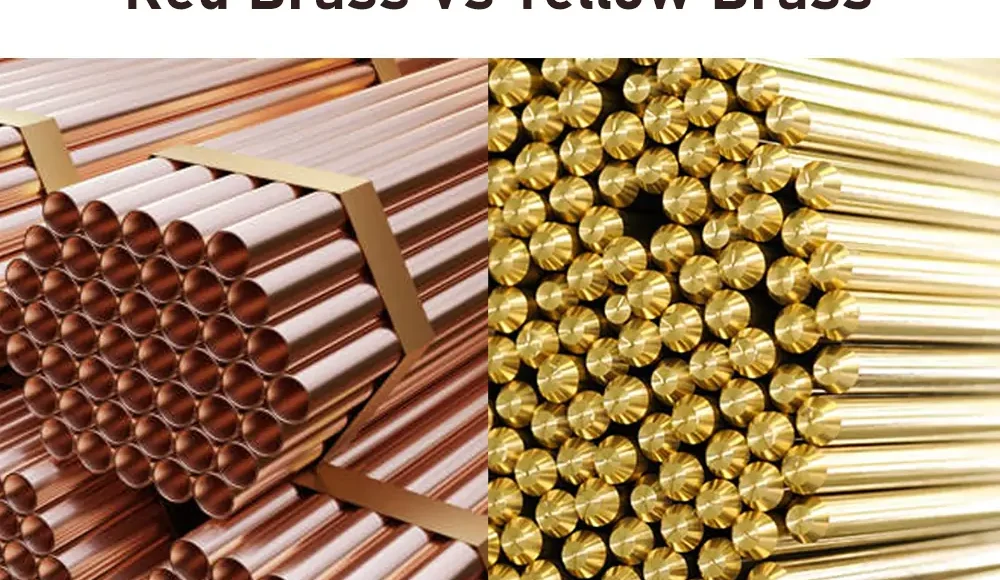

Laiton est un alliage métallique polyvalent principalement composé de cuivre et de zinc. Les ajustements dans ces éléments centraux donnent des variantes telles que le laiton rouge et le laiton jaune, chacun avec des propriétés distinctes, utilise, et les avantages. Ce guide offre une comparaison approfondie entre le laiton rouge et le laiton jaune pour vous aider à choisir le meilleur alliage métallique pour vos applications spécifiques.

Qu'est-ce que le laiton rouge vs. Laiton jaune?

Bien que le laiton rouge et le laiton jaune sont dérivés des mêmes éléments de base -cuivre et zinc - le rapport de ces éléments a un impact significatif sur leurs propriétés, les rendre adaptés à des applications diverses.

Comprendre les cuivres rouges

Laiton rouge, communément appelé GunMetal, se distingue par son contenu en cuivre supérieur (85-90%), complété par le zinc, étain, et traces de plomb, fer, manganèse, et l'arsenic. Cette riche concentration en cuivre confère au laiton rouge sa couleur rougeâtre caractéristique et sa force supérieure.

Cependant, En raison de la réaction du zinc avec l'eau de mer, il convient moins aux environnements marins.

Comprendre le laiton jaune

Le laiton jaune contient moins de cuivre (60-80%) Et plus de zinc (30-40%), Donner un brillant, apparence dorée. Son contenu en zinc supérieur fournit une ductilité améliorée, malléabilité, et machinabilité, rendre le laiton jaune idéal pour les conceptions complexes et l'usinage CNC.

Composition chimique: Laiton rouge vs. Laiton jaune

| Élément | Laiton rouge (%) | Laiton jaune (%) |

| Cuivre | 85–90 | 60–80 |

| Zinc | 5–10 | 30–40 |

| Étain | 2 min | 1 maximum |

| Plomb | 1 maximum | 1 maximum |

| Fer | 0.1 | 0.1 |

| Manganèse | 0.5 | 0.5 |

| Arsenic | 0.01 maximum | 0.01 maximum |

Comparaison de la force: Laiton rouge vs. Laiton jaune

Une teneur en cuivre plus élevée fournit en laiton rouge avec une plus grande résistance (580 Force de traction MPA) par rapport aux laiton jaune (315 MPa). Cela rend le laiton rouge plus adapté aux applications structurelles et à haute pression.

Comparaison des propriétés physiques et mécaniques

Propriétés physiques

| Propriété | Laiton rouge | Laiton jaune |

| Couleur | Rougeâtre | Jaune vif |

| Densité | 8.5–8,7 g / cm³ | 8.3–8,5 g / cm³ |

| Point de fusion | 900–940 ° C (1652–1724 ° F) | 880–920 ° C (1622–1690 ° F) |

| Conductivité électrique | 21–24 ms / m | 25–28 ms / m |

| Conductivité thermique | 118–122 w / m · k | 109–113 w / m · k |

Propriétés mécaniques

| Propriété | Laiton rouge | Laiton jaune |

| Résistance à la traction | 580 MPa | 315 MPa |

| Limite d'élasticité | 400 MPa | 200 MPa |

| Élongation | 30% | 40% |

| Dureté (HB) | 80–90 | 70–80 |

| Usinabilité | Super | Excellent |

Comparaison des coûts: Laiton rouge vs. Laiton jaune

Le laiton rouge a tendance à être plus cher en raison du contenu élevé en cuivre, surtout compte tenu des récentes pointes des prix du cuivre. Le laiton jaune est plus économique et largement disponible, le rendre préférable pour les projets sensibles aux coûts.

Comparaison des prix de rebut

La ferraille en laiton a une valeur marchande plus élevée ($2.10- 2,40 $ la livre) par rapport aux laiton jaune ($1.50- 1,80 $ la livre), reflétant la valeur intrinsèque des alliages riches en cuivre.

Comparaison de poids: Laiton rouge vs. Laiton jaune

Avec une densité légèrement plus élevée, laiton rouge (8.5–8,7 g / cm³) est plus lourd que le laiton jaune (8.3–8,5 g / cm³), qui peut influencer son aptitude à des applications spécifiques nécessitant des matériaux plus robustes.

Résistance à la corrosion

Laiton rouge, Avec plus de cuivre, démontre une résistance à la corrosion supérieure. Cette propriété rend le laiton rouge préférable pour les environnements exposés à des conditions difficiles, Bien que le laiton jaune fournit également une résistance à la corrosion raisonnable dans des scénarios moins exigeants.

Comparaison de durabilité

Le laiton rouge est notamment plus durable, capable de maintenir son intégrité sous le stress, pression, et une exposition environnementale prolongée. Laiton jaune, Bien que moins robuste, reste bien dans les applications plus légères.

Similitudes entre le laiton rouge et le laiton jaune

Malgré leurs différences, Les deux alliages partagent des propriétés précieuses:

Excellente usinabilité

Haute conductivité électrique et thermique

Résistance au ternissement

Applications communes dans les instruments de musique, objets décoratifs, et composants électriques

Évaluation de la force: Ce qui est plus fort?

Dans l'ensemble, Le laiton rouge est plus fort, Convient aux applications à stress élevé, tandis que le laiton jaune offre une flexibilité et une machinabilité plus facile, Convient pour un travail détaillé et des composants décoratifs.

Laiton rouge vs. Laiton jaune: Graphique de comparaison

| Propriété | Laiton rouge | Laiton jaune |

| Apparence | Or rougeâtre | Jaune vif |

| Contenu en cuivre (%) | 85–90% | 60–80% |

| Contenu du zinc (%) | 5–10% | 30–40% |

| Résistance à la traction | Plus haut (580 MPa) | Modéré (315 MPa) |

| Limite d'élasticité | Plus haut (400 MPa) | Modéré (200 MPa) |

| Dureté | Plus haut (80–90 HB) | Modéré (70–80 hb) |

| Usinabilité | Bien | Excellent |

| Densité | Légèrement plus haut (8.5–8,7 g / cm³) | Légèrement inférieur (8.3–8,5 g / cm³) |

| Point de fusion | Plus haut (900–940 ° C) | Inférieur (880–920 ° C) |

| Résistance à la corrosion | Excellent | Bien |

| Durabilité | Haut | Modéré |

| Coût | Plus cher (Contenu en cuivre supérieur) | Plus abordable (Contenu en cuivre inférieur) |

| Applications typiques | Pièces lourdes, composants électriques, bijoux, instruments de musique nécessitant des tons plus riches | Objets décoratifs, plomberie, composants automobiles légers, instruments de musique nécessitant des tons stables |

Laiton rouge vs. Laiton jaune: Ce qui est mieux dans l'ensemble?

Avantages en laiton rouge:

Résistance et durabilité plus élevées

Résistance à la corrosion supérieure

Meilleure conductivité électrique

Avantages en laiton jaune:

Rentable

Machinabilité plus facile

Largement disponible

Choisir la meilleure option dépend de vos exigences d'application spécifiques, budget, et les conditions environnementales.

Comparaisons spécifiques à l'application

Bijoux: Le laiton rouge est durable et a un attrait rougeâtre distinct, Idéal pour les pièces de haute qualité; Le laiton jaune est rentable, plus facile à façonner.

Instruments de musique:

Saxophone: Le laiton rouge offre plus profondément, tons plus riches; Le laiton jaune offre une qualité sonore stable.

Trombone et trompette: Le laiton rouge cède plus sombre, sons plus riches; Le laiton jaune produit stable, tons plus brillants.

Composants d'avion: Le laiton rouge offre une résistance et une durabilité plus élevées, tandis que la machinabilité du laiton jaune convient complexe, composants légers.

Composants marins: Généralement inadapté en raison du contenu du zinc; Matériaux alternatifs recommandés.

Composants électriques: Le laiton rouge est préféré pour une meilleure conductivité; Le laiton jaune reste pratique et abordable.

Pièces automobiles: La force du Brass rouge convient aux pièces structurelles; Le laiton jaune est rentable pour les composants décoratifs ou non critiques.

Choisir le bon fabricant

La sélection d'un fabricant expérimenté et fiable garantit la plus haute qualité de pièces de laiton. Fabrication KDM est l'un des principaux fournisseurs de composants de laiton de haute précision, Assurer des produits adaptés précisément à vos besoins industriels.

Conclusion

Le laiton rouge et le laiton jaune ont des avantages distincts adaptés aux besoins spécifiques. Le laiton rouge excelle en force, résistance à la corrosion, et durabilité, tandis que le laiton jaune est préféré pour l'abordabilité, disponibilité, et machinabilité. Évaluer soigneusement les exigences de votre projet est essentiel pour choisir le bon alliage de laiton.

Ressources supplémentaires

- Comprendre les alliages en laiton

- Point de fusion du laiton

- Techniques d'usinage en laiton

- Le laiton est-il magnétique?

- Anodisation en laiton