Alluminio is one of the most widely used metals in the world. It is lightweight, forte, resistente alla corrosione, easy to form, and highly recyclable. These properties make aluminum an essential material across construction, trasporto, elettronica, aerospaziale, medico, e produzione industriale.

If you are sourcing materials, designing products, or evaluating alternatives to steel or copper, capire il real-world uses of aluminum will help you make better technical and commercial decisions.

Questa guida spiega where aluminum is used, why it is chosen, and which aluminum products are most common, with practical examples from multiple industries.

1. Introduction to Aluminum

Aluminum is a non-ferrous metal known for its elevato rapporto resistenza/peso, natural corrosion resistance, and excellent thermal and electrical conductivity. Unlike steel, aluminum does not rust. Unlike copper, it is much lighter and more cost-effective for large structures.

Key characteristics of aluminum:

Lightweight but structurally strong

Naturally corrosion-resistant (oxide layer protection)

Facile da lavorare, extrude, rotolo, and cast

Excellent heat and electrical conductivity

100% recyclable without loss of properties

These advantages explain why aluminum is used in both everyday consumer products E high-precision industrial systems.

2. Most Common Applications of Aluminum

You encounter aluminum daily, often without realizing it. From buildings and vehicles to electronics and packaging, aluminum supports modern infrastructure and technology.

Common application areas include:

Construction and architecture

Automotive and rail transportation

Aerospace and aviation

Electrical and electronics manufacturing

Household and kitchen products

Industrial machinery and safety systems

Compared to steel, aluminum reduces weight and maintenance. Compared to copper, it lowers cost while still providing reliable conductivity.

3. Industrial Applications of Aluminum

In industrial manufacturing, aluminum is valued for its process flexibility and long-term cost efficiency. It can be extruded into complex profiles, rolled into sheets and coils, or cast into precision components.

Industries rely on aluminum because:

It reduces total system weight

It lowers transportation and installation costs

It resists corrosion in harsh environments

It supports mass production and customization

It aligns with sustainability and recycling goals

Factories, infrastructure projects, and OEM manufacturers consistently choose aluminum for both structural and functional components.

4. Uses of Aluminum in Construction (Aluminum Building Products)

After steel, aluminum is the second most commonly used metal in construction. Unisce la forza, estetica, and durability while reducing structural load.

4.1 Structural and Architectural Applications

Aluminum Building Studs

Aluminum studs are used as vertical framing inside walls. They are lightweight, Dritto, fire-resistant, e facile da tagliare. Builders prefer them for modular layouts and modern construction.

Aluminum House Framing

Aluminum framing systems create strong, corrosion-resistant structures with minimal maintenance. They are ideal for residential and commercial buildings in humid or coastal environments.

Staircases and Safety Ramps

Aluminum staircases and ramps offer high load capacity with reduced weight. They are commonly used in public buildings, fabbriche, and accessibility projects.

4.2 Exterior Building Components

Cladding

Aluminum cladding protects buildings from weather while improving appearance. It resists UV exposure, piovere, and wind and requires minimal upkeep.

Roofing Systems

Aluminum roofs, piastrelle, and shingles are durable and lightweight. They reduce structural load while providing long service life in extreme weather conditions.

Curtain Wall Systems

Aluminum curtain walls support glass façades in high-rise buildings. Forniscono forza, flessibilità, and weather sealing without excessive weight.

Solar Panel Frames

Aluminum frames are standard in solar panels due to corrosion resistance, peso ridotto, and easy installation.

4.3 Interior Building Components

Window and Door Frames

Aluminum frames are strong, slim, e durevole. They support large glass panels and provide long-term dimensional stability.

Aluminum Skirting

Used at the base of walls, aluminum skirting resists moisture, impatto, and warping, making it superior to wood in commercial and residential interiors.

4.4 HVAC and Thermal Systems

Heating Systems and Heat Exchangers

Aluminum distributes heat evenly and efficiently. It is widely used in radiators, scambiatori di calore, and thermal transfer systems.

Air Conditioning Systems

Aluminum coils, fins, and frames improve cooling efficiency while reducing system weight and energy consumption.

5. Aluminum in Household and Daily-Use Products

5.1 Kitchen and Food-Related Products

Aluminum is widely used in cookware because it heats quickly, è facile da pulire, and is non-toxic.

Common aluminum kitchen products include:

Frying pans and pressure cookers

Kettles and baking trays

Piatti, bowls, and ladles

Cups, tumblers, and food containers

Why aluminum is used in kitchen foil

Aluminum foil blocks air, leggero, e umidità. It is flexible, food-safe, and ideal for food storage and cooking.

5.2 Furniture and Home Décor

Aluminum furniture is strong, rust-resistant, e leggero. It is widely used for:

Outdoor chairs and tables

Kitchen cabinets

Decorative panels and frames

Its durability makes it ideal for long-term indoor and outdoor use.

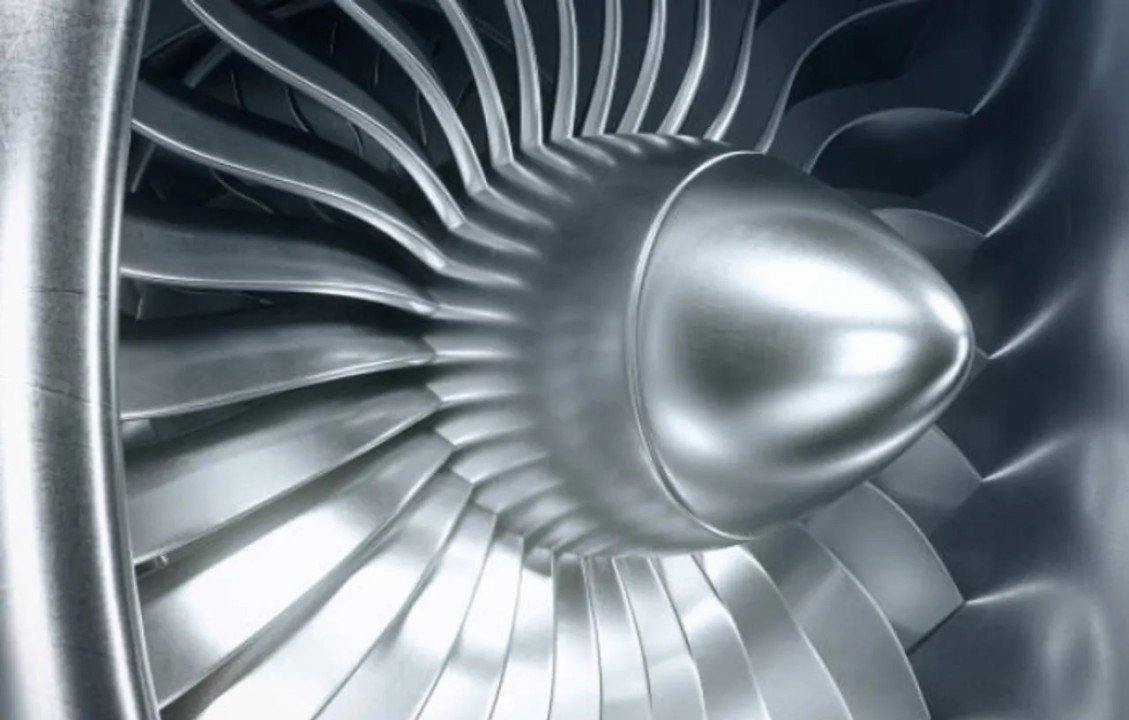

6. Aluminum Alloys in Aerospace Applications

Pure aluminum is too soft for aerospace use. Invece, aluminum alloys are created by adding elements such as copper, magnesio, o zinco.

These alloys provide:

High strength with low weight

Fatigue resistance

Stability under extreme conditions

Applications in aerospace include:

Aircraft fuselages and wings

Componenti del carrello di atterraggio

Engine housings

Cabin and seat frames

Aluminum alloys remain critical in both aviation and space exploration.

7. Aluminum in Electronics and Electrical Products

Aluminum is widely used in electronics due to its thermal conductivity and lightweight structure.

Le applicazioni comuni includono:

Smartphone and laptop housings

Heat sinks and cooling plates

Printed circuit boards (PCB)

Cables, connettori, and wires

LED lights and street lighting systems

Batteries and capacitors

Aluminum helps electronic devices dissipate heat efficiently and operate reliably.

8. Aluminum in Traffic and Safety Products

Aluminum is the preferred material for outdoor safety and traffic systems because it is rust-free and highly durable.

Typical aluminum traffic products include:

Traffic and road signs

Safety and warning signs

Aluminum road studs

LED sign frames

Control boxes and enclosures

Aviation obstruction lights

Aluminum ensures long service life in harsh outdoor environments.

9. Aluminum Applications in Transportation

9.1 Industria automobilistica

Automotive manufacturers use aluminum to reduce vehicle weight and improve fuel efficiency.

Applications include:

Body panels and doors

Chassis and wheels

Componenti del motore

Scambiatori di calore

Lighter vehicles consume less fuel and produce lower emissions.

9.2 Rail Transportation

Trains use aluminum to increase speed and reduce energy consumption. Aluminum rail cars offer high load capacity with lower overall weight.

9.3 Industria marina

Aluminum is widely used in boats, yachts, and ships due to its resistance to saltwater corrosion. It reduces maintenance costs and improves vessel performance.

10. Aluminum in Sports and Recreation

Sports equipment manufacturers use aluminum for its strength and light weight.

Common products include:

Bicycles

Baseball bats

Tennis rackets

Hockey sticks

Gym equipment

Aluminum improves performance while reducing fatigue for athletes.

11. Aluminum in Medical and Healthcare Equipment

Nella sanità, aluminum supports hygiene, sicurezza, e precisione.

Medical applications include:

Hospital beds and frames

Diagnostic machines (X-ray, MRI housings)

Medical device enclosures

Aluminum is easy to clean and meets strict industry standards.

12. Aluminum in Packaging Industry

Aluminum packaging protects products from moisture, ossigeno, and light.

Gli usi comuni includono:

Lattine di bevande

Food trays

Foil wraps

Pharmaceutical packaging

Its recyclability makes aluminum packaging environmentally responsible.

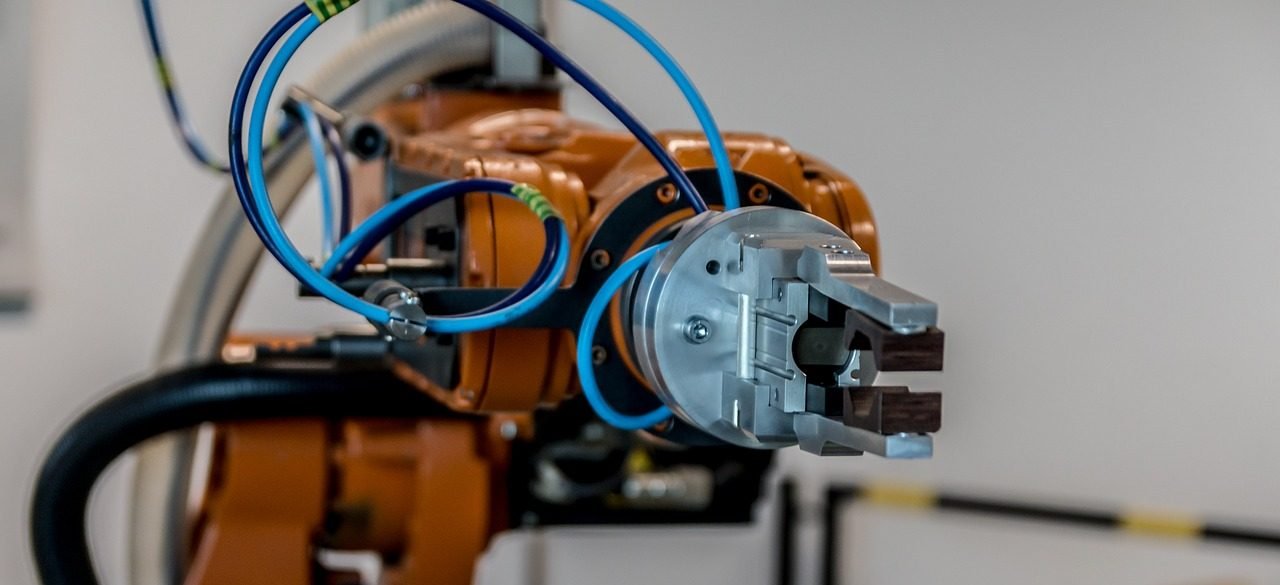

13. Uses of Aluminum in Robotics and Automation

Robotics relies on aluminum for lightweight and precise structural components.

Applications include:

Braccia robotiche

Frames and housings

Automation equipment

Aluminum enables faster movement, higher payloads, and long-term durability.

14. Domande frequenti

Why is aluminum used in cars?

To reduce weight, improve fuel efficiency, and enhance performance.

Why does aluminum not react with water?

A protective oxide layer prevents corrosion.

È a prova di ruggine in alluminio?

SÌ, it does not rust like steel, though surface corrosion can occur in extreme conditions.

What is annealing used for in aviation?

To reduce internal stress and improve formability.

Is aluminum safe?

SÌ, aluminum is non-toxic and safe for daily use.

Is aluminum stronger than steel?

NO, but it offers better strength-to-weight efficiency.

Why is aluminum used in power lines?

It is lighter and more economical than copper while maintaining good conductivity.

Is aluminum flammable?

NO, it does not burn under normal conditions.

How long does aluminum last?

30–70+ years depending on application and environment.

15. Summary of Aluminum Uses

Aluminum is one of the most versatile engineering materials available today. From homes and vehicles to aerospace and robotics, it supports innovation while reducing weight, costo, e manutenzione.

Choosing the right aluminum grade depends on your application:

Soft aluminum for household and packaging

Structural alloys for construction and transportation

High-strength alloys for aerospace and industrial systems

Per i produttori, builders, e ingegneri, aluminum remains a future-proof material with unmatched versatility and value.