1. Précision et cohérence

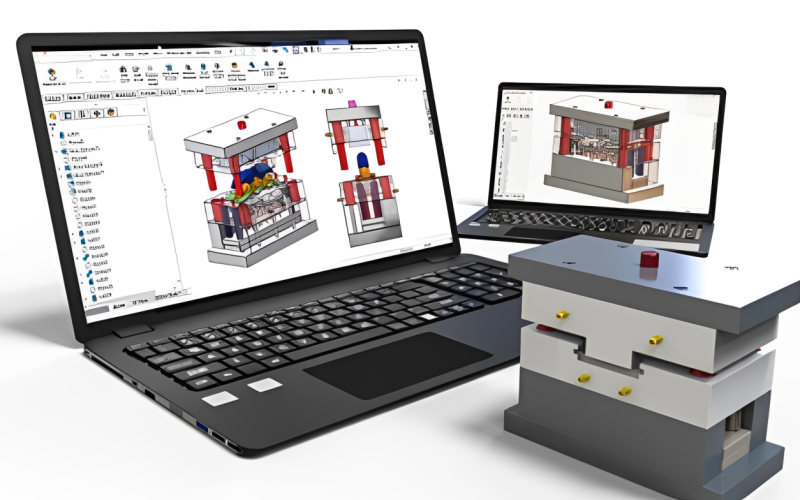

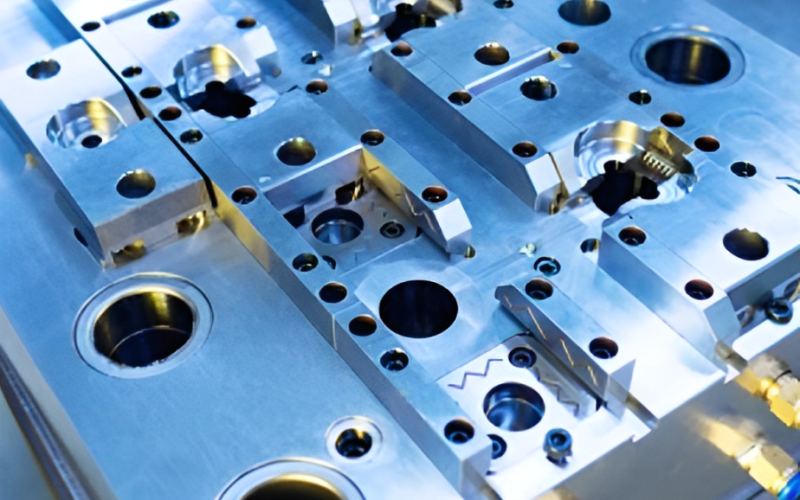

- Le processus atteint des niveaux de précision élevés pour atteindre des tolérances de pièces de ± 0,01 mm.

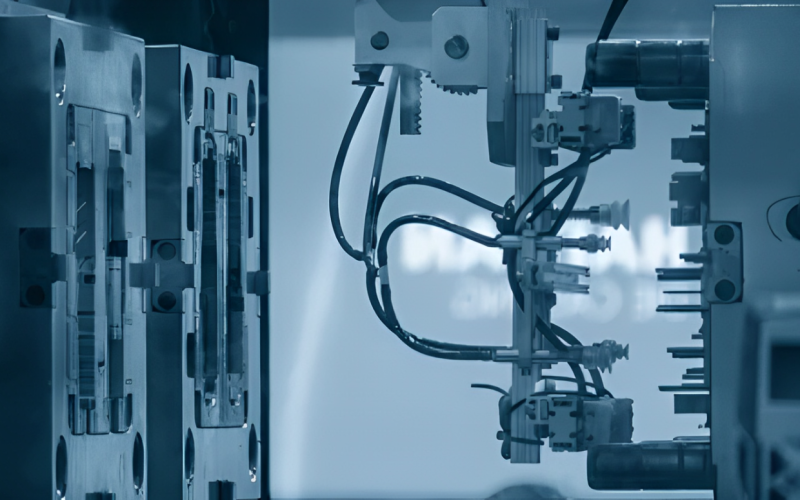

- Le processus exécute ses machines de moulage contrôlées par CNC dans des systèmes de contrôle automatisés avancés, Assurer une performance de qualité maximale et une cohérence opérationnelle exceptionnelle.

2. Options de matériaux polyvalents

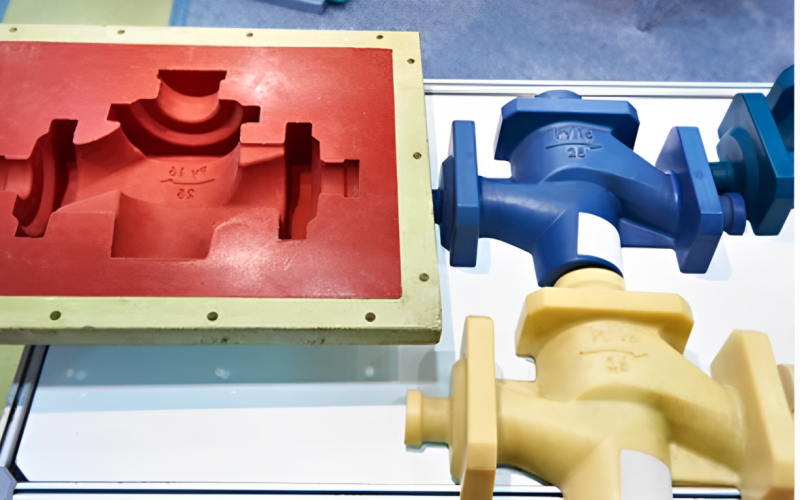

- Les hauts fonctionnent avec tous les matériaux thermosés et thermoplastiques, y compris l'ABS et le polycarbonate, nylon, polypropylène, et un coup d'œil.

- Le processus crée des pièces qui comportent des formes complexes et des caractéristiques dimensionnelles serrées.

3. Délai d'exécution rapide & Haute efficacité

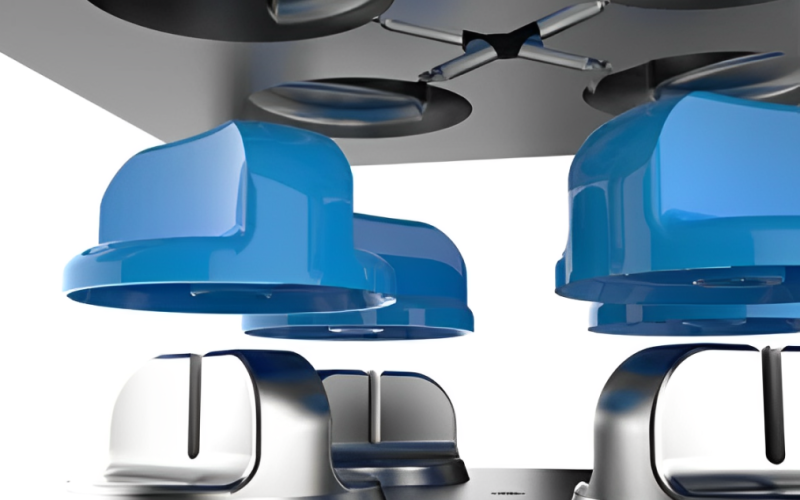

- Le processus de configuration prend moins de temps tandis que les cycles de production fonctionnent à une efficacité maximale pour réduire les délais globaux.

- Les deux approches correspondent les uns aux autres car ils conviennent aux applications entre les prototypes de développement de produits et les productions à l'échelle de masse.