- Precision and Accuracy: Fine, shaven edges with tolerances ranging from ± 0.2mm are realized instead of burred edges for intricate design work.

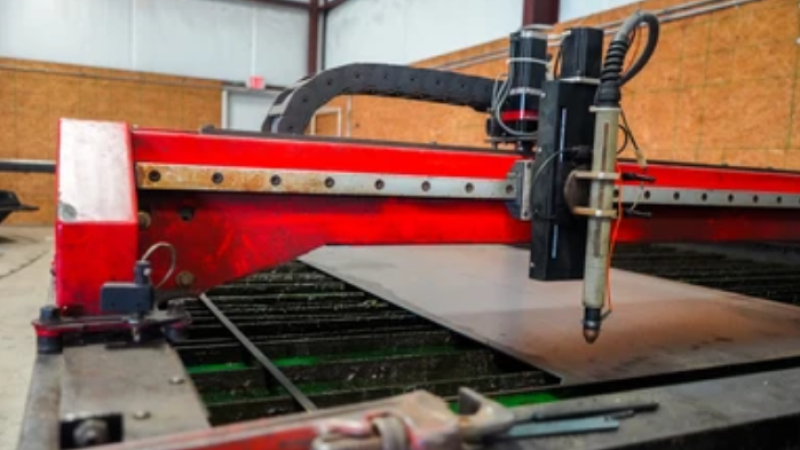

- Material Versatility:Designed to efficiently cut through types of metals including stainless steel, aluminum, solid brass, copper, and more.

- Fast Turnaround Times:Perfect for large fabrication lots and short turnaround time; small lots take only 8 to 10 days to have the parts fabricated.

- Large Material Sizes: This is flexible to accommodate sheets of up to 3000mm x 1500mm – enabling the manufacture of many large and complex parts.