Qu'est-ce que le moulage en silicone?

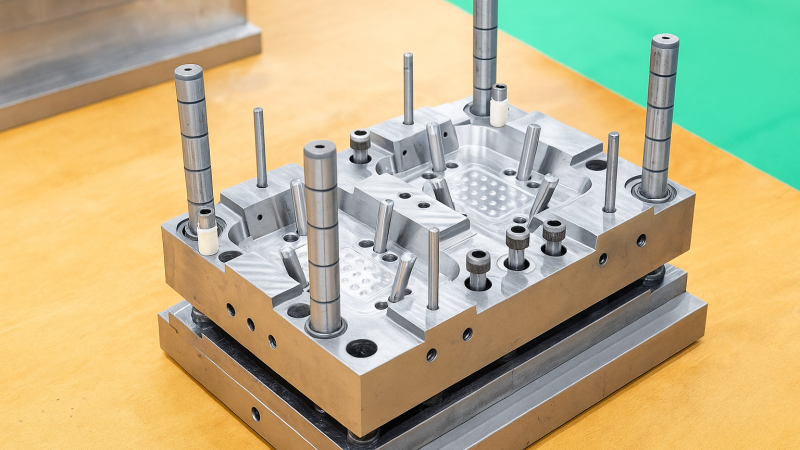

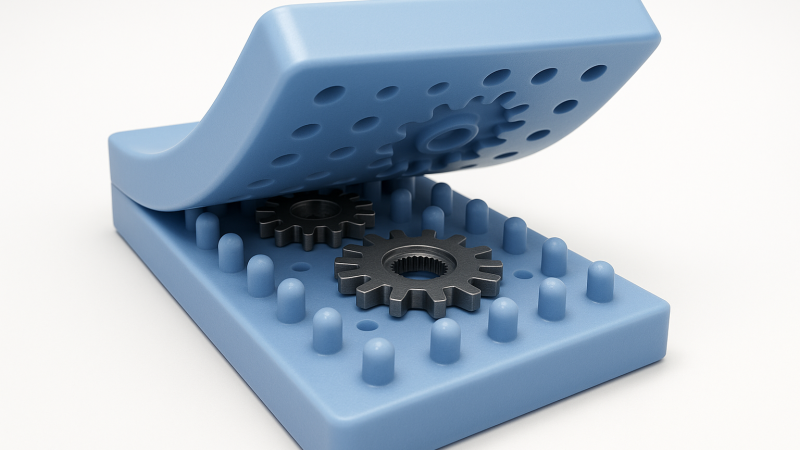

Le processus de moulage en silicone permet la production de composants d'élastomère en silicone résistants et résistants à la température et résistants. La séquence de fabrication commence par injecter ou comprimer du liquide de silicone ou un matériau solide dans une cavité de moule jusqu'à ce que le durcissement se termine pour créer la forme finale approuvée.

Le moulage en silicone reste une technique de fabrication proéminente car elle offre des propriétés distinctes qui incluent:

- Le silicone présente une résistance à la chaleur remarquable en maintenant sa flexibilité lorsqu'il est exposé à des températures extrêmes.

- Durabilité -Résistance à l'usure élevée pour des performances durables.

- Biocompatibilité - Idéal pour les applications médicales et de qualité alimentaire.

- Résistance -Ce matériau démontre une résistance aux agents chimiques pour assurer la protection des UV et l'immunité du pétrole.

- La flexibilité & Douceur -Ce matériau offre une flexibilité et une douceur qui la rend idéale pour les applications souples.

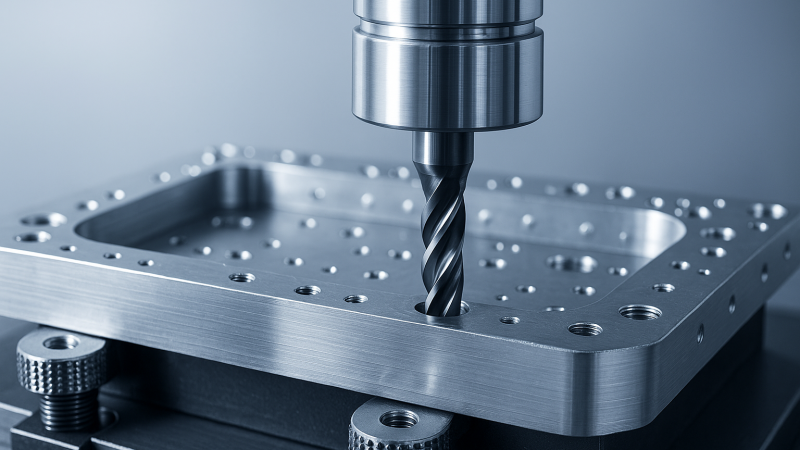

Notre méthode de haute précision permet à chaque produit moulé en silicone de respecter des normes dimensionnelles précises tout en conservant des références de qualité de matériau exactes.