L'importance de die-cast metals in modern manufacturing has surged due to their exceptional blend of high strength, durabilité, stabilité, et une rentabilité remarquable dans la production en grand volume. La capacité du processus de moulage sous pression à produire de manière cohérente des formes complexes avec des tolérances dimensionnelles serrées le rend indispensable pour les composants critiques du secteur automobile., électronique, et secteurs industriels.

This guide provides a comprehensive analysis of the strength of die-cast metals, detailing the factors that influence performance and examining the unique mechanical advantages of the primary alloys used.

Overview and Definition of Die Cast Metals

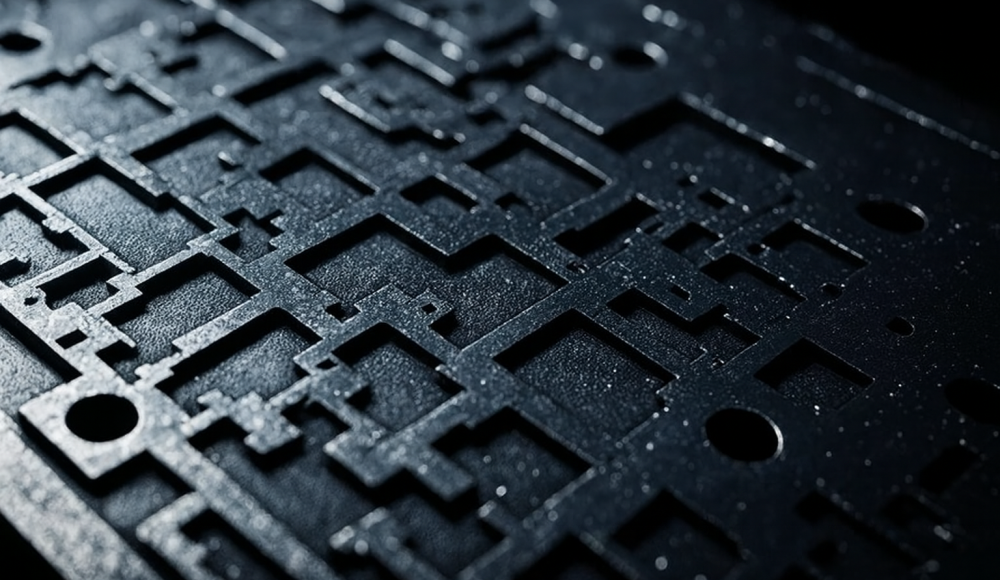

The term moulage sous pression describes a rapid, high-volume manufacturing method where molten non-ferrous alloys are injected into a steel mold (mourir) under extreme pressure. This high-pressure environment is what gives the final product its superior internal integrity and surface quality.

Die-Cast Metals sont, donc, the alloys specifically chosen for this process, primarily comprising materials with relatively low melting points to ensure the longevity of the hardened steel dies. Common examples include Aluminum (Al), Zinc (Zn), et magnésium (Mg) alliages.

Determining the Strength of Die Cast Metals

The strength of a die-cast component is not inherent to the process itself, but is fundamentally determined by two critical factors:

UN. The Specific Alloy Composition

Strength is directly linked to the quality and type of alloy selected. Par exemple, high-silicon aluminum alloys (like A380) offer excellent casting properties and good strength, while dedicated structural alloys (like A390) provide greater ultimate tensile strength but may be harder to cast.

B. Structural Integrity and Porosity

Le die casting process significantly enhances the effective strength of the metal:

High-Pressure Injection: The extreme pressure minimizes the formation of internal voids and gas porosity, resulting in a denser, more homogenous part. Low porosity leads to more consistent mechanical properties and greater resistance to failure under stress.

Rapid Solidification: Contact with the cold steel die causes rapid cooling, often producing a fine-grained structure (a “chill zone”) near the surface, which contributes to higher surface hardness and enhanced fatigue resistance.

Industry Strength Comparison:

While steel-cast parts are generally considered the most compatible choice for the most extreme, critical load-bearing applications (due to steel’s raw strength), die-cast aluminum and zinc alloys frequently outperform other metals in terms of strength-to-weight ratio and manufacturing efficiency.

Primary Die Cast Metal Alloys and Their Advantages

The industry largely favors Aluminum, Magnésium, and Zinc alloys, each providing a unique performance profile tailored to specific engineering demands.

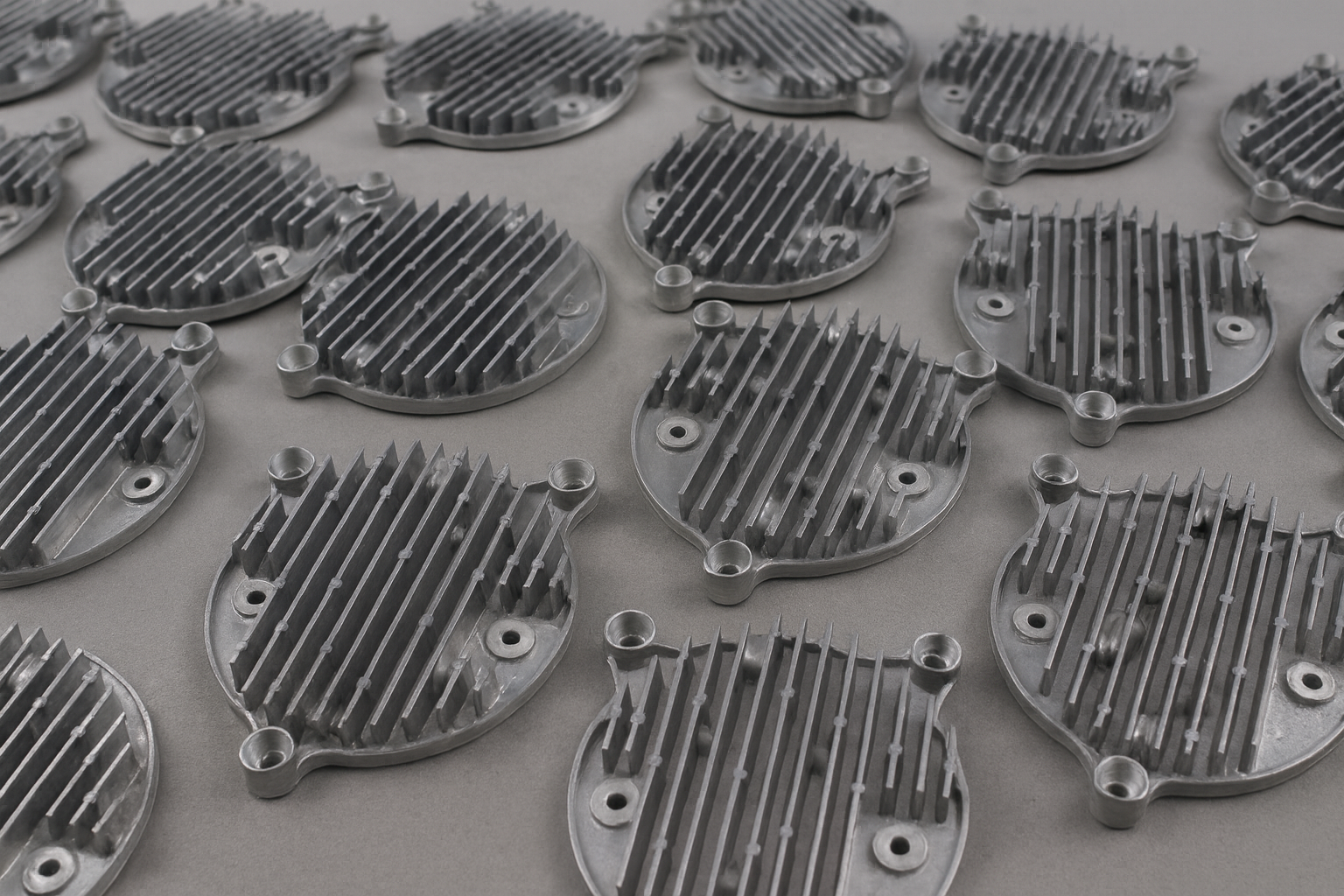

Aluminium (Al) Moulage sous pression Avantages

Aluminum alloys are the workhorses of the die casting industry, providing an excellent balance of properties:

Low Density and Corrosion Resistance: Aluminum offers substantial weight reduction compared to steel and possesses natural corrosion resistance, making it ideal for automotive body and engine components.

Précision dimensionnelle élevée: The process yields high precision and excellent repeatability crucial for complex electronic enclosures and mechanical housings.

Thermal Performance: Exhibits superior heat dissipation, enabling its widespread use in high-temperature applications such as heat sinks, culasses, and engine manifolds.

Durabilité: The inherent hardness of many aluminum die-cast alloys provides strong durability, allowing them to withstand harsh operating and environmental conditions.

Magnésium (Mg) Moulage sous pression Avantages

Magnesium is chosen when minimizing mass is the absolute priority:

The Lightest Structural Alloy: It is unmatched in its low density, offering the best available rapport résistance/poids for any die-cast material.

Exceptional Tensile Strength: Despite its lightness, magnesium maintains strong mechanical properties.

Processing: It is often softer than aluminum, making it easier to machine (opérations secondaires) and highly beneficial for components in portable electronics and complex aerospace interiors.

Zinc (Zn) Moulage sous pression Avantages

Zinc alloys are the dark horse, often overlooked but possessing critical strengths:

Highest Ultimate Strength: Among the non-ferrous die-cast alloys, Zinc (particularly Zamak series) typically exhibits the strongest strength to withstand load-bearing applications et résistance à l'impact.

High Yield Strength: Ideal for components that must resist permanent deformation under repeated stress.

Superior Castability for Complexity: Zinc’s low melting point and excellent flowability allow it to be cast with zero flash into the most intricate and thin-walled features, making it the best choice for highly complex, small castings where precision is critical.

Conclusion

The definitive strength of a die-cast metal component is a direct result of balancing material properties with manufacturing requirements. The selection process must align the needs of the project—including volume, budget, environmental compatibility, required durability, and geometric complexity—with the specific performance advantages offered by Aluminum, Magnésium, or Zinc. By leveraging the inherent strength of the chosen alloy through the high-pressure die casting process, manufacturers ensure components meet the highest standards of performance and reliability.

FAQ

1. How does the “strength-to-weight ratio” of aluminum and magnesium compare to steel?

The strength-to-weight ratio is a critical metric for aerospace and automotive engineers. While steel has a higher ultimate strength, aluminum and magnesium alloys offer significantly better strength-to-weight ratios. Le magnésium est le plus léger, providing the best ratio among die-cast metals. This means you can achieve the required structural performance with a much lighter part by using these alloys, leading directly to improved fuel efficiency and reduced inertia.

2. Why is Zinc casting preferred for very complex, small components despite Aluminum’s popularity?

Zinc has a much point de fusion inférieur and superior flowability compared to aluminum. This allows the molten zinc to fill intricate, thin-walled features and complex micro-cavities within the die more completely and smoothly. This superior castability ensures that complex parts can be produced with exceptional detail and minimal defects, making zinc the ideal choice for highly detailed or small, precise components (like locking mechanisms or electronic connectors).

3. Does the high pressure in die casting make the metal stronger than if it were cast by gravity?

Oui, indirectly. The high pressure (jusqu'à 4,500 psi) is crucial because it minimizes internal porosity (air bubbles and voids) that naturally occur in gravity-fed casting (like sand casting). By creating a denser, more uniform internal structure, the part has more consistent mechanical properties, increased effective load-bearing capacity, and significantly improved resistance to fatigue and cracking.

4. Why is die-cast aluminum used for high-temperature applications like engine parts?

Die-cast aluminum alloys, particularly those containing silicon, maintain their structural integrity and stiffness well even when operating at températures élevées (up to 300℃). En plus, aluminum’s excellent thermal conductivity allows it to efficiently dissipate heat away from critical engine components, contributing to overall thermal management and preventing overheating.

5. What is the main trade-off when choosing Magnesium over Aluminum?

The main trade-off is cost and corrosion resistance. Magnesium alloy is significantly more expensive than aluminum. En outre, while magnesium has good corrosion resistance in many environments, it is more susceptible to corrosion galvanique when coupled with other metals (like steel fasteners) and requires more careful surface finishing or plating than aluminum.

6. Why are Iron and Steel rarely used in the die casting process?

Iron and Steel have extremely high melting temperatures (over 1,500℃). These temperatures cause rapid thermal fatigue and damage (known as heat checking) to the hardened steel dies. The resulting maintenance costs and dramatically reduced die lifespan make the die casting process economically unfeasible for ferrous metals, which are typically manufactured using sand casting or investment casting instead.

7. What specific property makes die-cast alloys ideal for electronic enclosures?

Die-cast metals, especially aluminum and magnesium, are ideal for electronic enclosures due to two properties: EMI/RFI Shielding et Dissipation de chaleur. As metals, they naturally block electromagnetic and radio-frequency interference (EMI/RFI). En outre, their high thermal conductivity efficiently transfers heat away from sensitive internal components, protecting the electronics from heat damage.

1 réfléchi à "La force du métal moulé sous pression: Une plongée profonde dans les alliages, Propriétés, et performances”