- Toolpath Preparation: CAD models are converted to CAM toolpaths that are optimized to utilize alloy characteristics and part shape.

- Enlèvement de matière: Cutting occurs on a multi-axis machine with milling, tournant, affûtage, and drilling operations being carried out under controlled speed-feed regimes in order to control buildup.

- Contrôle thermique:To eliminate the effects of parts and the effects on work-hardening coolants are used to control the heat.

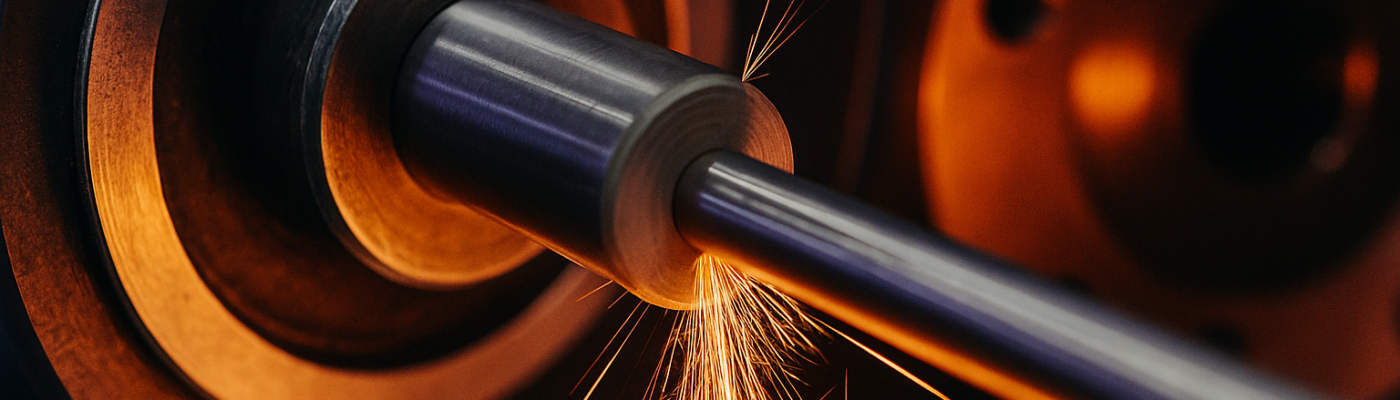

- Finishing Operations: Surface finish and tolerances may be achieved by completion with precision grinding, clapotis, or chemical finishing.

- Traitement thermique (Post-Machining): Carburization, nitruration, and annealing can produce the strength and surface characteristics.

- Maison

- Prestations de service

- Usinage CNC

- Moulage sous pression

- Fabrication de moules

- Moulage sous pression en aluminium

- Moulage sous pression de zinc

- Moulage sous pression de magnésium

- Services de supports moulés sous pression

- Services de boîtiers moulés sous pression

- Services de logements moulés sous pression

- Services de moulage sous pression automobile

- Services de moulage sous pression par gravité

- Services de moulage sous pression basse pression

- Fabricant de moulage sous pression en Chine

- Moulage sous pression haute pression

- Services de moulage sous pression de prototypes

- Services de moulage sous pression à grand volume

- Services de moulage sous pression à faible volume

- Fabrication de tôles

- Moulage par injection plastique

- Fabrication sous contrat

- Fabrication à faible volume

- Production massive

- les industries

- Automatisation

- Electronique grand public

- Usinage médical CNC

- Broyage de PCB

- Usinage aérospatial

- Usinage CNC automobile

- Pièces de vélo usinées CNC

- Usinage d'ouverture de la bouteille CNC

- Usinage d'arbre à cames CNC

- Usinage à vis CNC

- Pièces de rechange d'usinage CNC

- Usinage de pistons CNC

- Cadeaux usinés CNC

- Volant usiné CNC

- Rasoir de sécurité usiné CNC

- Fidget Spinner usiné CNC

- Dés usinés CNC

- Pièces d'échecs usinées CNC

- Galerie

- Ressources

- À propos de nous

Alloy Steel Machining Services

- Finished Alloy Processing: Experienced with products that include such high strengths as wear-resistant alloy processes, tel que 4140, 4340, 8620, et 17-4 PH.

- Vanishing precision: Machining precision to the level of plus or minus 0.005 mm at tolerance with hard tools, stabilité thermique, and continuous monitoring.

- Surface and Structural Integrity: Provide finishes that are suitable for nitride, grind, or plate, and maintain control over heat to avoid metallurgical alteration.

- All-Round Process Support: This applies to CAD/CAM analysis and quenching to finishing and inspection, being a one-stop production in terms of all-around.

Envoyez votre demande aujourd'hui

Chez TOPS Précision, we have alloy steel machining services that are a combination of technical expertise, high-tech CNC machining equipment, and quality processes to provide precision-machined components with a high technical level of difficulty. Our team works in industries such as automotive, aérospatial, and energy, or heavy machinery delivery, entre autres, high-performance driveshafts or complex aerospace brackets.

Using design-for-manufacturing expertise and long-established machining technology, we can deliver even non-standard high-strength, wear-resistant alloy steel parts accordingly, whether you are prototyping or requesting full production.

What is Alloy Steel?

Alloy steels are iron products that are compounded with various elements such as chromium, molybdène, nickel, or vanadium in order to enhance strength, dureté, résistance à la corrosion, and wear properties. These developments allow steels to be used in high-duty mechanical, de construction, and aerospace structures in which the performance of the material is essential.

Envoyez votre demande aujourd'hui

What is the Process of Alloy Steel Machining?

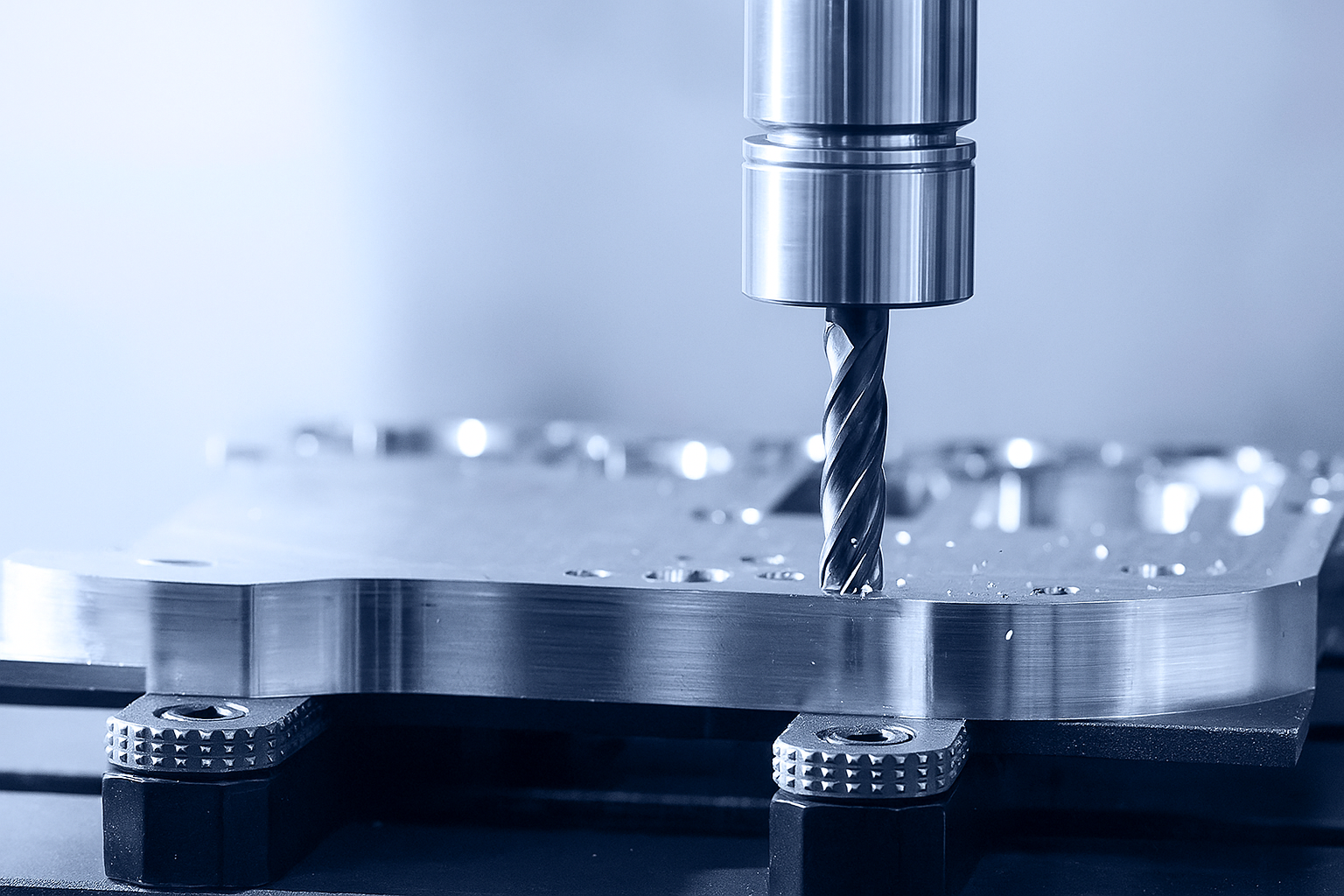

Milling of alloy steel is a process of high precision under control, utilizing controlled CNC structured designs and high-acting cutting tools of the cutting type, and also an intelligent use of feed rates and coolant.

Alloy Steel Material Properties

The following table gives a summary of the properties of Alloy steel:

Grade | Résistance à la traction (MPa) | Limite d'élasticité (MPa) | Notable Properties |

4140 | 655 | 415 | Vaisseaux de pression, arbres, and oilfield components |

4340 | 895 | 740 | Aircraft landing gear, vilebrequins, and high-fatigue parts |

8620 | 620 | 380 | Case-hardened gears, pinions, et pièces à haute résistance |

17-4 PH | 1,030 | 760 | Résistance élevée à la corrosion, aérospatial, and chemical parts |

Envoyez votre demande aujourd'hui

Properties of Alloy Steel

It is designed by adding different alloying additives to carbon steel to improve certain aspects of mechanical, thermique, et propriétés chimiques. The modifications render it very appropriate for applications that require strength, porter, et durabilité.

1. Haute résistance

The alloy steel has a high tensile as well as a yield strength compared to conventional carbon steel, et donc, it finds its application in structural members, récipients sous pression, and load-bearing parts. This is the strength attributed to its capability to withstand stressful environments, yet not deform or fail.

2. Improved Hardness

Alloy steels have the potential to produce superb surface and core hardness due to the relocation of factors such as chromium, molybdène, or vanadium, so that heat-treating can be involved. They are therefore appropriate for cutting tools, engrenages, and wear-resistant applications.

3. Enhanced Toughness

Alloy steel is tough, can absorb shock, and does not fracture even though the loading is sudden or recurring. It is also reliable in critical engineering applications since it possesses impact resistance at high as well as low temperatures.

4. Superior Wear Resistance

Most grades of alloy steel have high wear resistance, as is their hard microstructure and carbide-forming elements. This is a particularly fine property when it comes to areas that experience friction, abrasions, or constant motions.

5. Résistance à la corrosion (Chosen Grades)

Not every alloy steel is corrosion resistant, but some (par exemple., with larger amounts of chromium) are better resistant to oxidation, rouiller, et attaque chimique, and fit in an outdoor or demanding chemical environment.

6. Résistance à la chaleur

Even under high temperatures, alloy steel remains strong in terms of mechanical properties and has structural integrity. This qualifies it to be applied to the engine elements, boilers, and other high-temperature uses of industry.

7. Bonne usinabilité (Grade-Dependent)

Most alloy steels are developed to be a compromise between strength and machinability. CNC Grades, doing Leaded or resulfurized grades, are improved in the chip formation, which gives them the ability to perform at higher cutting speeds and great tool life.

8. Stabilité dimensionnelle

The steels in alloy steels are superb in terms of dimensional stability, especially following the heat treatment process. This guarantees parts stay in form and within the tolerance, even after a long season of mechanical or thermal loads.

Envoyez votre demande aujourd'hui

Design Guide for Alloy Steel Machining

Best practice design methods need to be adhered to so that cost-effective and exacting machining of alloy steel components can be carried out. Such guidelines reduce wear on the tool, enhance precision, and induce a faster production rate.

Fonctionnalité | Recommended Guideline | But |

Épaisseur de paroi | ≥ 2.5 mm | Ensures part rigidity and reduces warping risk |

Rayons de filet | Internal fillets ≥ 1 mm | Reduces stress concentration and tool wear |

Profondeur de trou | Depth-to-diameter ratio ≤ 4:1 | Prevents drill deflection and improves hole quality |

Tread Design | Use standard threads with relief grooves | Enables smooth tapping and longer tool life |

Plage de tolérance | ±0.02 mm to ±0.05 mm | Balances precision with manufacturability |

Slot Width | ≥ Diamètre d'outil (typically ≥ 3 mm) | Allows chip removal and prevents tool breakage |

Engraving Depth | ≥ 0.5 mm with ≥ 1.5 mm stroke width | Ensures clear, durable markings |

Boss Height | Keep ≤ 3× the boss diameter | Maintains structural stability and prevents bending |

Contre-dépouilles & Grooves | Use standard tooling dimensions | Simplifies machining and reduces setup time |

Finition de surface | Design for Ra 1.6–3.2 µm unless specified | Achieves functional and aesthetic surface quality |

Envoyez votre demande aujourd'hui

Alloy Steel CNC Machining Methods

Alloy steel is strong and versatile; c'est à dire., easily molded by various CNC processes. In TOPS Precision, we adopt a complex machining skill to achieve high quality and specifications of parts produced to match their standards in terms of their demands in work and accuracy.

Fraisage CNC

CNC milling is suitable for the shaping of flat shapes, machines à sous, trous, and other tricky 3D shapes on alloy steels. Our multi-axis machines are highly precise and produce batch-to-batch consistency, even on difficult or heat treatment grades.

Tournage CNC

Turning is used in cutting the stock alloy steel bar material as it rotates, and the material is cut away by a cutting tool to shape cylindrical products such as shafts, bagues, or threaded blanks. In hard alloys, CNC turning provides superior control over concentricity and surface finish.

Forage

Precise holes in parts made of alloy steel are cut through precision drilling. In this hard material, specialized carbide drills and coolant systems, which ensure dimensional stability and eliminate the risk of overheating or tool wear, are used.

Tapotement and Threading

Threads may be internal or external and are made by CNC threading or by tapping. The toughness of alloy steel means that a suitable selection of tools and good feed rates would be necessary to avoid distortion of sufficiently clean and strong threads.

GED (Usinage par décharge électrique)

EDM can be applied to intricate features or hard alloy steel components that could not be easily cut by a conventional method. It applies electrical discharges to remove material with high precision, which makes it great for the highest tolerance and most complex parts.

Affûtage

Grinding achieves finishes so smooth and provides close dimensional control, particularly when it is required to have high wear resistance or when the quality of fitment is of the essence. It is a common secondary operation that is offered to the hardened alloy steel components.

Envoyez votre demande aujourd'hui

Finishing Options Available

TOPS has a multitude of post-machining finishing services that can be carried out to enhance surface quality, durabilité, et esthétique. Such finishes also serve to increase wear and corrosion resistance.

- Precise grinding, with surface, finishes to Ra 0.2um.

- Toughness and hardness heat treatments, induction or furnace heating, or hardening

- Nitruration, carburizing, titanium nitrides, chrome/nickel plating wear wear-resistant

- Cleaning or bead blasting of polishing, and corrosion control

- Finishing and welding of fabricated assemblies

Envoyez votre demande aujourd'hui

Popular Machined Alloy Steel Parts

We produce most parts in the most difficult industries of high-strength. These components have gained acceptability qualities of durability, fiabilité, and tolerance in mission-critical conditions. Our common products are:

Envoyez votre demande aujourd'hui

- Automotive equipment or energy equipment drive shafts, engrenages, or camshafts

- Aerospace parts such as landing gear, aircraft fittings, and turbine parts.

- Têtes de perceuse, pump shafts, key fasteners, and pilots

- Heavy machinery structural connections, tiges, and welding assemblies

Various Grades of Alloy Steel Machining

The use of appropriate grade alloy guarantees performance, life, et l'économie. TOPS machines the entire range of alloy steels according to your application.

- Low-Alloy Steels (par exemple., 4140, 4340, 8620) - Steels with high strength, good fatigue and hardenability; good to use in structural and mechanical components.

- Stainless Alloys (par exemple., 17-4 PH, 316) - They are more resistant to corrosion and have high mechanical strength; they are recommended in the marine, nourriture, and medical areas.

- AFFAIRES DE TOLL (par exemple., D2, A2) - High wear, dureté élevée; jigs, meurt, et outils de précision.

- MARAGIER AEDELS (par exemple., 300, 350) -Ultra-high strength, facile à usiner; find application in aerospace, défense, and die-making.

Envoyez votre demande aujourd'hui

Applications of Alloy Steel Machining

Performance-sensitive systems in industries are powered by machined alloy steel parts. They are very strong, dur, and fatigue-resistant, et, donc, they are essential in contemporary industry. Parts of alloy steel can be used in:

- Automobile:axle, crankshaft, steering knuckle

- Aérospatial:trains d'atterrissage, Structures de soutien

- Énergie: oilfield equipment, pump shafts, vannes

- Équipement industriel: engrenages, cam followers, décors

- Équipement médical: implant tooling, surgical tooling

Benefits of Alloy Steel Machining

This machining has both practical and cost benefits, which are very beneficial to applications that demand strength, résistance à l'usure, and accuracy in dimensions.

- Extreme fatigue and hard resistance

- Terrific strength-to-size ratio, treated wear-resistant characteristics

- Capability to work on close geometric and surface specs

- Wide applicability in the industries

Envoyez votre demande aujourd'hui

Challenges of Alloy Steel Machining

Alloy steel machining may have some production challenges, although it has its benefits. Knowing them will prevent the pitfalls.

- Rugged tooling is needed for hard materials

- Part tolerances and microstructure can be influenced by heat buildup.

- There are alloy steels that need to be machined both before and after heat treatment.

- Machining can include additional processes in hardening.

5 Cost-Effective Tips for Alloy Steel Machining

An efficient design, planning, and implementation will reduce your unit cost per part while maintaining the quality. Optimizing your project is as follows:

- Material selection: Select the minimum grade necessary to be within the requirements

- Minimum Post-Heat Machining: Do as much pre-machining as you can

- Support Batch Runs: drop tooling/setup cost/piece

- Use DFM Advice Early: Simplify shapes to cut cycle times.

- Align QC and Production:Rework is minimized by checking in real-time.

Choose TOPS Precision to Make Machined Alloy Steel Parts

Whether it is design review, usinage de précision, ou finition, we are a leading end-to-end alloy steel machining business at TOPS Precision. Be it the prototypes or even full production, we guarantee accuracy, quick turnaround, and consistency in all production batches.

We support:

- DFM optimization & Engineering consultation

- Fraisage, tournant, GED, and finishing CNC Surfaces

- Full check report, traitement thermique, enrobage, and reports

Send us your CAD files or drawings, and we will offer a quick quote and a project step-by-step plan to meet your needs.

Envoyez votre demande aujourd'hui

Our Alloy Steel Machining Services are Guaranteed

TOPS Precision produces all of its components with ISO 9001-certified procedures, and a complete examination of components is a part of this procedure using customized inspection equipment. We ensure:

- Strict tolerance conformity

- Certified materials traceability

- Zero-defect delivery

- In-time delivery, all the time

Put your confidence in TOPS with alloy steel components.

Envoyez votre demande aujourd'hui

FAQs About Alloy Steel CNC Machining

±0.005mm on simple profiles; ±0.01mm usual.

Oui, we do quench/bore machining workflow.

A definite yes, and the entire gamut, including PH grades.

Placage, affûtage, soudage, and nitriding.

The normal lead time is between 7 et 10 jours; it can be urgent.

ÉTAPE, IGES, DXF, Dwg, STL, et ainsi de suite.