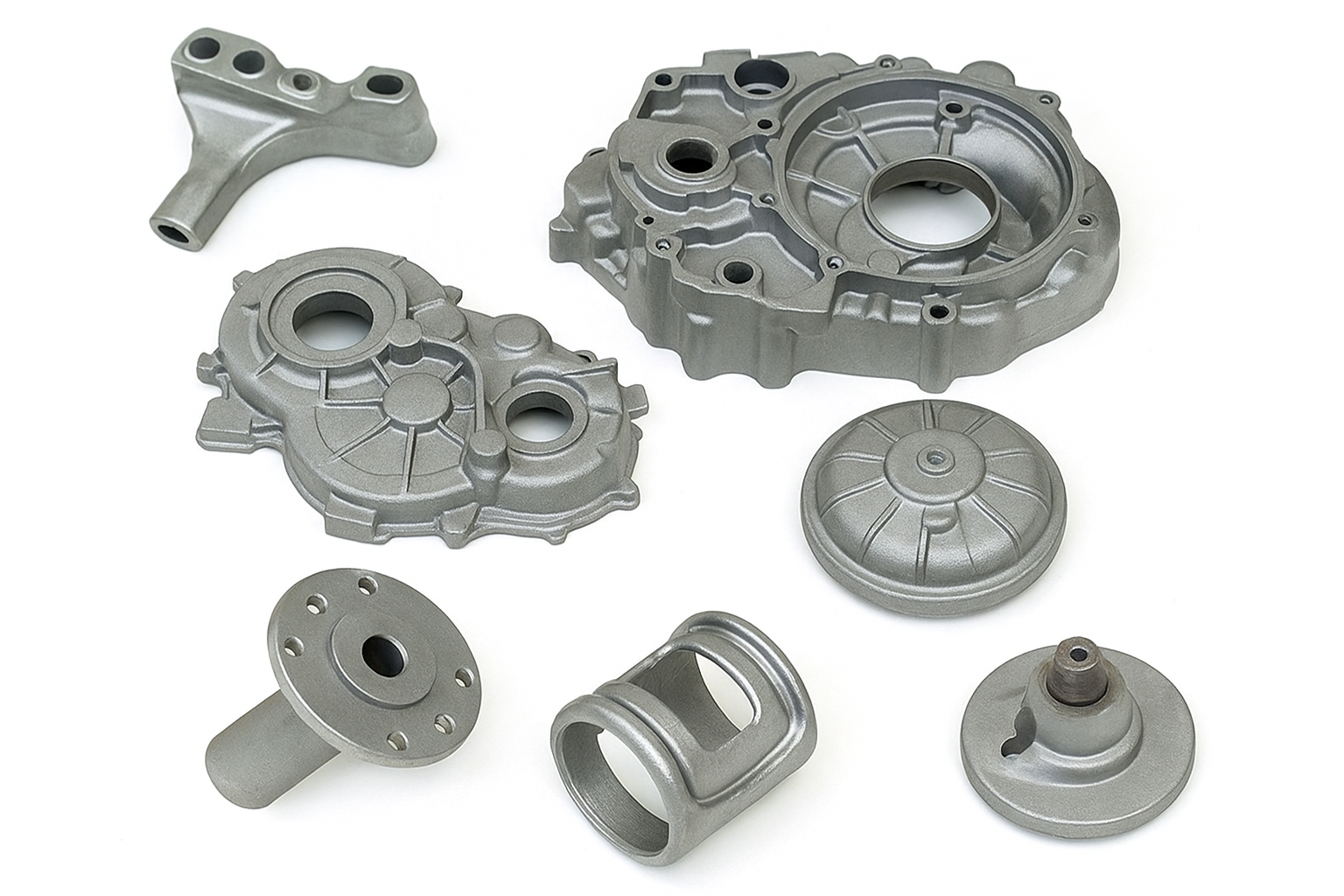

Moulage est une technique avancée de fabrication de métaux largement reconnue pour produire efficacement des, pièces métalliques en grand volume. Parmi les facteurs critiques qui affectent la qualité du moulage sous pression, la sélection de l’alliage d’aluminium approprié est primordiale. Cet article explore les alliages d'aluminium populaires utilisés dans le moulage sous pression, examiner minutieusement leurs caractéristiques uniques, points forts, limites, et applications adaptées.

Pourquoi la sélection des alliages est importante

Un alliage est une combinaison homogène de deux ou plusieurs métaux ou éléments conçus pour améliorer la mécanique, thermique, et propriétés physiques. Dans moulage sous pression en aluminium, allier l'aluminium avec des matériaux tels que le cuivre, silicium, zinc, et le magnésium influence considérablement les performances des pièces.

Le choix correct de l'alliage affecte directement:

Force et durabilité: Détermine la capacité de la pièce à résister aux charges mécaniques sans défaillance.

Résistance à la corrosion: Définit l'efficacité de l'alliage dans des conditions environnementales difficiles.

Résistance à la chaleur: Indique l'aptitude aux applications à haute température.

Propriétés de coulée: Influence la façon dont l'alliage remplit les moules et reproduit les géométries détaillées.

La sélection d'un alliage inapproprié peut entraîner des défaillances de pièces, usure prématurée, coûts excessifs, ou fonctionnalité inadéquate. Ainsi, comprendre les caractéristiques des alliages d’aluminium est essentiel pour réussir le moulage sous pression.

Alliages d'aluminium populaires pour le moulage sous pression

2.1 Alliage d'aluminium A380

L'alliage A380 est l'alliage d'aluminium moulé sous pression le plus courant en raison de son équilibre favorable entre coût et performances..

Avantages:

Excellent alliage à usage général

Coût inférieur par rapport aux alliages spécialisés

Léger avec un bon rapport résistance/poids

Conductivité électrique supérieure

Bonne coulabilité pour des conceptions détaillées et complexes

Limites:

Résistance à la corrosion modérée; peut nécessiter des traitements de surface supplémentaires

Non recommandé pour les environnements hautement corrosifs ou soumis à de fortes contraintes

Applications typiques:

Composants électriques

Supports de moteur

Boîtes de vitesses

Produits de consommation

2.2 Alliage d'aluminium A383

L'alliage d'aluminium A383 partage de nombreuses propriétés avec l'A380 mais excelle en termes de coulabilité..

Avantages:

Capacité exceptionnelle de remplissage de moules, surtout pour les géométries complexes

Résistance thermique améliorée, réduisant le risque de fissuration thermique

Bonne stabilité dimensionnelle à des températures élevées

Limites:

Coût légèrement plus élevé par rapport à l'A380

Durabilité mécanique réduite dans les applications fortement sollicitées

Applications typiques:

Composantes de logements complexes

Structures à parois minces

Raccords électriques nécessitant des détails fins

2.3 Alliage d'aluminium A360

Pour les projets exigeant de plus grandes performances mécaniques, L'A360 se démarque.

Avantages:

Résistance et ductilité exceptionnelles, surtout à des températures élevées

Résistance supérieure à la corrosion adaptée aux environnements agressifs

Excellente stabilité dimensionnelle

Limites:

Difficile de couler des géométries complexes en raison des capacités limitées de remplissage de moules

Coût de production plus élevé par pièce

Applications typiques:

Composants automobiles

Des équipements industriels performants

Pièces marines exposées à des conditions difficiles

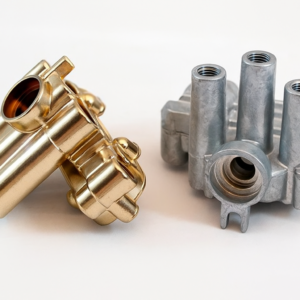

2.4 Alliage d'aluminium ZA-8 (Alliage zinc-aluminium)

ZA-8 est un alliage zinc-aluminium, présentant une teneur en aluminium inférieure, ce qui entraîne une densité plus élevée et un point de fusion plus bas.

Avantages:

Haute résistance, dureté, et durabilité

Utilisable dans les processus de moulage sous pression en chambre chaude, accélération des cadences de production

Excellente qualité de finition de surface et stabilité dimensionnelle

Limites:

Augmentation du poids en raison d'une teneur plus élevée en zinc

Pas idéal pour les applications sensibles au poids

Applications typiques:

Composants industriels

Boîtiers mécaniques

Quincaillerie décorative nécessitant une grande résistance et précision

2.5 Alliage d'aluminium ZA-12 (Alliage zinc-aluminium)

Avec une teneur accrue en aluminium, ZA-12 offre un mélange bien équilibré de propriétés mécaniques.

Avantages:

Plus solide et plus léger que l'alliage ZA-8

Bonnes performances de coulée dans les procédés en chambre froide

Excellente résistance à la traction et aux chocs

Bonnes qualités de roulement et résistance à l'usure

Limites:

Nécessite un moulage en chambre froide, limiter la vitesse de production

Coûts de traitement plus élevés par rapport à l'alliage ZA-8

Applications typiques:

Pièces automobiles nécessitant une résistance accrue

Composants mécaniques soumis à de fortes contraintes

Éléments de machine et engrenages résistants à l'usure

2.6 Alliage d'aluminium ZA-27 (Alliage zinc-aluminium)

L'alliage ZA-27 possède la teneur en aluminium la plus élevée de la série ZA, offrant une résistance mécanique inégalée.

Avantages:

Résistance et durabilité exceptionnelles avec une faible densité par rapport aux autres alliages ZA

Résistance à l’usure et stabilité thermique supérieures

Point de fusion le plus élevé des alliages ZA, adapté aux conditions exigeantes

Limites:

Alliage ZA le plus difficile à couler en raison de sa capacité limitée de remplissage du moule

Nécessite un contrôle précis de la température et des opérateurs qualifiés

Coûts généralement plus élevés et disponibilité limitée des installations de coulée

Applications typiques:

Composants robustes

Des équipements industriels performants

Connecteurs structurels et engrenages exposés à une utilisation rigoureuse

Choisir le bon alliage pour votre projet

La sélection du bon alliage nécessite un examen attentif de facteurs spécifiques:

Environnement d'application: Évaluer la résistance à la corrosion de l’alliage, stabilité thermique, et les conditions environnementales.

Complexité des pièces: Les géométries complexes peuvent nécessiter des alliages avec une meilleure coulabilité, comme l'A383.

Besoins de résistance et de durabilité: Si la force est essentielle, envisager des alliages à plus haute résistance comme l'A360 ou le ZA-27.

Volume de production & Rentabilité: L'équilibre entre les performances des matériaux et les contraintes budgétaires influence le choix de l'alliage.

Comprendre ces considérations permet des choix d'alliages précis, garantir des pièces fiables qui répondent à vos exigences et contraintes spécifiques.

Travailler avec un expert en moulage sous pression

La consultation d'experts du secteur comme Tops Precision améliore considérablement la sélection des alliages et la réussite du projet.. Des professionnels du casting expérimentés offrent des informations précieuses sur:

Performances des alliages pour des applications spécifiques

Recommandations de conception pour une fabricabilité améliorée

Stratégies de moulage et méthodologies de production rentables

La collaboration avec des fournisseurs de moulage sous pression compétents garantit des résultats optimisés, réduction des coûts, et des résultats de projet réussis.

Conclusion

Les alliages d'aluminium jouent un rôle crucial dans la réussite des projets de moulage sous pression. Le choix du bon alliage a un impact direct sur la résistance des composants, durabilité, résistance à la corrosion, et les coûts de production globaux. Que votre priorité soit le faible coût et l'utilité générale (A380), coulabilité complexe (A383), force améliorée (A360), ou alliages zinc-aluminium spécialisés (Série ZA), bien comprendre les caractéristiques de chaque alliage est essentiel.

S'engager avec des fournisseurs professionnels de moulage sous pression maximise encore ces avantages, optimisant la sélection des alliages et l'efficacité de la fabrication pour une qualité supérieure, pièces fiables.

FAQ

Q: Quel est l’alliage d’aluminium le plus rentable pour le moulage sous pression général?

UN: L'alliage d'aluminium A380 est l'alliage à usage général le plus rentable, équilibrer efficacement le prix et les performances.

Q: Quel alliage d'aluminium convient le mieux aux géométries de pièces complexes?

UN: L'alliage A383 offre d'excellentes capacités de remplissage de moules et réduit les fissures thermiques, idéal pour les conceptions complexes.

Q: Quel alliage offre la meilleure résistance pour les applications industrielles exigeantes?

UN: Le ZA-27 offre une résistance mécanique et une durabilité inégalées parmi les alliages à base d'aluminium, idéal pour les composants lourds.

Q: Les alliages ZA peuvent-ils être utilisés dans le moulage sous pression en chambre chaude?

UN: Seul le ZA-8 convient au moulage sous pression en chambre chaude en raison de son point de fusion plus bas.. ZA-12 et ZA-27 nécessitent des processus en chambre froide.