Custom Precision Die Casting Services

Precision in Every Cast: From Aluminum to Zinc and Beyond - Your Ideal Die Casting Services

- Powerful Processing with Large Equipment

- Comprehensive Precision Die Casting Solutions

- Strong Problem-Solving Capabilities

One-Stop Service For Metal Die Casting Parts

YOUR ONE-STOP DESTINATION FOR PRECISION METAL DIE CASTING PARTS, ENSURING QUALITY FROM START TO FINISH.

Patented Mold Design

21 Years of Industry Expertise Patented Innovations in Mold Design

Patented Mold Design

21 Years of Industry Expertise Patented Innovations in Mold Design

Patented Mold Design

21 Years of Industry Expertise Patented Innovations in Mold Design

Patented Mold Design

21 Years of Industry Expertise Patented Innovations in Mold Design

Patented Mold Design

21 Years of Industry Expertise Patented Innovations in Mold Design

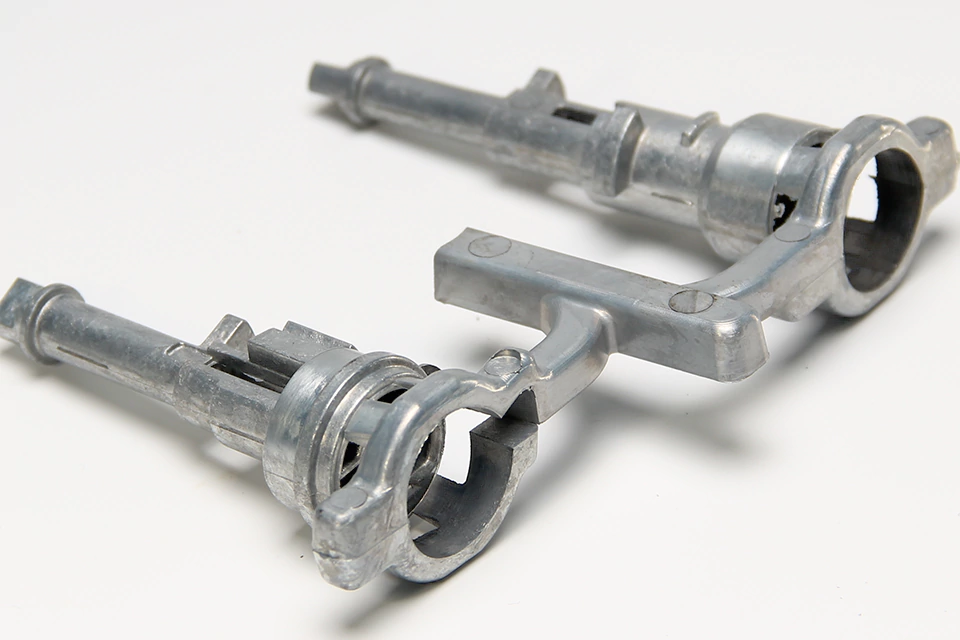

Custom Die-Casting Cases

HERE IS THE TYPICAL WORKING ORDER TO EXPECT WHEN YOU HIRE US FOR OUR DIE CASTING SERVICES:

Automotive Industry

1. Engine components (e.g., cylinder heads, pistons)

2. Transmission parts Structural components (e.g., chassis parts)

3. Wheel spacers Automotive housings (e.g., for alternators, starters)

4. Heat sinks for LED headlights

Consumer Electronics

1. Enclosures for smartphones and laptops

2. Frames for tablets and other devices

3. Heat sinks for electronic components

4. Connectors and interface ports

Industrial Machinery

1. Gear housings

2. Pump parts and housings

3. Valve bodies

Medical Equipment

1. Surgical instrument components

2. Enclosures for imaging devices (e.g., X-ray, MRI machines)

3. Dental equipment parts

Aerospace

1. Aircraft seat frames

2. Engine components

3. Instrument housings

4. Communication device casings

Advanced Parts Manufacturing Techniques

MULTIPLE PROFESSIONAL PARTS MANUFACTURING OR COMPONENTS FABRICATION TECHNOLOGIES ARE MADE USE OF AT PROTOTOOL WHICH PROVIDES TECHNOLOGICALLY ADVANCED SOLUTIONS FOR YOUR BUSINESS. THESE INCLUDE:

Not Sure About The Capabilities?

Uncertain About The Quality Control?

Unsure If The Delivery Will Be On Time?

Not Sure About The Capabilities?

Uncertain About The Quality Control?

Unsure If The Delivery Will Be On Time?

Advantages Of Prototool's Die Casting Services

BY UNDERSTANDING THE SIX MAJOR ADVANTAGES OF THE RENOWNED DIE CASTING SUPPLIER, PROTOTOOL, YOU'LL FIND THAT ALL THE SIX CONCERNS MENTIONED ABOVE CAN BE COMPLETELY ADDRESSED.

Advanced Die Casting Equipment

Our advanced die casting equipment ensures precision and efficiency, utilizing the latest technology for consistent high-quality results across all projects.

Expertise & Experience

With decades in the die-casting industry, our seasoned team combines deep expertise with hands-on experience. We’ve mastered the nuances of the craft, ensuring each project meets the highest standards. Clients can rely on our industry veterans for unparalleled guidance and results.

Quality Assurance

Our unwavering commitment to quality is evident in every product. Each piece undergoes stringent quality checks, ensuring it meets top industry standards. From die casting material selection to final inspection, our dedication ensures unparalleled excellence in every die-cast component.

Client-Centric Approach

At the heart of our die casting service is a client-first philosophy. We tailor our processes to each client’s unique needs, ensuring open communication and results that align with their vision.

Reliable Delivery

In our die casting service, punctuality meets precision. We’re committed to delivering top-quality products efficiently, ensuring every order reaches our clients on time, every time.

Competitive Pricing

Delivering top-tier die casting excellence without the premium price. Our optimized processes ensure clients receive unmatched value, blending quality with cost-effectiveness.

Custom Processing Workflow For Metal Alloy Die Casting Products

EXPERIENCE A SEAMLESS AND INNOVATIVE DIE CASTING WORKFLOW, TAILORED TO DELIVER UNPARALLELED PRECISION AND QUALITY IN EVERY PRODUCT

Materials Used For Die Casting

MOST DIE CASTINGS ARE MADE UP OF NON-FERROUS METALS. THERE ARE FOUR MOST COMMON MATERIALS USED FOR DIE CASTING, INCLUDING:

Aluminum Alloys

1. Lightweight & Strong: Aluminum die casting delivers robust components without added weight.

2. Corrosion Resistance: Aluminum die-cast parts naturally withstand corrosion, ensuring longevity.

3. Malleability: Aluminum's adaptability allows for intricate die-cast designs.

4. Cost-Effective: Aluminum's abundance makes die casting more affordable.

5. Thermal Conductivity: Aluminum die casting excels in heat dissipation, ideal for heat-sensitive components.

Zinc Alloys

1. Precision & Detail: Zinc alloy die casting allows for high-precision components with intricate details.

2. High Strength: Zinc die-cast parts offer exceptional durability and resistance to wear.

3. Ease of Casting: Zinc's fluidity makes it ideal for die casting, ensuring smooth and defect-free components.

4. Extended Lifespan: Zinc alloy die-cast parts are resistant to environmental impacts, ensuring a longer product life.

5. Cost-Effective Finishing: Zinc die casting achieves a smooth finish, reducing post-processing costs.

Magnesium Alloys

1. Ultra-Lightweight: Magnesium alloy die casting produces the lightest metal components, ideal for weight-sensitive applications.

2. High Strength-to-Weight Ratio: Despite its lightness, magnesium die-cast parts maintain impressive strength, ensuring durability.

3. Excellent Damping Capacity: Magnesium alloys absorb vibrations, making die-cast parts ideal for noise and vibration reduction.

4. Rapid Production: Magnesium's properties allow for faster die casting cycles, leading to quicker production times.

5. Eco-Friendly: Magnesium die casting is recyclable and requires less energy in production, supporting sustainable manufacturing.

Ready For Flawless Die Casting?

TAKE THE NEXT STEP WITH US. ENSURE PRECISION AND QUALITY FOR YOUR PROJECT. GET STARTED WITH A QUOTE TODAY.

Prototyping

Creating prototype components for testing and design validation.

Mass Production

Large-scale production of die-cast components.

Custom Die Casting

Tailored solutions based on specific client requirements.

Post-Casting Services

Including trimming, machining, finishing, and assembly.

Die Casting FAQs

UNLOCKING THE MYSTERIES OF DIE CASTING: YOUR GO-TO GUIDE FOR UNDERSTANDING THE INTRICACIES AND ADVANTAGES OF PRECISION METAL CASTING.