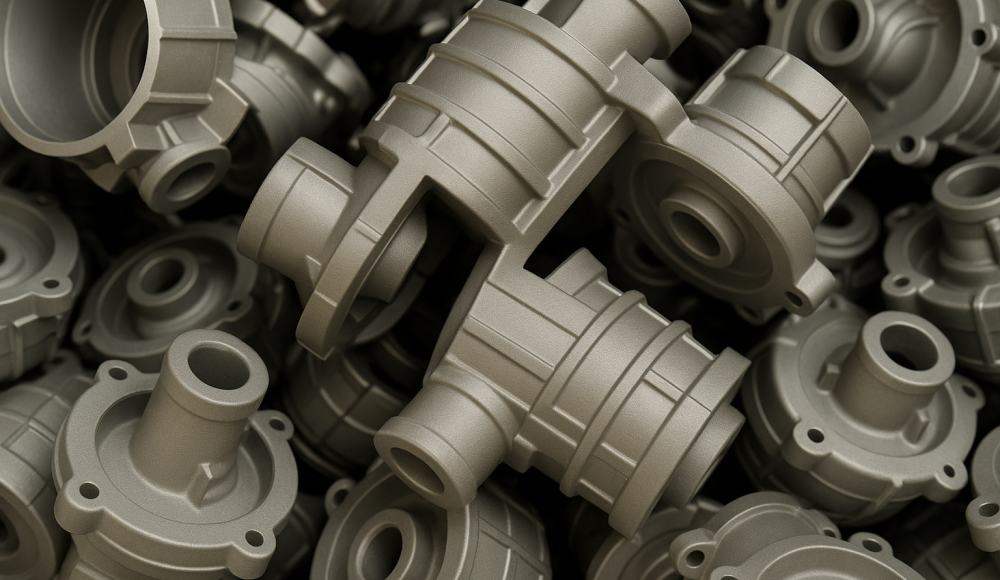

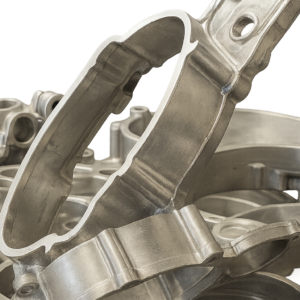

Casting da morire in alluminio è uno dei processi di produzione più essenziali nel panorama industriale di oggi. Combinando le proprietà leggere dell'alluminio con la precisione dello stampaggio ad alta pressione, Questa tecnica produce complesse, Parti ad alta resistenza in modo efficiente e su scala.

Questa guida fornisce una panoramica completa del processo di fusione dell'alluminio, comprese le leghe chiave, finiture superficiali, considerazioni di progettazione, e applicazioni nei principali settori.

Introduzione

L'alluminio è leggero, Metallo resistente alla corrosione con alta conduttività termica ed elettrica. Queste proprietà lo rendono ideale per la produzione di componenti intricati con tolleranze strette attraverso la colata. Tra tutti i processi di formazione, Il casting da morire in alluminio si distingue per la sua ripetibilità, precisione dimensionale, ed efficienza dei costi, soprattutto per la produzione ad alto volume.

Qual è il processo di fusione di alluminio?

Definizione

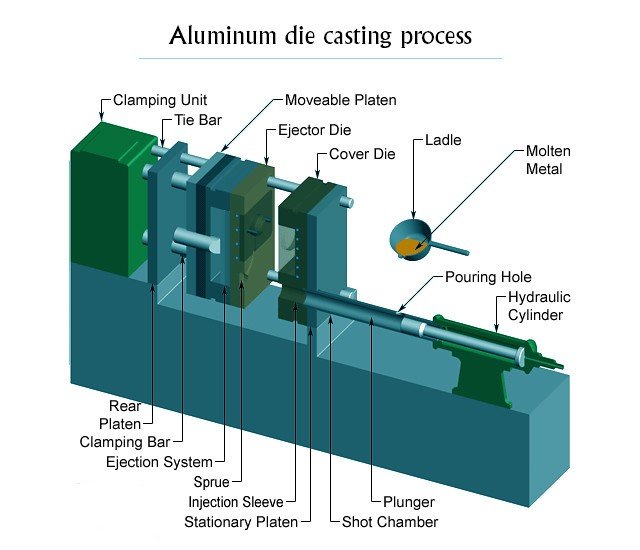

La fusione di stampo in alluminio è un metodo di produzione ad alta pressione che inietta l'alluminio fuso in uno stampo in acciaio (morire) per produrre complessi, parti metalliche accurate. È condotto principalmente usando Macchine da fusione della camera fredda A causa dell'alto punto di fusione dell'alluminio (~ 660 ° C o 1220 ° F.), che danneggerebbe i componenti sommersi in una macchina da camera calda.

Processo passo-passo:

Fusione: I lingotti in alluminio vengono sciolti in una fornace separata.

Mettono: Il metallo fuso viene meselico manualmente o robotico nella manica del tiro.

Iniezione: Un pistone costringe l'alluminio fuso nella cavità dello stampo ad alta pressione (10–175 MPA).

Solidificazione: Il metallo si raffredda e si indurisce all'interno del dado, in genere in pochi secondi.

Eiezione: Lo stampo si apre e la parte viene espulsa, Spesso con pin di espulsione automatizzato.

Rifilatura e rifinitura: Materiale in eccesso (flash) viene rimosso, e viene applicata la finitura della superficie opzionale.

Muore il casting si può essere riutilizzato migliaia di volte, Rendere questo metodo ideale per la produzione di grandi volumi.

Vantaggi del casting in alluminio

Il casting di stampo in alluminio offre diversi vantaggi tecnici ed economici:

✅ Finitura superficiale superiore: Superfici lisce che richiedono poca o nessuna post-elaborazione.

✅ Precisione ad alta dimensione: Sono realizzabili tolleranze strette come ± 0,1 mm.

✅ Elevato rapporto resistenza/peso: Le parti sono sia leggere che strutturalmente.

✅ Eccellente termico & Conduttività elettrica: Ideale per dissipatori di calore e recinti.

✅ Porosità minima: Lo sfiato e il gate avanzati riducono i vuoti interni.

✅ Flessibilità di progettazione: Supporta geometrie complesse e sezioni a parete sottile (<1.5 mm).

✅ Efficienza dei costi: Stampi riutilizzabili, tempi di ciclo veloci, e l'automazione riduce il costo per parte.

✅ Sostenibilità: L'alluminio è 100% riciclabile senza perdita di prestazioni.

Common Alluminio Die Casting Leghes

Scegliere la lega giusta è cruciale per le prestazioni, durabilità, e colabilità. Ecco i voti più utilizzati:

| Lega | Caratteristiche chiave | Applicazioni |

| A380 | Ottima colabilità, forza, resistenza alla corrosione | Staffe del motore, utensili elettrici, recinti elettronici |

| A390 | Elevata durezza, resistenza all'usura, bassa duttilità | Blocchi cilindri, Componenti idraulici |

| A360 | Tenuta a pressione, Resistenza alla corrosione superiore | 5G di alloggiamento, shell controller |

| A413 | Buona fluidità, tenuta a pressione | Parti complesse a parete sottile |

| ADC-12 | Standard giapponese; Simile a A383 | Componenti automobilistici e industriali |

| ADC-1 | Forza migliorata, meno restringimento | Casting ad alta precisione |

Ogni lega differisce nelle proprietà meccaniche, comportamento termico, lavorabilità, e resistenza alla corrosione o al cracking.

Caratteristiche chiave delle leghe di alluminio

Le leghe in alluminio eservato offrono una potente miscela di proprietà meccaniche e funzionali:

Leggero: Riduce la massa complessiva e migliora l'efficienza energetica.

Resistente alla corrosione: Forma uno strato di ossido naturale per proteggere dalla ruggine.

Termicamente efficiente: Ottima dissipazione del calore per recinti elettronici.

Elettricamente conduttivo: Ideale per la schermatura EMI/RFI.

Elevati resistenze di trazione e snervamento: Affidabile per carichi strutturali.

Completamente riciclabile: Ecologico sostenibile con minimo degrado.

Opzioni di finitura superficiale per l'alluminio

Sebbene i getti in alluminio abbiano spesso una finitura liscia, I trattamenti di superficie vengono applicati per migliorare l'aspetto o le prestazioni funzionali.

Anodizzazione

Converte la superficie in uno strato di ossido di alluminio.

Migliora la resistenza all'usura e alla corrosione.

Elettricamente non conduttivo, Buono per l'isolamento.

Verniciatura a polvere

Aggiunge uno spesso, colorato, e strato protettivo durevole.

Graffio, UV, e resistente alla corrosione.

Flessibilità estetica: opaco, lucentezza, o finiture strutturate.

Film chimico (Rivestimento di conversione cromata)

Fornisce resistenza alla corrosione mantenendo la conducibilità elettrica.

Ideale per parti aerospaziali e di livello militare.

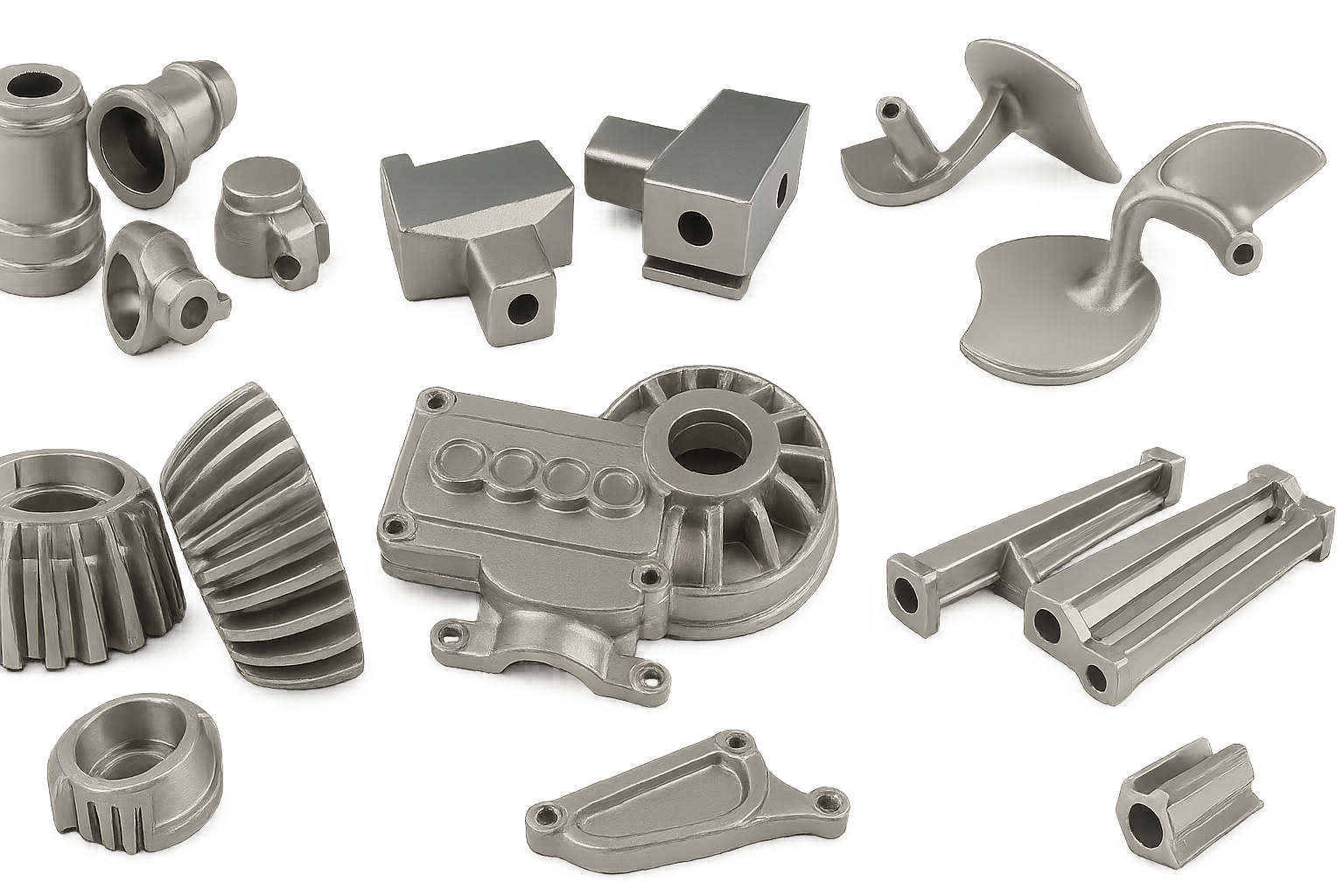

Applicazioni del casting di stampo in alluminio

Costruzione

Frame delle finestre, staffe per pareti per tende, Strutture di supporto.

Aumentare l'uso nei ponti e nei sistemi di costruzione modulare.

Settore automobilistico

Cali di trasmissione, blocchi motore, parentesi, padelle di petrolio.

Aiuta a ridurre il peso e le emissioni del veicolo.

Elettronica

Dissipatori di calore, recinzioni, cornici per smartphone, 5G di alloggiamento dell'antenna.

Combina la gestione termica con la schermatura EMI.

Mobilia

Componenti durevoli ma eleganti come le basi della sedia, maniglie, e serrature.

Aerospaziale

Teste di pistone, Alloggiamenti degli ingranaggi, recinti di illuminazione, parti del motore.

Combina a basso peso con prestazioni di trazione elevate.

Considerazioni di progettazione per parti in alluminio est-cast

Progettazione di stampi

Ottimizza per flusso di metallo liscio e facile espulsione.

Definire le linee di separazione chiare e aggiungere angoli di tiraggio.

Punto di iniezione

Fondamentale per ridurre l'aria intrappolata e garantire il riempimento completo.

Possono essere necessari più porte per parti complesse.

Spessore della parete

Le pareti più sottili riducono il peso ma devono mantenere l'integrità strutturale.

Punta allo spessore uniforme delle pareti per evitare punti caldi e deformarsi.

Fattori di costo del fusione in alluminio

Il casting da morire in alluminio è più economico su vasta scala. Le variabili dei prezzi chiave includono:

Costi degli utensili: In genere $ 7.000– $ 75.000 a seconda della complessità.

Volume: I volumi elevati riducono i costi per unità dovuti al riutilizzo della muffa.

Geometria in parte: Le forme complesse richiedono strumenti più intricati e tempi di ciclo più lunghi.

Materiale & Tempo macchina: Tipo in lega e parte della durata del ciclo di impatto di massa e costi del materiale.

Lavoro: Impostare, taglio, e il tempo di ispezione contribuisce ai costi del lavoro.

Servizi di casting di alluminio - Esempio di director

Offerte di precisione in cima:

Tolleranze strette come ± 0,004 " (0.1 mm)

ISO 9001:2015 processi certificati

Feedback DFM e citazioni rapide dai modelli CAD

Prototipazione completa alla capacità di produzione di massa

Benefici:

Fino a 30% risparmi

Finiture e specifiche personalizzate

Controllo di qualità end-to-end

Conclusione

Il casting da morire in alluminio è un'alta precisione, scalabile, e metodo di produzione economico. È particolarmente ideale per applicazioni che richiedono componenti leggeri ma forti con tolleranze strette e finiture pulite. Quando si lavora con volumi di produzione più grandi, Die Casting offre un valore senza pari nelle prestazioni, velocità, e ripetibilità.

Che tu stia costruendo componenti automobilistici, elettronica, o parti architettoniche, Scegliere la lega giusta, Strategia di progettazione, e il partner di servizio può avere un impatto significativo sul successo del tuo progetto.

Domande frequenti

Q1: In che modo il casting di alluminio differisce dal casting di sabbia?

La fusione di stampi utilizza stampi in acciaio per la precisione; La fusione di sabbia utilizza stampi sabbiato saggibili.

Il casting da morire ha una migliore precisione dimensionale e finitura superficiale ma un costo di strumenti più elevato.

Casting di sabbia in abiti a basso volume, produzione di grandi parti; Die Casting eccelle in corse ad alto volume.

Q2: È costoso in alluminio?

Gli utensili sono costosi in anticipo, Ma il processo diventa altamente economico per grandi lotti.

Q3: Quanto è veloce il casting?

Una volta impostato gli strumenti, I tempi di ciclo vanno da 30 Seconds o pochi minuti per parte.

Articoli correlati:

Muori casting vs. Lavorazione CNC

Pressofusione o fusione a cera persa

Alluminio lavorato vs alluminio pressofuso

1 pensato a “Guida completa al casting da morire in alluminio: Processi, Leghe, Finitura & Applicazioni”