Le secteur de l'électronique exige des composants de plus en plus petits, tolérances plus étroites, et un délai de marché rapide. Usinage CNC meets these needs by delivering precision, répétabilité, and flexibility—whether you’re prototyping a new PCB layout or producing thousands of heat sinks. This deep-dive explores comment CNC transforms electronics manufacturing, quoi parts you can make, lequel techniques and materials are involved, et comment surface finishes and advanced capabilities elevate your products.

How CNC Machining Benefits Electronics Manufacturing

Qualité constante

Automated Precision: CNC programs execute the same toolpaths to micron-level accuracy, eliminating operator variability.

Complex Features: From micro-channels on cooling plates to fine PCB routing, CNC machines hold tight tolerances part after part.

Haute précision & Précision

Tolérances strictes: Electronics often require ±0.005–0.001 mm. Modern multi-axis CNC centers routinely achieve these specs.

Ajuster & Fonction: Precision mating features (dowel holes, snap-fits) ensure components assemble reliably, preventing misalignment that can ruin circuits.

Prototypage rapide

Low Tooling Costs: Unlike injection molding, CNC prototypes need no expensive molds—just a CAD model and setup.

Iterative Design: Engineers can test form, ajuster, and function within days, then refine toolpaths immediately for the next run.

Évolutivité & Personnalisation

Flexible Runs: Switch from a single prototype to hundreds without retooling, simply by loading a new program.

On-Demand Parts: Custom connectors, specialized housings, or one-off repair parts—CNC accommodates small or large batches with equal ease.

Reduced Lead Times

No Complex Tooling: CNC setups involve clamps and fixtures, not custom molds or stamping dies.

Quick Changeovers: Modern tool-changer systems swap cutting tools in seconds, keeping production moving fast.

Common CNC-Machined Electronic Products

CNC machining is used to make all kinds of electronic parts—big, petit, simple, and super precise. Let’s break it down into the real-world parts you’ve probably seen (or even used) without realizing they came from a CNC machine.

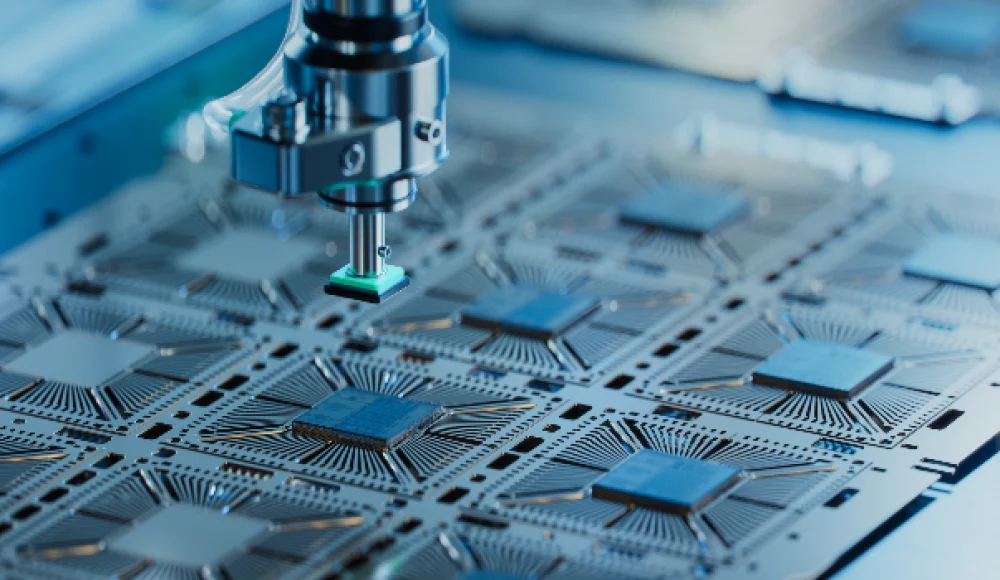

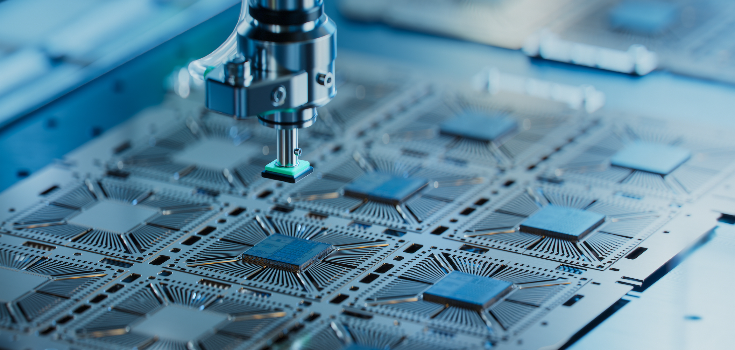

Cartes de circuits imprimés (PCBS)

These are the flat green (ou bleu) boards inside pretty much every electronic device. CNC machines help cut the exact shape, drill tiny holes, and even carve out paths for electricity to flow. Sans précision CNC, these boards wouldn’t fit or work properly.

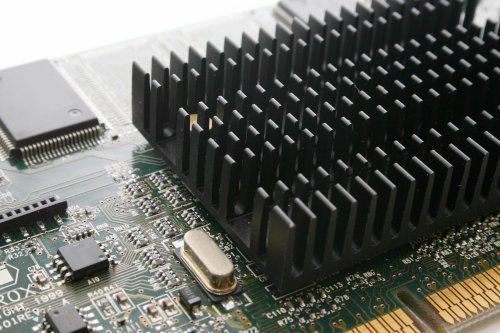

Chauffer

Ever wonder how your laptop or gaming console doesn’t overheat? That’s partly thanks to heat sinks—little metal parts with fins that pull heat away from processors. CNC machines shape these to exact specs so they can keep electronics cool and running smoothly.

Enclos et enveloppes

From smartphone shells to control box housings, CNC machining helps create the outer bodies that protect delicate electronics. Whether it’s aluminum for a tough outer shell or plastic for a sleek phone case, CNC helps make it fit and look just right.

Connectors and Plugs

CNC machining makes tiny metal or plastic connectors that allow cables to fit snugly—like USB ports, charging connectors, or data transfer pins. Precision is everything here, or things just won’t click into place.

Switches and Buttons

The power buttons, toggle switches, and control knobs you use on electronic devices are often CNC-machined to make sure they feel right and last long. Especially for custom or industrial electronics, CNC ensures perfect shapes and reliable movement.

Semiconductor Components

In high-tech electronics, CNC is used to make the frames, couvertures, and cooling parts for semiconductors—the tiny chips that power everything from your phone to satellites.

Camera and Sensor Housings

For drones, security cameras, and medical scanners, CNC machining helps create compact housings that protect lenses and sensors, while allowing precise alignment for performance.

CNC Techniques for Electronics

Broches à grande vitesse: 20,000–60,000 RPM routers carve small features with 0.5–1 mm end mills.

Micro-Milling: Tools as small as 0.2 mm enable fine channels on microfluidic PCBs or heat spreaders.

Live Tooling Lathes: Combine turning and milling operations for pins, standoffs, and threaded inserts in one setup.

High-Precision Shafts: Achieve concentricities of a few microns for electrical contacts.

Multi-Spindle Heads: Drill arrays of vias or mounting holes simultaneously, reducing cycle time.

Peck Cycles: Clear chips in deep printed-circuit drilled holes to avoid burring and overheating.

Gravure CNC

Laser Marking: Non-contact, high-speed lasers etch serial numbers, barcodes, or logos on housings without tool wear.

Diamond Engraving: On hard plastics or metals for tactile switches and legends with micron-level depth control.

Common Materials in Electronics Machining

Les métaux

Aluminium: 6061, 5052 alloys for lightweight enclosures, dissipateurs de chaleur, and EMI shields.

Cuivre & Alliages de cuivre: Machined for high-performance thermal applications and electrical contacts.

Laiton: Corrosion resistance and good conductivity for connectors and decorative trims.

Acier inoxydable: Structural supports, attaches, and rugged housings that require durability.

Non-métaux

Plastiques d'ingénierie: COUP D'OEIL, abdos, PC, and PTFE for insulation, display covers, and chemical-resistant parts.

Acrylique & Polycarbonate: Transparent windows, light guides, and impact-resistant panels.

Matériaux composites & Laminates: FR-4, G-10 for PCBs; specialty composites for RF and high-voltage applications.

Typical Surface Finishes for Electronic Components

Microbillage: Uniform matte finish that hides tool marks and improves paint adhesion.

Placage autocatalytique au nickel: Enhances corrosion resistance and surface conductivity on metal parts.

Anodisation: Adds a durable oxide layer (and color options) to aluminum enclosures.

Revêtement en poudre: Décoratif, resilient coatings in varied colors and textures.

Passivation: Cleans and strengthens stainless steel, preventing surface oxidation.

Polissage: Mirrors finishes on contacts and RF seals for optimal conductivity.

CNC Machining Capabilities in Electronics

Multi-Axis Centers: 5-axis gantries and mills machine undercuts, Cavités profondes, and angled holes in a single setup.

Micro-Machining Spindles: High-RPM spindles (jusqu'à 100,000 RPM) for ultra-fine features.

Automated Probing: On-machine measurement systems verify critical dimensions mid-cycle.

Lights-Out Operation: Automated tool changers and bar feeders enable overnight production runs.

Hybrid Additive/Subtractive: Combine CNC with selective laser sintering for conformal cooling channels or integrated structures.

Conclusion

CNC machining empowers electronics manufacturers to deliver precision, cohérence, and speed that no other subtractive process matches. From intricate PCB routing to robust EMI-shielded enclosures, CNC’s flexibility and accuracy help bring modern electronic devices to life. By understanding the right techniques, matériaux, and finishes—and leveraging advanced CNC capabilities—you can achieve parts that meet the tightest tolerances and the fastest time-to-market.

FAQ

What drives CNC electronics machining costs?

Part complexity, choix de matériel, exigences de tolérance, and production volume all factor into pricing.

What tolerances can electronics CNC machining achieve?

Typical tolerances range from ±0.005 mm to ±0.001 mm, depending on machine precision and inspection methods.

Is CNC machining better than 3D printing for electronics?

CNC offers superior material choices (metals and high-performance plastics), tolérances plus étroites, and better surface finishes for functional electronic parts—whereas 3D printing excels at complex internal geometries and rapid concept models.