Le magnésium est réputé pour ses propriétés légères, machinabilité exceptionnelle, et le rapport forte force / poids. This makes it ideal for numerous industries including aerospace, automobile, électronique, and medical applications. Cependant, machining magnesium poses unique risks, particularly its flammability. Adopting proper safety measures is essential to harness magnesium’s advantages safely and efficiently.

Risks of Magnesium Machining

Understanding potential hazards when machining magnesium alloys helps ensure workplace safety and optimal machining outcomes. Key risks include:

Fire Hazard

Magnesium machining generates fine chips and dust, which are highly flammable. These can ignite from sparks or excessive heat produced during CNC operations, leading to serious fire hazards.

Usure des outils

Magnesium alloys are soft yet abrasive, leading to rapid tool wear. Increased tool wear affects machining efficiency and significantly raises tooling costs due to frequent replacements.

Production de chaleur

Magnesium’s poor thermal conductivity results in concentrated heat accumulation within the cutting zone, reducing tool life and potentially deforming the workpiece.

Problèmes de finition de surface

Machining magnesium alloys often leads to burrs and surface deformation. Atteindre la précision, high-quality finishes thus requires specialized tools and careful process control.

Important Tips for Machining Magnesium Safely

To safely machine magnesium and mitigate the above risks, observe the following critical safety measures:

Maintain Proper Tooling Condition

Always use sharp, carbide-tipped cutting tools. Sharp tools minimize frictional heat generation, thus reducing ignition risks.

Avoid Tight Clearance Angles

Use larger clearance angles. Tight clearances create long, unbroken chips that can wrap around cutting tools, significantly raising fire risks by generating excessive heat.

Produce Discontinuous Chips

Program CNC machines to produce short, discontinuous chips. This can be achieved by:

Using small back rake angles.

Adjusting feed rates appropriately.

Applying moderate-to-high cutting speeds.

Discontinuous chips efficiently dissipate heat and reduce ignition risks.

Avoid Water-Based Coolants

Never use water-based coolants. Magnesium reacts with water-based fluids to produce flammable hydrogen gas. Plutôt, mineral oil coolants effectively dissipate heat, reduce ignition risks, and enhance surface finish quality.

Utilize Explosion-Proof Vacuum Systems

Employ explosion-proof vacuum systems to safely remove magnesium dust and chips, minimizing the risk of ignition during cleanup processes.

Sécurité incendie

In case of fire, never use water to extinguish magnesium fires. Water intensifies magnesium fires, causing explosive reactions. Plutôt, utilize Class-D fire extinguishers or dry sand.

Advantages of Choosing Magnesium for CNC Machining

Despite inherent risks, magnesium alloys offer outstanding benefits for CNC machining, y compris:

Excellente usinabilité

Magnesium alloys have low cutting resistance, enabling faster cutting speeds and reduced tooling stress, resulting in lower overall machining costs.

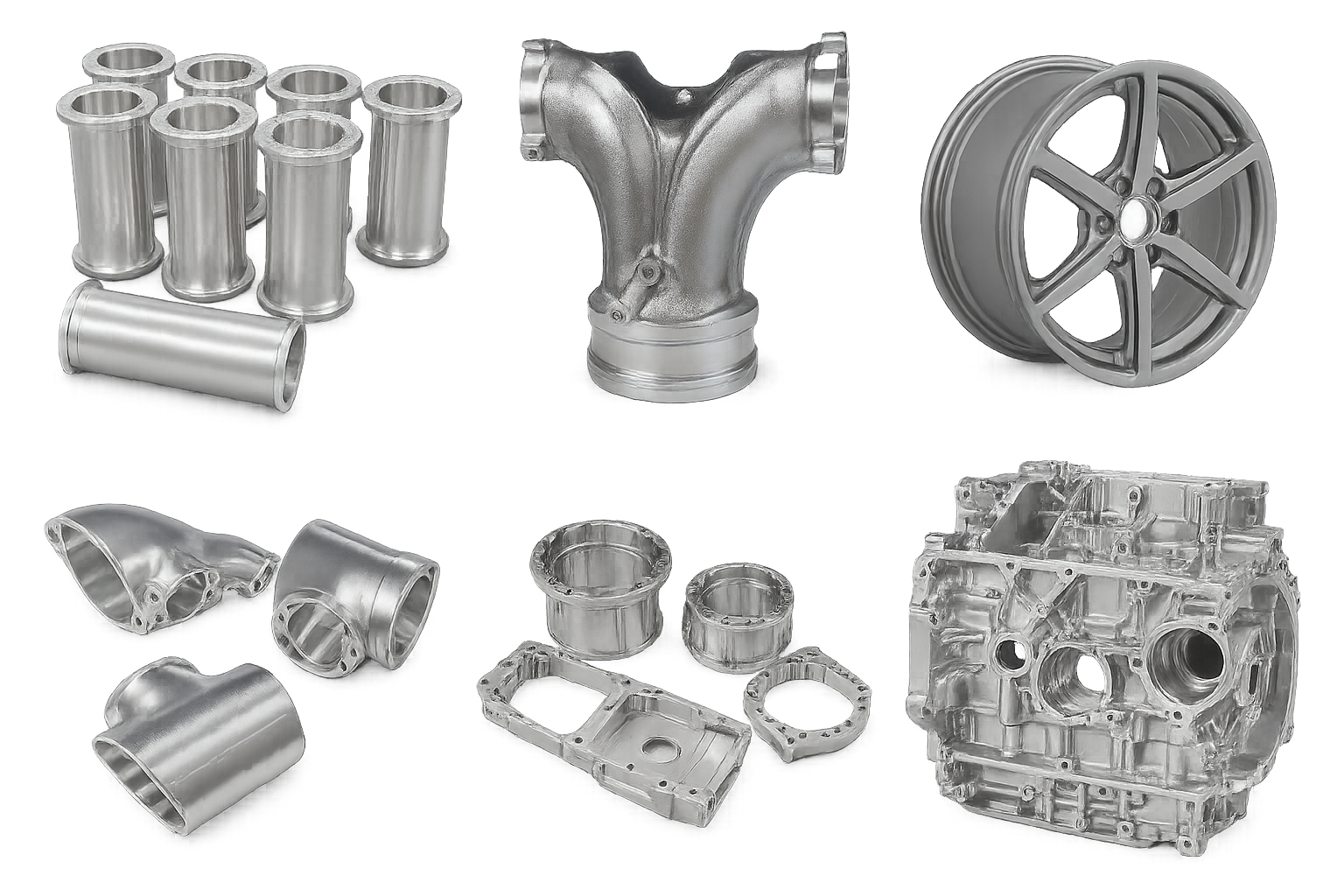

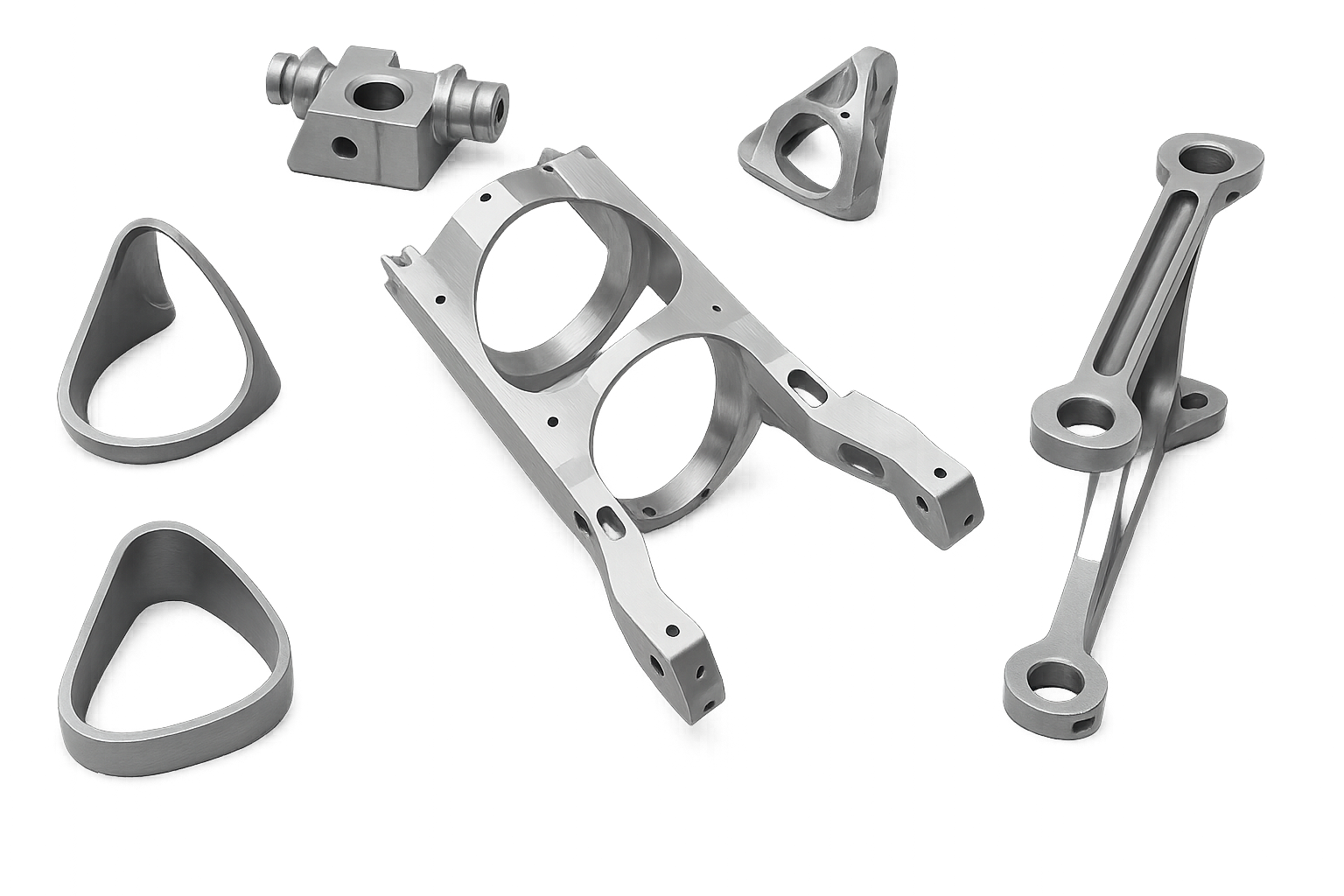

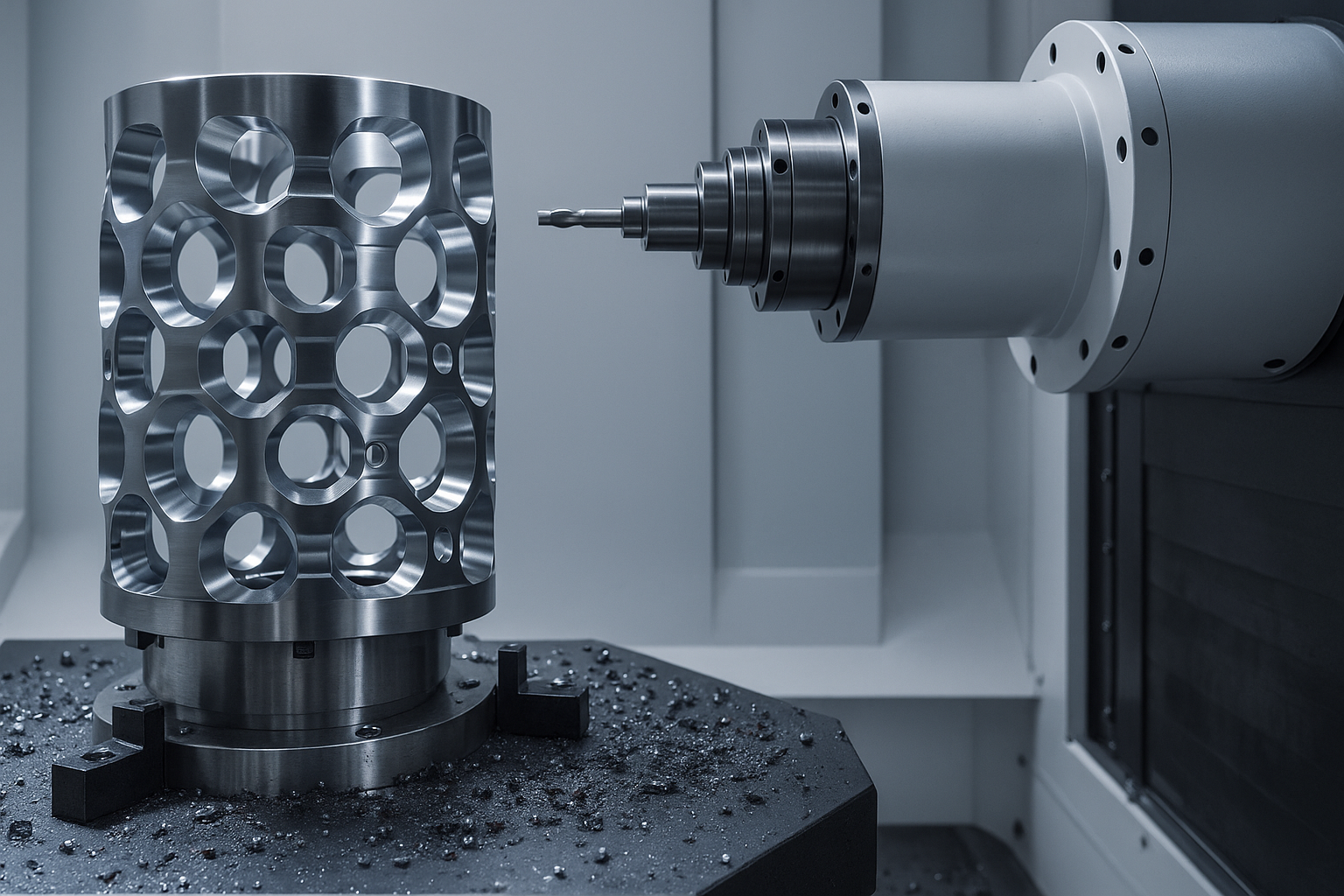

Capability to Produce Complex Geometries

CNC machining can easily shape magnesium alloys into complex, intricate geometries with high dimensional accuracy. Multi-axis machining further enhances the ability to produce complicated components precisely.

Recyclability and Sustainability

Magnesium alloys are environmentally friendly due to their high recyclability. CNC machining processes also generate recyclable waste, promoting sustainable manufacturing practices.

Popular Magnesium Alloys You Can Use for CNC Machining

AZ31

Why choose it? C'est léger, facile à usiner, and affordable, making it perfect for parts that need strength without extra weight. It has good flexibility, making it easy to shape.

Typical uses: Electronic casings, laptop covers, pièces d'avion, et composants automobiles.

AZ91

Why choose it? AZ91 is tougher and slightly stronger than AZ31, making it suitable for parts that must withstand higher stress. It’s a bit harder, so your parts hold their shape and dimensions very well after machining.

Typical uses: Camera bodies, outils électriques, automotive housings, and mechanical equipment parts.

These two alloys are the most popular, but remember, the best alloy for your project depends on your specific needs—whether that’s strength, flexibilité, usinabilité, ou le coût.

Tool Selection for Magnesium Alloy Machining

Selecting appropriate cutting tools is crucial for efficient, sûr, and high-quality magnesium machining. Popular tools include:

Acier à haute vitesse (HSS) Outils

HSS cutters are economical, durable, and suitable for less demanding or low-volume magnesium machining operations due to their lower thermal resistance.

Solid Carbide Tools

Outils en carbure solides (fraises en bout, exercices, alésus) provide excellent hardness, résistance à l'usure, and heat tolerance, ideal for high-performance machining of magnesium.

Coated Carbide Tools

Carbide tools coated with TiAlN or TiN significantly reduce friction, enhance thermal stability, and minimize tool wear when machining magnesium alloys.

Diamant polycristallin (PCD) Outils

PCD tools offer superior durability and exceptional surface finish, making them ideal for high-precision magnesium machining, especially for abrasive alloys.

CNC Machining Methods for Magnesium

Different CNC machining methods suit various magnesium alloy machining applications:

Forage CNC

Ideal for creating precise holes and detailed hole patterns in magnesium components with exceptional accuracy.

Fraisage CNC

Highly versatile for shaping magnesium into simple or complex geometries. This process efficiently produces detailed, précis, and high-quality magnesium parts.

Tournage CNC

Suited for creating cylindrical components (arbres, épingles, threaded parts). Magnesium’s machinability makes turning fast, précis, et rentable.

Découpe au laser

Effective for precision-cutting thin magnesium sheets or plates. Laser cutting delivers clean, précis, et des résultats efficaces.

Tapotement

Automated CNC tapping ensures precise internal threading, providing reliable accuracy and consistency in magnesium alloy components.

Practical Uses for CNC-Machined Magnesium Parts

Electronics and Gadgets

Pourquoi le magnésium? Poids léger, durable, and great at dissipating heat.

Common products: Laptop frames, smartphone casings, camera bodies, and tablets.

Pièces automobiles

Pourquoi le magnésium? Reduces vehicle weight, improving fuel efficiency and handling.

Common products: Steering wheels, logements de boîte de vitesses, engine covers, and seat frames.

Composants aérospatiaux

Pourquoi le magnésium? High strength-to-weight ratio is ideal for flight applications.

Common products: Aircraft engine casings, cockpit panels, pièces d'atterrissage, and structural supports.

Équipement médical

Pourquoi le magnésium? Poids léger, précis, and easily sterilized.

Common products: Surgical instrument handles, portable medical device housings, and imaging equipment.

Équipement sportif

Pourquoi le magnésium? Provides strength without adding unnecessary weight.

Common products: Cadres de vélo, cadres de raquettes de tennis, clubs de golf, and protective gear.

Magnesium Machining Services at HAUTS

Choosing an experienced CNC machining provider like TOPS ensures the successful machining of magnesium components. TOPS boasts over a decade of expertise in precision CNC machining of magnesium alloys, aluminium, titane, and various plastics. With comprehensive capabilities and stringent safety protocols, TOPS ensures your magnesium machining projects are executed safely, efficiently, et rentable.

Conclusion

Magnesium offers exceptional machinability, rapport résistance/poids élevé, and excellent recyclability. Cependant, CNC machining magnesium requires careful consideration and strict adherence to safety guidelines due to inherent risks, including flammability and rapid tool wear. By implementing the proper tooling, safety procedures, and machining methods, manufacturers can effectively leverage magnesium’s many benefits for high-quality, précis, and safe machining operations.

FAQ

T1: Which magnesium alloy is best for CNC machining?

AZ91 and AZ31 are most commonly machined magnesium alloys, with AZ91 offering higher hardness (Knoop’s hardness of 76.2 compared to AZ31’s 51.1 HK).

T2: What disadvantages are associated with machining magnesium alloys?

Magnesium alloys can be difficult to source, exhibit relatively poor corrosion resistance, and their lower density can limit certain structural applications.

T3: What are common uses of magnesium alloys?

Magnesium alloys are widely utilized for lightweight components in electronic devices (par exemple., téléphones, ordinateurs portables), pièces automobiles et aérospatiales, Équipement médical, and camera casings

T4: Can magnesium alloys be welded?

Oui, magnesium alloys are weldable through arc welding, resistance welding, and oxyfuel gas welding techniques, given proper handling and safety measures.

Liens internes