Pourquoi l'usinage CNC compte-t-il autant dans différentes industries? Parce qu'il apporte cohérence. Du premier morceau au millionième, Une machine CNC offre identique, Résultats de haute qualité. Et lorsque des industries comme l'aérospatiale ou la santé exigent la perfection - où une seule erreur peut coûter des millions ou même des vies - l'usinage du CNC augmente à mesure que l'étalon-or.

Cet article explorera 30 industries où l'usinage CNC est indispensable. Nous irons au-delà des descriptions au niveau de la surface et plongerons profondément dans les rôles spécifiques que joue CNC, les types de composants qu'il produit, Et pourquoi il continue d'être le choix préféré pour les fabricants du monde entier. À la fin, Vous aurez une image claire de la façon dont l'usinage CNC alimente tout, des avions aux bijoux.

Qu'est-ce que l'usinage CNC?

À la base, Usinage CNC est le mariage de Ordinateurs et outils mécaniques. Au lieu de contrôler manuellement les tours, moulins, exercices, ou broyeurs, Un ordinateur prend le relais. Les ingénieurs nourrissent une conception numérique - généralement sous la forme de CAO (Conception assistée par ordinateur) Fichiers - dans le système CNC, Et la machine l'interprète en mouvements précis. Le résultat? Une partie de partie impeccable, percé, ou façonné exactement comme conçu.

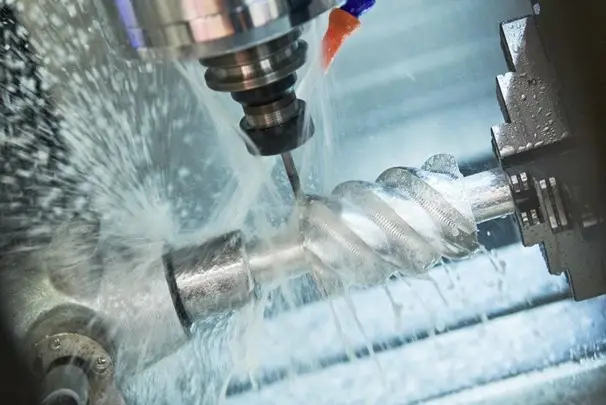

Il existe plusieurs types de machines CNC:

Fraiseuses CNC - utilisé pour couper, percer, et façonner les matériaux solides.

Tours CNC - parfait pour créer des objets symétriques comme les arbres et les vis.

Routeurs CNC - Idéal pour couper des matériaux plus doux comme le bois, plastiques, et composites.

Broyeurs CNC - Utilisé lorsque des finitions ultra-lisses sont nécessaires.

Contrairement à l'usinage traditionnel, où l'erreur humaine est toujours un risque, L'usinage CNC prospère sur Automatisation et répétabilité. Une fois un design téléchargé, La machine peut la reproduire avec la même précision des centaines ou des milliers de fois. Cela accélère non seulement la production, mais réduit également considérablement les déchets et les coûts.

Une autre distinction clé est la capacité de gérer géométries complexes. Les outils traditionnels peuvent lutter contre des motifs complexes ou des conceptions courbes, Mais les machines CNC peuvent sculpter, moulin, ou percer avec une précision chirurgicale. Par exemple, composants comme lames de turbine d'avions ou Implants médicaux personnalisés serait presque impossible à faire à la main avec une telle précision.

En bref, L'usinage CNC est plus qu'un simple outil - c'est un révolution de la fabrication. Il comble l'écart entre l'imagination et la production, transformer les plans numériques en réalité physique avec une précision inégalée.

Avantages de l'usinage CNC

Le succès de l'usinage CNC dans les industries provient de son multitude d'avantages. Décomposons les principaux avantages qui le rendent indispensable:

Précision et précision

Les machines CNC atteignent des tolérances aussi serrées que quelques microns. Pour des industries comme l'aérospatiale ou les soins de santé, où même la plus petite erreur pourrait conduire à des résultats catastrophiques, Ce niveau de précision est vital.

Vitesse et efficacité

Une fois programmé, Les machines CNC peuvent fonctionner 24/7 sans fatigue. Ce qui avait l'habitude de prendre des semaines peut maintenant être fait en quelques jours - ou même des heures. L'automatisation permet aux fabricants de respecter les délais serrés sans sacrifier la qualité.

Évolutivité et répétabilité

Besoin d'un seul prototype? CNC peut le faire. Besoin 10,000 pièces identiques? CNC peut aussi le faire - sans perdre la cohérence. Cela en fait le choix idéal pour le prototypage et la production de masse.

Polyvalence avec des matériaux

Les machines CNC gèrent une large gamme de matériaux, depuis métaux comme l'aluminium, acier, et titane à plastiques, matériaux composites, bois, Et même la céramique. Cette flexibilité signifie que les industries de l'aérospatiale aux bijoux peuvent tous bénéficier de la même technologie.

Rentabilité

Alors que les machines CNC nécessitent un investissement initial important, Ils réduisent les coûts à long terme en réduisant les déchets, Accélérer la production, et minimiser les erreurs humaines. Au fil du temps, Cela fait l'usinage CNC économiquement imbattable.

La complexité rendue simple

Machines CNC modernes, en particulier 5-modèles d'axe, peut gérer les conceptions qui semblaient autrefois impossibles. Imaginez la taille d'une sculpture en titane solide - CNC rend des emplois aussi complexes réalisables et efficaces.

Ces avantages expliquent pourquoi l'usinage CNC est devenu le Fondation de la fabrication moderne, Power Industries aussi divers que l'aérospatiale, automobile, Et même le divertissement.

Industrie aérospaciale

Peu d'industries exigent une précision autant que l'aérospatiale. Un seul avion est composé de millions de pièces, Et même la moindre faille pourrait entraîner une catastrophe. C'est pourquoi l'usinage CNC n'est pas seulement utile - c'est critique pour l'aérospatiale.

Composants clés produits

Pièces de moteur: Aubes de turbines, carburant, et buses

Pliage d'atterrissage: Composants à haute résistance qui supportent une contrainte extrême

Structures de cellule: Fuselage, ailes, et supports de support

Cabin et pièces intérieures: Sièges, instruments de cockpit, bacs de stockage

Ces pièces sont généralement fabriquées à partir de aluminium, titane, et composites, choisi pour leur Ratios de force / poids. Les machines CNC peuvent gérer ces matériaux difficiles avec facilité, produisant des composants légers mais durables.

Pourquoi CNC est essentiel en aérospatial

Normes de sécurité: La précision n'est pas négociable; Les tolérances sont minces de rasoir.

Durabilité: Les pièces aérospatiales sont confrontées à des températures et des pressions extrêmes.

Personnalisation: Les prototypes et les nouveaux conceptions sont rapidement testés à l'aide de CNC.

Par exemple, Création d'un lame de turbine à réaction nécessite des courbes d'usinage, trous, et géométries complexes. Une approche manuelle prendrait des mois et risquerait de risquer. Les machines CNC gèrent ce défi en heures avec une précision impeccable.

En bref, L'usinage CNC est le Héros méconnu de l'aviation et des voyages spatiaux, Rendre le vol moderne possible.

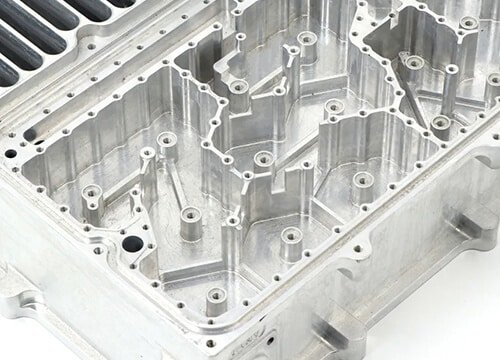

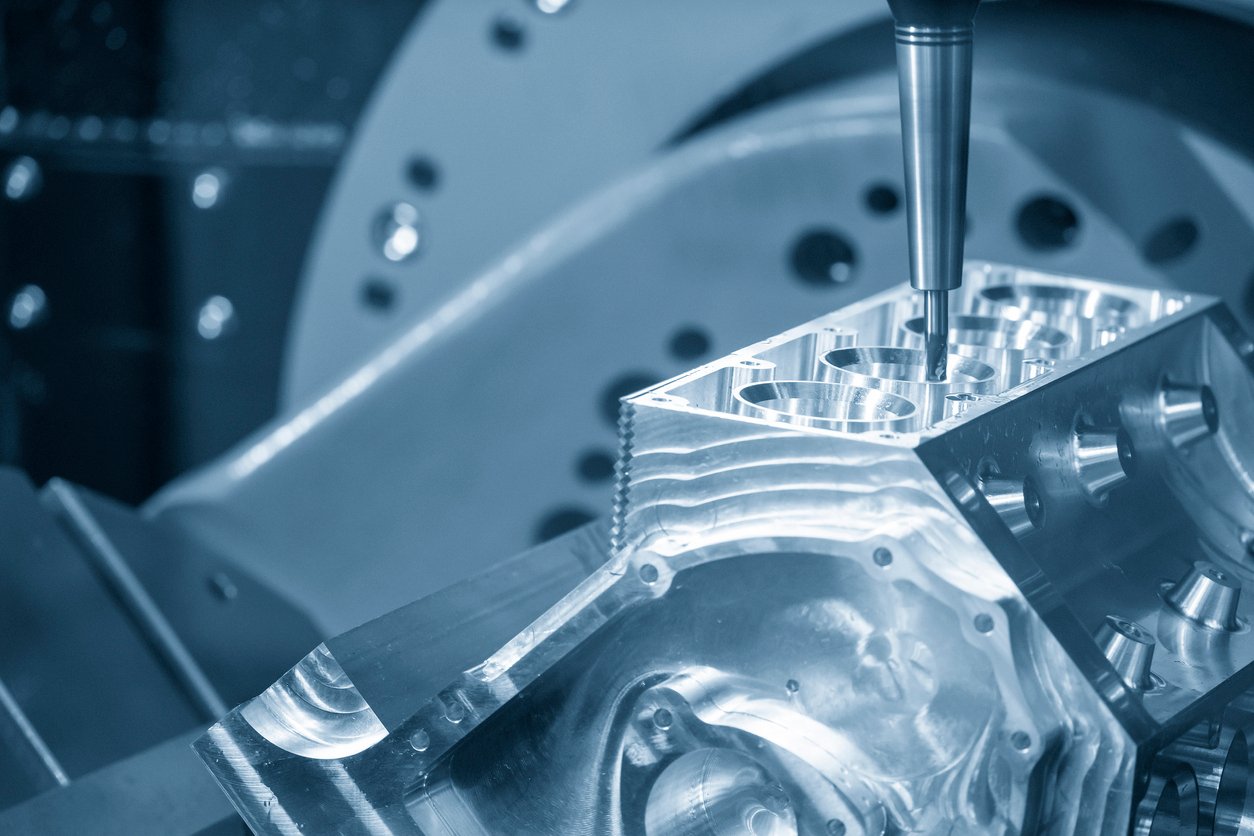

Industrie automobile

Le centre d'usinage à 5 axes coupant le bloc de cylindre de moteur V8. Le broyage à 5 axes coupant le processus de fabrication de blocs de cylindre en aluminium.

Le secteur automobile en est un autre Utilisateur lourd de l'usinage CNC. De la conception d'une voiture de sport élégante à la production de véhicules de banlieue quotidiens, CNC joue un rôle essentiel dans la création de voitures plus rapidement, plus sûr, et plus fiable.

Applications automobiles clés

Composants du moteur: Pistons, culasses, et blocs de soupape

Transmission et boîtes de vitesses: ENGARGES DE PRÉCISION ET LES CONSEILS

Suspension et direction: Amortisseurs, racks de direction, et articulations.Jantes en alliage: Jantes en alliage léger qui nécessitent des tolérances strictes pour des raisons de sécurité, équilibre, et performances

Prototypage: Concept de concept-car et de tests de pièces avant la production de masse

Corps et parties intérieures: Tableaux de bord, panneaux de porte, et roues de direction

L'usinage CNC garantit que chaque partie s'adapte parfaitement, qui est vital pour Sécurité et performances des véhicules. Imaginez un piston qui est légèrement éteint - il pourrait compromettre l'ensemble du moteur.

Pourquoi CNC compte en automobile

Production de masse: CNC permet des millions de composants identiques.

Vitesse de prototypage: Les concepteurs peuvent tester les concepts rapidement.

Durabilité: Les métaux maachés à CNC résistent à la chaleur, friction, et stress.

Personnalisation: Les constructeurs de luxe utilisent CNC pour des fonctionnalités personnalisées.

Par exemple, Lorsque des entreprises comme Tesla ou BMW prototypent les véhicules nouveaux, L'usinage CNC leur permet de passer de la conception au test en temps record. Entre-temps, Les fabricants comme Toyota comptent sur CNC pour production à grande échelle, Assurer que chaque voiture qui coule de la chaîne de montage répond aux normes strictes.

En termes simples, Usinage CNC maintient le monde automobile en mouvement, Équilibrer la production de masse avec l'innovation.

Industrie médicale

Peu d'industries exigent autant la précision et la fiabilité que secteur médical. Ici, La différence entre le succès et l'échec peut être mesurée dans la vie humaine. L'usinage CNC a révolutionné la fabrication médicale en permettant la production de très précis, stérile, et des pièces complexes qui répondent aux normes de santé strictes.

Applications en médecine

Instruments chirurgicaux: Scalpels, forceps, pinces, et les scies osseuses nécessitent une précision microscopique.

Implants orthopédiques: Joints de la hanche en titane, remplacement du genou, et les implants dentaires doivent s'adapter parfaitement aux patients.

Équipement de diagnostic: Scanners IRM, Scanners CT, et les machines à ultrasons contiennent des boîtiers et des composants maachés à CNC.

Micro-appareils: Les boîtiers de stimulateur cardiaque et les minuscules vis pour la chirurgie orthopédique sont souvent produites par CNC.

Pourquoi CNC est indispensable

Précision pour la sécurité des patients: Même une fraction d'un millimètre peut déterminer si un implant intègre correctement.

Production stérile: Les machines CNC peuvent fonctionner avec Matériaux de qualité médicale comme l'acier inoxydable, titane, et plastiques biocompatibles.

Personnalisation: Les patients ont souvent besoin d'implants personnalisés, et l'usinage CNC rend les conceptions personnalisées possibles.

Un exemple clair est la production de implants dentaires. La structure de la mâchoire de chaque patient est unique, et l'usinage CNC permet la création d'implants adaptés aux mesures exactes d'un individu. Cette personnalisation ne serait pas pratique avec l'usinage traditionnel.

En assurant précision, répétabilité, et biocompatibilité, L'usinage CNC est devenu la pierre angulaire des soins de santé modernes, permettant des vies plus longues et de meilleurs résultats de traitement.

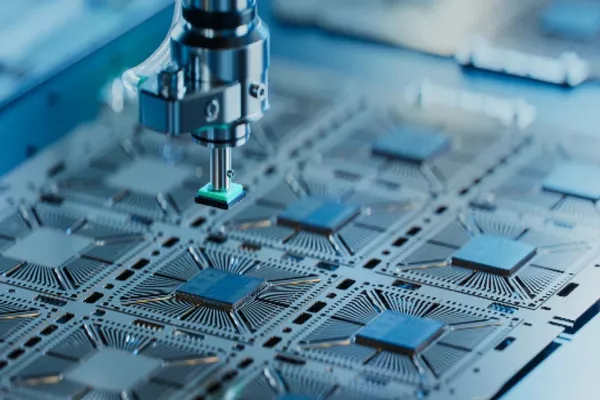

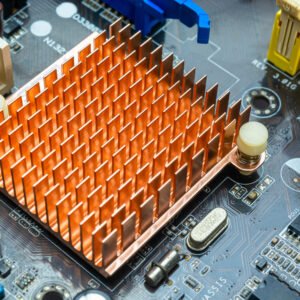

Industrie électronique

Le secteur électronique prospère miniaturisation et précision- Deux qualités où l'usinage CNC excelle. Des smartphones aux systèmes de communication avancés, La technologie CNC garantit que les composants délicats sont fabriqués avec précision.

Applications en électronique

Cartes de circuits imprimés (PCBS): Les routeurs et les usines CNC sont utilisés pour former des micro-trous et des cartes de mise en forme.

Enclos et enveloppes: Couvertures de protection pour les ordinateurs portables, téléphones, et routeurs.

Chauffer: Les machines CNC coupent les rainures et les ailettes pour une gestion thermique efficace.

Composants RF: Connecteurs, logements d'antenne, et guides de vagues.

Pourquoi CNC est crucial en électronique

Micro-précision: De nombreuses pièces électroniques sont plus petites qu'un ongle mais nécessitent des ajustements exacts.

Polyvalence des matériaux: CNC peut machine les plastiques, aluminium, cuivre, et composites - tous largement utilisés en électronique.

Évolutivité: La fabrication d'électronique implique souvent production de masse de petit, pièces complexes.

Innovation: Le prototypage de nouveaux gadgets est plus rapide avec les machines CNC.

Prenez des smartphones comme exemple. Les corps élégants en aluminium d'iPhones ou de dispositifs Samsung sont MACHINGS à la perfection, Assurer un ajustement transparent pour les panneaux de verre et les composants internes. De la même manière, dissipateurs de chaleur pour les processeurs comptez sur CNC pour maintenir les dimensions exactes pour un refroidissement efficace.

Dans un monde où l'électronique devient plus petite et plus puissante, L'usinage CNC fournit le précision et cohérence Pour répondre aux demandes des consommateurs.

Militaire et défense

Le industrie de la défense s'appuie sur l'usinage CNC pour la production de composants qui doivent résister conditions extrêmes-chaleur, pression, corrosion, et impact. Ici, L'échec n'est pas une option, Faire de la technologie CNC une partie vitale de la fabrication de défense.

Applications dans l'armée et la défense

Systèmes d'armes: Barils, mécanismes de tir, et des étendues de précision.

Véhicules et avions: Véhicules blindés, drones, et les hélicoptères contiennent de nombreuses pièces maachés à CNC.

Équipement de communication: Radios sécurisés, logements radar, et composants satellites.

Équipement de protection: Casque, plaques d'armure, et boîtiers d'équipement tactique.

Pourquoi CNC est vital

Fiabilité sous stress: Les pièces de CNC-Machin peuvent supporter des environnements de combat.

Ciblage de précision: La précision des armes dépend des composants impeccables.

Prototypage rapide: Les entrepreneurs de la défense peuvent tester rapidement de nouveaux modèles.

Normes de sécurité: Les pièces de défense doivent rencontrer le certifications de la plus haute qualité.

Par exemple, composants de jet de chasse- des lames de turbine aux boîtiers du cockpit - CNC-Machin avec des tolérances serrées. De la même manière, Les armes avancées comme les systèmes de missiles guidés s'appuient sur les pièces CNC pour assurer des performances sans faille.

Le secteur de la défense fait confiance à l'usinage CNC car il combine précision, durabilité, et évolutivité, permettre aux nations de maintenir, Capacités de défense fiables.

Industrie pétrolière et gazière

Le industrie du pétrole et du gaz fonctionne dans certains des environnements les plus difficiles de la terre - les mers de profondeur, déserts, et régions arctiques. L'équipement ici doit gérer pression extrême, chaleur, et des conditions corrosives, faire de l'usinage CNC une nécessité.

Applications en pétrole et en gaz

Outils de forage: Forets, tuyaux, et accouplements.

Vannes et raccords: Composants à haute pression qui régulent le flux de fluide.

Pompes et compresseurs: Logements et séances de précision.

Équipement sous-marin: Composants conçus pour résister à la corrosion dans les environnements d'eau salée.

Pourquoi CNC compte

Résistance au matériau: L'usinage CNC fonctionne avec l'acier durci, titane, et alliages exotiques.

Fiabilité: Les échecs peuvent entraîner des déversements de pétrole catastrophiques ou des fuites de gaz.

Efficacité: CNC permet une production plus rapide de pièces de remplacement, Minimiser les temps d'arrêt.

Personnalisation: Différentes plates-formes nécessitent des pièces spécialisées que CNC peut produire.

Considérer un opération de forage en haute mer: chaque partie, des têtes de forage aux systèmes de soupape, Doit résister aux pressions écrasantes et à l'eau de mer corrosive. L'usinage CNC garantit que ces composants répondent aux normes exigeantes de l'industrie.

En fournissant force, précision, et durabilité, L'usinage CNC maintient le secteur de l'énergie en douceur, même dans les conditions les plus difficiles.

Industrie des énergies renouvelables

Alors que le monde se déplace vers énergie durable, L'usinage CNC joue un rôle central dans la construction de l'infrastructure pour le vent, solaire, et hydro-puissance. Les composants d'énergie renouvelable nécessitent souvent grand, complexe, et parties précises, que l'usinage CNC offre avec efficacité.

Applications en énergie renouvelable

Éoliennes: Poyeuses de rotor, arbres, et composants de la boîte de vitesses.

Énergie solaire: Cadres en aluminium, montures, et systèmes de suivi. Il existe de nombreux fournisseurs de panneaux solaires qui s'appuient sur des pièces métalliques fabriquées avec précision, tel que HBOWA.

Plantes hydroélectriques: Lames de turbine et les pièces de logement.

Stockage d'énergie: Enveloppes de CNC pour les systèmes de batterie.

Pourquoi CNC est important

Évolutivité: Les projets renouvelables nécessitent souvent une production à grande échelle.

Durabilité: Les composants doivent durer les décennies dans les environnements extérieurs.

Flexibilité matérielle: Les machines CNC fonctionnent avec des composites, les métaux, et alliages.

Adapté à l'innovation: À mesure que les technologies renouvelables évoluent, CNC prend en charge le prototypage et les pièces personnalisées.

Par exemple, boîtes de vitesses d'éoliennes sont massifs mais doivent être usinés avec des tolérances microscopiques pour fonctionner de manière fiable pour 20+ années. De la même manière, L'usinage CNC est utilisé pour créer des supports de panneaux solaires qui peuvent résister à une exposition constante au soleil, vent, et la pluie.

En fournissant l'épine dorsale pour les infrastructures d'énergie renouvelable, L'usinage CNC aide à alimenter le changement global vers un avenir plus vert.

Industrie des biens de consommation

Le secteur des biens de consommation est vaste, Couvrant tout, des appareils électroménagers aux jouets et à l'électronique personnelle. Ce qui les attache ensemble, c'est le besoin de rentable, durable, et des produits esthétiquement attrayants- et l'usinage CNC joue un rôle majeur pour les livrer.

Applications dans les biens de consommation

Appareils: Tambours de machine à laver, lames de mélangeur, et pièces de machine à café.

Électronique: Boîtiers pour ordinateurs portables, Enclos de conférencier, et consoles de jeu.

Jouets et gadgets: Composants en plastique ou métal de précision pour les pièces mobiles.

Produits de luxe: Montres haut de gamme, accessoires de créateurs, et outils personnalisés.

Pourquoi CNC compte dans les produits de consommation

Cohérence: Les consommateurs s'attendent à ce que chaque élément ressemble et fonctionne de manière identique.

Personnalisation: Étuis de téléphone personnalisés, articles gravés, ou les gadgets sur mesure sont adaptés aux CNC.

Durabilité: L'usinage CNC assure des pièces durables par rapport aux plastiques moulants en masse.

Flexibilité de conception: CNC permet aux concepteurs d'expérimenter des formes complexes.

Prendre l'exemple casque haut de gamme. Le boîtier en aluminium autour des haut-parleurs n'est pas seulement esthétique - il protège l'électronique délicate et assure une bonne qualité sonore. CNC Machining fournit les dimensions précises requises pour les performances et le style.

En substance, Les machines CNC permettent aux fabricants de livrer fiable, élégant, et des produits abordables qui répondent aux attentes des consommateurs sur le marché au rythme rapide d'aujourd'hui.

Industrie ferroviaire

Le industrie ferroviaire dépend des pièces qui peuvent durer charges lourdes, frottement constant, et conditions extérieures. Depuis que les trains se déroulent pendant des décennies, la durabilité et la sécurité sont non négociables. L'usinage CNC fournit le précision et force que les systèmes ferroviaires modernes nécessitent.

Applications dans les chemins de fer

Moteurs: Cylindres, logements, et pistons.

Systèmes de freinage: Disques de frein et tampons nécessitant une tolérance élevée.

Composants de piste: Interrupteurs, Systèmes de fixation, et joints de rail.

Intérieurs automobiles: Structures de sièges, panneaux, et accessoires.

Pourquoi CNC est la clé pour les chemins de fer

Longévité: Les pièces de train doivent les dernières années avec un minimum d'usure.

Normes de sécurité: Même un petit défaut pourrait provoquer des déraillement.

Personnalisation: Chaque système ferroviaire a des besoins d'infrastructure uniques.

Évolutivité: CNC permet une production de grands lots pour les flottes entières.

Par exemple, systèmes de freinage doit fonctionner de manière fiable sous des charges massives. L'usinage CNC assure des tolérances exactes afin que les freins s'engagent uniformément, Réduire les risques d'accident. De la même manière, L'usinage de précision des joints de rail assure des promenades plus fluide et moins d'usure sur les trains et les pistes.

Finalement, L'usinage CNC aide l'industrie ferroviaire sûr, fiable, et des systèmes de transport durables.

Industrie de la robotique

Le secteur de la robotique est l'un des champs à la croissance la plus rapide aujourd'hui, Et l'usinage CNC est en son cœur. Les robots nécessitent complexe, léger, et composants très précis, Faire de l'usinage CNC la méthode de production incontournable.

Applications en robotique

Cadres et châssis: Squelettes structurels des robots industriels et de service.

Vitesses et actionneurs: Pièces de mouvement de haute précision.

Logements électroniques: Enclos de capteurs et processeurs.

Prototypage: Armes robotiques personnalisées, articulations, et les pièces jointes.

Pourquoi CNC alimente la robotique

Tolérances strictes: Les robots ont besoin de précision pour un mouvement reproductible.

Polyvalence des matériaux: La robotique utilise des métaux, plastiques, et composites.

Personnalisation: CNC permet des versions uniques pour les robots spécialisés.

Innovation: Le prototypage rapide prend en charge de nouveaux designs.

Par exemple, Les robots industriels utilisés dans les lignes de montage de voitures nécessitent engrenages usinés avec précision micrométrique Pour assurer des performances cohérentes sous stress. Entre-temps, Les robots de service comme les drones utilisent des pièces en aluminium léger ou en fibre de carbone en fibre de carbone pour maximiser l'efficacité.

En termes simples, L'usinage CNC alimente la robotique en fournissant le précision et adaptabilité requis pour cette industrie de pointe.

Industrie minière

Le industrie minière fonctionne dans des environnements difficiles pour les machines -, abrasion, humidité, et usure constante. L'usinage CNC fournit le robuste, durable, et pièces fiables qui permettent aux opérations minières de se poursuivre sans pannes coûteuses.

Applications dans l'exploitation minière

Équipement de forage: Têtes de perceuse, tiges, et accouplements.

Machinerie d'excavation: Seaux, engrenages, et composants structurels.

Systèmes d'écrasement: Pièces de précision pour les concasseurs et les pulvérisateurs.

Systèmes de convoyeur: Rouleaux, arbres, et soutiens.

Pourquoi CNC est vital dans l'exploitation minière

Durabilité: Les pièces CNC résistent à l'usure des matériaux abrasifs.

Résistance au matériau: L'usinage CNC peut gérer l'acier durci et les alliages.

Fiabilité: Les temps d'arrêt dans l'exploitation minière sont coûteux - la prévision réduit les échecs.

Échelle: Les grands composants pour les machines lourds peuvent être usinés efficacement.

Prendre un broyeur de roche par exemple. Ses engrenages doivent supporter un broyage constant sans s'user rapidement. L'usinage CNC garantit que les engrenages sont non seulement durables, mais aussi précisément pour minimiser les pannes.

En bref, L'usinage CNC garantit que les machines de l'industrie minière restent fiable, fort, et productif même dans les environnements les plus durs.

Industrie de l'optique

Le industrie de l'optique exigences précision microscopique, Et l'usinage CNC fournit exactement que. Des lentilles de caméra de fabrication aux assemblages de télescope, Les machines CNC fournissent la précision impeccable nécessaire pour la clarté optique.

Applications en optique

Moule à l'objectif: Moules de précision pour les lentilles en verre ou en plastique.

Montures et boîtiers: Frames structurelles pour les microscopes et les télescopes.

Micro-optique: Minuscules composants pour les endoscopes et les systèmes laser.

Bancs optiques: Assemblages complexes pour la recherche scientifique.

Pourquoi CNC excelle en optique

Précision au niveau du micron: Essentiel pour l'imagerie claire.

Finitions lisses: Le broyage CNC assure des surfaces optiques impeccables.

Personnalisation: CNC permet des configurations d'objectif uniques.

Manutention des matériaux: Verre, plastiques, et les boîtiers métalliques tous les avantages.

Par exemple, dans les endoscopes médicaux, De minuscules composants optiques doivent s'aligner parfaitement pour que les médecins puissent voir clairement à l'intérieur du corps humain. L'usinage CNC garantit que ces alignements sont cohérents et fiables.

En substance, L'usinage CNC est la raison pour laquelle pointu, fiable, et vision précise.

Industrie de la transformation des aliments

Les machines de transformation des aliments doivent être sanitaire, durable, et efficace. L'usinage CNC joue un rôle essentiel dans la production d'équipements de restauration alimentaire qui peuvent résister nettoyage constant, Coupe, et opérations d'emballage.

Applications de transformation des aliments

Lames de coupe: Lames de précision pour trancher le pain, viande, ou légumes.

Moules et matrices: Formes de cookies, pâtes, ou chocolat.

Systèmes de convoyeur: Rouleaux, arbres, et pièces mécaniques.

Équipement d'emballage: Mâchoires, composants d'étanchéité, et former des tubes.

Pourquoi CNC compte dans l'industrie alimentaire

Normes d'hygiène: Les machines CNC produisent des surfaces lisses qui résistent aux bactéries.

Durabilité: Plastiques en acier inoxydable et de qualité alimentaire résiste aux produits chimiques de nettoyage.

Efficacité: L'usinage CNC assure de longue date, outils de coupe pointus.

Personnalisation: Différents aliments nécessitent des moules et des outils sur mesure.

Par exemple, moules de pâtes sont des CNC-MACHING à des formes précises, Assurer des produits uniformes à chaque fois. De la même manière, L'équipement d'emballage alimentaire repose sur les pièces CNC pour sceller les sacs et les boîtes rapidement et de manière fiable.

Sans usinage CNC, La production alimentaire serait plus lente, Moins hygiénique, et beaucoup moins efficace.

Industrie textile

Le industrie textile utilise l'usinage CNC pour améliorer production de tissu, broderie, et tissage. Bien que souvent négligé, CNC contribue à la précision et à la durabilité des machines textiles modernes.

Applications en textiles

Broderies: Composants fabriqués au CNC pour les coutures de précision.

Tisser les machines: Parties à mécanisme, fuseau, et bobines.

Outils de coupe: Lames pour la coupe de tissu.

Motifs: Routeurs CNC pour créer des conceptions textiles complexes.

Pourquoi CNC prend en charge les textiles

Cohérence: Assure une production en douceur sans défauts.

Durabilité: Les machines textiles fonctionnent en continu - les pièces CNC prolongent la durée de vie.

Personnalisation: Les motifs textiles uniques nécessitent des outils de précision.

Efficacité: CNC réduit les temps d'arrêt avec de haute qualité, pièces durables.

Par exemple, fuseaux à mécanisme doit tourner parfaitement pour que le tissu tisse uniformément. L'usinage CNC garantit cette précision, Réduire les erreurs et les déchets dans la fabrication de textiles.

Cela fait de l'usinage CNC un partenaire invisible mais essentiel dans la production vêtements, tissus, et accessoires de mode mondial.

Industrie du divertissement

Le industrie du divertissement prospère sur la créativité et l'usinage CNC aide à donner vie à l'imagination. Des ensembles de scène aux accessoires de cinéma, CNC rend des conceptions complexes pratiques et reproductibles.

Applications de divertissement

Accessoires et modèles: Armes, costumes, et répliques pour les films.

Sets de scène: Panneaux sculptés CNC, frameworks, et des pièces de décor.

Instruments de musique: Cas de guitare, corps de violon, et coquilles de tambour.

Parcs à thème: Conduisez des composants et des structures décoratives.

Pourquoi CNC alimente la créativité

Conceptions complexes: Les machines CNC coupent les formes complexes impossibles à la main.

Répétabilité: Les accessoires et les décors peuvent être reproduits pour les productions.

Durabilité: CNC assure fort, pièces durables pour une utilisation répétée.

Personnalisation: Chaque projet créatif exige des conceptions uniques.

Par exemple, Dans les films hollywoodiens, réaliste accessoires de science-fiction Comme les armes ou les casques sont MACHING pour la précision et la durabilité. Entre-temps, Les fabricants d'instruments de musique utilisent CNC pour sculpter les corps en bois avec une qualité sonore cohérente.

L'usinage CNC permet de Transformez la fantaisie en réalité, Soutenir les industries créatives avec précision d'ingénierie.

Industrie des télécommunications

Le industrie des télécommunications s'appuie sur l'usinage CNC pour créer l'infrastructure physique pour la communication mondiale. Si ce sont des smartphones, satellites, ou tours d'antenne, CNC assure la durabilité et la précision.

Applications dans les télécommunications

Connecteurs: Bouchons et prises de précision.

Composants d'antenne: Bases, supports, et logements.

Enclos: Enveloppes de protection pour l'équipement de télécommunications.

Gestion de la chaleur: Dissipateurs de chaleur pour les systèmes 5G.

Pourquoi CNC compte dans les télécommunications

Précision: Telecom s'appuie sur des ajustements exacts pour les signaux à haute fréquence.

Durabilité: Les antennes extérieures doivent résister aux conditions météorologiques extrêmes.

Personnalisation: Les installations uniques nécessitent des supports personnalisés.

Évolutivité: CNC prend en charge la production de masse de pièces standardisées.

Réfléchir à 5G infrastructure—Antennes nécessitent des boîtiers et des supports de CNC pour des performances sans faille. Sans précision CNC, La connectivité ne serait pas fiable.

Cela rend l'usinage CNC essentiel pour garder le monde connecté et communiquant.

Recherche & Développement (R.&D)

Le R.&D secteur prospère sur l'innovation, Et l'usinage CNC est l'un de ses outils les plus puissants. Des modèles conceptuels aux appareils expérimentaux, CNC rend les idées tangibles.

Applications en r&D

Prototypage: Création rapide de pièces testables.

Équipement de test: Logements et accessoires de précision.

Composants personnalisés: Conceptions ponctuelles pour les expériences.

Modèles éducatifs: Les aides pédagogiques dans les universités et les laboratoires.

Pourquoi CNC autorise R&D

Vitesse: Transforme rapidement les idées en prototypes physiques.

La flexibilité: Gère divers conceptions et matériaux.

Précision: Fournit des résultats de test fiables en éliminant les erreurs de pièce.

Innovation: Soutient les industries à repousser les frontières technologiques.

Par exemple, Les chercheurs en biotechnologie peuvent concevoir un instrument personnalisé pour le séquençage d'ADN. L'usinage CNC leur permet de prototype et affiner Cet outil sans retards longs.

En substance, L'usinage CNC est le Pont entre l'imagination et l'innovation, Permettre aux scientifiques et aux ingénieurs de tester et de perfectionner leurs idées.

Industrie de la fabrication de meubles

Le industrie du meuble a adopté l'usinage CNC pour répondre à la demande croissante de conceptions personnalisées, durabilité, et efficacité de production de masse. Il est révolu le temps où les meubles fabriqués à la main étaient la seule option - Today, Les machines CNC permettent de réaliser à la fois le talent artistique et l'évolutivité.

Applications de meubles

Frameworks: Chaises, tables, et les cadres de lit.

Éléments décoratifs: Sculptures et gravures complexes.

Meubles personnalisés: Designs sur mesure adaptés aux besoins des clients.

Armoires et panneaux: Pièces de meubles de cuisine et de bureau.

Pourquoi CNC compte dans les meubles

Précision de conception: CNC peut reproduire des sculptures détaillées de manière cohérente.

Personnalisation: Les clients peuvent demander des formes ou des motifs personnalisés.

Flexibilité matérielle: Fonctionne avec le bois, matériaux composites, les métaux, et les plastiques.

Efficacité: Accélère la production de masse tout en maintenant la qualité.

Par exemple, un table à manger de luxe peut présenter des sculptures ornées le long de ses bords. Les machines CNC reproduisent ces conceptions complexes, S'assurer que chaque unité semble identique sans nécessiter des centaines d'heures de travail des mains.

En bref, CNC Usining combine artisanat avec technologie, Permettre à l'industrie du mobilier de fournir à la fois la créativité et l'efficacité.

Industrie pharmaceutique

En pharmaceutique, précision et hygiène sont essentiels. L'usinage CNC garantit que l'équipement utilisé dans la fabrication de médicaments, conditionnement, Et les tests répondent aux normes de sécurité strictes de l'industrie.

Applications en pharmaceutique

Équipement de production: Mélangeurs, machines d'encapsulation, et des presses sur tablette.

Machines d'emballage: Former des matrices, Scellant des mâchoires, et les systèmes de remplissage.

Équipement de laboratoire: Outils personnalisés pour les expériences et les tests.

Pourquoi CNC est vital

Normes stériles: L'usinage CNC crée un lisse, Surfaces résistantes aux bactéries.

Durabilité: Les machines fonctionnent souvent 24/7 et ont besoin de pièces fiables.

Précision: Le dosage et l'emballage précis dépendent de machines impeccables.

Personnalisation: Les projets de recherche uniques ont besoin de composants spécialisés.

Par exemple, presses de pilules Comptez sur des matrices de CNC qui garantissent que chaque comprimé est de forme et de dose identique. Sans cette cohérence, La sécurité des médicaments pourrait être compromise.

L'usinage CNC joue un rôle caché mais critique pour assurer sûr, efficace, et des médicaments fiables atteindre les patients dans le monde entier.

Industrie de la biotechnologie

Le secteur de la biotechnologie repousse les limites de la science, Souvent exigeant unique, complexe, et composants miniatures. L'usinage CNC est la technologie incontournable pour produire ces outils hautement spécialisés.

Applications en biotechnologie

Équipement médical: Séquenceurs d'ADN, microscopes, et instruments de laboratoire.

Équipement de recherche: Logements spécialisés et pièces de précision.

Composants personnalisés: Constructions uniques pour la recherche expérimentale.

Pourquoi CNC soutient la biotechnologie

Précision micron: Essentiel pour les appareils micro-échelles.

Compatibilité des matériaux: Fonctionne avec l'acier inoxydable, titane, et plastiques biocompatibles.

Prototypage rapide: Aide les chercheurs à tester rapidement de nouveaux modèles.

Innovation: Permet les percées en fournissant des solutions uniques.

Par exemple, un Machine de séquençage d'ADN repose sur des boîtiers de CNC à aligner les composants optiques et électroniques avec une précision extrême. Sans CNC, De tels assemblages complexes seraient impossibles.

En activant Recherche scientifique de pointe, L'usinage CNC est une pierre angulaire des progrès rapides de la biotechnologie.

Industrie des articles de sport

Le secteur des articles de sport Mélange les performances avec la durabilité, et l'usinage CNC garantit que l'équipement répond à ces demandes. Des vélos aux chauves-souris de baseball, CNC apporte cohérence et personnalisation aux équipements de sport.

Applications dans les sports

Vélos: Cadres, engrenages, et les systèmes de freinage.

Clubs de golf: Têtes et arbres personnalisés.

Équipement extérieur: Couteaux, planches à roulettes, et outils de camping.

Équipement de protection: Casques et structures de support.

Pourquoi CNC compte dans les sports

Précision de performance: De petites différences peuvent avoir un impact sur les performances sportives.

Personnalisation: Les athlètes ont souvent besoin d'équipement adapté à leur style.

Durabilité: Les métaux et les composites de MACHACHING CNC durent plus longtemps.

Production de masse: CNC assure une qualité identique entre les gammes de produits.

Par exemple, golfeurs professionnels Utilisez souvent des clubs personnalisés de CNC qui correspondent parfaitement à leur style swing. De la même manière, Les vélos à haute performance reposent sur des engrenages et des systèmes de freinage maachés par CNC pour la sécurité et la vitesse.

L'usinage CNC garantit que les articles de sport non seulement ont l'air bien mais aussi Offrez des performances de haut niveau sur le terrain.

Industrie de la technologie spatiale

Quand il s'agit de exploration spatiale, Les enjeux ne pourraient pas être plus élevés. Un seul échec de composant dans l'espace pourrait signifier l'échec de la mission - ou pire. L'usinage CNC garantit que les pièces sont conçues pour les normes les plus exigeantes sur terre.

Applications dans l'espace

Parties satellites: Antennes, logements, et supports.

Composants de fusée: Moteurs, boîtiers, et les systèmes de carburant.

Assemblages spatiaux: Logements d'instruments scientifiques, panneaux, et connecteurs.

Pourquoi CNC est critique dans la technologie spatiale

Précision ultra-élevée: Les composants de l'espace doivent s'adapter parfaitement.

Durabilité des matériaux: Machines CNC Titanium et alliages qui résistent à des conditions extrêmes.

Fiabilité: Pas de place à l'échec dans les missions spatiales.

Innovation: CNC permet des prototypes pour les vaisseaux spatiaux de nouvelle génération.

Par exemple, moteurs à fusée nécessitent un usinage impeccable pour résister à une chaleur et une pression extrêmes lors des lancements. L'usinage CNC rend cela possible avec une cohérence inégalée.

En termes simples, L'usinage CNC est le Épine dorsale de l'exploration spatiale, transformer la science-fiction en réalité scientifique.

Industrie de transformation chimique

Le industrie chimique nécessite des machines qui peuvent durer Matériaux corrosifs et températures élevées. CNC Machining offre des pièces suffisamment coriaces pour survivre à ces conditions exigeantes.

Applications de traitement chimique

Réacteurs: Vessels de précision pour les réactions chimiques.

Pompes et vannes: Pièces conçues pour gérer les liquides agressifs.

Échangeurs de chaleur: Composants qui nécessitent des tolérances précises.

Pourquoi CNC est essentiel

Résistance à la corrosion: Machines CNC alliages exotiques résistants aux produits chimiques.

Précision: Assure un contrôle précis des processus chimiques.

Durabilité: Prolonge la durée de vie de l'équipement dans des environnements difficiles.

Sécurité: Réduit le risque de fuites ou d'accidents.

Par exemple, composants de vanne dans les produits chimiques doit s'adapter parfaitement pour éviter les fuites de produits chimiques dangereux. L'usinage CNC garantit la précision requise.

Sans usinage CNC, Les plantes chimiques auraient du mal à maintenir le sécurité et fiabilité nécessaire dans leurs opérations.

Secteur éducatif

Même l'éducation bénéficie de l'usinage CNC. Écoles, collèges, et les instituts de formation utilisent des machines CNC pour Projets de l'apprentissage et de recherche pratiques.

Applications de l'éducation

Machines de formation: Équipement CNC pour la pratique des étudiants.

Outils de recherche: Prototypage pour les expériences universitaires.

Modèles éducatifs: Aide à l'enseignement et démonstrations.

Pourquoi CNC compte dans l'éducation

Développement des compétences: Prépare les étudiants à la fabrication moderne.

Innovation: Permet aux étudiants d'expérimenter avec des conceptions du monde réel.

Accessibilité: Les machines CNC abordables facilitent l'apprentissage.

Formation pertinente de l'industrie: Crée une avenir future qualifié.

Par exemple, Les étudiants en génie construisent souvent prototypes robotiques Utilisation de pièces de CNC-Machin, Apprendre de précieuses compétences du monde réel.

L'usinage CNC aide l'éducation à combler le fossé entre théorie et application pratique, responsabiliser la prochaine génération d'innovateurs.

Industrie de la fabrication de bijoux

Le secteur des bijoux a été transformé par l'usinage CNC, qui permet complexe, reproductible, et designs personnalisés.

Applications de bijoux

Pièces personnalisées: Noms de noms, anneau, et bracelets.

Designs complexes: Motifs qui étaient autrefois sculptés à la main.

Fabrication de moules: Moules de CNC-Machin pour la production de masse.

Pourquoi CNC compte dans les bijoux

Détails de précision: Même les plus petits modèles sont possibles.

Personnalisation: La personnalisation est facile avec la conception CNC.

Efficacité: Réduit les coûts de main-d'œuvre tout en augmentant la production.

Flexibilité matérielle: Fonctionne avec l'or, argent, platine, et plus.

Par exemple, un réglage de la bague en diamant Doit tenir parfaitement des joyaux en place. L'usinage CNC assure des tolérances exactes pour la sécurité et le style.

Merci à CNC, Les fabricants de bijoux peuvent combiner créativité et technologie, produisant superbe, pièces personnalisées à grande échelle.

Industrie du traitement de l'eau

Le secteur du traitement de l'eau nécessite des pièces qui peuvent résister Utilisation constante et exposition à l'eau et aux produits chimiques. L'usinage CNC assure la durabilité et la fiabilité.

Applications en traitement de l'eau

Composants de la pompe: Arbres, échange, et logements.

Pièces de soupape: Systèmes de contrôle pour l'écoulement des fluides.

Systèmes de filtration: Cadres et pièces de précision pour les filtres.

Pourquoi CNC est crucial

Durabilité: Gère les conditions corrosives et à haute pression.

Précision: Assure un débit d'eau propre et fiable.

Efficacité: Prolonge la durée de vie de l'équipement de traitement.

Sécurité: Réduit le risque de contamination.

Par exemple, boîtiers de filtre nécessitent des spécifications de l'usinage CNC afin qu'aucune impureté ne fuit dans l'eau traitée.

En activant traitement de l'eau sûre et efficace, L'usinage CNC joue un rôle essentiel en santé publique.

Industrie du CVC

Chauffage, Ventilation, et la climatisation (HVAC) Les systèmes s'appuient sur l'usinage CNC pour fiable, efficace, et pièces personnalisées.

Applications en CVC

Conduits: Panneaux et raccords de coupe CNC.

Lames de fans: Précision de précision pour l'efficacité.

Compresseurs et vannes: Pièces de tolérance serrée pour les performances.

Installations personnalisées: Pièces uniques pour les systèmes à grande échelle.

Pourquoi CNC compte en CVC

Efficacité énergétique: L'usinage CNC assure des composants de précision pour le flux d'air optimal.

Personnalisation: Les bâtiments ont souvent besoin de systèmes CVC sur mesure.

Durabilité: Les pièces de CNC-Machin durent plus longtemps sous une utilisation continue.

Évolutivité: Active la fabrication à petite et à grande échelle.

Prendre lames de fans par exemple. Même un petit déséquilibre peut gaspiller l'énergie. L'usinage CNC garantit que les lames sont parfaitement équilibrées, Alimentation de l'efficacité et réduisant le bruit.

Ainsi, L'usinage CNC est central pour créer confortable, environnements intérieurs économes en énergie.

Conclusion

De l'aérospatiale aux bijoux, L'usinage CNC a fait ses preuves comme le Épine dorsale de l'industrie moderne. Sa capacité à livrer précision, durabilité, personnalisation, et évolutivité le rend indispensable dans tous les secteurs.

À mesure que la technologie progresse, avec 5-usinage sur l'axe, automation, et l'intégration de l'IA, Les machines CNC ne deviendront plus puissantes. Le futur promet une production encore plus rapide, plus grande personnalisation, et de nouvelles industries qui s'appuieront sur CNC d'une manière que nous ne pouvons pas encore imaginer.

En bref, L'usinage CNC ne soutient pas seulement les industries - cela motive l'innovation dans le monde entier.

Questions fréquemment posées

- Quel est le haut 10 Applications de l'usinage CNC?

Aérospatial, automobile, médical, électronique, défense, énergie renouvelable, construction, robotique, produits de sport, et HVAC sont parmi les applications les plus courantes. - Quels matériaux peuvent être usinés avec CNC?

Les machines CNC gèrent l'aluminium, acier, titane, laiton, cuivre, plastiques, bois, matériaux composites, Et même la céramique. - Qu'est-ce que l'usinage CNC est le plus souvent utilisé pour?

Il est le plus souvent utilisé pour Fabrication de précision des pièces métalliques et en plastique, des prototypes à la production de masse. - Pourquoi l'usinage CNC est-il meilleur que l'usinage traditionnel?

Parce que CNC propose vitesse, répétabilité, précision, et évolutivité- Tout en réduisant l'erreur humaine. - Quelles industries bénéficient le plus de l'usinage CNC?

Alors que presque tous les avantages de l'industrie, aérospatial, automobile, médical, et l'électronique sont les meilleurs secteurs compter fortement sur CNC.