Material Properties of Nylon

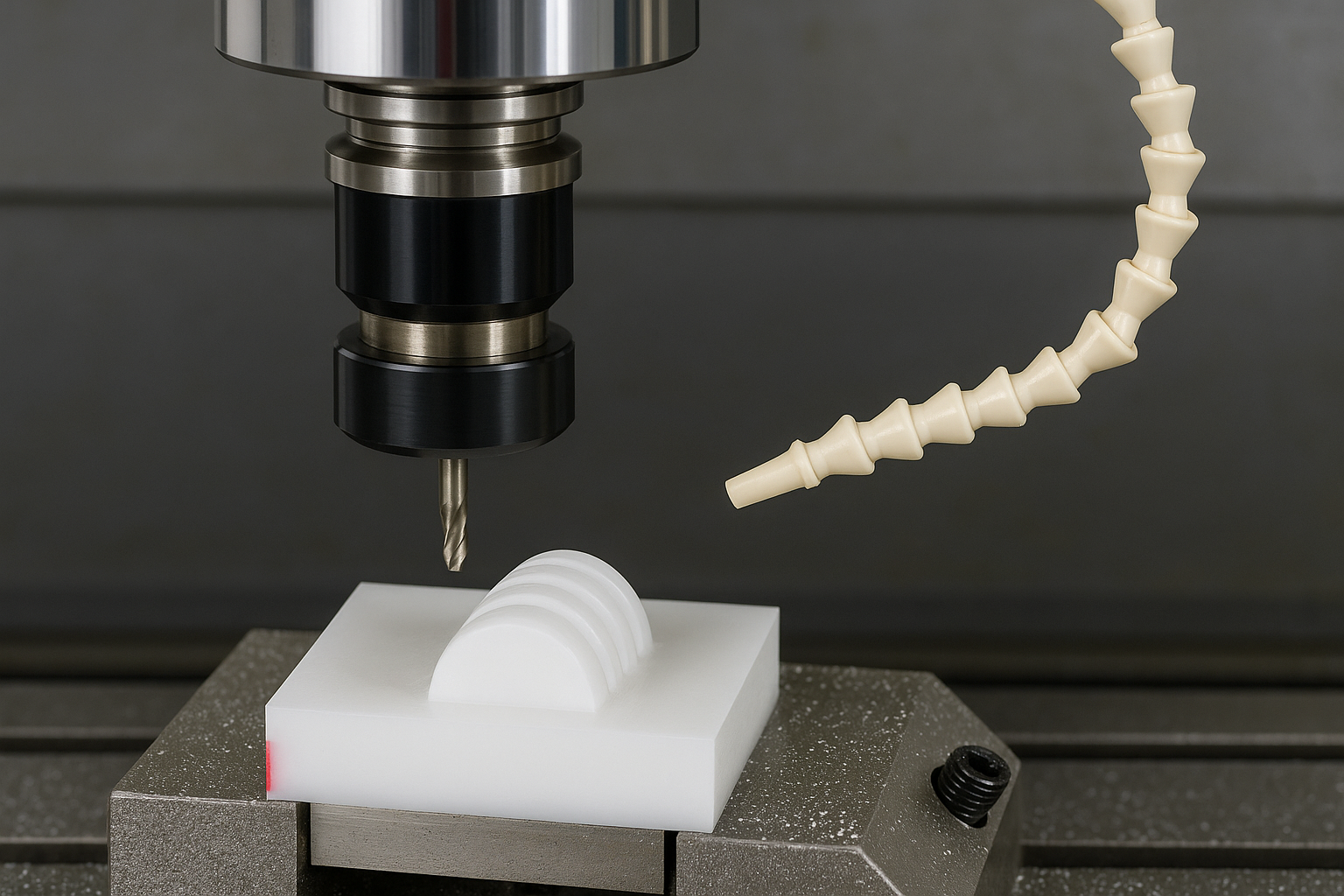

Nylon is a high-performance engineering thermoplastic known for its strength, durabilité, and adaptability in machining operations. Its low friction, strong chemical resistance, outstanding mechanical and thermal properties, and overall toughness make it ideal for various demanding industrial applications. These key characteristics make nylon an excellent choice for precision CNC machining tasks.

Property of Nylon | Standard Values |

Densité | Upto 1.14 g/cm³ |

Résistance à la traction | ~76 MPa (Nylon 66) |

Point de fusion | ~255°C |

Coefficient of Friction | Faible (~0.25 – 0.35) |

Absorption d'humidité | Modéré (affects dimension over time) |

Résistance aux chocs | Haut |

Résistance chimique | Bien (resists oils, greases, solvants) |

Operating Temp Range | -40°C to 100°C (varie selon le niveau) |