Polyether Ether Ketone (COUP D'OEIL) est l'un des thermoplastiques hautes performances les plus polyvalents utilisés dans l'ingénierie moderne. Connu pour sa solidité exceptionnelle, résistance chimique, et stabilité thermique, Le PEEK est largement choisi pour les applications exigeantes de l'aérospatiale, Équipement médical, et équipements industriels à forte charge.

Bien que le PEEK s'usine relativement bien par rapport à d'autres plastiques techniques, it has unique characteristics that require careful process planning. Without the right techniques, issues such as thermal cracking, dimensional instability, or poor surface finish can occur. This article explores what makes PEEK special, its benefits and challenges in machining, practical tips for better results, and key industrial applications.

What is PEEK (Polyether Ether Ketone)?

PEEK is a semi-crystalline thermoplastic belonging to the polyaryletherketone (PAEK) famille. It offers a balance of mechanical performance, stabilité chimique, and thermal endurance that few other plastics can match.

Propriétés clés

Haute résistance & Résistance à l'usure – Comparable to some metals while retaining the benefits of a lightweight polymer.

Point de fusion élevé – ~343 °C (649 °F), enabling use in continuous service up to 250 °C (482 °F).

Excellent Chemical Resistance – Unaffected by most organic and inorganic chemicals.

Low Moisture Absorption – Maintains dimensional stability in humid or wet environments.

Radiation Resistance – Withstands gamma and X-ray exposure without significant degradation.

Biocompatibilité – Certain medical-grade PEEK complies with ISO 10993 and USP Class VI standards.

Available Forms

Granules – For injection molding and extrusion.

Filament – For additive manufacturing.

Rods, Barres, and Plates – Common starting shapes for CNC machining.

PEEK is available in unfilled grades for general applications, et reinforced grades (fibre de verre, fibre de carbone, or PTFE-filled) for enhanced wear, force, or thermal properties.

Advantages of Machining PEEK

Super fort, Even Under Stress

PEEK is tough. It holds its shape and strength even when it’s under pressure or carrying heavy loads, which makes it perfect for parts that need to work hard every day.

Can Handle the Heat

While many plastics get soft or warp when things get hot, PEEK can handle continuous temperatures up to around 250°C (480°F) without breaking a sweat.

Resists Chemicals Like a Pro

Oils, carburants, acids — PEEK doesn’t care. It’s resistant to many harsh chemicals, so it stays reliable in environments that would damage other materials.

Lightweight Yet Durable

You get the strength of metal but with a fraction of the weight. This is why aerospace and automotive industries love it — lighter parts mean better fuel efficiency.

Excellent Wear Resistance

Parts made from machined PEEK last a long time because it can handle friction without wearing down quickly.

Easy to Machine Into Complex Shapes

Even though it’s tough, PEEK machines well with the right tools, so you can create very detailed and precise parts without major headaches.

Biocompatible and Safe for Medical Use

Medical-grade PEEK is safe to use inside the human body, which is why it’s often used in implants and surgical tools.

Limitations of PEEK Machining

It’s Not the Cheapest Option

PEEK is pricey compared to many other plastics. If you’re making a lot of parts or working on a budget-sensitive project, material cost can be a big factor.

Needs Sharp Tools and Careful Machining

Even though PEEK machines well, it’s still tough on cutting tools. You’ll need sharp, high-quality tools and proper speeds/feeds to get a smooth finish without damaging the part.

Heat Buildup Can Be a Problem

PEEK can handle high temperatures, but during machining, too much localized heat from the cutting tool can cause melting, gauchissement, ou défauts de surface. Good cooling is essential.

Limited Color Options

Most PEEK is naturally beige or tan. If you need colorful parts for design or branding, you might have to consider coatings, dyes, or other plastics.

Not Always the Best Choice for Very Soft or Flexible Parts

PEEK is rigid and strong, which is great for structural parts, but not ideal if you need flexibility or cushioning.

Long Lead Times for Special Grades

Standard PEEK is usually easy to find, but special grades (like carbon-filled or medical-grade) might take longer to source, slowing down production.

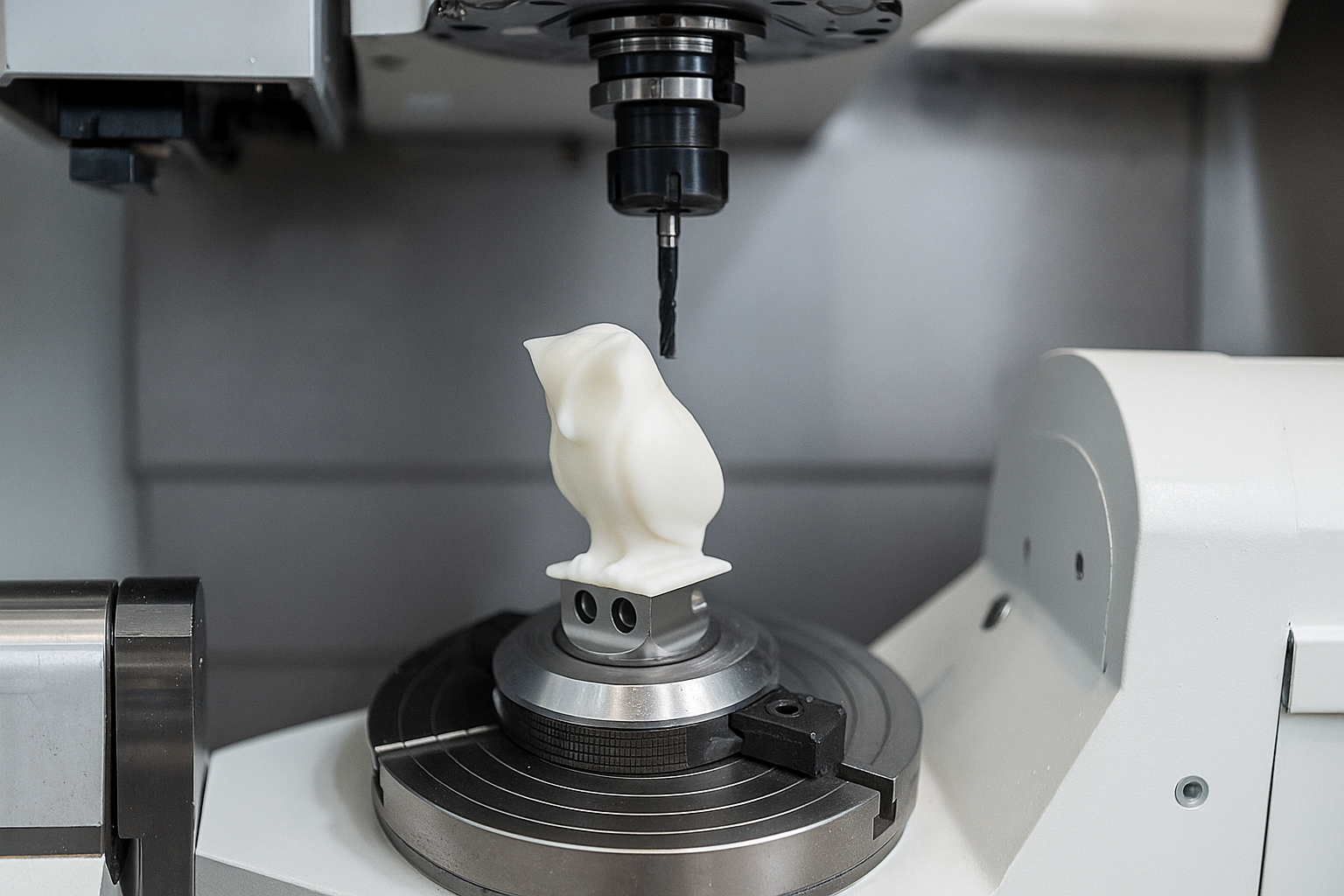

How Do You Machine PEEK?

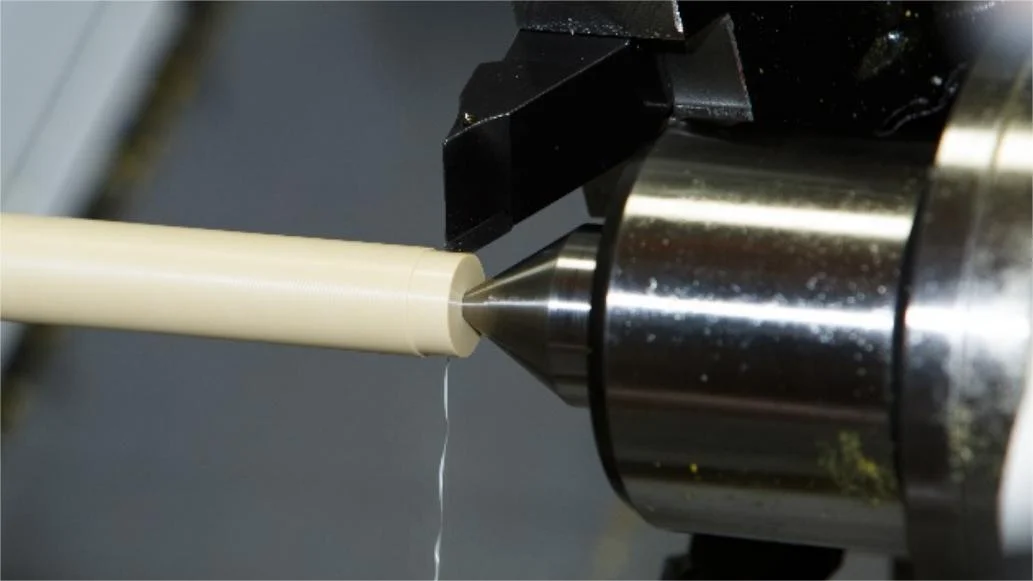

Fraisage CNC

Great for creating flat surfaces, machines à sous, les poches, et des formes 3D complexes. En utilisant sharp carbide tools and high spindle speeds helps keep the edges clean and prevents melting.

Perfect for round parts like bushings, tiges, and seals. Turning PEEK works well with light cuts and steady feed rates to avoid heat buildup and maintain tight tolerances.

Forage

You can drill PEEK cleanly using standard twist drills, mais chip evacuation is key. If chips aren’t cleared quickly, heat can build up and cause surface damage.

Tapping and Threading

Internal and external threads can be cut in PEEK with proper tool lubrication. This is often used for mechanical fasteners or custom fittings.

Finition de surface

Après l'usinage, PEEK parts can be polished, bead blasted, or coated depending on the application — whether you want a functional finish or a sleek look.

What Surface Finishes Can You Get When CNC Machining PEEK?

Typical CNC-Machined Finish

Most PEEK parts straight off the CNC have a smooth, finition mate. This is fine for mechanical components where looks aren’t the priority. Surface roughness here is usually around Ra 1.6–3.2 μm.

Fine Machining for a Better Finish

En utilisant sharp carbide tools, slower feed rates, and light cuts, you can improve the surface to about Ra 0.8–1.6 μm, giving it a cleaner, more refined look.

Polishing for High-End Applications

If you need a glossy or near-mirror surface — for example, in medical implants or visible aerospace parts — PEEK can be polished after machining. Polishing can bring surface roughness down to Ra 0.2–0.4 μm.

Other Surface Treatments

Dynamitage des perles for a uniform, texture mate

Revêtements for extra wear or chemical resistance

Laser marking for permanent labels without damaging the surface

What is the Tolerance of PEEK in Machining?

Typical Tolerances:

Dans la plupart des cas, you can hold tolerances of ±0,05mm (±0.002 in) without much trouble. With fine-tuned equipment, you can even go tighter, vers le bas ±0,025 mm (± 0,001 po).

Factors That Affect Tolerance:

Accumulation de chaleur – Too much heat can cause slight expansion, affecting precision.

Moisture – PEEK absorbs some water over time, which can change dimensions. Drying it first helps.

Usure – Dull tools reduce accuracy and surface finish.

Machine stability – A rigid, well-calibrated CNC machine is key for high-precision work.

Applications of Machined PEEK

Pièces aérospatiales

PEEK can handle high stress, vibration, and extreme temperatures, making it perfect for lightweight aircraft components like brackets, pinces, scellés, and insulation parts.

Équipement médical

Because it’s biocompatible (safe for the human body), PEEK is used for surgical tools, dental parts, spinal implants, and other medical equipment that needs to be strong, lumière, and sterilizable.

Composants automobiles

Dans les voitures, PEEK is used for high-performance gears, bagues, and seals that can stand up to heat from engines and friction from moving parts.

Electronics and Electrical Equipment

PEEK is an excellent electrical insulator, so it’s used in connectors, circuit board supports, and insulation components for high-voltage systems.

Huile, Gaz, and Energy Industry

PEEK resists harsh chemicals, haute pression, and extreme heat — which is why it’s used in valve seats, composants de la pompe, and seals for drilling equipment.

Machines industrielles

In manufacturing plants, PEEK’s wear resistance makes it a great choice for bearings, rouleaux, and parts that face constant mechanical stress.

Tips for Machining PEEK

Use Sharp, High-Quality Tools

PEEK is abrasive, so dull tools will wear out fast and leave poor surfaces. Carbide or diamond-coated tools last longer and cut cleaner.

Control the Heat

PEEK can soften if it gets too hot during machining. Use proper coolant or air blasts to keep temperatures down and prevent warping.

Don’t Rush the Feed Rate

Going too fast can overheat the material, while going too slow can cause tool rubbing. Aim for a balanced speed and feed for smooth cutting.

Clamp the Material Securely

PEEK is tough but not brittle — still, vibrations can ruin accuracy. Use firm, even clamping to keep your part stable during the cut.

Pre-Dry Before Machining (Si nécessaire)

PEEK can absorb moisture over time, which might cause bubbles or rough spots during machining. Dry it in an oven before cutting for best results.

Finish With Care

If you need a super-smooth surface, consider fine polishing or grinding after machining. PEEK can achieve an almost glossy finish with the right touch.

Watch for Chip Build-Up

PEEK chips can be stringy and may wrap around tools. Use proper chip removal methods so your cutting edges stay clean.

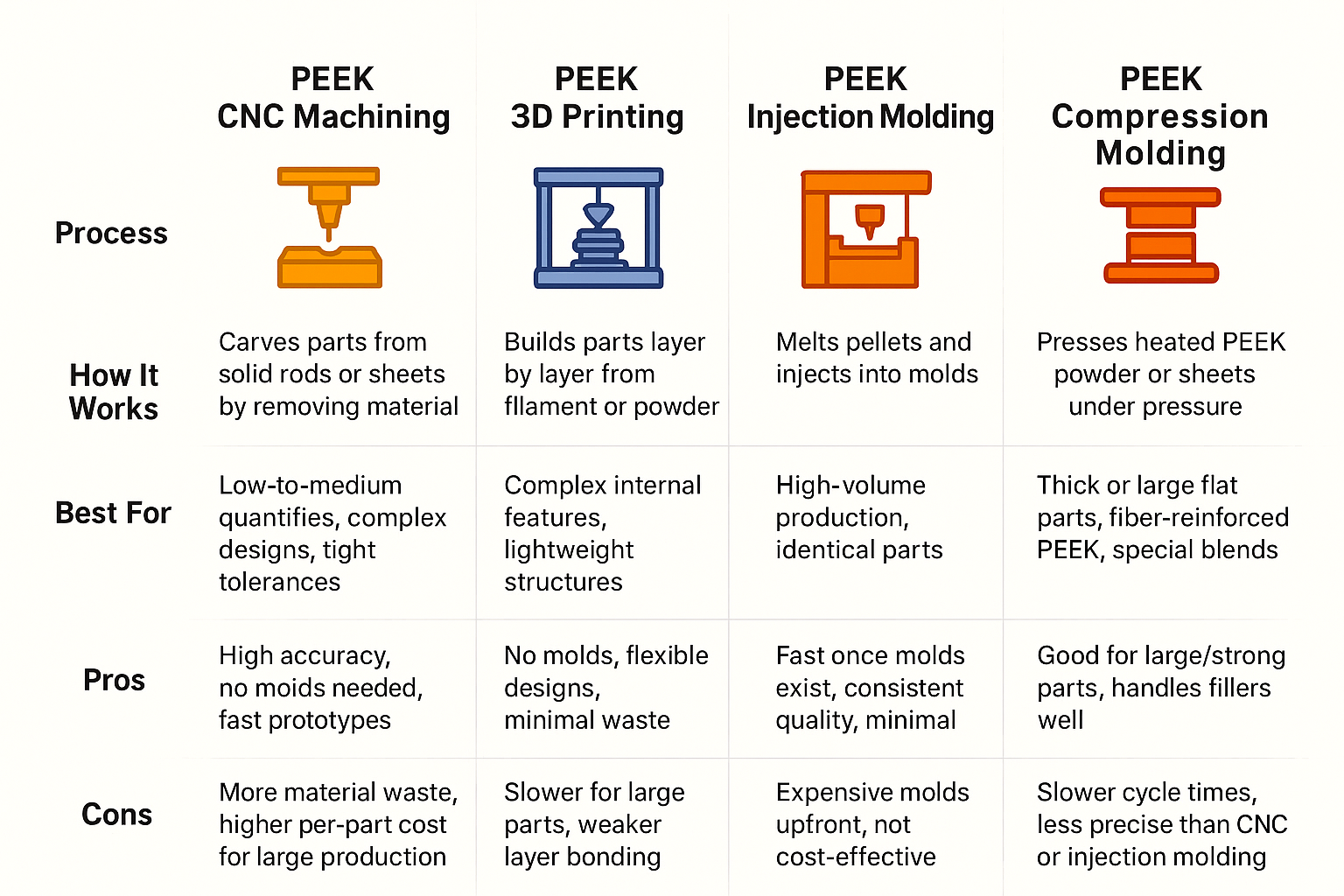

Comparing Manufacturing Methods for PEEK

Conclusion

PEEK’s unique combination of strength, résistance chimique, and biocompatibility makes it a go-to material for industries where failure is not an option. By understanding its machining challenges—especially heat management and stress relief—manufacturers can produce high-quality components with excellent performance and longevity.

Choosing the right manufacturing method depends on your production goals: CNC machining for precision and versatility, 3D printing for design complexity, and injection molding for mass production. With the right process strategy, PEEK can deliver outstanding results across both industrial and medical fields.

FAQ

1. Why is heat control so critical when machining PEEK?

Although PEEK has an extremely high service temperature, controlling localized heat during machining is crucial to prevent dimensional instability and thermal cracking. Excessive friction from the cutting tool can cause the material to slightly melt or warp near the cutting zone, leading to poor surface finish and difficulty holding tight tolerances. En utilisant coolant or air blasts is essential to manage this thermal buildup.

2. Should PEEK parts be stress-relieved (annealed) before or after machining?

It is highly recommended to stress-relieve (anneal) PEEK stock material before machining. This process releases internal stresses induced during the stock’s extrusion or molding, stabilizing the polymer’s crystalline structure. This stabilization minimizes the risk of the part warping or deforming once significant material has been removed, ensuring the final component meets its required tolerance.

3. What is the difference between “unfilled” PEEK and “reinforced” PEEK, and how does it affect machining?

Unfilled (or Virgin) COUP D'OEIL is the standard grade, offering maximum toughness and ductility, and is the easiest to machine. Reinforced PEEK contains additives like carbon fiber, fibre de verre, or PTFE.

-

Carbon/Glass Fiber-Filled PEEK: Offers enhanced strength and stiffness but is highly abrasif, requiring diamond-coated or specialized carbide tools, as it causes significantly faster tool wear.

-

PTFE-Filled PEEK: Used for improved wear resistance and lower friction.

4. What are the tightest tolerances that can typically be held when CNC machining PEEK?

With proper preparation (soulagement du stress, drying) et rigide, high-precision CNC equipment, tolerances can typically be held to ±0.05 mm(±0.002 dans). For specialized, high-precision applications, tolerances can sometimes be tightened down to ± 0.025 mm (± 0.001 dans), provided temperature is meticulously controlled throughout the process.

5. Can PEEK be sterilized for medical applications after machining?

Oui. One of PEEK’s major advantages is its resistance to various sterilization methods. Medical-grade PEEK can withstand repeated cycles of common sterilization techniques, y compris autoclaving (steam sterilization), gamma irradiation, and chemical sterilization, without significant degradation in its mechanical properties or biocompatibility.

6. Why is PEEK often compared to metals like stainless steel?

PEEK is compared to metals because it offers a rapport résistance/poids élevé and maintains its mechanical performance at elevated temperatures where most other plastics fail. It provides similar stiffness and strength to some metals but is much lighter, chemically inert, et non corrosif, making it a viable high-performance replacement in aerospace, automobile, and medical fields.

7. When should I choose Injection Molding over CNC Machining for PEEK parts?

The choice depends on volume and complexity:

-

Usinage CNC: Mieux pour low-to-medium volumes, prototypes, géométries complexes, and when the absolute tightest tolerances are required. Tooling costs are low.

-

Moulage par injection: Required for high-volume mass production runs (thousands of units). While tooling is expensive, the per-part cost is dramatically lower, and it’s the fastest way to produce simple parts in large quantities.