra diferencia clave proviene de las herramientas mismas. Uso de máquinas de fresado vertical largo, herramientas cilíndricas delgadas, que puede llegar a espacios tTa y manejar diseños intrincados. Estas herramientas son perfectas para operaciones como la perforación, ranurado, y contornear donde se requieren detalles finos. Sin embargo, Su estructura delgada los hace más propensos a la vibración y la deflexión cuando se les encarga los cortes más profundos o la eliminación de material más pesado.

Por otro lado, Las máquinas de fresadoras horizontales confían en más corto, Herramientas más gruesas. Estos cortadores están diseñados para soportar una mayor resistencia sin doblar ni tambalearse. La geometría los hace ideales para abordar piezas de trabajo más voluminosas y realizar cortes profundos o anchos en menos pases. Además, Las fábricas horizontales pueden acomodar cortadores especializados, como cortadores laterales, fábricas de losas, y configuraciones de molienda de pandillas, que permiten múltiples cortes simultáneamente.

La geometría de la herramienta afecta directamente la productividad y la calidad de la parte. Por ejemplo, Si está mecanizando un pequeño componente de aluminio que requiere ranuras precisas, La herramienta delgada de una máquina vertical es perfecta. Pero si está trabajando con acero endurecido y necesita eliminar una cantidad significativa de material rápidamente, La robustez de las herramientas horizontales ofrecerá resultados mucho mejores.

Esta diferencia en el diseño de herramientas subraya por qué cada máquina tiene su nicho. Mientras que las fábricas verticales se centran en precisión y accesibilidad, Las fábricas horizontales enfatizan potencia y eficiencia.

Cortar especificaciones y precisión

Cuando se trata de precisión, Las máquinas de fresado vertical generalmente toman la delantera, Especialmente para bien, trabajo detallado. Su orientación al huso vertical proporciona una excelente visibilidad, permitiendo que los maquinistas vean exactamente qué está haciendo la herramienta. Este control práctico ayuda a lograr tolerancias estrechas, Hacer que las máquinas verticales sean la opción para los prototipos, moldes, y piezas que requieren un acabado intrincado.

Sin embargo, La precisión no siempre es igual a la eficiencia. Herramientas verticales, Debido a su diseño más largo y más delgado, volverse menos estable cuando se necesitan cortes más profundos. Esta inestabilidad causa vibración, charla, o incluso desviaciones del diseño previsto. Como resultado, Las fábricas verticales son limitadas en cuánto material pueden eliminar en un solo pase.

Máquinas de fresado horizontal, en contraste, Puede que no coincidan con la precisión extrema de las configuraciones verticales en trabajos delicados, Pero se destacan en consistencia bajo carga. Gracias a sus herramientas más gruesas y su diseño rígido., Pueden manejar más profundamente, cortes más pesados sin sacrificar la precisión. Las fábricas horizontales CNC modernas incluso integran sistemas de control avanzados que les permiten rivalizar con máquinas verticales con precisión al tiempo que ofrecen una productividad inigualable.

La comida para llevar? Si su proyecto involucra paredes delgadas, ranuras poco profundas, o acabado estético, Una fábrica vertical es a menudo superior. Pero si necesitas perforaciones profundas, surcos anchos, o mecanizado de servicio pesado con tolerancias consistentes, Las máquinas horizontales superarán cada vez.

Costo y mantenimiento

El costo es a menudo el factor decisivo para muchos talleres al elegir entre máquinas verticales y horizontales. Las fábricas verticales son generalmente mucho más asequible para comprar, con modelos de nivel de entrada disponible para pequeños talleres y centros de capacitación. Su diseño es más simple, lo que significa requisitos de mantenimiento más bajos y menos desgloses. Además, Porque son tan comunes, Encontrar repuestos o operadores calificados rara vez es un problema.

Máquinas de fresado horizontal, sin embargo, Ven con un Tag de precio más pesado. No solo son más caros de comprar por adelantado, pero también requieren mayores costos continuos para el mantenimiento y la reparación. Su compleja construcción y carga de trabajo más pesada significan que los operadores necesitan capacitación especializada., y las piezas de repuesto pueden ser más difíciles de obtener. Estos factores se combinan para hacer de las fábricas horizontales una mayor inversión tanto en tiempo como en dinero..

Dicho esto, El costo más alto viene con beneficios proporcionales. Las fábricas horizontales pueden eliminar el material más rápido, manejar trabajos más grandes, y mantener la productividad en entornos de fabricación de alto volumen. Para las grandes empresas que producen miles de partes idénticas, La inversión a menudo se paga a sí misma en un tiempo reducido de mecanizado y una mayor producción.

Para pequeños talleres y startups, La asequibilidad de las máquinas verticales los convierte en la elección práctica. Pero para las empresas establecidas donde el rendimiento y la eficiencia son críticos, El mayor costo de las máquinas horizontales está justificado.

Tasa de eliminación de material

La tasa a la que se puede eliminar el material es una métrica de rendimiento definitoria en la molienda, y aquí las máquinas horizontales son el claro ganador. Su geometría y orientación de herramientas permiten más rápido, cortes más profundos, lo que significa que se puede eliminar más material en menos tiempo. En un entorno de producción, Esto se traduce en tiempos de ciclo más cortos, mayor eficiencia, y la capacidad de completar grandes pedidos rápidamente.

Máquinas de fresado vertical, Mientras que preciso, son más lentos en comparación. Sus herramientas solo pueden manejar cortes más pequeños a la vez, y los operadores a menudo necesitan hacer múltiples pases para lograr la profundidad deseada. Esto no solo extiende el tiempo de mecanizado, sino que también reduce la productividad general., especialmente cuando se trabaja en piezas grandes o complejas.

Otro factor es la gestión de chips. Las máquinas horizontales se aclaran naturalmente los chips de la pieza de trabajo debido a la gravedad y la orientación de la herramienta, Prevención de bloqueos y sobrecalentamiento. Máquinas verticales, sin embargo, a menudo lucha con la acumulación de chips, que puede retrasar las operaciones e impactar negativamente el acabado de la pieza.

En breve, Si la productividad y la velocidad son las principales prioridades, La fresación horizontal es inigualable. Máquinas verticales, Aunque más lento, Proporcione un mejor control para un buen trabajo, haciéndolos más adecuados para trabajos más pequeños o piezas personalizadas.

Número de lados y flexibilidad de mecanizado

La flexibilidad en el mecanizado a menudo se reduce a cuántos lados de la pieza de trabajo se puede acceder sin reclamar. Las máquinas de fresado vertical se limitan principalmente a operar en un avión único a la vez. Mientras que los archivos adjuntos pueden expandir sus capacidades un poco, siguen siendo menos versátiles en comparación con sus contrapartes horizontales.

Máquinas de fresado horizontal, particularmente aquellos equipados con mesas universales, ofrecer una flexibilidad mucho mayor. La tabla universal permite que la pieza de trabajo se gire y reposicione, permitiendo que el cortador se acerque desde múltiples ángulos. Esta característica permite mecanizar formas complejas, contornos, y piezas de múltiples lados en menos configuraciones.

Además, Las fábricas horizontales se pueden equipar con complementos como tablas rotativas, cabezas divisorias, y múltiples cortadores, Ampliando aún más su versatilidad. Para industrias que requieren complejos, mecanizado de múltiples eje, Las configuraciones horizontales proporcionan un nivel de adaptabilidad que las máquinas verticales no pueden igualar.

Para trabajos simples, La capacidad de un solo plano de las máquinas verticales es suficiente y rentable. Pero para piezas con intrincadas geometrías o múltiples superficies, La flexibilidad de las máquinas horizontales ahorra un tiempo y esfuerzo significativos.

Elegir la máquina adecuada para sus necesidades

Seleccionar entre una máquina vertical u horizontal no es una decisión de talla única para todos. La elección correcta depende en gran medida de tu Requisitos de la pieza de trabajo, volumen de producción, presupuesto, y experiencia disponible. Desglosemos estas consideraciones:

1. Tamaño y complejidad de la pieza de trabajo

Si sus proyectos involucran principalmente piezas pequeñas a medianas que requieren un acabado detallado, como ranuras, surcos, o patrones intrincados: una fresadora vertical suele ser la opción más inteligente. Su geometría de herramientas permite un trabajo delicado y su visibilidad facilita a los maquinistas supervisar los cortes de precisión.

Sin embargo, Si estás mecanicando piezas de trabajo grandes o voluminosas, como los componentes del motor, marcos estructurales, o moldes industriales, Una máquina horizontal es mucho más eficiente. Su diseño de herramientas resistente y su potente orientación del huso pueden manejar cargas más grandes sin comprometer la estabilidad.

2. Volumen de producción

Para de bajo volumen, costumbre, o trabajo prototipo, Las fábricas verticales a menudo son ideales. Son fáciles de configurar, programa, y operar, que reduce el tiempo de entrega. Esta flexibilidad los convierte en los favoritos entre las pequeñas empresas y las tiendas de creación de prototipos..

Pero si tu objetivo es producción de alto volumen, Las máquinas horizontales son inmejorables. Su tasa de eliminación de material superior y su capacidad para mecanizar múltiples lados en una configuración significan que puede producir más piezas en menos tiempo. Esta productividad es crítica para la fabricación a gran escala.

3. Presupuesto y costos

El costo es uno de los factores más decisivos. Las máquinas de fresado vertical son más asequible, tanto en términos de precio de compra como de mantenimiento continuo. Incluso los talleres pequeños pueden permitirse instalar uno, y los operadores están ampliamente disponibles.

Máquinas horizontales, por otro lado, representar un inversión fuerte. El costo inicial es alto, y el mantenimiento requiere más recursos. Los operadores calificados son más difíciles de encontrar, que puede agregar a los gastos laborales. Dicho esto, para empresas con altas demandas de producción, El costo se justifica porque la máquina se paga rápidamente por sí misma a través de la eficiencia.

4. Habilidad y disponibilidad del operador

Otro factor pasado por alto es el Disponibilidad de maquinistas calificados. Las máquinas de fresado vertical son más comunes, lo que significa que más operadores están capacitados para usarlos. La capacitación también es más fácil porque el proceso es más simple.

Las máquinas de fresadoras horizontales requieren un conocimiento especializado. Dado que menos talleres los usan, Encontrar operadores con experiencia en el mundo real puede ser un desafío. Para pequeñas empresas, Esto puede ser un factor decisivo, A menos que subcontrate el trabajo a los servicios de mecanizado CNC.

5. Consideraciones del modelo de negocio

Para startups y pequeñas tiendas de fabricación, una máquina vertical tiene sentido: es versátil, asequible, y confiable para proyectos cotidianos. Si no fuera por Empresas manufactureras establecidas que se centran en la eficiencia, rendimiento, y piezas complejas de mecanizado, Una máquina horizontal es a menudo la mejor inversión a largo plazo.

Conclusión

El debate entre las máquinas de fresadoras verticales y horizontales se reduce a precisión versus productividad. Ambas máquinas comparten el mismo principio fundamental, utilizando una herramienta giratoria para eliminar el material de una pieza de trabajo fija, pero sus diferencias de diseño las hacen adecuadas para tareas muy diferentes..

Fresadoras verticales Excel en trabajo de precisión, piezas pequeñas a medianas, y proyectos personalizados o prototipos. Son asequibles, Fácil de mantener, e ideal para empresas con menor demandas de producción.

Fresadoras Horizontales son las potencias para las operaciones de servicio pesado, grandes piezas de trabajo, y producción de alto volumen. Su capacidad para realizar cortes profundos, manejar varios lados, y expulsar los chips de manera eficiente los hace invaluables en la fabricación a gran escala, aunque a un costo mayor.

Al final, La decisión se reduce a su necesidades específicas, Objetivos de producción, y presupuesto. Para talleres pequeños, La fresadora vertical es a menudo el punto de partida natural. Para operaciones a escala industrial, La productividad superior de la máquina horizontal justifica la inversión.

Y no olvidemos, en la salida de Servicios de mecanizado CNC es una alternativa práctica. Las empresas que no pueden pagar la inversión de capital de las máquinas horizontales aún pueden acceder a las capacidades de fresado de nivel superior a través de proveedores de servicios profesionales.

Si eres propietario de una pequeña empresa, un maquinista, o un ejecutivo de fabricación, Comprender estas diferencias clave ayuda a garantizar que elija la herramienta adecuada para el trabajo. En mecanizado, Al igual que en la vida, Elegir la herramienta correcta a menudo determina la calidad del resultado.